A stove with a remote firebox can be brick, metal factory or metal homemade. We will focus on the cheapest and fastest option - a stove with a remote firebox will be made of metal and lined with bricks.

Installing the stove in a bath with a remote firebox

Why did we choose this option?

- At cost, our option is several orders of magnitude cheaper than all the others.

- Does not require a large amount of construction work.

- According to its performance indicators, it satisfies even the most demanding users.

It is not necessary to brick the factory metal stove, it has reliable protection against getting burns, this simplifies the work, but worsens the comfort of being in the bath. The fact is that the stove cools down very quickly, you need to constantly add firewood. The firewood burned up in full force - it is too hot in the steam room, the fire began to die out - it is getting cool. A homemade metal stove can be bricked - not only increases the safety of use, but also significantly stabilizes the temperature indicators.

Another important point. On many sites, it is recommended to use fireclay bricks during furnace work. It is right. But only on one condition - only "heavy" fireclay is used. The fact is that there is also "light" fireclay. It also withstands significant temperatures, but has one feature - it does not let heat through. Such "light" chamotte is used in smelting furnaces, where minimal heat transfer is required: at very high temperatures inside the furnace, the temperature of the outer walls rises insignificantly.

Can you imagine how the stove will be heated in a bath made of "light" fireclay? This type of bricks can be used during the construction of chimneys - no additional thermal insulation is needed. It is very simple to distinguish between two types of fireclay bricks: the first is heavier than ordinary red in weight, the second is much easier.

Varieties of fireclay bricks

In our version, you can get by with an ordinary red brick, it is much cheaper and in all operational and fire-fighting characteristics it fully complies with the existing state regulations.

A few more "introductory" data. The portable firebox can be both outside the bathhouse and in the dressing room (rest room). For a personal bath, the second option is preferable: the rest room is heated at the same time and there is an opportunity to throw firewood on your own at any time. It is recommended to make a firebox on the street in cases when strangers often wash in the bath and it is not always possible to enter the rest room.

A Few Practical Tips for Choosing a Remote Fireplace Metal Furnace Project

You should briefly dwell on this issue, knowing some of the details will allow you to avoid troubles during its operation.

| Advice | Photo | Description |

| Heating water. |

Heat exchanger-register for the furnace, internal

Heat exchanger tank per pipe

Very important! Not all stones are suitable for the heater, some may emit carbon monoxide when heated. There are quite a few such stones, but there is one universal advice - never take stones with streaks or splashes of white!

Video - How to make a metal stove for a bath with a remote firebox with your own hands

How and where can you install a stove with a remote firebox

The wood-burning stove can be installed in the bath in various ways.We must say right away that it is quite possible to do this with your own hands, there are many illustrative examples on YouTube from amateurs who demonstrate the whole process in the video.

Inside:

The stove can be installed both inside the bath and outside. In the first option, there is a danger, since all procedures will have to be done directly in the steam room. There is usually not much space in the bath, there you will also have to store fuel for a wood-burning stove and ask everyone to move over while you are working with this unit. The plus is that you do not need to go out into another room every hour or an hour and a half and throw up firewood, as is the case when the firebox is remote.

Also, the disadvantages of a wood-burning stove located inside the steam room include the "burning out" of oxygen. To make people feel comfortable and can take a steam bath without fear, it will be necessary to make an excellent ventilation system.

In the dressing room:

The remote firebox is good in that it takes up less space and heats not only the air inside the steam room, but also the dressing room, where everyone usually changes clothes. Agree, you do not want to be in a cold room after several hours "tormenting" the body with warm air and cold water.

Also, such an arrangement is many times better for people - oxygen is burned out in the steam room much less, which means that the whole rest will be more comfortable. It costs a lot. You can stock up on much more firewood and keep all of them in the dressing room, where there is a "window" to the firebox.

Of the minuses, as you may have guessed, the need to leave the steam room in order to throw up the next batch of firewood. But this needs to be done only once every 50-80 minutes, so it's not particularly annoying, especially when the company is large and it is done in turn.

On the street:

The last option, which is extremely rarely used, is a stove with a remote firebox that faces the street. It has only one advantage - if you use coal as fuel, then there will be no unpleasant smell and soot inside the steam room. All this will be on the street, in the very same bathhouse - only warm. But in this case, every time you have to run outside, which is not to everyone's liking, although often people do it just to freshen up, lie in the snow and then run back to steam. But the weather is not always conducive to this. It should be said that this method of placing the firebox is used extremely rarely.

Foundation

There are two options here.

The first one - the floors of the bath are already laid

The option, let's say right away, is not very pleasant. How to solve the problem? First, you need to approximately calculate the total weight of the stove along with the brickwork.

The weight of the furnace can be found in the manufacturer's passport or catalog.

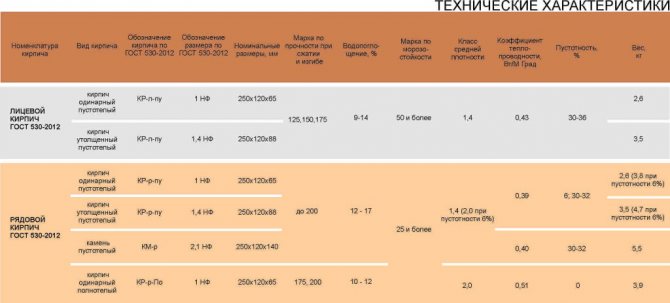

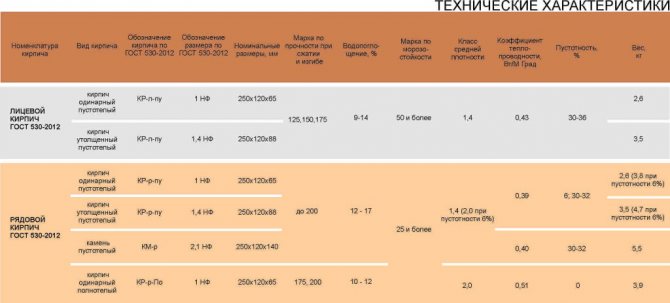

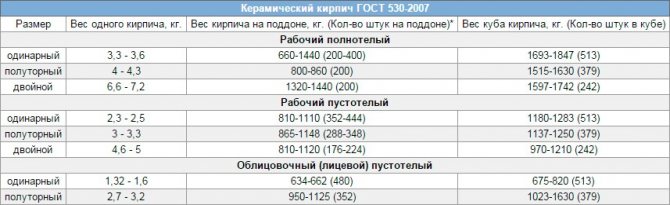

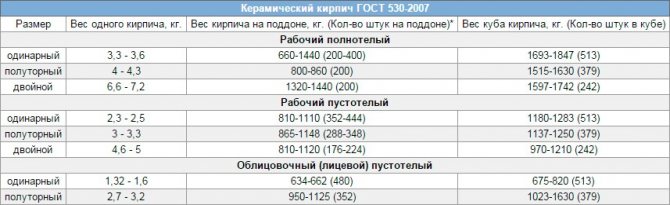

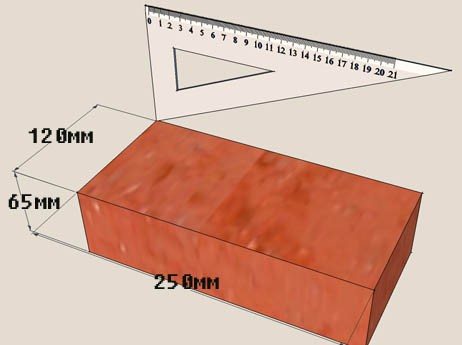

The weight of one red solid brick is ≈ 3.5 kg, the masonry will be half a brick. There is no longer a need, such a thickness will provide both normal heat transfer and sufficient structural stability.

Red brick weight

Pallet weight with brick

There are recommendations to do the brickwork in a quarter (to put the brick on the edge), but we would not recommend it. First of all, a solid experience is required for laying on the edge. Secondly, the stability of the structure is unsatisfactory.

For reference. The dimensions of a standard single brick are 250 × 120 × 65 mm. For one cubic meter of masonry, approximately 520 pieces are needed with a mortar thickness of about one centimeter. To facilitate the calculations, you need to remember that for 1 m2 of masonry in a half-brick, ≈ 53 bricks are needed. Take with a margin, there will inevitably be waste.

Standard sizes of solid bricks

Very important. Most "experts" advise using a clay solution when laying a stove, "long and tedious" talk about the types of clay and other intricacies of preparing such a solution. Please read this information carefully and only use it when laying stoves in your home.In the bath, the clay will "flow" over time and wash out, you will have to make unscheduled repairs and close up ugly seams. Conclusion - use only cement-sand mortar for laying stoves in a steam room; to minimize the risks of cracking, slightly reduce its thickness.

Find the location of the floor beam, you can find it by the floor nails. As a rule, during the construction of a bath, a timber is used under the floor covering with a size of at least 100 × 100 mm, it can withstand up to 500 kg of weight. This is quite enough for a small metal oven; there is no need to reinforce the timber.

Photo of floor beams

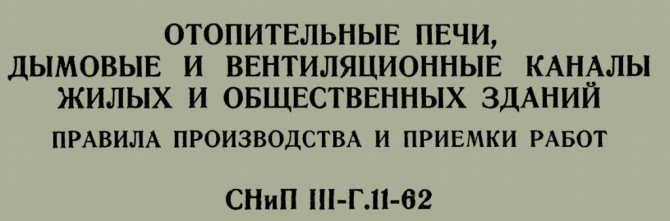

Put a sheet of metal under the perimeter of the furnace, it is desirable to make thermal protection, strictly adhere to the rules of SNiP III – G.11–62.

It is not recommended to use asbestos sheets as heat-insulating material, today there are harmless materials made of pressed mineral wool in the market.

Mineral wool prices

For brickwork, you need to make waterproofing (for fireclay - no need, it is not afraid of moisture). For waterproofing, it is better to take two layers of ordinary transparent plastic film - this is much more beautiful than black roofing felt. The protruding film must then be carefully cut around the perimeter of the masonry. Do not be afraid that such a stove base raises doubts about its reliability. If the chimneys were brick - yes, even a slight "wobble" of the stove can cause big problems. In our version, the chimneys will be made of metal pipes. At the junctions and at the places where they exit to the outside, the structure is "floating", capable of compensating for small fluctuations.

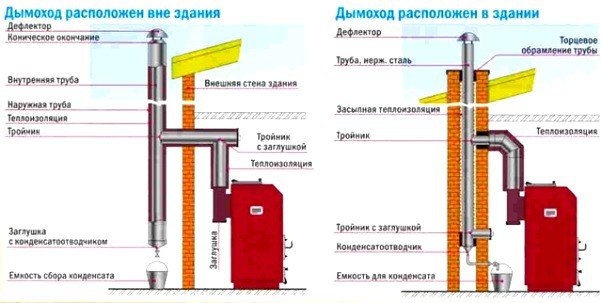

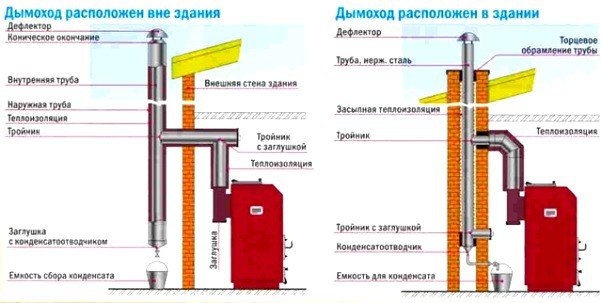

Types of chimneys for a bath

Second option. The floors have not yet been laid

The best option is to make a stable foundation for the stove. And the presence of a foundation significantly expands the possible options for furnaces, both in weight and in terms of design. How to make a foundation?

Furnace installation

You have already decided where the firebox will go. This does not have a particular effect on the technology of construction work, but it does affect the comfort of using the bath.

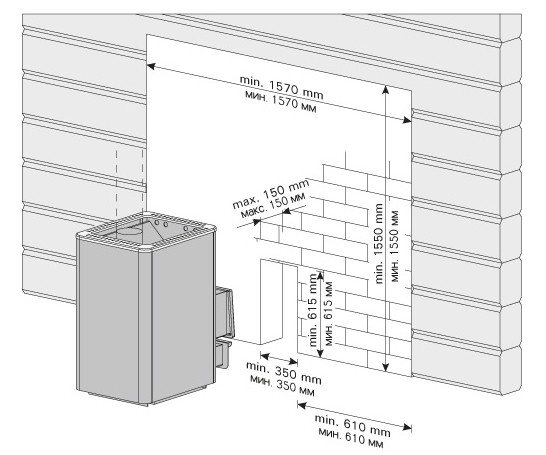

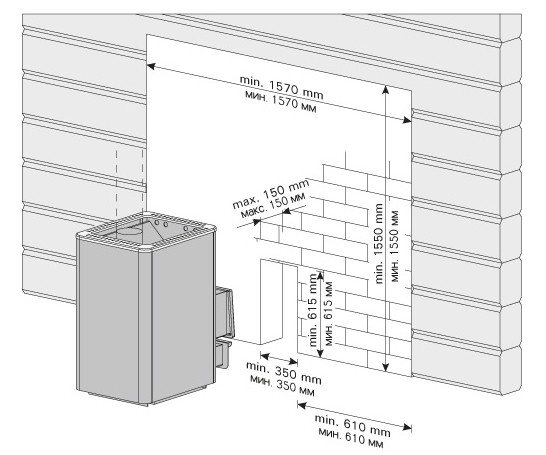

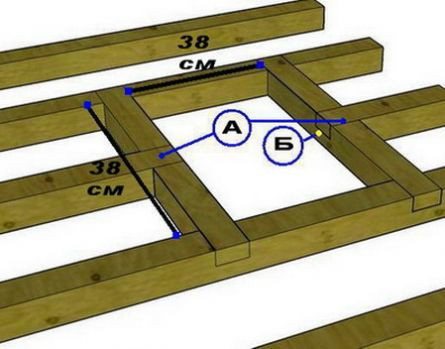

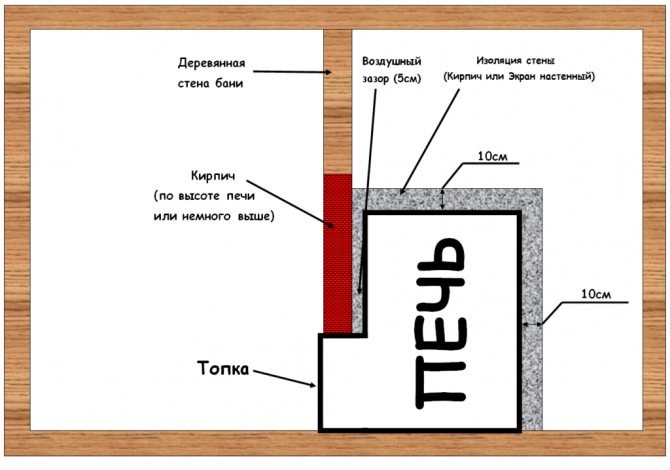

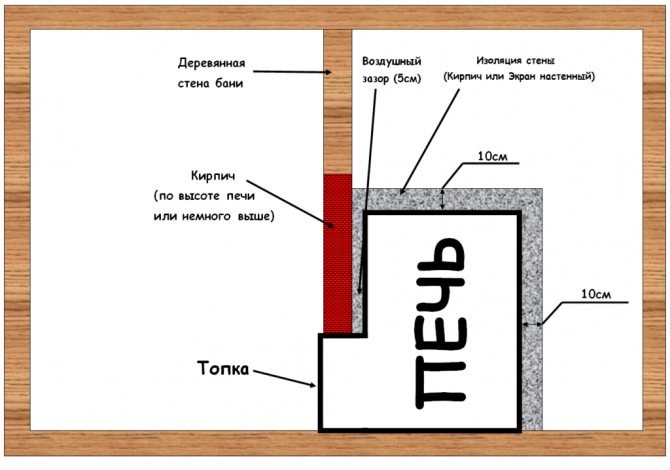

Step 1. Mark the firebox outlet. Cut a hole for the firebox. The hole should be 20-30 centimeters more along the perimeter than the firebox.

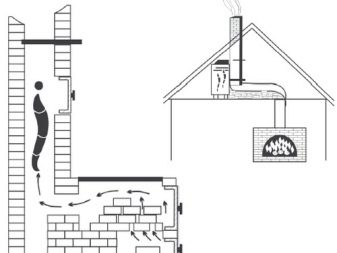

Opening scheme for a furnace with a remote firebox

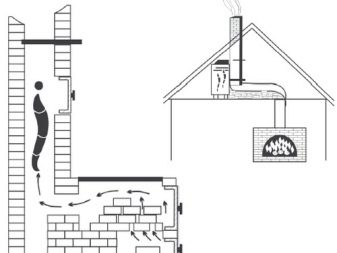

Step 2. Solve the chimney issue. We recommend that you do not take it out on the roof for several reasons. First, there is no need to do quite complex and time-consuming work to ensure fire safety on the ceiling and roof. Secondly, any additional "holes" in the roof significantly increase the likelihood of leaks in these places. Thirdly, it is much more expensive and more complicated, it requires the use of various additional elements for roofing, depending on the specific material. We recommend bringing the chimney through the wall - quickly, cheaply and reliably.

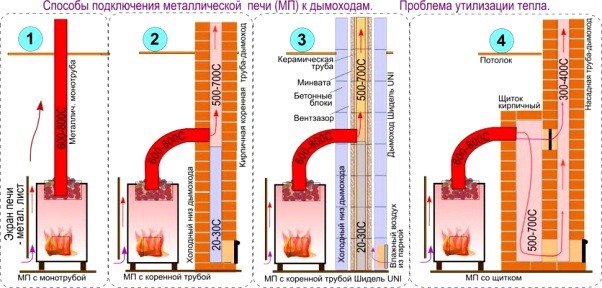

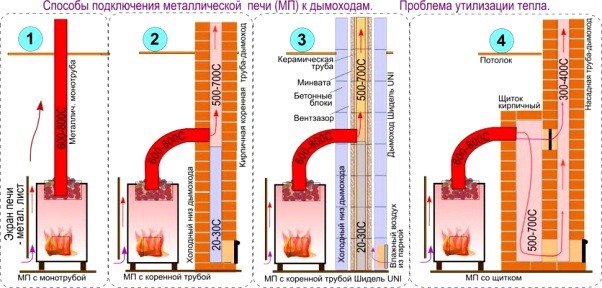

Options for connecting a chimney to a sauna stove

Exterior view with mounted chimney

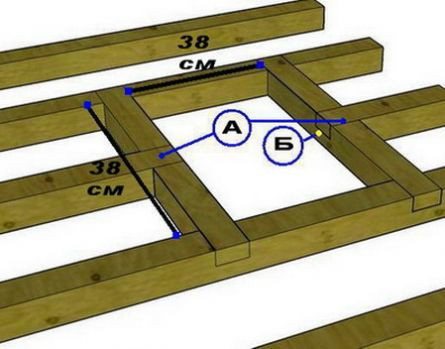

Step 3. Make holes in the wall or ceiling and roof (depending on the way the gases are discharged). And in this case, the holes should be oversized.

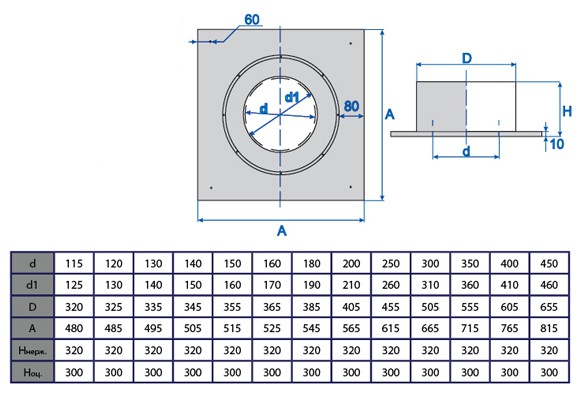

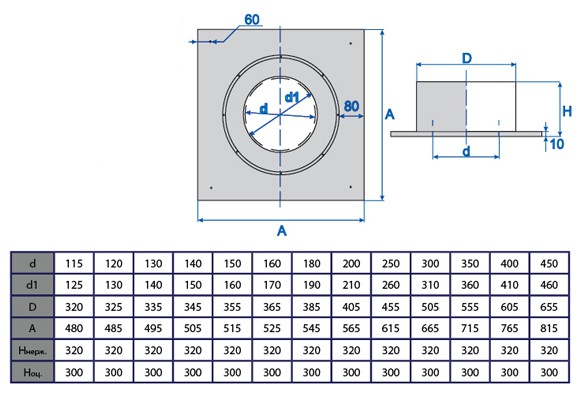

Chimney duct size

Holes in the roof and in the ceiling are cut for the installation of the chimney pipe

Dimensions of the ceiling cut-out for the chimney

Step 4. Temporarily install the stove in its place, check the position of the remote firebox and chimneys. If necessary, correct the position of the holes, make precise markings. Collect all the elements of the stove and chimney. Assemble the gas exhaust pipes, adjust their dimensions, determine the methods of fixation and thermal insulation. We will talk about installing pipes a little later. This is a very important and rather complex topic.

Sauna stove installation diagram

"Fitting" work has been completed successfully - you can proceed to the capital installation of the furnace with a remote firebox.

How is the installation carried out?

First of all, you need to take measurements. To do this, representatives of our company visit the site, carefully check the features of the structure, and then draw up an estimate. After that, you can start the installation process and insulate the structure with refractory materials. Further, our employees install heating equipment with all the elements, connect it to the chimney, and proceed with the exterior decoration.

We offer you to familiarize yourself with Heat-resistant tile adhesive: types, characteristics, choice

We draw your attention to the fact that in the course of the work, specialists necessarily conduct instructions on observing fire safety rules and acquaint the client with the operation of the furnace. At the end, an act of completion is drawn up for signing by both parties.

Installation and construction works

Some useful knowledge to simplify fire safety work. The ignition temperature of the phosphoric head of the match is + 200 ° C, the temperature of spontaneous combustion of wood, depending on its moisture content, ranges from 350 ° C to 450 ° C. Why do we remind this? There is always high humidity in the bath, do not be too afraid of overheating of the walls and spontaneous ignition of a log house or floorboards. But do not neglect the elementary rules of fire safety, all work must be done wisely. They need to be done slowly and very carefully.

Let's start with a remote firebox. It is better to fill the gap between the firebox and the wall with red brick. Brick on both sides can be plastered or sheathed with sheet metal. If there is a remote firebox in the bathhouse, nail a sheet of galvanized (or any other) iron about 40 × 40 cm in size to the floor. If you wish, you can put asbestos under it, but we do not recommend doing this. First, asbestos releases carcinogenic substances and is banned for use in all developed countries. Secondly, even without asbestos (or other insulating material), the probability of a floor fire under the iron sheet is zero.

Chimney

This is more complex work, we will consider both options for exhausting gases - through the wall and through the roof.

In order for the bath to meet all expectations, it must have a good stove. It should perform the functions of a heating element, provide safe and soft heat, and also provide heat to several rooms at once. In addition, the oven must guarantee safe use.

All of the above requirements are met by a brick oven with a firebox from the dressing room.

Features: pros and cons

The design of a stove with a firebox in the dressing room is more complex than the design of a conventional stove. The firebox can be removable or included in a one-piece structure.

Despite the complexity of the implementation of such a project, it is worth paying attention to its following advantages:

- two rooms are warmed up at once: a dressing room and a steam room. This creates additional convenience when preparing for bathing events and staying in the dressing room after them;

- garbage along with firewood will not be brought into the steam room, which will ensure ease of cleaning, since dust will not turn into dirt in a damp room;

- it is convenient to organize a place for drying firewood near the firebox, which is impossible in a steam room;

- in the steam room, you can install brick protection, which will prevent burns;

- the steam room will keep clean air, unpolluted by smoke from burning wood when you open the door directly in the steam room;

- saving space in the steam room due to the absence of a firebox door;

- during the heating of the bath, it will not be necessary to constantly go out and go into the steam room in order to throw up firewood, which will not allow the room to cool down every time the door is opened.

Along with all the advantages of a remote firebox, one can also note such disadvantages as:

- the complexity of the installation, especially for a beginner in this business. To implement such a project, it is better to seek advice from specialists;

- to maintain the temperature in the steam room, you will have to leave it for less heated air.

The firebox can be placed not only in the dressing room. Sometimes she is taken out of the room.... This is realized if the dressing room is too small or if the bath is used for commercial gain. With such a firebox arrangement, the bath attendant does not need to enter the room to the guests, he can keep the temperature in the steam room from the street.

The advantages of this option include protection against the spread of dirt in the premises.

Selection and arrangement of a heater with an external firebox

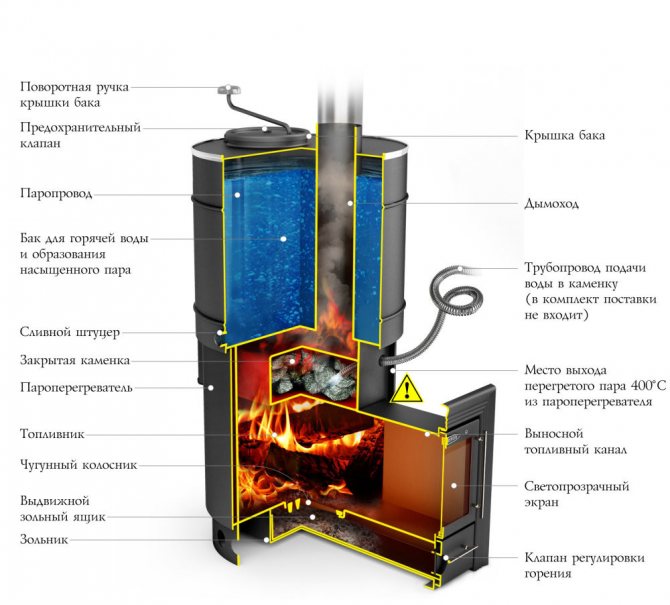

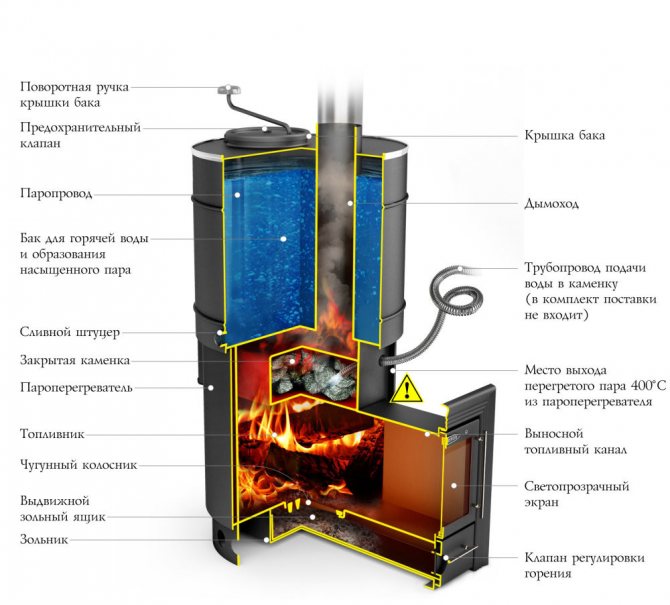

Furnace device with a remote firebox.

You can buy metal stoves for a bath, for which a remote firebox is provided, in a specialized store. Industrial models have reliable protection, which ensures the safe operation of the device. You don't need to worry about which brick to choose, since there is no need to line metal stoves to protect against burns. A certain discomfort caused by the operation of the model is associated with the need to constantly add firewood. Since it becomes too hot in the steam room due to the full heat of the fuel, the gradual extinction of the fire leads to the cooling of the room.

You can use a metal sheet to make your own oven. It won't take long to complete such a project. The costs will also not be too high. It will not be difficult to make the walls of a sauna stove out of bricks if you completely overlay a homemade structure with special fireclay bricks for safety reasons. Heat dissipation from the device will be uniform and safe.

Many experts recommend using heavy fireclay for lining a sauna stove, since ordinary brick devices can have a low level of heat transfer. This is typical for smelting furnaces made of fireclay bricks. The stove structure for the bath must withstand high temperatures due to the easier heat transfer.

Fireclay bricks, which are usually used to equip chimneys for baths, can be replaced with red. The cost of this material is lower in comparison with the price of other similar ones, therefore its use is considered more profitable when installing brick ovens for a bath with external furnaces. This material meets all standards, meets operational requirements and fire-fighting characteristics.

Advantages of the firebox from the dressing room

Installation of a furnace with a remote firebox.

The installation scheme of the stove structure involves the separation of the dressing room and the steam room. The heating device is usually installed near a partition, which is very convenient both in cold and warm seasons. There are a number of advantages that such a scheme of the oven and dressing room has:

- The lowest degree of air burnout in the dressing room eliminates the need to install a ventilation system.

- Storing and laying firewood in the dressing room allows you to constantly maintain cleanliness in the steam room.

- The intake and renewal of combustion air ensures the necessary ventilation and freshness in the steam room.

- The installed stove in the bath does not require a passage through the wall, since the firebox door is located in the steam room.

- Possibility of direct control of the temperature inside the bath rooms.

- Additional heating of the steam room due to the firebox door.

- Convenient laying of firewood, which can be brought closer to the stove.

- Saving the area of a small steam room, amounting to about 1 sq.

Designs of stoves with a firebox in the dressing room allow you to create "light" steam, get aesthetic pleasure from the sight of a flame in a firebox with a glass door. Removing ash and chips from a dry dressing room will not be difficult, as well as garbage left after walking in this room in street shoes. By tradition, it is very convenient to heat the bath from the dressing room, since the laying of firewood is carried out outside the steam room, where it will always be clean.

Safety requirements

The material for the construction of a bath is most often initially hazardous for the outbreak of fires. To avoid fires, you need to follow the safety rules even at the planning stage of the construction site. The first time after construction, a wooden bathhouse will shrink, therefore, before installing the stove, it is necessary to make sure that the structure has settled sufficiently and will not crack.

Since the walls of the furnace unit in the bath heat up to high temperatures, which is fraught with harm to health in the form of burns, you must strictly follow the fire safety rules when installing the furnace. Installation rules are spelled out in SNiP 41-01-2003 (chapter 6.6).

- Install a solid foundation under the base of the oven. It will be adjacent to the wall between the dressing room and the steam room. It must be covered with heat-resistant material. In the event of damage to the foundation, the stove can crack or lurch, and this is dangerous by a fire in a wooden building.

- From the oven door to the walls of the bath, the distance should be at least half a meter. If the oven is in a corner, then all surfaces to which it is adjacent must be insulated with a heat-resistant material.

DIY installation

To independently install a brick oven for a bath with a firebox from the dressing room, you should perform the following preparatory work:

- it is better to think over the place for mounting the furnace at the stage of building the premises;

- before starting work, the foundation for the furnace is equipped. For this, a foundation pit is pulled out. Its bottom is covered with crushed stone, then sand and covered with waterproofing material. The foundation is strengthened with pieces of reinforcement and poured with concrete;

- a platform for the oven is laid with bricks;

- in the area of the firebox door, a metal sheet is attached to the floor;

- the structure of the furnace, passing through the opening in the wooden wall, is lined with brickwork;

- before laying the oven, the bricks are immersed in water so that the pores of the material are filled with moisture;

- insulating material is laid between the furnace metal and the brick.

After the preparatory work, you should proceed directly to the construction of the furnace:

- The first stage is laying out the oven itself with bricks. Brick, which is used to lay the walls of the house, will not work. For a sauna stove, you need one that has increased heat resistance. It must be in perfect shape, without cracks and chips.

- First, each row is laid out without using a solution. This is done in order to find the ideal bricks in shape and size. The laying of any of the rows begins with a corner brick.

- The first row is laid out from the corners around the perimeter. First, the mortar is applied, then a number of pre-selected bricks are laid. Before laying, each brick is dipped in water for 20 seconds. The seam thickness should be no more than 5 mm.

- The second row is laid out with an offset. The seams in the second row should be in the middle of the first. The following rows are laid out similarly.

- A blower door is installed at the level of the fourth row. It must be fixed with galvanized wire. On the side of the steam room, the stove is lined with a stone screen to protect it from burns.

- The second stage is to install the combustion door. It is fixed with galvanized wire twisted several times.

- Next, a stone chamber is being built. The size is calculated based on the number of stones. Finally, it is finished with steel sheets.

- After the furnace of the required height has been erected, a steel sheet is placed on top, on which a hole has been previously cut.

Chimney installation

The final step is to connect the chimney to the stove. This can be done in several ways, using brick, metal or ceramics. Installation can be external and internal. Correct installation of the chimney will not only save the room from soot and soot, but also save health from the harmful effects of fuel combustion products.

A brick chimney is the safest in terms of fire safety, but its construction is a complex process.It is used to remove smoke from two or more ovens. The ceramic chimney is heavy and expensive. However, it has good characteristics: it is resistant to corrosion, does not overheat, with a smooth surface inside, which prevents the accumulation of soot on the walls. This variety is not very popular.

It is not difficult to install a metal chimney, it is affordable at a price. Of the shortcomings, rapid heating is noted, and this is fraught with ignition. In addition, condensation forms when hot air passes through the outdoor half of the pipe. therefore thermal insulation material is used in modern metal pipes... The advantage of this type of outlet pipe is the absence of edges, which makes it possible for the smoke to escape freely outside.

The external chimney is a pipe that goes out from the wall and rises along it to the roof. It will not be difficult to install such a chimney both at the construction stage and in an already finished bath. The advantages are safety, ease of maintenance. The downside is the need to insulate the pipe so that condensation does not collect inside when the temperature drops.

Installation of the pipe to the side of the wall is carried out using a bend or elbow. The chimney section passing through the brickwork of the wall is sealed with a metal box filled with heat-resistant material. The pipe is fixed vertically along the wall using holders. A protective fungus is installed on the top.

The indoor version of the chimney is a pipe extending from the sauna heater to the ceiling through the attic and the roof. The advantage of this method is the preservation of heat in the bathhouse and attic for longer. Of the minuses is the complexity of installation through the roof.

A chimney is assembled from several parts, any higher part is put on the lower one, and then it is well fastened with clamps. Before fixing the elements, the joints are lubricated with a heat-resistant sealant... The pipe is then passed through the ceiling and roof.

Places of passage of the pipe from the inside and outside are protected by an under-roof sheet and a roof cut. Heat-resistant insulation is laid around the pipe.

After laying the roof, waterproofing is carried out so that water does not get into the joints. A protective umbrella is installed on top of the pipe.

What you need to know about ovens

Furnaces are selected for their intended purpose.

If the task is to heat the house and the stove is the only source of heat, then first of all its power and heat capacity should be taken into account.

The power of the oven depends on its size. 1 square meter of the furnace surface produces an average of 0.5 kW. Heat loss of a dwelling with good insulation - 1 kW per 10 square meters of house area or 40 W per 1m3 if you count by the volume of the room. From these calculations, it turns out that a stove with a size of 1000x1000mm produces an average power of 4 kW, which is enough to heat a room with an area of 40 square meters. If the size of the stove does not correspond to the area of the heated room, you will overheat it wanting to get as much heat as possible in the cold season, which leads to the destruction of the stove.

You can calculate more accurately the heat loss at home using special online carculators.

The heat capacity of the furnace depends on the thickness of its walls. Non-heat-consuming stoves include all types of metal stoves that give off heat while the wood is burning. Heat-consuming thick-walled ovens slowly warm up and do not cool down during the day, maintaining a comfortable temperature in the house. The heat capacity of the furnace is increased by lining the furnace walls with fireclay bricks. The lining also increases the strength and lifespan of the kiln itself, protecting the kiln brick from sudden temperature changes.

In order not to overheat the stove, it should be heated for 1.5 - 2 hours 1 - 2 times a day.

Fireplace stoves, unlike conventional heating stoves, have a voluminous firebox and a large furnace door, which allows not only to admire the fire, but also to quickly heat the room with the radiant heat emanating from the flame. Also, the fireplace stove can be stoked with the door open, like a regular fireplace. To do this, the forward valve is opened and the smoke goes directly into the chimney without heating the walls of the fireplace stove, which is convenient in the warm season.

For cooking, Russian ovens, ovens with a bread chamber and Swedish ovens are used.

The Russian stove is designed to heat the room and cook food in a large chamber, in addition, you can always warm up on a warm stove bench. The average size of a Russian stove is 1500x2000mm. To increase the efficiency of the Russian stove, its modifications are used: a Russian stove with bottom heating and a Russian stove with a flood, popularly called a teplushka.

The construction of the baking chamber resembles the chamber of a Russian oven with a flood but of a more compact size. Bread chambers are most often equipped with fireplace stoves. They prepare food and bake bread in the chamber after the wood is burned in the firebox of the stove.

Shvedka is a heating stove with a cast iron hob. It is convenient to use a Swedish stove in the country, thanks to a hot stove, such a stove quickly heats the air in the room. But such a stove also cools down faster, so the hob reduces the efficiency of the stove.

If the area of the heated room is more than 100 square meters, then it makes sense to build a boiler furnace. A heat register of 1.5 - 2-inch stainless steel pipes is built into such a furnace. This register is connected to the water heating system of the house. Register power is 8-15 kW. The register can not be installed in every oven. In such a furnace, a heating hood is required, which allows the gases to move freely along the set register. Duct furnaces are not suitable for installing a heating register in them. It is not recommended to install the register in an oven with a hob. The hob, like the register, quickly lowers the temperature of the gases in the oven, which contributes to strong soot formation and abundant condensation.

Open fireplaces are not intended for heating the house; they are more of a decorative element of the house. The fireplace emits radiant heat during the burning of wood, the walls of the fireplace do not heat up. Closed fireplaces (with a glass door) and fireplace stoves are much more effective.

Sauna stoves of the heater are subdivided into intermittent and continuous stoves.

In intermittent kilns, stones and cast iron are placed in a closed kiln chamber and heated directly by fire and high-temperature flue gases. The stones are red-hot and have a temperature of 500 - 800 ° C. At this temperature, all the soot on the stones and in the chamber burns out without a trace. You can take a steam bath after the firewood in the firebox has completely burned out. Usually, such a stove is heated for 4-5 hours, and then they stand for another 1-2 hours before going steamed. The temperature in the steam room is maintained within 50 - 70 ° С for more than a day without additional heating of the stove. The steam is dry and light. The optimal temperature for bathing procedures is 60 ° C at 60% humidity.

In continuous furnaces, the stone fill is placed in a stainless steel tank and heated to a temperature of 400-450 ° C, which is sufficient to obtain high-quality steam. Due to the fact that the stones are partially openly located in the steam room, the temperature in the room rises higher than when using a batch heater, about 70 - 90 ° C. You can also steam without waiting for the wood in the stove to burn out, and even vice versa, you can put wood in the firebox during the bath procedures. The constant-action sauna stove is called RusSauna, allowing you to get the modes typical for both the bath and the sauna.

Tips & Tricks

Experts recommend adhering to the following rules:

- first of all, when installing the oven in a bath, it is necessary to act in accordance with the rules of SNiP. This will ensure operational safety and extend the service life of the heating element;

- you should not save on materials, especially on heat-resistant insulation;

- when choosing a place for a bath, it is better to give preference to a free-standing structure. If the bath is an extension to another building, then you need to take care of the insulation of the adjoining wall;

- when choosing a brick, you need to pay attention to its heat-resistant and moisture-resistant properties. If finances do not allow you to purchase an expensive brick that meets these requirements, you can cover a more affordable brick with a special compound;

- the pit for the foundation must be dug out larger than the size of the furnace. The base of the stove should be 10 cm larger than the perimeter of the heater on all sides;

- bricks with small defects can be used in the masonry of the stove, but at the same time it is impossible to lay the damaged brick inside the smoke channel and to the outside of the stove, and it is also necessary to trim the chipped edges and corners so that when laying it does not get too thick joints;

- when installing the stove into the wall of the bath, you must follow the characteristics of the unit described in the attached instructions. If the stove is made independently, then you need to take the average power values;

- the ideal chimney should be 2 m high without knees and slopes. This will provide normal traction;

- After installation, the oven should be heated several times in a gentle mode for half an hour to check its correct operation and dry. It is necessary to dry the oven so that cracks do not appear during operation;

- for several days, the stove door, as well as the windows and doors of the bathhouse, should be kept open, creating a draft in the room. The absence of condensation on the damper will be a sign that the furnace is ready;

- despite the observance of fire safety rules and the use of a high-quality stove, you need to remember about fire extinguishing means. They must be available at all times;

- the most common fire source is the ceiling. Therefore, one should not forget about its protection. It must be covered with a metal sheet;

- in the bath, it should be as safe as possible, even in case of poor health of visitors. The oven must be shielded with a protective screen.

What you should pay attention to?

Before placing an order for the installation of a stove in the house, you must determine for yourself what functions it will perform, where to place it, what area of the room you need to heat. These parameters directly affect the overall dimensions and design. It is also worth remembering that it is better to install the fireplace stove in a room with good ventilation.

We suggest that you familiarize yourself with Installing the stove in a bath with a remote firebox

Information about the materials from which heating devices are made will help you choose the best option for yourself. Metal stoves are quite popular. They are easy to install and take up little space. Cast iron - are able to provide good fuel economy, have a simple design, and metal cool down a little faster.

The brick device is the most traditional. Basically, now they are ordered to install a stove in a bath. They retain heat for a long time, warm up a large area well, but have significant weight with a complex structure.

If you have a power outage or poor gas supply, you can install a wood-burning stove. You can harvest wood yourself or buy it, and you should not forget that wood is an ecological product that does not have a harmful effect on nature and humans.

There are also solid fuel stoves, the features of which can be called a rather long burning time and high heat. Often in the design itself, a hob is already provided, thanks to which you can not use electricity, which also sometimes allows you to save well.

Experienced employees of our company will help you figure out what kind of device you need, as well as perform high-quality installation of the stove in the bath. They will advise you on issues of interest and always help you find a way out.