Pipe production methods

Stainless steel pipes are a derivative of rolled metal products. Based on the production method, the following types of stainless steel pipes are distinguished:

- Hot deformed;

- Cold-deformed;

- Heat-deformed;

Products can be produced from flat-rolled products, which are subjected to technological bending and subsequent welding. In this way, welded pipes are obtained. For seamless pipes, a stainless circle is used as the starting material, and in this case, piercing, rolling and calibration are used in the manufacture of the pipe. Seamless stainless steel pipe as a single piece has increased strength and high mechanical properties.

Varieties of pipes

- Seamless. On the Russian market, seamless pipes can be found of domestic and Chinese production. Seamless ones are made in two ways: cold-rolled and hot-rolled. Both methods have their advantages, but you need to pay attention to the fact that pipes made by hot-rolled method are much inferior in quality to cold-rolled products, therefore they are not used in those enterprises where the quality requirements are overestimated. But also in the production process, the material can undergo additional processing. After that, they can be further divided into types (mirrored, rough, polished). The wall thickness also plays a huge role, so it must be taken into account. Up to 20 different alloys can be used in the manufacturing process, which must be corrosion resistant. And also a feature of seamless products is high strength, so they are used in many industries. For example, seamless polished stainless steel pipes are very often used for decorative purposes for decorating the facades of houses and interiors.

- Electrowelded. On the Russian market, this type is presented by Asian and European manufacturers. They are also used in many industries.

- Profile. Products of this type can be rectangular, square, sometimes oval. Due to the fact that the pipes have different shapes and high technical characteristics, the scope of their application is wide enough, so they can be seen in many industries.

- Corrugated. This type is used for water supply and heating systems.

- Mirrored. This variety is highly resistant to corrosion due to its smooth coating. And also perfectly withstands the effects of chemical and other aggressive substances. In addition, the product can withstand high temperatures (from 400 to 800 C⁰), which allows the pipes to be used where there are such requirements.

- Square and rectangular products are used to create all kinds of frames (furniture, awnings).

- Polished. Most often, polished pipes are used in the food industry, since the smooth surface of the products avoids the formation of all kinds of bacteria. Therefore, such products are polished not only from the outside, but also from the inside.

Classification

Stainless steel pipes differ in geometric characteristics depending on the diameter and shape of the pipe section, as well as the type of surface treatment. In cross-sectional shape, pipes can be round, square and rectangular. According to the type of processing, they are divided into:

- Matte

- Sanded

- Polished

The pipe wall thickness makes it possible to divide stainless pipes into thick-walled with high strength and thin-walled. Thin-walled pipes are characterized by high flexibility, therefore they are necessary for the manufacture of complex structures.

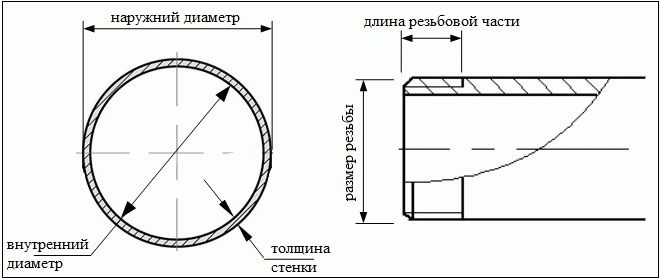

Diameters of stainless pipes - GOST and size table

Pipes made of stainless steel alloys are actively used today for the installation of heating systems, water supply and sewerage systems. Choosing the diameters of stainless pipes according to a special table of sizes, you can successfully select such products for solving various problems.

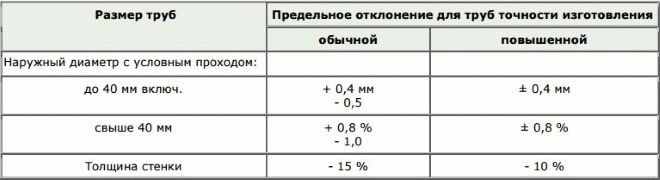

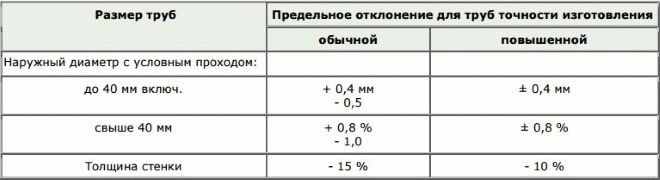

For each type of stainless steel pipe, there are maximum permissible deviations from the parameters defined by the relevant standards.

All pipes for the production of which stainless steel is used are produced in strict accordance with the regulatory document. GOST specifies not only the chemical composition of the material of their manufacture, but also the technology of their production, size and assortment.

Classification options

The entire range of pipes made of stainless steel is divided into several categories. The parameters by which such a division is carried out are:

- design features (seam and seamless);

- production technology (cold rolled, cold drawn and hot rolled);

- cross-sectional shape (round and profile);

- wall thickness (thick-walled and thin-walled).

Corrosion-proof pipes of various sizes are actively used for the arrangement of communications through which cold and hot water is transported, as well as for the installation of sewer systems. Such pipes, differing in significant diameter, are successfully used for the installation of oil and gas trunk pipelines.

The ratio of the outer diameter to the inner diameter for thick-walled stainless pipes is in the range of 0.05-0.1

The high popularity of stainless steel pipe products is explained by a whole list of its advantages:

- exceptional durability;

- the ability to operate under high pressure;

- resistant even to significant temperature extremes;

- high plasticity;

- resistance to corrosion, demonstrated even when operated under constant exposure to aggressive media.

It should also be noted that the minimum service life of stainless steel pipes is 10 years.

Main varieties

GOST stipulates, among other things, a range of stainless steel pipes, which includes products:

- used for the transportation of liquid and gas media - water and gas pipelines;

- covered with a special anti-corrosion compound;

- differing in insignificant wall thickness and having threads at the ends (such steel pipes, the diameters of which may be different, also have a reduced weight);

- produced using welding technologies and having longitudinal seams;

- seamless, made by hot-rolled technology.

Each of the types of stainless pipes, the range and diameters of which are stipulated by GOST, should be discussed in more detail. Water and gas pipes

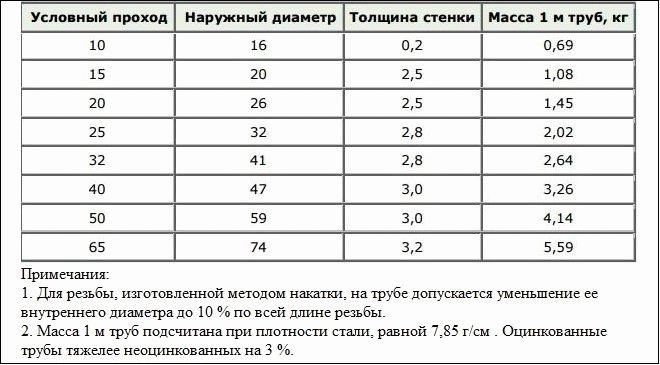

The diameter of pipes of this type, as indicated by GOST, can vary within a fairly wide range: 15–50 mm. Such stainless pipes, depending on what pressure they are intended for operation, are divided into lightweight, standard and reinforced.

Parameters of water and gas pipes

GOST stipulates that the ends of water and gas pipes must be cut at an angle of 90 °, and the welded seams on their surface must be completely welded and sealed. In accordance with the standard, there may be minor chips on the surface of such steel pipes, but in general, their walls should be smooth and free of cracks.

Read also: Welding of thin stainless steel with an electrode

Anti-corrosion coated pipes

These pipes, which are also listed in the stainless steel product range, are distinguished by the fact that they have a zinc coating on their surface, which provides additional corrosion resistance. In accordance with the regulatory document, they should not have areas uncoated with zinc, coating blisters, burrs and other defects.

The dimensions of the thread, if applied to the ends of such pipes, should not exceed 10 percent of the length of the product itself.

Thin-walled threaded pipes

These pipes, available in various sizes, are used in cases where it is necessary to repair or change the design of the pipeline. Products of this type, which make it possible to obtain reliable and tight connections, are not thick-walled and are not produced with large cross-sectional dimensions.

Parameters of light series pipes made for thread

On the surface of hot-rolled pipes, which can be thick-walled, there are no welds, which gives such products a high tightness and allows them to withstand even very significant pressure. These products, the standard sizes of which are also stipulated in the assortment, are distinguished by the smoothness of the walls and the minimum coefficient of thermal expansion.

The most common areas of application for such pipes, the dimensions of which can vary within a fairly wide range, are:

- installation of highways for supplying cold and hot water;

- arrangement of sewerage systems;

- installation of heating systems and communications for other purposes.

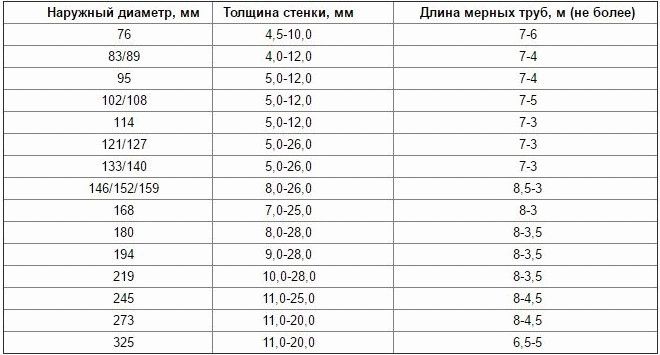

Sizes of Seamless Hot Wrought Stainless Tubes

It should be borne in mind that both thin-walled and thick-walled tubular products produced by welding can be used to supply water used for technical purposes, and not for drinking or cooking.

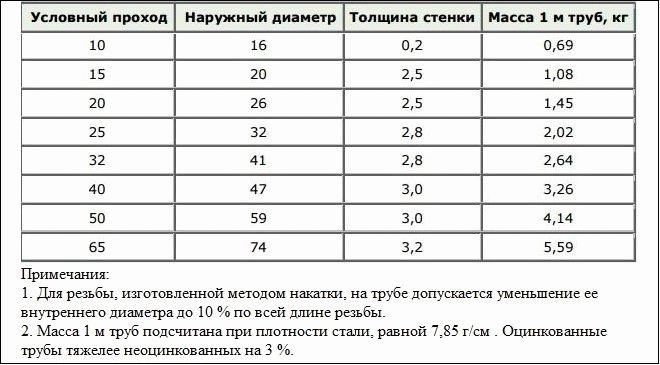

Standard sizes

The list of standard sizes of stainless pipe products includes the following parameters:

- nominal bore size - inner diameter, which can vary within 10–150 mm (the larger this parameter, the higher the permeability of the pipes);

- thread sizes (in accordance with the requirements of the standard, this parameter can vary in the range of 3 / 8-6 inches);

- outer diameter, which, taking into account the dimensions of the welded seam, can vary in the range of 17–156 mm;

- the outer diameter of steel pipes, which are made without the use of welded joints, is 16–159 mm.

Main dimensions of stainless pipes

Stainless steel pipes, depending on their type, are manufactured in accordance with the requirements of various regulatory documents:

- GOST number 3262-75 - water and gas pipelines;

- 10705-80 - obtained by welding;

- 20295-85 - designed for laying main pipelines.

Each of the above regulatory documents contains tables that indicate the assortment and standard sizes of such products.

Brands and guaranteed parameters

The tables contained in the regulatory documents for stainless steel pipes contain various parameters. In particular, from these tables, you can take information about the steel grades used for the production of such pipes.

Permissible deviations from dimensions must be within the values indicated in the table.

Knowing the grade of the material from which the pipe is made allows you to get an idea of which of its parameters are guaranteed. These include, in particular:

- A - mechanical characteristics of the steel used;

- B - its chemical composition;

- B - the ratio of the chemical composition and mechanical properties of the alloy used.

Application of stainless pipes

Today pipes are indispensable in various fields: in the food industry, in mechanical engineering, in the petrochemical and mining industries, etc. They are used for laying utility lines and pipelines, transporting, among other things, aggressive gases and liquids.

Passat LLC supplies seamless and welded stainless steel pipes, round and profile sections.

| SEAMLESS PIPES | ELECTRIC WELDED PIPES | PROFILE PIPES |

The range includes stainless pipes of the following steel grades: AISI 201, AISI 202, AISI 304, AISI 321, AISI-316L, AISI-316Ti, AISI 409, AISI 430, various sizes (square from 20x20mm to 300x3000mm, rectangular from 10x20mm to 400x200mm, round diameter from 10mm to 300mm), and types of surface (polished, mirror, matte).

Why do you need to know the weight of a stainless steel pipe?

"Why know the weight of steel pipe products?" - the question is really reasonable.First of all, the calculation of this parameter is not so much an economically justified action as it is correct from a safety point of view. If you miss this stage when designing any structure (pipeline or building), construction work may not even be completed before the destruction of the structure.

Of course, the calculation of the required number of steel products and significantly saves the budget of a company or a group interested in construction. You will know exactly what costs will have to be faced and what adjustments can be made to the plan. Correct calculations also allow the consumer to understand how many fasteners will be needed for a given structure load.

Similar calculations are carried out when installing pipelines from products from other materials: from reinforced polypropylene, cast iron, copper, etc. Typical dimensions are indicated in the product documents.

Characteristics of electrowelded pipes

International standards: electrowelded pipes from austenitic steel grades ASTM A554, A270, A312, A249, A269, DIN 17457, 17455 Seam welding type - TIG, laser seam. Surface: • Matt • Sanded (180, 320, 400 Grit) • Mirror (400,600 Grit)

Symbols for determining the type of surface of an electrowelded pipe

| Surface type | Designation | |

| Matt | Matt, Mill finish | Matt |

| Sanded | Brushed | Brushed, primary grinding |

| Satin 180 Grit Satin 320 Grit Satin 400 Grit | Grinding degree | |

| Mirrored | Mirror 400 Grit Mirror 600 Grit | Polishing degree |

The form: • round • profile Length: 6m (delivery of pipes of any length is possible on request). Sizes: • diameter from 6 mm to 325mm • section from 10x10mm to 300x300mm, 400x200mm Wall thickness: from 0.8 mm to 6 mm

Fields of application of electrowelded pipes

• Heat exchangers and heaters • Decorations, structures • Oil and chemical industry • Food industry • Shipbuilding and mechanical engineering • Water transportation systems

Product standards according to intended use (stainless welded pipes)

| USING | E.N. Euro Norm | S.S. | ASTM-ASME | DIN | NFA | GOST |

| Chemical industry | EN 10217-7 | 219711 219713 | A 358-SA 358 A 312-SA312 A 269-SA 269 | 17457 | 49147 | GOST 11068-81 |

| Food products | EN 10217-7 | A 270 | 11850 | 49249 | ||

| Heat exchanger | EN 10217-7 | 219711 219713 | A 249-SA 249 | 17457 2818 | 49247 49244 | GOST 11068-81 |

| Pipeline | EN 10217-7 | A 778 A 269 | 17455 | 49147 | ||

| Drinking water | EN 10312 | DVGW541 | ||||

| Decoration, construction | EN 10296-2 | A 554 | 17455 2395 | 49647 |

Seamless pipe characteristics

International standards:

- ASTM A312 - Seamless (cold-rolled) pipes made of austenitic stainless steels,

- ASTM A213 - Seamless Ferritic and Austenitic Alloy Boilers,

- superheating and heat exchange tubes.

Surface: Matt The form: round Length: 5-7m Sizes: diameter from 6mm to 325mm Wall thickness: from 1mm to 13mm

Applications of seamless pipes

• Pipes of general purpose, chem. and nuclear industry • Heat exchangers • Stoves and chimneys

Product standards according to the intended use (stainless seamless pipes)

| using | GOST | International standard |

| General purpose pipes | GOST 9940-81, GOST 9941-81 | ASTM A312 |

| Heat exchange tubes | GOST 9941-81 (dimensional) | ASTM A213, DIN 17458-85, ASTM SA268, ASTM A269 |

| Instrument tubes | GOST 19277-73, GOST 10498-82, GOST 14162-79, | DIN 17458-85 |

| Boiler pipes | TU 14-3R-55-2001, TU 14-3-460-75, TU 14-3R-197-2001 | |

| Furnace pipes | GOST 9940-81, GOST 9941-81, m / s 10X23H18, 15X25T, | ASTM A312, m / s TP 310S |

Dimensions and weight of stainless steel pipes according to GOST

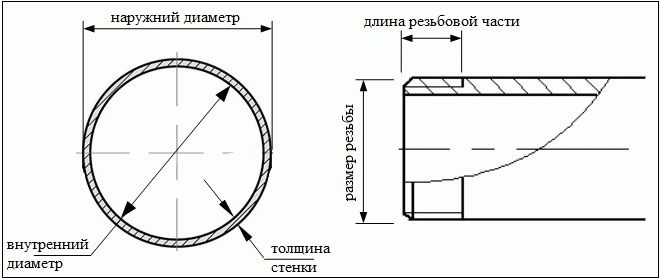

At the present time, stainless steel pipes are actively used in construction. Their diameter depends on several factors - the manufacturer's company, manufacturing method, wall thickness. In addition, it affects the parameters of the pipes and the purpose for which they will be used. Diameter is the length between the outer edges of the pipe. This distance is equal to two radii.

Read also: Ax from a circular saw blade drawings

Such an indicator is measured in millimeters and is indicated by a special sign?. But, there is also the only exception - samples of GOST 3262-75 in modern industry are usually measured by the inner diameter. Such models are designated by the symbol Du.

What are provided by state standards dimensions of stainless pipes, table will allow you to find out in detail.

It should be noted that according to GOST 8734-75, thin-walled and cold-worked pipes are distinguished.In the first case, models of such dimensions are produced - 2.5 x 0.3; 4.0 x 0.2; 10 x 4.0; 16 x 2.0; 20 x 3.0; 22 x 1.5; 38 x 1.0; 40 x 2.0; 60 x 1.8. As for hot-deformed samples, here the standard provides for the production of pipes, the parameters of which are - 23 x 5.0; 26 x 4.0; 40 x 5.0; 48 x 6.0; 57 x 2.8; 60 x 4.5; 68 x 4.0; 75 x 5.0; 85 x 9.0; 102 x 10; 120 x 6.0; 133 x 3.0 160 x 4.5; 180 x 10.

According to experts, it is best to use pipes with a standard diameter in production. Stainless steel pipe, dimensions according to GOST which belongs to this category, allows you to work as simply as possible. If you have information about what the diameter is, then you can select all the necessary elements without any problems - plugs, transitions, fittings, and so on. In addition, the diameter will allow you to calculate the weight, size. The pipe is stainless, taking into account all these parameters, it will be as effective as possible.

If the same diameter is noted, then the throughput of stainless models will be an order of magnitude higher than in the case of steel samples. All pipes according to the current standard are divided into three large groups - small, medium and large.

The first category includes those models whose diameter exceeds 50, namely - 59, 89, 108, 114, 159. Pipes of medium diameter are already correspondingly large. As a rule, there are models with sizes - 219, 325, 377, 530. There are other samples, but they are not used so often for one reason or another. And finally, the dimensions of large diameter stainless pipes are 630,820,1220,1620. It should be noted that according to the standard, there are no restrictions. That is, it is quite realistic to purchase pipes of larger sizes than those listed above.

Weight of a running meter of stainless pipe directly depends on the diameter. The mass is calculated, taking into account the grade of the metal used in the production. With information regarding the mass of the pipe, you can easily translate such data into length. The approximate weight of a running meter of stainless steel pipes is indicated in the corresponding GOST.

If you need a stainless steel pipe aisi 304 in production, order them in our online store for various samples that differ in outer diameter, wall thickness. This steel grade is good in that it does not react with liquid and gaseous media. It is classified as austenitic and contains up to 0.08% carbon. Its domestic counterpart is 08X18H10. An alternative could be the A500 fittings.

|

|

|

There are other alloys with excellent corrosion, chemical and mechanical resistance. We recommend paying attention to such products as stainless steel aisi 316 pipe, whose characteristics are improved due to alloying with molybdenum (addition of 2.5%). Chemical resistance allows the product to be used even in the cold and salty waters of the northern seas. The enterprises control the compliance of the chemical composition of products with GOST 5632. Also, many of our products are manufactured in accordance with GOST, for example, a professional sheet, which can be found here.

Read also: Wood planer for home workshop

Price for stainless steel pipes with VAT

| Nomenclature | Weight 1 r.m. | Price, RUB / kg | ||

| Seamless 08 / 12Х18Н10Т GOST 9940-81 | ||||

| 57x4.0 | 5,300 | 365,00 | . | |

| 60x5.0 | 6,875 | 365,00 | . | |

| 76x4.5 | 8,044 | 365,00 | . | |

| 76x5.0 | 8,875 | 365,00 | . | |

| 89x4.0 | 8,500 | 365,00 | . | |

| 89x5.0 | 10,500 | 365,00 | . | |

| 108x3.0 | 17,870 | 365,00 | . | |

| 133x6.0 | 28,800 | 365,00 | . | |

| 152x8.0 | 32,950 | 365,00 | . | |

| 159x6.0 | 34,900 | 365,00 | . | |

| 168x10.0 | 39,460 | 365,00 | . | |

| Seamless 08 / 12Х18Н10Т GOST 9941-81 | ||||

| 15x1.5 | 0,600 | 378,00 | . | |

| 16x1.5 | 0,700 | 378,00 | . | |

| 18x2.0 | 0,800 | 378,00 | . | |

| 20x4.0 | 1,275 | 325,00 | . | |

| 21x4.0 | 1,000 | 325,00 | . | |

| 22x4.0 | 1,425 | 325,00 | . | |

| 25x2.0 | 1,548 | 387,00 | . | |

| 25x2.5 | 1,604 | 387,00 | . | |

| 25x3.0 | 1,650 | 387,00 | . | |

| 25x4.0 | 1,770 | 387,00 | . | |

| 28x3.0 | 1,875 | 387,00 | . | |

| 32x2.0 | 1,889 | 335,00 | . | |

| 32x2.5 | 1,841 | 335,00 | . | |

| 32x4.0 | 2,800 | 335,00 | . | |

| 38x2.0 | 1,880 | 335,00 | . | |

| 38x4.0 | 3,400 | 335,00 | . | |

| 42x3.0 | 2,925 | 335,00 | . | |

| 45x3.0 | 3,150 | 335,00 | . | |

| 45x5.0 | 5,000 | 335,00 | . | |

| 48x4.0 | 4,400 | 335,00 | . | |

| 57x3.0 | 4,050 | 365,00 | . | |

| 57x3.5 | 4,681 | 365,00 | . | |

| 76x3.0 | 5,475 | 355,00 | . | |

| 83x3.0 | 5,925 | 355,00 | . | |

| 85x3.0 | 6,075 | 355,00 | . | |

| Profile AISI 304 / 18H10 | ||||

| Sanded | Polished | Matt | ||

| 20x20x1.5 | 286,69 | 288,36 | 222,02 | . |

| 20x20x2.0 | 376,16 | 307,00 | 283,87 | . |

| 25x25x1.5 | 402,00 | 332,21 | 275,96 | . |

| 25x25x2.0 | 435,00 | 426,00 | 404,41 | . |

| 30x30x1.5 | 399,00 | 370,00 | 329,90 | . |

| 30x30x2.0 | 523,68 | 503,00 | 428,18 | . |

| 40x20x1.5 | 552,70 | 402,58 | 389,00 | . |

| 40x20x2.0 | 580,15 | 529,27 | 428,18 | . |

| 40x40x1.5 | 589,00 | 487,64 | 523,35 | . |

| 40x40x2.0 | 783,02 | 714,11 | 778,15 | . |

| 50x25x1.5 | 425,06 | 458,00 | 476,47 | . |

| 50x25x2.0 | 680,00 | 725,00 | 749,35 | . |

| 50x40x2.5 | 980,00 | 995,00 | 1000,00 | . |

| 50x50x1.5 | 690,00 | 744,20 | 626,45 | . |

| 50x50x2.0 | 985,84 | 970,00 | 905,68 | . |