The most important parameter of the chimney system is draft. Everyone knows that it is very important for the operation of a furnace or boiler, but few people know - what is draft? This parameter determines the speed and volume of flue gas movement through the chimney. It is necessary for the removal of gases and the flow of oxygen to maintain the combustion process. The very phenomenon of draft arises from the different densities of cold and hot air. The hot one is less dense and, accordingly, is replaced by the cold one. This is how the hot streams move from bottom to top.

The thrust efficiency can depend on several parameters:

- Internal section of the chimney. The smaller its diameter, the faster the rate of release of hot gases. But when they reach a certain minimum size, they will begin to fall into the interior of the room. If the pipe is too large, then the flow of cold air can form the so-called reverse draft.

- The amount of soot deposited on the walls of the chimney. It can significantly reduce the effective pipe diameter, resulting in a loss of thrust speed.

- The number of turns in the chimney. Each turn or bend is an additional obstacle to the passage of smoke.

- Tightness of the system. If there are slots in the structure, then cold air can enter the system through them, forming a cold curtain and preventing the passage of smoke.

- Weather. Low atmospheric pressure and high humidity reduce the rate at which hot air is replaced by cold air in the heater.

Failure to comply with the above conditions is often the cause of poor traction. But how can this indicator be determined without special instruments and devices?

Determining thrust yourself

If the efficiency of the furnace (boiler) has noticeably deteriorated, then there are several ways to check the draft. You can use a special device - an anemometer, but in most cases, purchasing it for home use is economically ineffective. It is best to resort to proven folk methods:

- Candle. If you light a candle, bring it to the chimney and immediately extinguish it, then in the direction of the smoke movement you can see if there is a draft.

- Smoke level in the room.

- A thin piece of paper. The degree of its deviation may indicate the presence of thrust.

Once the problem has been identified, you can begin to resolve it.

Ways to improve traction

There are several ways to improve your cravings, and each one is effective in its own way. But before proceeding with the implementation of one of them, a number of preventive procedures should be done with the very design of the chimney:

- Soot removal (read about it here). To do this, use a special set consisting of a ruff, a sinker and a steel rope.

To do this, you need to go up to the roof and lower the ruff into the outlet of the chimney along the entire length of the pipe. Then, with progressive movements, begin to clean the walls of the chimney. At the same time, layers of soot will begin to fall into the furnace, which are then removed.

- Complete sealing of the chimney... Using one of the above methods, it is necessary to check the structure for the absence of cracks or holes. This problem is typical for brick chimneys, when in the process of operation there is a partial destruction of the masonry.

If after these measures the thrust has not improved, then you need to resort to more radical methods.

Draft regulator

This device is installed on the outlet of the chimney.

After preliminary adjustment, it compensates for the pressure in the pipe with external pressure.In this case, not only the normalization of the heater's operation takes place, but the thrust speed is the same, regardless of external weather conditions.

Deflector

This additional structural element is also installed on the outside of the chimney.

Its outer diameter is much larger than the cross section of the chimney itself. This is necessary for the appearance of the effect of pressure drop when the air flow around the obstacle. Those. When the air flow around the deflector design creates a low pressure area inside it, which contributes to the creation of conditions for a better thrust speed.

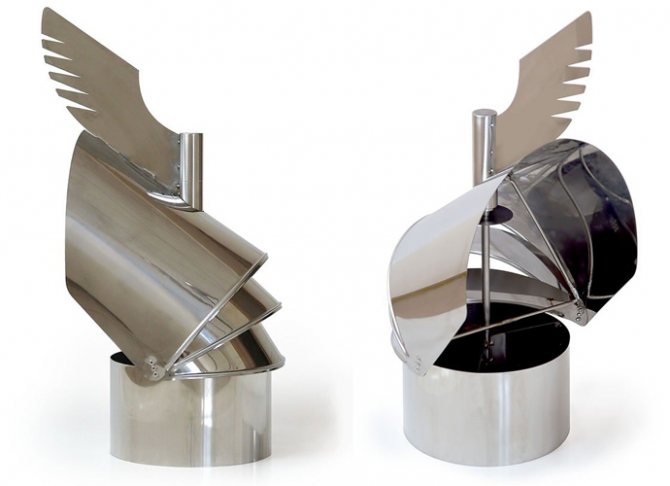

Chimney weather vane

An original design that can not only improve draft, but also protect the chimney from atmospheric precipitation.

Its operation is based on the principle of a deflector and flue gas outlet only from the leeward side. This makes it possible to reduce the external air resistance and thus to normalize the thrust speed.

Smoke fan

One of the most effective methods is to install a special fan on the chimney.

Hood deflectors

This is a fairly common option for forced ventilation. A deflector is an aerodynamic device that is installed above the chimney. It increases the draft in the chimney by changing the air flow. The essence of its work lies in the pressure drop when air flows around the obstacle, as well as on the principle of changing the air flows. It turns out that its shape allows you to increase the draft in the chimney. Made of stainless steel, they are resistant to corrosion, acids and high temperatures.

It cannot be called a full-fledged fan, since the deflector has a simple shape, without working mechanisms. But, there are varieties of smoke deflectors designed specifically for chimneys.

- Volpert deflector.

- Deflector Grigorovich.

- Round or spherical deflector.

It is the round deflector that can create rotational movements under the influence of the wind and remove smoke from the room. But, again, the disadvantage of the product is that it is ineffective in the absence of wind. The principle of operation of this draft amplifier of ventilation pipes and chimneys is demonstrated in the video *

In addition, weather vans, umbrellas and similar structures are often installed on chimneys. But they cannot do all that a high temperature chimney fan can do. Let's take a look at how they work and what makes them special.

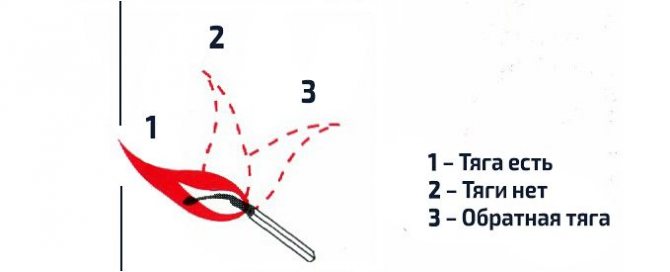

Determination of the presence of reverse thrust

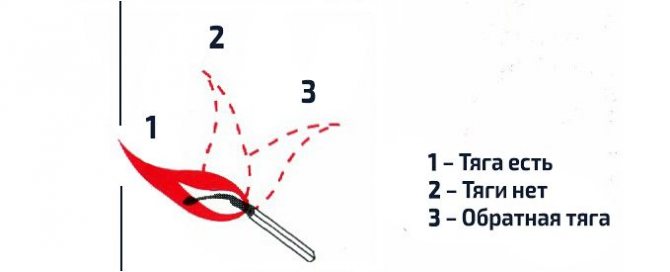

Flame direction with normal and reverse draft

The reverse draft in the chimney is also called "overturning". Air masses do not pass through the chimney, as it should be, but back into the house. This is a hazardous phenomenon that can lead to fire and severe poisoning with toxic gases.

To avoid negative consequences, it is recommended to always check the draft before starting the heaters. There are many ways to identify a violation. This can be done with simple folk methods:

- Light a candle, insert it into the furnace and observe the flame. If the light is directed inward, then the thrust is normal. If it remains in place and does not move, this indicates that there is no circulation of air masses.

- Bring a thin piece of paper or ribbon to the edge of the pipe. If they stretch into the sleeve, then the chimney is functioning correctly.

- The check can be done with a simple mirror. It must be brought to the chamber in which the fuel is burned. If moisture appears on the mirror surface, this indicates that the combustion products do not come out.

- The color of the flame in the oven may indicate that the air is not circulating properly. If the flame is bright orange, this indicates a violation. With the right pull, it will be yellow-gold.

Checking the correct draft in the chimney can be carried out using special devices. The measuring equipment allows you to get the most accurate readings in pressure units. Parameters from 10 to 20 PA are the norm. Measurements must be taken from two sides: at the base and at the top of the chimney. But this technique is rarely used in private homes or apartments.

Smoke fan

The chimney exhaust fan is a heat-resistant electrical device. It is mounted directly on the chimney to increase the draft in the chimney. It is important not to confuse a chimney fan with a fireplace fan, which is used to supply air to maintain combustion. Here the principle of operation is different. Simply put, a chimney fan is an electric motor with blades that allow the smoke to be forced out of the chimney and directed outside. For full operation of the fan, you will need a 220V supply.

In fact, a fan in a chimney to improve draft is somewhat reminiscent of a deflector, only it does not require wind power at all for its operation. He works constantly, doing an excellent job of his task. In addition, you can find economical models on sale. They work in two modes: when there is a strong wind outside, the rotation occurs naturally, without the use of electricity. And in calm weather, an electric motor starts up. It is the perfect chimney solution.

Fan - advantages and disadvantages

The exhaust fan can speed up the air flow by 3-7 times. At the same time, the volume of removed gases per unit of time increases by the same factor.

Moreover:

- the active system allows you to simply and at minimal cost increase traction;

- hood parameters do not depend on the weather. Does not affect the hood and indoor temperature;

- conditions for reverse thrust are excluded;

- it becomes possible to adjust the rate of smoke removal depending on the operating mode of the gas and furnace equipment. With a decrease in the power of the heaters, the fan speed is reduced.

Smoke removal requires a smaller duct cross-section due to the rapid air movement. This means that an active chimney requires less material to manufacture.

A modern chimney fan is protected from rain, leaves. It is installed on the pipe using special fasteners.

But there are also disadvantages:

- the fan is consuming energy. This increases the operating costs of the heating system;

- you need to lead a cable to the motor. This is not so easy to do. The active hood is placed on the pipe, and it is undesirable to make holes for the wire in the roof;

- it is necessary to provide protection measures against precipitation and icing of the impellers.

The listed disadvantages must be taken into account when switching to active smoke extraction. Then the cons can be neutralized.

Taking into account the positive properties of the active hood, the smoke exhauster is installed on the pipes of modern cottages, in houses, when installing fireplaces on wood or briquettes.

Not every impeller engine is suitable for carbon monoxide applications.

The smoke exhauster should be:

- Heat resistant. It should be borne in mind that when the stove or fireplace is in operation, the smoke heats up much more than in the column. The temperature of gases from the fireplace at the outlet of the chimney can reach 300 ° C and more.

- Resistant to aggressive gases.

- Economical. In windy conditions, the electric motor is switched off. The impeller spins up as in a rotary turbine.

- Waterproof. Weather conditions must not impede smoke extraction.

- Effective. The fan must ensure the rapid removal of furnace gases at all temperatures outdoors and indoors.

A duct fan for smoke removal is built into the air duct. But more often they use a smoke exhauster installed on a pipe.

The high temperature duct fan must operate in an aggressive environment.Therefore, it is made from smoke-resistant materials.

The chimney fan should not be confused with the forced draft in the fireplace. The latter is designed to ignite and maintain combustion in the furnace. While the blower fan is cut into the chimney, or the smoke exhauster is installed on the chimney. Modern devices for active removal of furnace gases withstand temperatures up to 600 ° C.

We suggest that you familiarize yourself with What firewood is better for the stove

An active smoke exhaust device monitors the temperature of gases and their speed using sensors. The data is used to control the engine and ensure the safe operation of the fireplace, stove and gas equipment.

Before installing the fan on the pipe, a number of preparatory work must be carried out. The first step is to ensure safe working at height.

To do this, a special ladder is installed on the roof next to the pipe with the possibility of securing safety elements

Next, mark on the pipe places for attaching the exhaust fan, and conduct a cable to power the engine. Signal wires are laid from controllers of gas equipment and other power devices.

In the following stages:

- Mount the fan assembly, eliminate cracks, check the tightness of the connections.

- Connect the power cable, connect the sensors to the wires.

- Power voltage is applied, the smoke exhauster is started.

- The parameters of the carbon monoxide removal system are checked with the help of measuring instruments.

- They complete the installation work, remove the fixtures from the roof.

- The sensors are connected to power plant control systems.

- They turn on gas equipment, stoves, fireplaces and check once again the effectiveness of smoke removal.

For the operation of the smoke exhauster, installed on top, cable and wires are passed through the roof. This is not always convenient. If you do not need to install a product with a rotary turbine function, they buy a high-temperature duct fan to remove furnace gases.

The device is cut as far as possible from the place where the exhaust air is heated. The installation algorithm for the duct exhauster does not differ from that discussed above.

Features of chimney designs

Since the smoke has a high temperature and constantly affects the structure, the chimney fan is made heat-resistant. The material is able to withstand temperatures up to 250 degrees. This is enough to serve faithfully for many years. Typically, products are made of specially coated die-cast aluminum. The engine has life-long bearing lubrication and is also heat-resistant.

As for the types of fans, it all comes down to differences in their shape and power. After all, chimneys are different, respectively, you need to choose a device that would fit inside and have the shape of a chimney. These are the features of the choice of products for the chimney. Usually the design is made in a square or round shape.

Popular fan reviews

MMOTORS JSC BO VO 90/25 T (+ 150 ° C)

An excellent circular fan used for intermittent or long term operation. Its productivity is 60 m 3 / h, with a power of 16 W. The product has an IP44 protection class. The landing diameter is 9.9 cm, and the depth is 2.5 cm. The fan produces 2.5 thousand revolutions. The product can be installed in channels with a short length. Thanks to the low-noise electric motor, which has double-encapsulated ball bearings, the device can work as much as 30 thousand hours. In this case, the fan can be mounted both vertically and horizontally. The body is made of an aluminum alloy that cools quickly and can withstand temperatures up to 150 degrees. The warranty is 3 years. The cost is about $ 38.

MMOTORS JSC BA VA 9/2 T (+150)

Unlike the previous version, the fan has a square shape, as for the parameters, they practically do not differ in anything. Power - the same 16 W, performance, protection class, speed and other indicators are the same.But the landing diameter is 9.3x9.3, with a depth of 2.5 cm. Warranty - 3 years, cost - $ 38.5.

MMotors BOK 150/120 (+ 150 ° C)

The fan is also used for a round chimney. It is much more powerful than the previous options. With a power of 18 W, the device has a capacity of 240 m 3 / h. Fitting diameter - 12 cm. Protection class IP44.

The model has a different cross-section along the fan axis, which allows it to be adapted to conventional air ducts. The material is heat-resistant, and the engine will last 30 thousand hours of operation. Manufacturer's warranty - 3 years. The cost is $ 90. Having bought such an exhaust fan for the chimney pipe, you can forget about the weak draft.

Reasons for poor traction

Reasons for insufficient outflow of gases in the chimney:

- too large or too small section. With a large cross-section, the pipeline heats up slowly, the gases cool and their speed decreases. A small cross-section may simply be insufficient to remove gases from heating equipment. The cross-sectional diameter must correspond to the design of a conventional brick or fireplace stove or correspond to the cross-section of the branch pipe according to the instructions for the heating boiler;

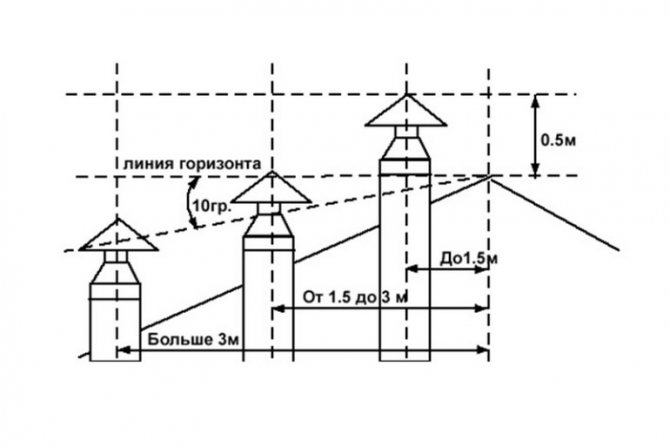

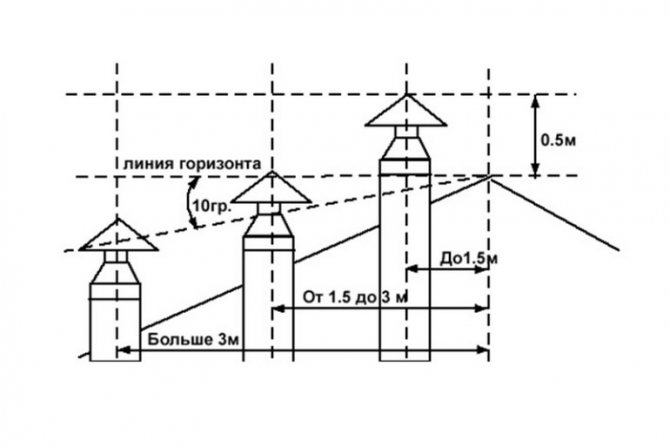

- the height of the pipe in accordance with SNiP 41-01-2003 must be at least 5 m (from the head to the grate). With a flat roof, the distance from the head to the roof must be at least 1 m; the heights of the pipeline relative to the ridge with a pitched roof are shown in the figure. In a pipe that is too low, the required gas vacuum will not be created and the outflow of waste gases will decrease. Too high - the gases will be more cooled, slowed down, and the outflow of gases will decrease;

- a horizontal chimney greatly inhibits the flow of gases. The presence of inclined and horizontal sections with a total projection onto the horizontal of no more than 2 m is allowed, while the vertical part of the pipe must be lengthened by the same distance;

- lack of a deflector (or cap). The deflector is designed in such a way that it enhances the movement of gases, and in addition, it protects the pipe from precipitation;

- lack of insulation on a single-layer steel pipe. Hot gases cool very quickly and the upward movement disappears;

- tightness of a room with a stove or fireplace and the absence of air supply or an open window;

- the smoke duct must be regularly cleaned of soot. "Overgrown" with soot or rough walls greatly reduce the emission of smoke;

- during ignition and during operation, it is necessary to ensure that the damper is not completely closed, that the blower is open.

Poor hood - reasons

Before talking about the use of forced draft devices for the chimney, let us dwell on the essence of the process, as well as the reasons for the drop in draft in the chimney.

The set of factors affecting the efficiency of chimney extraction can be conditionally divided into three groups:

- Internal conditions in the house;

- Conditions for moving air flows inside the room.

- Air temperature in the heated area of a residential building.

- The total volume of air inside the premises, which are linked to the furnace compartment of the furnace through a blower.

- The number of other oxygen consumers living in the house - people or animals.

Simple reasons

Some users have to deal with situations where the thrust “overturns” for several days, although before that everything functioned without failures.

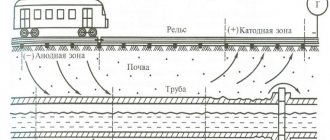

Backward thrust is formed due to the fact that:

- the weather outside is bad;

- the firebox or stove has not functioned for a long time.

As a result of these phenomena, a large amount of heavy cold air is collected in the chimney. Cold air masses will just become an obstacle to the air flow.

Ventilation problems

There are a number of other reasons why reverse thrust is formed. They are associated with ventilation: warm air has a much lower density than cold air, which is why heated air masses are directed upward.In the case when the weather is cool outside the window, and somewhere in the house there are windows or doors to the street, then turning on the heating unit, the air will be directed exactly there, and not into the chimney.

The architecture of the building also plays an important role in this issue:

- if the house has a large number of windows, there are balcony openings, a staircase to the second floor, then all these factors will certainly cause drafts;

- in those rooms that are located above the level of the combustion chamber, it is not worth opening windows and doors to the street.

If you neglect the above rules, air currents will appear knocking down the thrust.

Prevention of the condition of the chimney

So that there is no need to use means of forced exhaust of the chimney from a heat-resistant material, it is necessary to use preventive measures to maintain it in working order.

Since the main reason for reducing the intensity of flue gas extraction is a decrease in the passage of the pipe with soot accumulated on the walls, we will consider means of combating this phenomenon.

These ways can be:

- Burning naphthalene in the furnace of about half a tablespoon. Vapors of naphthalene decompose soot into loose components, large ones fall out into the furnace and are further removed with ash, and small ones fly out through the pipe together with furnace gases. This product must not be used for chimney removal from the fireplace and for pipes of open hearths - after it, a characteristic suffocating smell remains in the rooms.

- Burn from time to time in the potato peeling furnace. They are pre-dried. Starch vapors loosen the soot deposit and it will fall into the firebox. Pure starch acts similarly, which is fed into a well-burnt firebox in the amount of one tablespoon.

- A good pipe cleaner for soot is a nutshell. It burns at high temperatures, burning off soot deposits on the inner walls. A single dose of shells should be no more than three liters. The frequency of use is as it accumulates.

- Aspen firewood has a similar effect on soot. One or two logs are burned at the end of the last firewood. They burn at high temperatures.

The frequency of application of high-temperature agents should be regular, at least twice a week, so that soot does not have time to accumulate. Otherwise, you can cause a serious fire, since the soot burns with the release of a very large amount of heat.

In addition to those listed on the market, there are many anti-soot agents, both chemical and thermal decomposition of soot. The use of preventive measures can eliminate the need to apply coercive measures to improve the exhaust air on the chimney.