DISTINCTIVE FEATURES

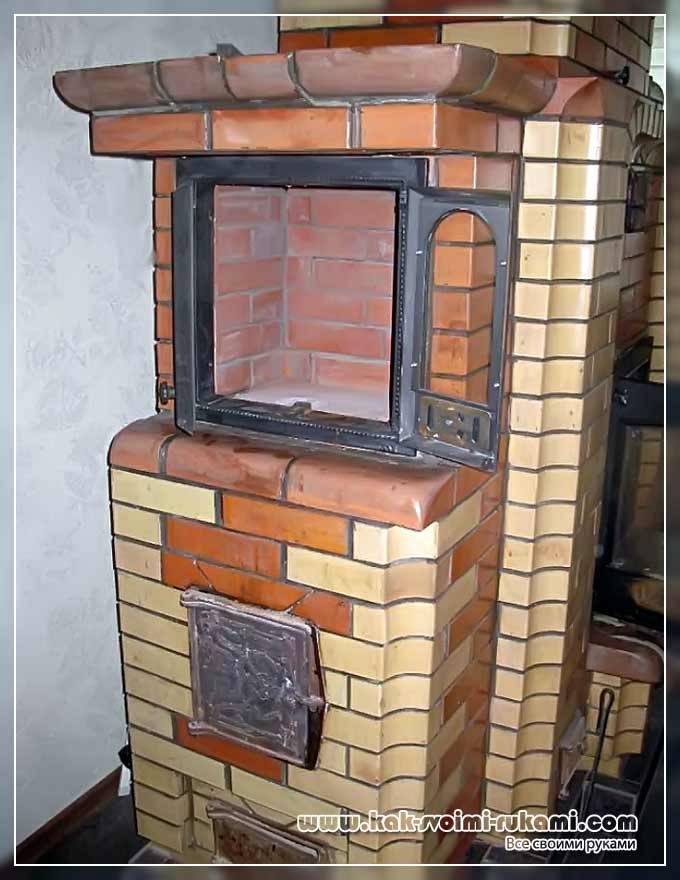

The main load in this the structure carries a fireplace stove

(hereinafter for brevity - oven). It provides for the possibility of transit of hot flue gases for heating the second floor, both due to the operation of the furnace and due to flooding. Moreover, the flue gases from the flooding follow in transit, practically not taking part in the heating of the first floor. This decision is due to the following considerations:

EVERYTHING YOU NEED FOR THIS ARTICLE IS HERE >>>

- - the inclusion of smoke channels, flooding into the smoke circulation system of the first floor will require an increase in the mass of the entire structure, which is undesirable;

- - the presence of underflooding is caused not by a lack of heat from the main structure of the oven, but by considerations of convenience - the ability to cook food;

- - the chimney from the underflooding adjoins the left circulation channel of the furnace and merges with it, without negatively affecting its operation.

It is possible to link the furnace with underflooding using structurally defining sections (KOS). This method does not require detailed ordering in most cases, but it allows you to compactly link all the necessary elements - blowers, furnaces, chimneys.

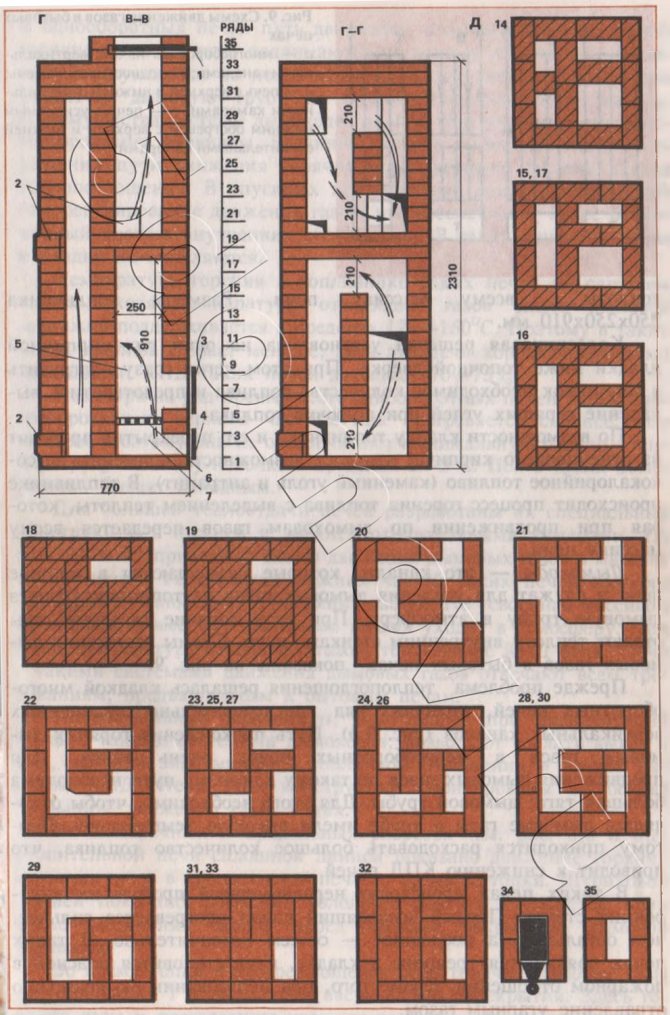

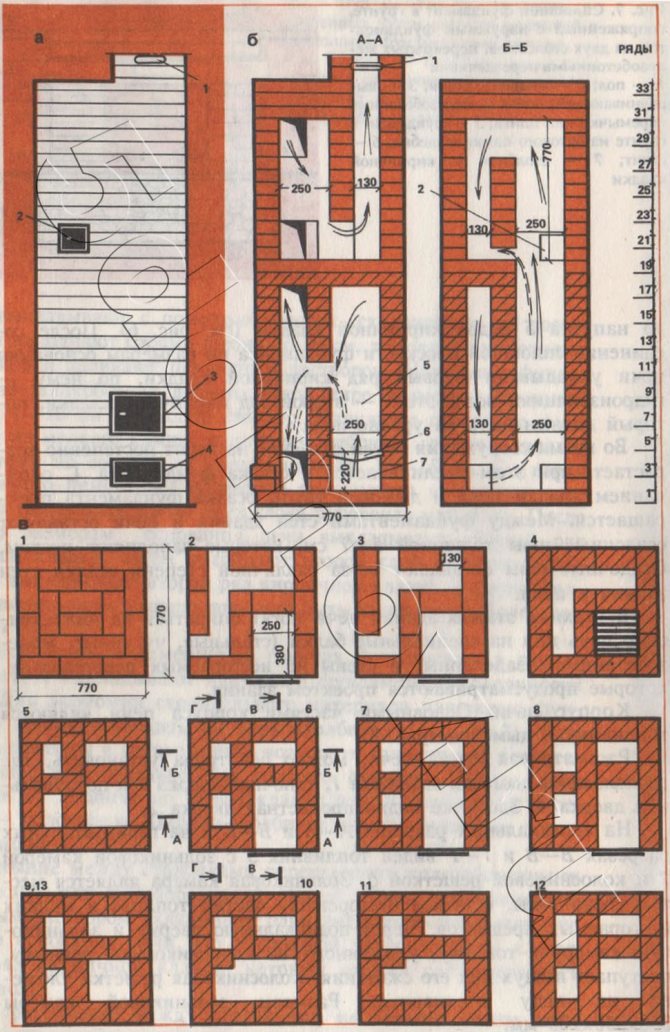

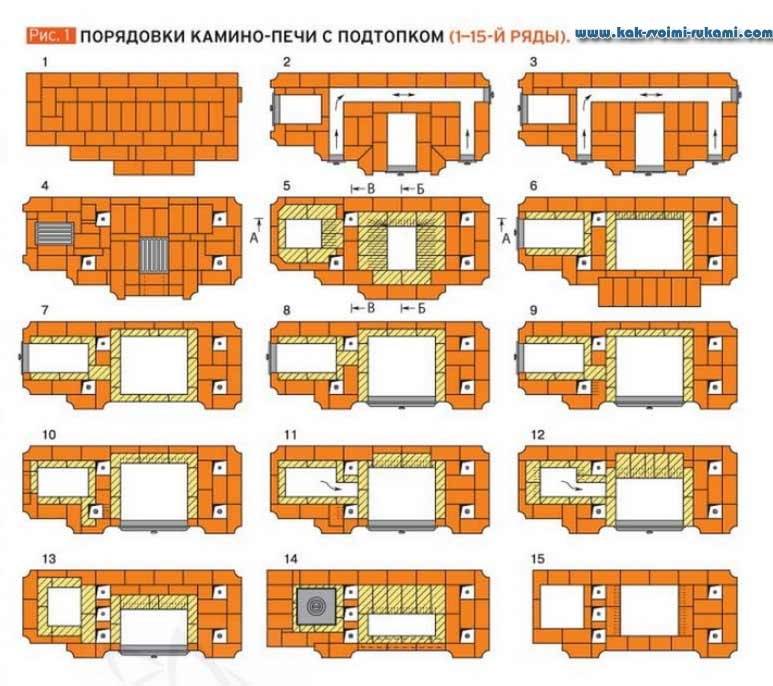

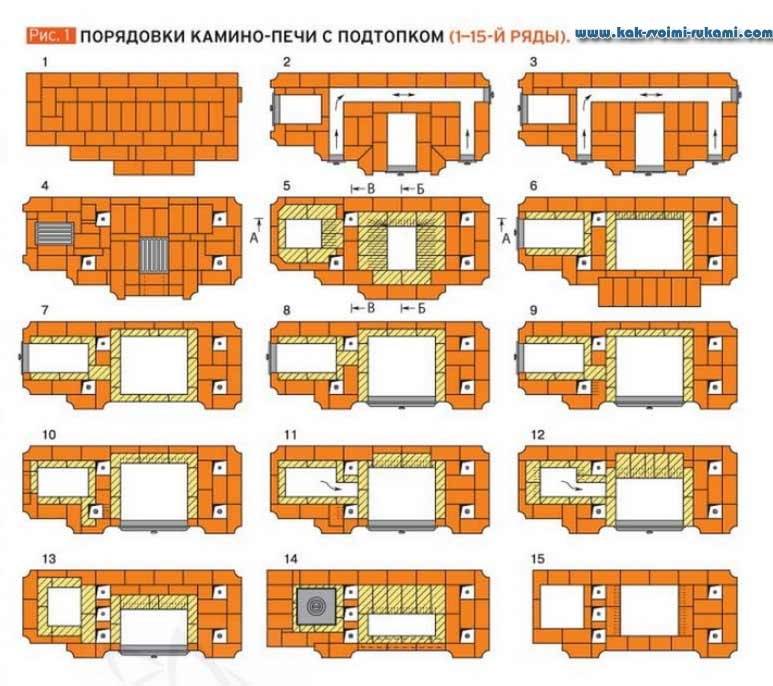

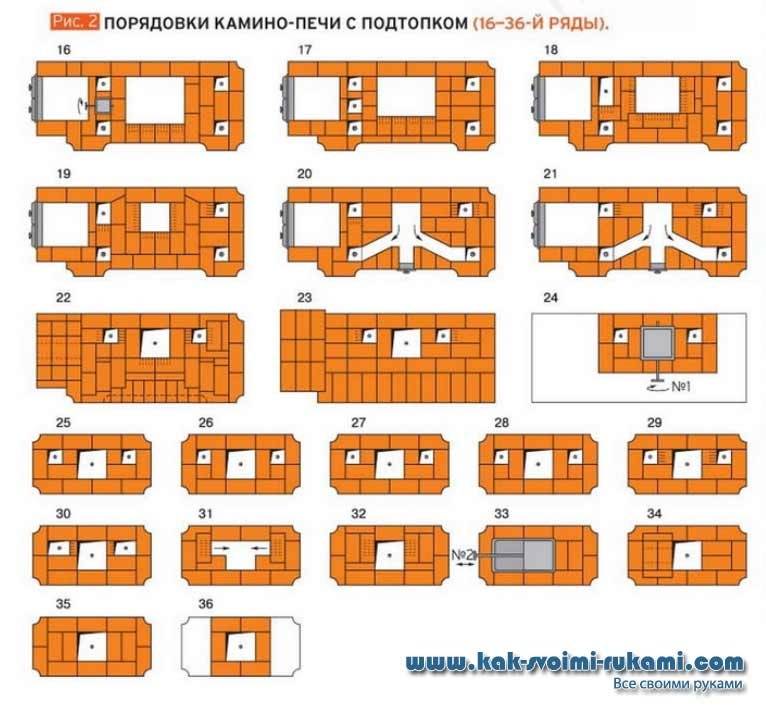

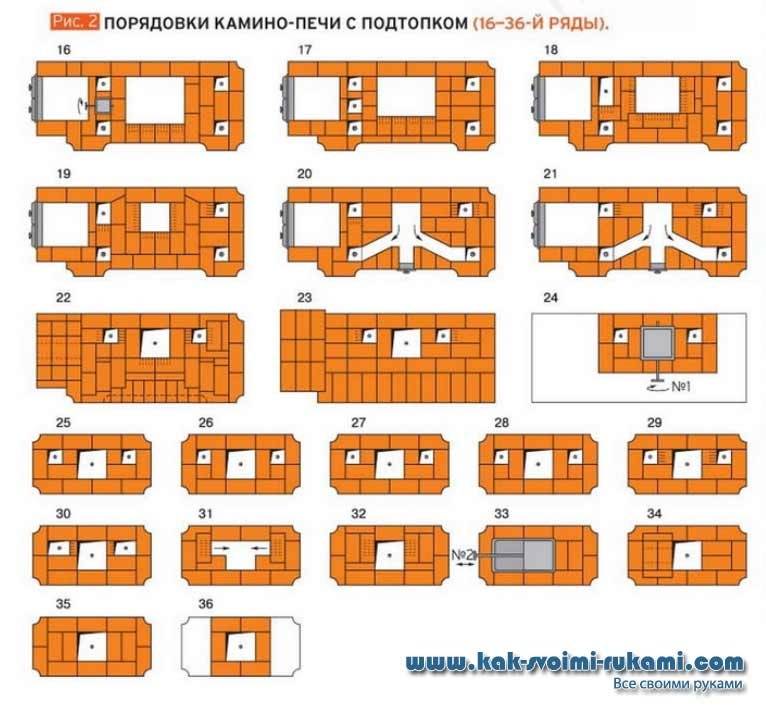

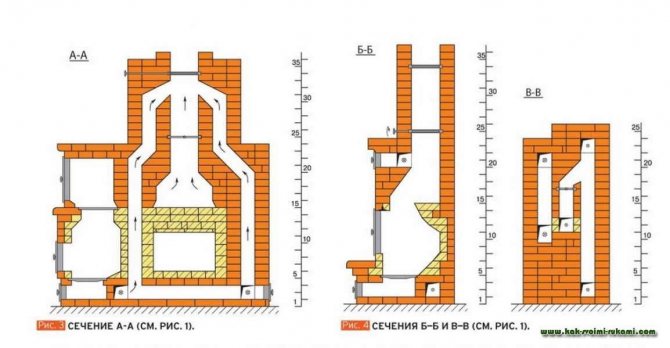

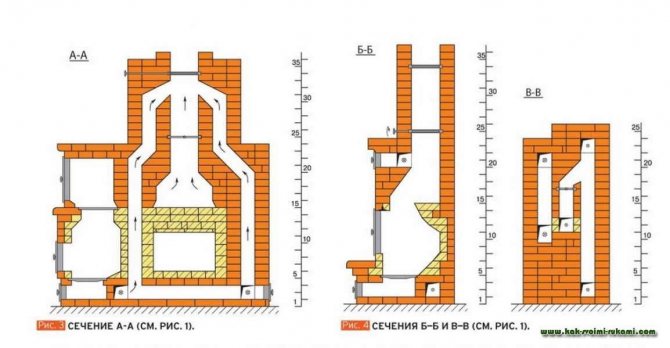

For this design, such KOS we choose the 3rd, 14th, 20th rows (Fig. 1, 2), as well as vertical sections A-A and B-B (Fig. 3, 4).

So, what are the elements of the Russian stove and accessories called

An overtube, a shield - a smoke collector above the pole, for collecting flue gases and bringing them into the chimney.

Six is a platform in front of the mouth of the Russian stove. The six is open, closed and closed on both sides. Hot dishes were placed on the pole.

Metal finishing and artistic forging made by Alexey Kozhin

Cutting - fire cut at ceiling level. Thickening of the brickwork at the ceiling passages.

The damper is a sheet of iron that closes the entrance to the crucible; the damper can also be made of wood. The dampers always have a metal or wood handle. In modern times, the dampers of Russian stoves are made to order. They add extra flavor and are decorative elements in the oven. They cook in a Russian oven with a closed damper. Also modern dampers can be insulated.

The damper was made by the metal artist Alexei Kozhin

Epancha - a casing over the mouth of the Russian stove. The word came from the similarity with the outer clothing of the epanchi. Short sleeveless fur coat.

The valve is a metal plate that covers the chimney. The gate valve can adjust the draft, unlike the view.

Borov - a horizontal section of the pipe, which serves to bring the pipe closer to the ridge, since the stove was not located in the middle of the house.

A view is a device consisting of two and sometimes three parts. It is a steel plate or frame made of cast iron with a hole, closed by a blinker and a lid.

A pipe is a vertical channel through which smoke is removed from the stove to the street.

Overlap - the topmost layer of brick, located above the massif or backfill; a couch was usually arranged on the ceiling.

Lounger (lounger) - the top of the stove, a place to lie, sleep in the cold season. Basically, two people were placed on a sunbed, but the large stoves had sunbeds that could accommodate up to 6 people.

Crucible - the firebox of a stove, a cooking chamber in which fuel, wood is burned, and then food is prepared.

Arch, palate - the upper part of the furnace. It comes in different shapes and is often tilted towards the pole.

Stoves - shallow niches in the body of the stove, serve to improve heat transfer, clothes, shoes, dishes, mushrooms and herbs are also placed there for drying.

Mirror - the surface of the stove that gives off heat to the house, the wall of the stove. Backfill - sand and crushed stone were often filled under the hearth and above the vault as a heat accumulator.

Ochelok - the front part of the Russian stove, from the word jaw.

The forehead is the area of the stove above the arch or the overlap of the pole, like a man's forehead (a man's forehead is just at the level of the forehead of a Russian stove).

Gornushki - a hole for the preservation of coals in the crucible.

Under, flask - the lower layer of the furnace vault is the base of the upper vault of the furnace, it is laid to ensure strength from brick hewn into a cone on a cylindrical surface.

The hearth is the back side of the hearth, which is inside the hearth on top.

Gate, gas threshold, tooth - the upper part of the mouth to the arch, delays the exit of gases from the firebox, increasing the efficiency of the firebox.

Cheek, cheeks, cheeks - the front wall of the furnace.

The mouth is the opening between the cheeks.

Bending - the place where the coals were stacked in order not to resort to ignition in the next fire. Bending was done on the pole on the left. It is called a six-point bend. Sometimes it was arranged like a stove with an outlet into the chimney. The coals were slowly burning out in the enclosure.

Bakes - the Russian stove was set indented from the wall, this distance is called bakes.

The furnace is the lower part of the stove, unheated, serving as the base for the stove, and before it was often made of wood.

Pole window - the hole is often slightly larger than the entrance to the firebox.

Squeeze box samovar - a hole for connecting a samovar with a lid.

The stove is a niche in the wall of the oven. Served for drying things, as well as for better heat transfer from the oven.

Golbets is an arrangement, a partition, a structure made of wood or brick, which was a continuation of the stove, from above it is an extension of the stove bench, since the stove bench was often shorter than the length of a person, below is a place for storing all kinds of utensils. A curtain was hung on the headboard. Golbets is a word of Swedish origin. This design was also called in the Russian way "cabbage roll".

Polatya - the same was the name of the continuation of the oven, on which one could lie, put things, dry shoes and lay out vegetables for drying, such as onions. Added Alexander from Samara.

Polati is not only a lounger built between the stove and the wall, but also a wooden deck built under the ceiling above the stove. Plates were also located in the corner between the walls. You can dry vegetables on the beds. Here is what V.I. Dahl: "Polati (from half

) - in general, a platform or scaffold, flooring, raised above the floor and head; then: a platform in a peasant hut, from the stove to the opposite wall (above the doors, and to the koin, or on the other side, to the kuti); three corners of the boulders adjoin the walls, the fourth to the golbets, or the ward pillar, and the flooring lies, to one side of the pillar, on the ward bar, in the other - on the crow; this is a kind of semi-storey, mezzanine, useful, for the sake of cramped hut and for warmth; dormitory. In the old days, Polati were also in the boyar mansions. "

Podtopok - a small stove for heating with a Russian stove (usually under the stove) or on the side of the stove.

Underfloor in the Russian oven

Heating stove

Additional heating in the oven

The information was supplemented by a visitor to the blog KaminTeplo Yuri.

The base is a cold stove under the pole, in which small kitchen utensils were stored.

Podpechek, baking - a cavity under the pole and bottom of the stove, where firewood was most often stored, dried before heating, pets lived.

Half door - a small door for cleaning soot, an ash pan door. The half-door was placed in order to provide access to the view.

Khailo - a hole for exhausting flue gases into the chimney.

The throat is a hole above the pole, if the pole is open, then the oven simply does not have a throat.

Shpur - a window, for example, a window in the hearth of a stove, if the stove is not a classic one, but for example, a teplushka stove with underflooding.

The fill is a long box, a bench for storing utensils next to the stove.

Strainer, samovar - a hole for connecting a samovar with a lid

FEATURES OF OPERATION OF THE FIREPLACE OVEN

Before opening the furnace door when placing firewood in the stove in heating mode, it is necessary to switch the mode of its operation to the fireplace one. To do this, you must fully open the valve No. 1. Otherwise, smoke may be ejected through the open door.

Passing flue gases in transit to the second floor to heat it, the oven doors must be kept closed so that the gases have the highest temperature.

If it is necessary to use a heating stove for cooking in a warm season or when using the oven in open fireplace mode (when it is not required to heat the premises of the first or second floor), flue gases must be passed in transit, bypassing all smoke circulation systems, that is, with all valves open on both floors. (On the ground floor there are valves # 1 and 2.)

Reference by topic: Do-it-yourself fireplace stove - photo of alterations from an open fireplace

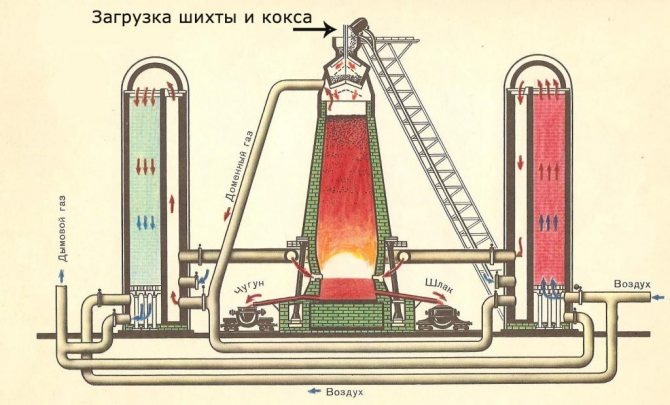

Blast furnace and smelting concept

Modern civilization is inextricably linked with the development of production technology, which is impossible without improving the tools and materials used for their manufacture.

Among all materials of natural origin or created by man, the most significant place is occupied by ferrous metals - an alloy of iron and carbon with the presence of other elements.

Alloys, in which a part of carbon is 2 - 5%, are classified as cast irons, in the presence of less than 2% carbon, the alloy is referred to as steels. A special blast furnace technology is used to melt metals.

Blast furnace smelting is the process of making pig iron from iron ore processed in blast furnaces or, as they are also called, blast furnaces.

The main materials required in the process of such production are:

- fuel in the form of coke obtained from coal;

- iron ore, which is the direct raw material for production;

- flux - special additives from limestone, sand, and other materials.

Blast furnace - a device for the production of pig iron by reducing the smelting of iron ores or concentrates.

The main equipment of the blast furnace shop - the blast furnace - is a round shaft furnace lined with refractory masonry.

Refrigerating devices are used to protect the furnace casing from overheating. The furnace casing and blast furnace are installed on the foundation and are supported by columns.

The starting material for smelting is called a charge and consists of iron ore, manganese ore, sinter, pellets. The charge is fed to the furnace top by skips or a belt conveyor. The skips are unloaded into the furnace through the hopper. The air is supplied through the air heaters, the smelted product comes out through the notches into the ladles located in the lower part.

Modern blast furnaces are equipped with a centralized control and monitoring system that provides registration of instrument indicators and complex indicators of blast furnace operation - coke consumption per 1 ton of pig iron and daily productivity of the blast furnace in tons.

Additional fuel is used, which reduces the consumption of coke and the cost of pig iron. The improvement of the blast furnace design is aimed at increasing its capacity (volume), improving the preparation of raw materials, introducing new progressive, high-performance technologies.

Pig iron is smelted in blast furnaces, which are a shaft furnace.The essence of the process of obtaining pig iron in blast furnaces is the reduction of iron oxides that are part of the ore, gaseous (CO, H2) and solid (C) reducing agents formed during the combustion of fuel in the furnace.

The blast-furnace smelting process is continuous. The starting materials (agglomerate, pellets, coke) are loaded into the furnace from above, and heated air and gaseous, liquid or pulverized fuel are fed into the lower part.

The gases obtained from fuel combustion pass through the charge column and give it their thermal energy. The descending charge is heated, recovered and then melted.

Most of the coke is burned in the lower half of the furnace as a source of heat, and some of the coke is used to reduce and carburize the iron.

A blast furnace is a powerful and efficient unit that consumes a huge amount of materials. A modern blast furnace consumes about 20,000 tons of charge per day and produces about 12,000 tons of pig iron per day.

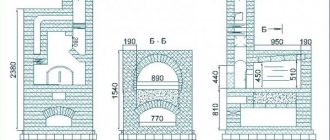

STOVE-FIREPLACE - ORDERS

ORDERS OF A FIREPLACE OVEN WITH A SINK (ROWS 1-15).

ORDERS OF A FIREPLACE OVEN WITH A SINK (ROWS 16-36).

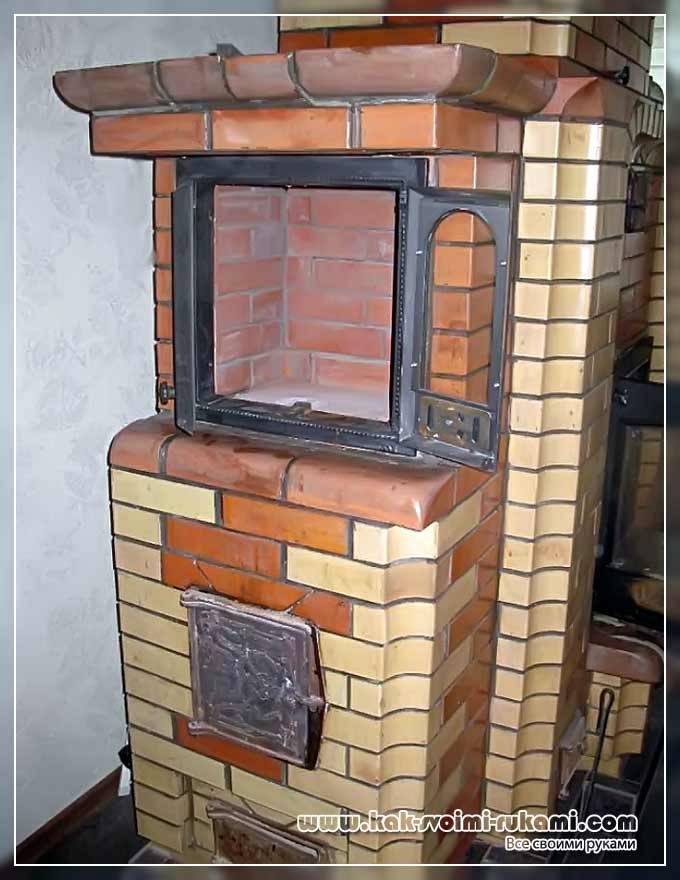

DO-HAND FIREPLACE - PHOTO

© Author: A. Smirnov Poryadovki E. Ozerina

TOOL FOR MASTERS AND MASTERS, AND HOUSEHOLD GOODS VERY CHEAP. FREE SHIPPING. THERE ARE REVIEWS.

Below are other entries on the topic "How to do it yourself - a householder!"

- Do-it-yourself fireplace-stove - photo and diagram HOW TO FOLD THE FIREPLACE-OVEN WITH YOUR HANDS IN ...

- DIY mini oven for a cauldron (+ PHOTO) MINI-OVEN WITH BLOWING FOR A CAZAN RECENTLY ...

- Do-it-yourself rustic stove - photo and diagram HOW TO BUILD A RURAL FURNACE - ...

- Combined stove - both fireplace and heating: DIY masonry Double-circuit heating stove and fireplace ...

- Do-it-yourself fireplace stove - photo of alteration from an open fireplace How to remake a fireplace (with an open ...

- Do-it-yourself stove for a cauldron - photo A stove for a cauldron from a gas ...

- A fireplace stove with a closed hearth - orders and photos of masonry How to fold a fireplace stove with your own hands ...

Subscribe to updates in our groups and share.

Let's be friends!

With your own hands ›Stoves, fireplaces, barbecue› Do-it-yourself fireplace stove with flooding - photos and orders