It is quite possible to heat the house with a wood-burning stove. Especially if it is a modern model with a powerful heat input. However, this applies to small houses with one or two rooms. For heating a large area and a larger number of rooms, a wood-burning stove with a water circuit and a heat exchanger is better. This combination will distribute heat evenly throughout the rooms and create truly comfortable conditions.

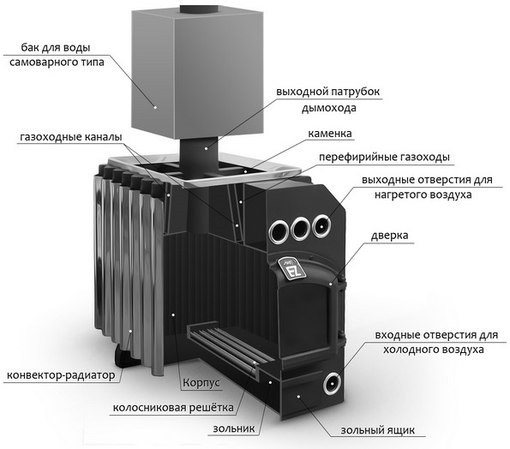

Device

In fact, almost any wood stove, even an old brick stove, can be converted and supplied with a water circuit. Nevertheless, it is better to give preference to ready-made solutions with a well-arranged structure, where the heat exchanger is inscribed harmoniously and does not spoil the combustion process and traction.

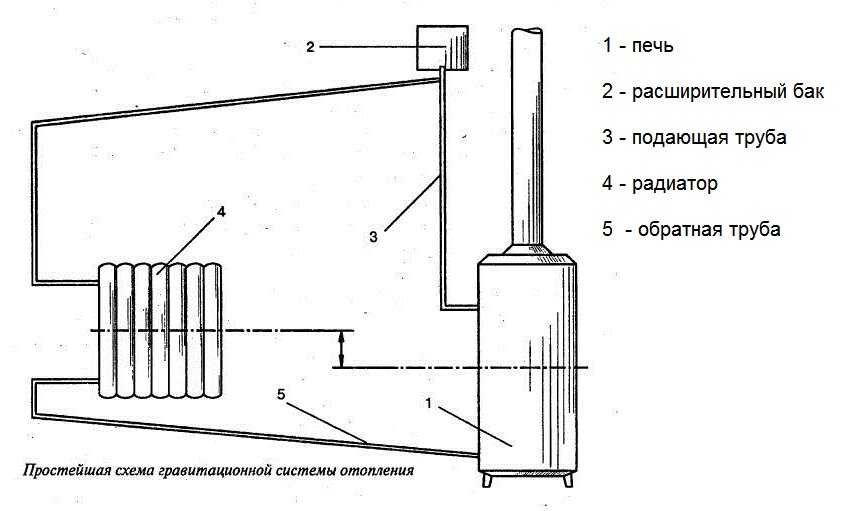

The idea is to place a water heat exchanger directly in the combustion chamber or in front of the chimney. Depending on its design and location, it is possible to organize radiator heating throughout the building.

There are five main types of heat exchangers:

- coil;

- register of pipes inside the furnace;

- built-in boiler, storage tank;

- pipe register on the outer wall of the oven, convection;

- chimney heat exchanger.

Coil

+ Simple execution.

+ Maximum heat dissipation.

- Forced circulation only.

Inside the furnace, often at the entrance to the chimney, there is a plate heat exchanger, approximately the same as that installed in gas boilers. Due to the hot air and combustion products, the coolant is heated. Since there is no natural convection of liquid in this case, and for circulation in the heating system, it will be necessary to install a circulation pump. This already makes the heating dependent on the availability of electricity.

Register of pipes inside the furnace

+ Fast heating.

+ Simplicity of design.

- Weak heating regulation.

A tubular direct-fired heat exchanger is formed inside the combustion chamber. A number of "П" -shaped pipes installed parallel to each other and united by two collectors, respectively, inlet and outlet. The heat from the fire and smoldering wood heats the coolant in the pipes. A rather risky option, since in the absence of circulation, the coolant boils. If there is no additional volume for expansion and vapor removal, a burst of the heat exchanger is possible. However, this is the simplest and most affordable option for self-execution and alteration of an existing wood-burning stove. In stoves originally equipped with such a register, a heat regulator is installed, which, depending on the heating of the water, adjusts the position of the damper, reducing the activity of burning wood.

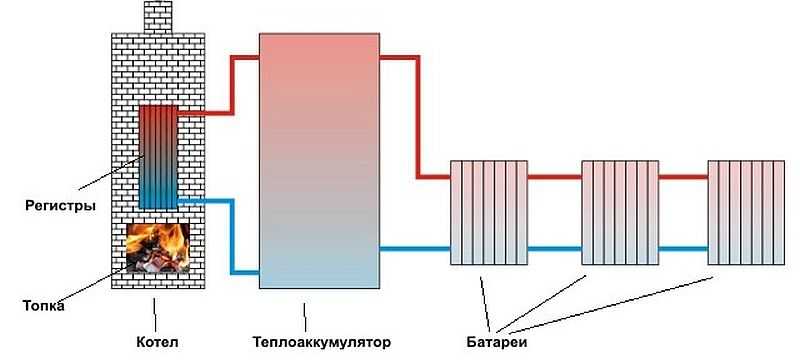

Boiler

+ Heat reserve, high inertia.

- Strong influence on the combustion process.

The storage tank is formed directly on the sides of the firebox and additionally on top. It is a direct alternative to the pipe register, only the heat exchanger is formed from sheet steel. In fact, the structure forms the main walls of the furnace itself. Replacing, for example, brickwork. Disadvantages are similar to the previous version. The advantage is more active convection and the ability to organize a heating system with natural circulation of the coolant. It is only important to provide cold water supply at the lowest point of the heat exchanger and hot water intake at the highest point.

Butakov's furnace with a boiler and a water circuit

Register of pipes along the furnace body

+ Good heat transfer.

+ Smooth heating.

+ Ability to regulate the temperature of the coolant.

+ The water circuit has little effect on the combustion process.

The convection type is typical for most modern wood-fired ready-made stoves. A register of shaped pipes is formed along the perimeter of the furnace, and also partially along the chimney channel from the outside of the main body of the furnace. The best option for organizing heating with natural circulation and with minimal risk that the coolant will boil.

Chimney heat exchanger

+ Simplicity of design.

+ Compatible with any oven design.

- Has a negative effect on cravings.

A chimney heat exchanger is a special case for organizing water heating based on a stove that is not equipped with a built-in heat exchanger. It is more often a cylindrical tank, fixed to the chimney so as to grip it around the perimeter. The water is heated by the heat of the gases emanating from the firebox. There is also a variant with a coil wound around the pipe. The first option is suitable for natural circulation heating, in the second case a pump is required. Both options are bad in that they significantly lower the temperature of the walls of the chimney, causing condensation and rapid clogging of the chimney.

The difficulty in designing a water circuit in a furnace is a strong heat removal from the combustion chamber or chimney. Due to this, the combustion temperature and, most importantly, the heating of gases can be significantly reduced, which affects the magnitude of the thrust. This is especially true for long-burning furnaces with a water circuit. Not only do they create a weak draft by themselves, heat removal can stop the smoldering of wood and thereby cause a dangerous situation when the stove dies out or, even worse, the draft collapses, and carbon monoxide, along with unburned flammable gas, will begin to flow into the room.

The main disadvantage of furnaces with a water circuit is the inability to regulate the temperature of the coolant and turn off the heating during the operation of the furnace. If the wood is already burning, then circulation must be maintained in the heat exchanger, otherwise the water will boil, and the metal will break from the excess pressure, and the stove will deteriorate, as will the interior situation in the house.

The problem is partially solved for external registers and plate heat exchangers. External convectors are capable of working as an air convector even without being connected to the heating system or quickly enough to dump the heat coming from the firebox. In the case of a coil and plate radiator, it can be positioned so that it is possible to shut off the flow of flue gases through it.

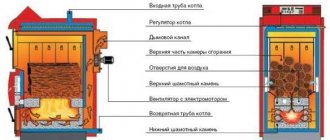

Inexpensive heating: modern stove with advanced technology

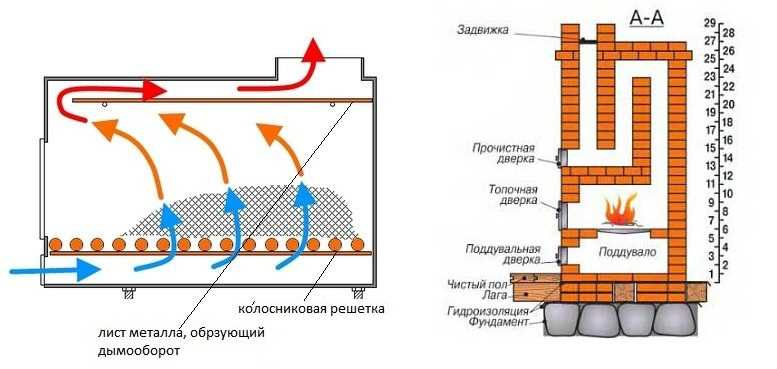

Stoves for wood-burning fireplaces, which use the so-called double combustion effect, are the most productive. To create it, oxygen is supplied to the furnace chamber through the ventilation holes located in it for two combustion zones: one above the wood, the second slightly higher.

Oxygen heats up, rising in the combustion chamber above the door window. The heavier and cooler incoming air sinks downward, creating a thermal convection effect. As a result, the smoke cannot settle down below and smoke the window.

The second vent is for feeding the fire from the back. One combustion zone is not able to cope with the complete combustion of fuel and gases, but due to oxygen penetrating through the holes in the upper part of the chamber, a second combustion zone is formed. The final combustion of the fuel takes place in it, and the amount of waste generated (in comparison with conventional wood-burning stoves) is reduced by 2-3 times. Gases that have not burned out in both zones go out through the chimney pipe.

To maintain maximum heat output, ovens are equipped with sealed doors, firewalls, refractory bricks, additional ceramic fiber insulation, etc.

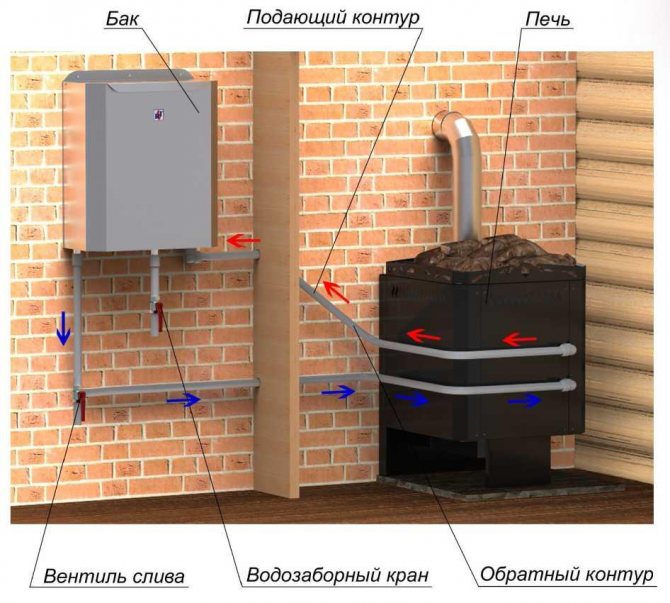

For a bath

For a bath, the main emphasis is on the heating rate.The stove is used sporadically and it is necessary to quickly heat the room. Water is needed to heat the dressing room using classic radiators or warm skirting boards and, possibly, for the underfloor heating system.

You can use any option with the exception of the boiler, which, by definition, picks up the temperature for a long time. Taking into account the active combustion of firewood in the heater, even a heat exchanger for the chimney is relevant. The temperature of the gases is more than enough to maintain traction and to heat the coolant.

In this case, it is impractical to organize heating with natural circulation, when the steam room is already ready in the bath, the heating will just start to warm up. Variants with extremely high heat transfer rates are not suitable.

It is easier and more efficient to install a pump and pump the coolant through radiators and floor heating pipes, build heating to use the coolant temperature in the range of up to 60 ° C and no higher.

Stoves for a bath with a heat exchanger: reviews

Reviews of consumers whose washing rooms receive hot water from a heat exchanger in a steam room or a bathhouse are heated with its help are usually positive.

According to one of the users, he kept a boiler for heating water in the bath for some time, but for the sake of economy he decided to switch to a cheaper design. And after thinking a little more, he did not buy the finished one at all, but on his own he twisted the coil and installed it inside the oven. I'm happy with the result.

Also, those who purchased a stove with an already built-in water circuit do not complain, because the water becomes hot in an hour and a half, and the steam room comes in two.

There are no problems with heating systems either - radiators brought into the cold dressing room by another bath owner solved the cold problem, the stove copes well with heating the combined washing and steam room, and heating the dressing room.

Are you convinced that a sauna stove with a heat exchanger is better and more profitable than a boiler? She will heat you and adjacent rooms, and make hot water for washing. And at the same time, the efficiency of the stove will increase if you hang the exchanger on the chimney pipe. Exchangers are inexpensive, but it's easy to make them yourself. In general, we recommend an affordable solution.

For home

The house needs heating for the entire cold period of the year, so proposals related to moderate and constant maintenance of the coolant temperature come to the fore.

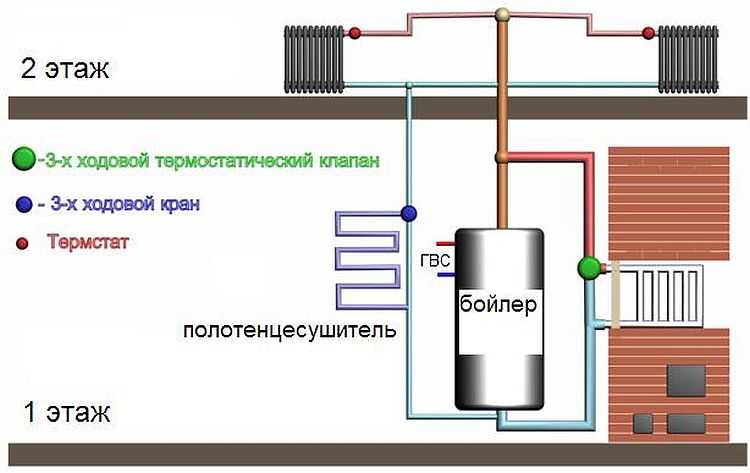

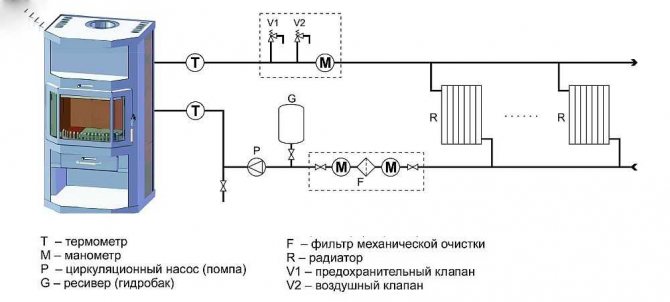

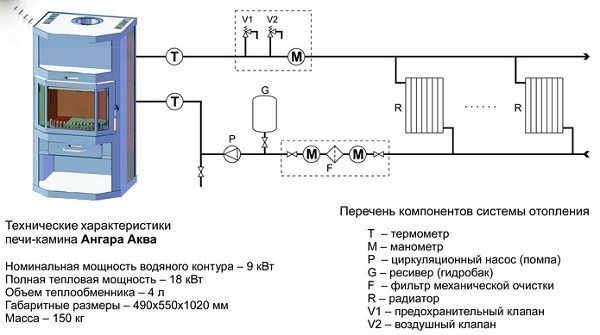

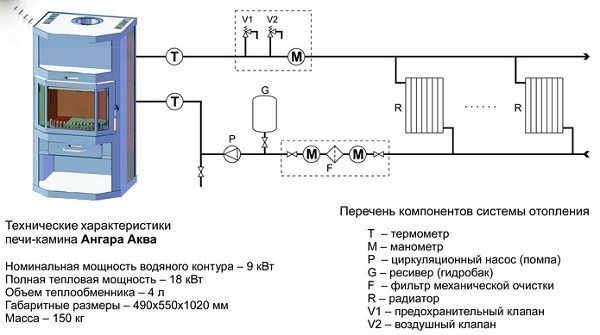

The principle of building a heating system is identical to that of solid fuel boilers. Preference is only given to a closed design with an expansion tank and a low pressure in the system not exceeding 2 atm., Which should be coordinated with the permissible pressure of the water circuit in the furnace.

Diagram of the organization of heating of a furnace with a water circuit Hangar Aqua

Heating circuit

Steam heating in a bath from a stove is recommended to be made of a forced type, with 2 circuits. The circulation pump is designed for condensate. With liquid heating, a pump is installed at the outlet of the boiler, increasing the flow of hot water into the system. What does the heating scheme for a bath look like?

- Furnace with heat exchanger. In the heat exchanger, an outlet for the water supply is made in order to fill the coil.

- Outlet pipe.

- If necessary, install an expansion tank. Steam can accumulate in it to prevent too high a load on the line.

- Steam supply pipe.

- If necessary, equip radiators. In the sauna, most often, pipes are located. A loop is made, a platform for stones is being set up. Batteries are installed in the break room. The washing compartment is heated by a stove that gives off heat, a pipe that comes out of the firebox or an expansion tank. A small room is allocated for the shower room. No special heating is done for it.

- Condensate line.

- Storage tank.

- A vertical pipe emerges from the tank. It is recommended to provide an air outlet in it.It is necessary so that an air lock does not form in the line.

- Water filter or sump.

- A circulation pump that pumps liquid from the storage tank to the boiler.

For the line, choose galvanized pipes with a diameter of up to 40 mm, a wall thickness of 5.5 mm. Radiators are also chosen from the same material. It is recommended to install a temperature and pressure regulator on the devices. In the steam room, the steam line is laid under the sun loungers. This will protect vacationers from burns when touching hot pipes. The sun loungers will not interfere with the heating of the sauna. The temperature of the pipes is over 100 ° C.

Source: OtoplenieBlog.ru