Features of the design of coal furnaces

If you look closely at a coal stove and its most common competitor, a wood-fired one, then, in principle, it will be difficult to find special differences at first glance. But with a closer examination and familiarization with the principle of operation of the furnace itself, it becomes clear that they differ fundamentally. (See also: Do-it-yourself stove housekeeper)

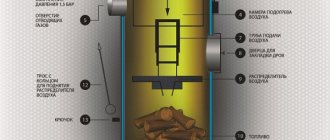

- The principle of combustion and air supply differs, if for wood-burning stoves the most efficient combustion can be achieved when air is supplied directly to the place of fuel combustion from above, then for coal stoves it is necessary to purge the fuel and supply the air mixture from below.

For wood-burning stoves, the use of dry fuel in the heating process is not particularly critical. It is only important that the initial kindling of the furnace occurs with dry material. It is advisable to preheat coal before adding it to the crucible in a special section of the furnace, which is heated by exhaust gases.

The design of the chimney for a coal stove differs slightly from wood-burning counterparts and is designed for a higher air flow rate. And the flow itself and its speed are regulated not with a yushka, but with the help of a blower. The very same damper that blocks the chimney (yushka) is completely absent. This feature is due to the fact that coal stoves smolder for a very long time, and do not quickly burn fuel like wood-burning ones. The disadvantages of coal stoves are also associated with this feature:

- it is impossible to block the chimney by preventing, the weathering of heat will be poisoned by carbon monoxide because of the danger, and therefore coal heating stoves cool down rather quickly.

- For normal combustion of a coal furnace in its lower compartment, it is desirable to exclude the presence of combustion products. To do this, it is necessary to periodically clean the ashtray, which will be constantly replenished with burnt coal. In this case, cleaning should occur more often than is necessary for a wood-burning stove.

The walls of coal stoves must withstand a higher temperature than ordinary wood stoves, respectively, they will be thicker, and more heat-resistant materials must be used for their assembly.

(See also: DIY camping stove)

A coal stove may have a special design for loading fuel, this is due to a higher ignition temperature of coal - that is, it will not be possible to flood such a stove with just a piece of newspaper and matches. Therefore, in a coal stove, firewood is first kindled, and coal is loaded from above, which gradually flares up as the wood burns out.

In practice, combined furnaces are often used, in which both coal and wood can be burned at the same time. In addition, the fuel can also be used as a fuel peat briquette, which is very similar in combustion to coal. In combined devices, all elements of both coal and wood stoves are simultaneously present.

Natural fuel stove properties

Foundation for a brick oven.

As already mentioned, the combustion temperature of coal is quite high. With sufficient air flow into the firebox, it reaches 1000-1100 ° C, so not every material is able to withstand such conditions for a long time.

For comparison: dry wood under identical circumstances is capable of giving no more than 700 ° C in the firebox, and even then very rarely. In addition, coal fuel is much more nutritious than firewood.

That is, when burning 1 kg of anthracite, almost 2 times more thermal energy is generated than from the same amount of wood, as shown in the table:

| Type of fuel | Calorific value | |

| MJ / kg | kW / kg | |

| Wood moisture 25% | 10,1 | 2,8 |

| Hard coals | 21,5 | 5,9 |

| Brown coals | 15,5 | 4,3 |

Previously, in old houses, heating stoves or stoves were laid out only of solid red brick. With constant burning of high-calorific coal from the high temperature, the masonry began to crumble, so the owners lined the firebox from the inside with thick steel soles from the railway tracks to protect the walls.

At the moment, the problem of coal combustion is solved much easier - with the help of fireclay bricks. The design of the furnace provides for lining the fuel chamber with fireclay stone of the SHA, SHB or SHV grade to a thickness of a quarter or half a brick. This material is able to maintain a temperature of 1400 ° C without problems and for a short time up to 1650 ° C

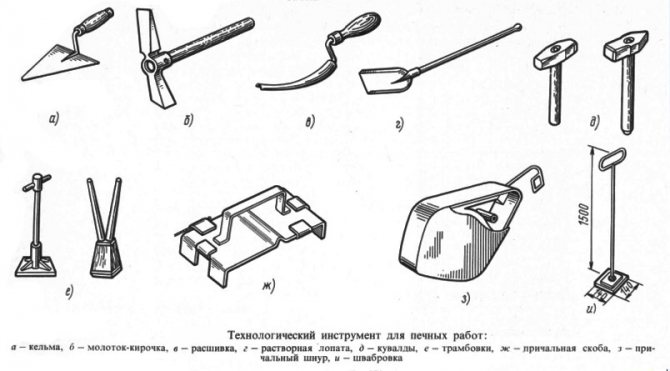

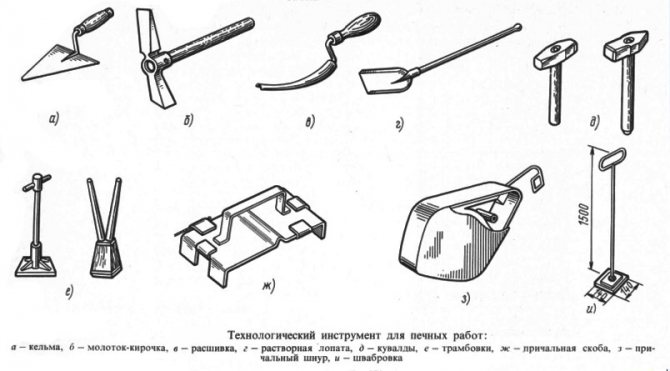

Furnace masonry tools.

There is another point: due to the higher calorific value than wood, a greater amount of heat is released, part of which goes with the combustion products into the chimney.

To avoid this, a more developed network of smoke circuits is provided in the coal furnace, where the flue gases have time to transfer heat to the brick walls, and not fly out straight into the chimney.

Otherwise, this is an ordinary brick stove with all the advantages and disadvantages.

Coal

Coal is a traditional raw material for solid fuel boilers. It burns for a long time and has good heat dissipation, but only if it is correctly laid in the firebox, competent ignition and subsequent support.

Coal selection

To increase the boiler efficiency and extend its service life, it is necessary to take into account the manufacturer's recommendations for choosing a coal grade. Usually the brand name and its fraction are indicated in the technical passport of the device. Each of the brands has a different ratio of carbon and impurities, different moisture content, structure, strength and age of formation.

The most popular types of coal for solid fuel boilers:

- Coal. The heat transfer of the fuel is 5500 kcal / kg. The average percentage of carbon and ash is 75% / 3%. Suitable for lighting most classic boiler models.

- Anthracite. Specific heat indicators - 9000 kcal / hour. The percentage of carbon is no more than 7%. The disadvantage of the variety is the difficulty in firing up and the extremely high combustion temperature.

The most demanded and convenient for ignition is hard coal of the long-flame category. This universal fuel for all types of boilers ignites quickly, burns for a long time and gives off a large amount of energy.

You can find brown coal and lingitis on sale. However, these grades are only recommended for commercial use due to their high ash content and high humidity levels.

How to heat a boiler with coal

The solid fuel plant consists of two main chambers: the upper one is used for stowing fuel, and the lower one (ash pan) is used for collecting ash and slag. As the fuel burns in the main chamber, the combustion products gradually fall into the ash pan, from where they are removed manually.

Before starting melting, it is necessary to prepare the installation for operation. For this, solid combustion products are removed from the ash pan, the walls of the combustion chamber are wiped and the chimney channels are cleaned.

As soon as the preparatory work is completed, you can start loading fuel and igniting.

- Place dry paper on the grate of the main chamber. It is recommended to pre-crumple it - this way it will ignite faster.

- On top, evenly lay the chips, brushwood - in the form of a well or a hut.

- Light a match and bring it to the paper from different sides - the paper will evenly flare up, involving chips in the process.

- Close the firebox door, open the ash pan flap for oxygen supply. At this stage, you will have to monitor the combustion process of the chips. The intensity can be adjusted using the ash pan (blower) door.

- As soon as the chips have completely ignited, pour a small layer of fine coal on top of it. Its amount should not exceed a third of the combustion chamber.

- After loading the first batch of coal, close the door again to reach the maximum combustion temperature. This usually takes about

- When the first layer of fuel completely engulfs the flame, add the remaining coal to the upper border of the door. Beforehand, it is recommended to slightly stir the burning coal.

- Close the blower door halfway. If there is strong smoke, leave a small crack.

As the combustion progresses, fuel is added in small portions to the main chamber, each time closing the ash pan flap. Do not put a large amount of coal at once - this will lead to solidification of the fuel on the grate and its premature deterioration.

Coal for the stove

To reduce heating costs during the cold season, coal remains the most demanded type of fuel. It has its merits:

- High heat dissipation.

- Low content of sulfur and volatile components, which speaks of environmental friendliness.

- Easy maintenance and storage - enough canopy and no groundwater.

- Affordable cost depending on the type of coal and manufacturer.

We offer a smart solution

For private sectors in the outback, as well as for enterprises with boiler equipment, there is a choice of fuel from leading producers - Kuzbass, Khakassia, Donbass. We offer a choice of:

- Long-flame coal of any manufacturer in bags and in bulk.

- Anthracite grades AKO, AK, AO. Which are the most promising fuel option for industrial scale and boiler houses, programmed for a certain size of the stone.

All coal has accompanying documents, which contain all the characteristics of the fuel. You can get acquainted with the documents in absentia or directly upon receipt.

Delivery is carried out by any convenient transport or company, including the railway, in all regions of the regions of Russia.

Firewood

Firewood is another popular type of boiler fuel. Only dried wood is suitable for burning. Underdried firewood in the firebox begins to release moisture, which accumulates on the inner surfaces of the firebox and chimney. In combination with smoke and carbon monoxide, tar is formed - it reduces the operational properties of the boiler and reduces the permeability of the exhaust gases.

Choosing firewood

For melting, hard wood with a long burning period and slow heat transfer is optimal. Deciduous trees should be preferred over conifers. In the process of combustion, conifers emit a large amount of resinous substances, quickly contaminate the combustion chamber and heat exchanger.

According to the degree of hardness, wood species are divided into 3 categories:

- hard - white acacia, ash, beech, oak, maple, yew, hazel, pear;

- medium hardness - walnut, alder, sycamore, birch, cherry, sweet cherry, cedar;

- soft - poplar, aspen.

How to heat a boiler with wood

- At the first stage, it is necessary to warm up the heating device well. This will prevent smoke from leaking into the room. Sheets of paper are laid at the bottom of the fuel chamber, on them are flammable birch bark, chips and splinters, and on top are small logs (up to 15 cm in diameter). The space between the wood chips can be filled with paper for faster ignition.

- When the firebox is about half full, you should set fire to the paper and open the ash pan valve for better draft. Close the main chamber door.

- When the chamber and chimney are warmed up, and the preparatory bookmark begins to burn out, the firebox can be filled with large firewood.Logs can be laid out in a row or in the form of a well, leaving gaps between them for air penetration.

- As the wood burns out, you will need to make a new bookmark, without waiting for the previous one to fade.

Long-burning boilers greatly simplify the work. The fuel is loaded in them every 6 hours due to the automatic regulation of the draft and the combustion process. Such devices should be melted in accordance with the attached instructions.

How to calculate coal consumption

The consumption of coal in a solid fuel boiler depends on many factors. Costs are affected by:

- Heated area.

- The amount of heat loss.

- Ambient temperature.

The exact costs can be calculated only after the end of the heating season. Moreover, depending on the winter, the average consumption of coal for heating can vary from 8 to 15 tons (for a building of 200 m²).

If you make averaged calculations based on real operating experience, you can get the following data:

- Costs for September - October will amount to 1 bucket per day.

- Fuel consumption rates in a coal boiler from November to February will increase to 10 buckets per day.

- In March and April, you will need to burn 1-2 buckets per day.

Calculation of the coal consumption for a boiler of 20 kW, using the above data, will show that the costs during the heating season will amount to 580 buckets or 10-10.5 tons.

How much is?

Here are some examples of the average price for 2 types of coal, which can vary depending on the region and the seller's company.

| Coal grade | Average price for 50 kg (bag) | Cost of 1 ton (when buying up to 10 tons) | Price (when buying over 10 tons) |

| Anthracite grade "AKO" | 700-750 p. | 13500 p. | RUB 10,000 |

| DPK brand. | 450 p. | From 6800 rub. | 6500 RUB |

The wholesale price per ton is significantly lower than the retail price.

Expert opinion

Pavel Kruglov

Stove operator with 25 years of experience

It is better to buy coal from a time-tested seller. For each region, you will need to find dealers of coal companies. In any region, such sellers distribute quality fuel at dealer prices.

The main thing is to check all the documentation for coal and its quality, compliance with the type upon delivery. If coal dust was brought to you under the guise of a nut, it is better to refuse the services of such a company.

How to do it yourself

- The design of a brick oven fired with coal or briquettes is quite simple, you just need to comply with two conditions:

the firebox must be made of refractory bricks; the stove must be equipped with cleanings in all parts of the chimney.

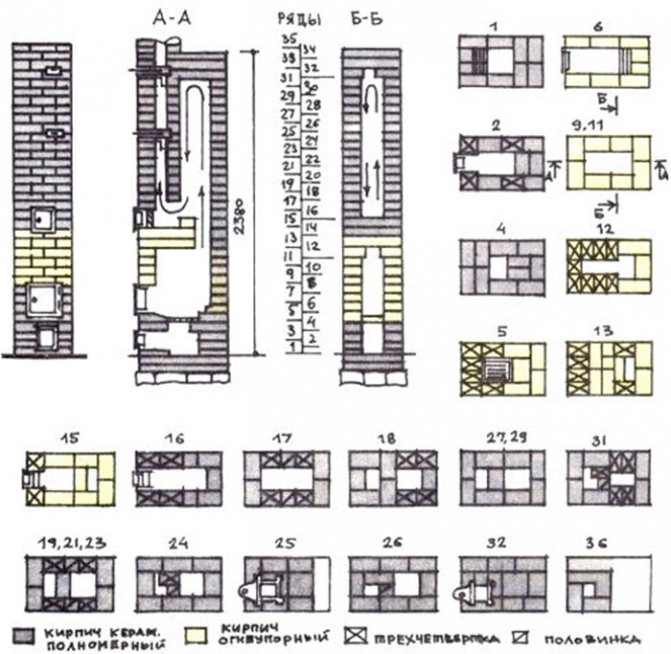

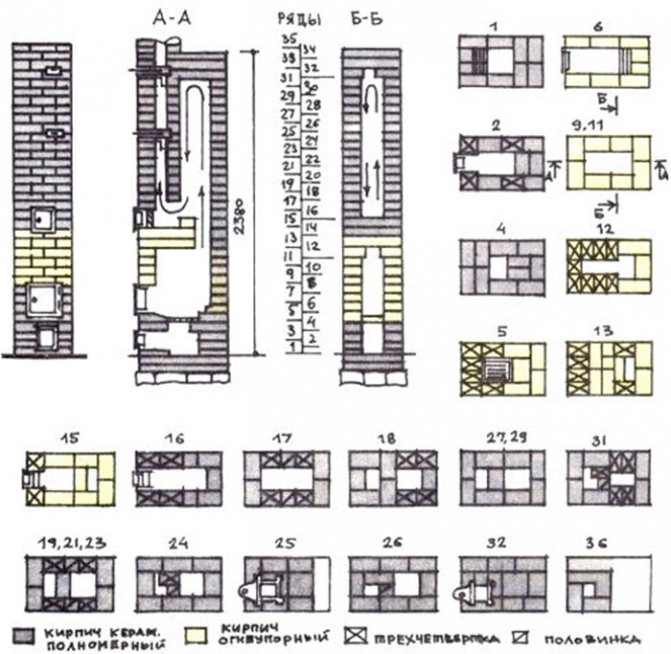

The ordering diagram of the universal furnace is shown in the figure. Thanks to a simple device, you can do it yourself, even without experience. The stove has a small size, it can be used to heat a country or country house with an area of up to 36 square meters, consisting of one or two rooms. In the latter case, the firebox is placed on the side of the kitchen, and the back wall, which heats up during the firebox, is taken out into the room.

The furnace consists of a do-it-yourself fireclay made of refractory fireclay bricks, and a supra-furnace channel with one roll-up.

The flue gases are retained in the duct, a bell effect is created, and the furnace body heats up. After cooling down, the smoke descends and through the curtain goes into the chimney. It is equipped with two dampers, eliminating the sharp boundary between warm and cold air and moisture condensation.

Below the firebox there is a blower combined with an ash pan. Pressurization is carried out through the grate, air movement is ensured by a simple chimney design and good draft.

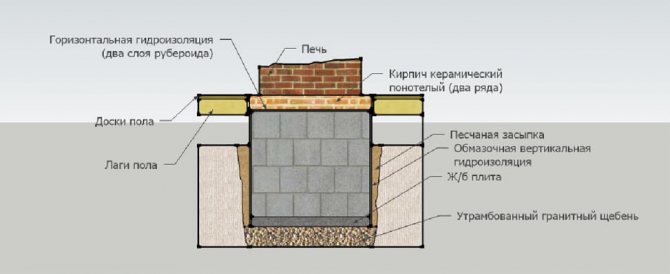

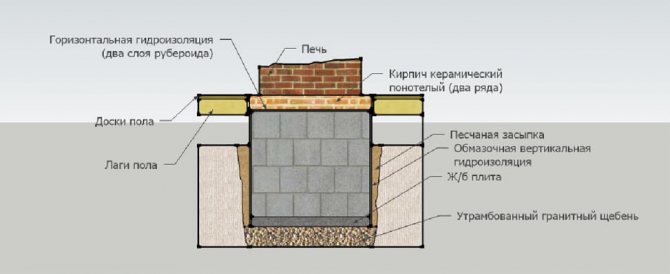

- Install the oven on a freestanding reinforced concrete foundation. The dimensions of the foundation should exceed the dimensions of the furnace by 5-10 cm, its height is 50-70 cm, while it should be 15 cm below the level of the final floor covering. After pouring and drying the foundation, it is leveled with cement mortar, two layers of roofing material or other rolled waterproofing are laid on it, after which they begin laying the furnace with their own hands.

- They lay out two rows of bricks - the base of the furnace, with solid masonry with a red brick bandage. They are placed on a cement mortar.

- Further, the laying is carried out in accordance with the scheme for a solution of fireclay clay. The first row forms the bottom of the ash pan.

- In the second and third rows, the blower door is exposed, securing it with the help of annealed wire laid between the bricks.

- The fourth row forms the overlap of the ash chamber and an opening for a blower and ash removal from the furnace.

- Starting from the fifth row, the masonry is carried out with fireclay bricks. In the fifth row, a grate is laid.

- In the sixth and seventh, the firebox door is installed similarly to the blower door.

- Rows 9 to 11 form the walls of the furnace, they are laid with a bandage.

- In the 12th row, a vault is made of ¾ part of the brick, and in the 13th and 14th, they cover the vault.

- In the 15th row, a cleaning door and a roll-up are installed.

- Starting from the 16th row, the laying is again made of red brick. Smoke channels are laid out according to the scheme.

- Valves are installed in the 25th and 32nd rows.

- Rows 33 and 34 complete the overlap of the furnace, then lay out the chimney of the desired height.

- The stove is dried in air, then it is carefully heated in multiple stages, first with wood, and after several furnaces with coal. During operation, it is allowed to use any solid fuel: coal, anthracite, firewood and wood waste, pellets and briquettes.

Any metal stove with the effect of long burning can be adapted for burning coal. having laid out a fireclay brick lining in the firebox with their own hands and equipped the blower with a fan. With such a refinement, the furnace metal will not burn out from high temperatures, and the coal will burn steadily for a long time.

Do-it-yourself charcoal stove

In order for the self-made installation to be erected in accordance with all the requirements and subsequently to work properly, only refractory fireclay bricks are used to assemble the combustion chamber. Also, special cleaning doors must be installed in the structure in all areas.

To ensure that the unit is fully suitable for your home, select the appropriate order before starting its assembly. You can take it from videos, pictures posted on proven Internet resources, in books. However, it is best to entrust the drawing up of the scheme, ordering to a professional stove-maker.

Instructions for doing masonry work with your own hands:

- The brick oven, due to its large mass, is installed only on a previously prepared foundation, which should be 10-15 centimeters larger than the installation itself on each side. It should also finish 10-16 centimeters before the finish level. After pouring the foundation with concrete and leveling it, lay out several layers of roofing material;

- First, we need to lay out the base for the stove. For this he uses red brick. Laying is performed with bandaging;

- Next, the lower part of the ash chamber is laid out, after which we install the blower door;

- We close the ash chamber, equip the blower with a hole. We begin to lay out the rows of fireclay bricks. At this stage, we are installing the grate;

- We are installing the door, thanks to which the combustion chamber will be closed. We spread it to the end of the wall of the combustion chamber, after which we make a vault and close it;

- Next, we need to install a cleaning door, after which we continue laying, but already with a simple red brick;

- We collect several smoke channels, install sliding mechanisms.

Charcoal oven with hob

Rounded standard wall-mounted model, suitable for installation in areas with limited space

The principle of fuel combustion in the hearth: the functioning of the unit

After the ceiling is completely assembled, you can start assembling the chimney system.

It is important to let the structure dry completely and only after that carry out a test furnace, for which standard logs are used first, and only after that coal, pellets and other fuel of your choice.

Homemade stove potbelly stove

Recently, many designers have been offering exclusive options for stoves or fireplace stoves, which are installed in country houses. For residents of prestigious cottages, they are not only an additional source of heat, but also the most beautiful accessory for the interior decoration of the premises. Such individual stoves fill the room with both warmth and special coziness. The firewood crackling in the stove or fireplace looks very beautiful and romantic when a winter blizzard is raging outside the window.

The most popular, primitive and efficient long-burning stove for temporary heating is the well-known potbelly stove. Its simple device is based on the "symbiosis" of the Russian stove and fireplace. With one load of fuel, it is able to maintain a comfortable indoor temperature for 4 hours. The potbelly stove can be installed in any space where the chimney can be brought out.

Today, everyone who has the skills to perform locksmith work can make a potbelly stove with their own hands from all kinds of scrap materials. This oven:

- Does not depend on electricity and gas.

- Easy to maintain and operate.

- Allows you to control the combustion process.

- Takes up little space.

- Compact and economical.

- May have a hole for placing utensils to cook food or heat water.

Among the disadvantages of such a furnace, it should be noted a low efficiency, a high rate of exhaust gases and rapid cooling. Therefore, to maintain the temperature in the room, it must be heated constantly.

As fuel for the stove, you can use:

Materials and equipment for independent work

Our craftsmen make stoves-stoves, having at hand a welding machine and used ones:

- large cans;

- metal corners;

- wide pipes;

- gas cylinders;

- metal boxes;

- large fire extinguishers;

- old barrels;

- steel sheets;

- chimney pipes;

- metal grates.

For the convenience of work, you can also use the technical fittings of factory production in the form of:

The main elements of the combustion unit

Detailed drawings are not needed to make a potbelly stove. The main thing is to get the most efficient design. Consider the main nodes that make up the homemade stove structure.

Combustion chamber

It is the combustion chamber that performs the function of heat transfer. The larger the area of its outer surface, the better.

It is important that the bottom of the chamber has sufficient area for storing firewood or filling coal there. Therefore, cylindrical home-made devices are placed on their side

Rectangular ovens are designed horizontally with a minimum dimensions of 250 × 350 mm.

Oversized stoves from barrels or gas cylinders are practical also in an upright position.

Finished product type

The ash pan, additionally welded or screwed to the bottom of the structure, is convenient for selecting ash. Its arrangement with a blower promotes better heat generation, and the lower door provides the required amount of oxygen and regulation of the combustion intensity.

Doors and openings

These elements are made by hand from the remnants of metal after cutting out the openings. After all, scraps from balloons repeat the bend of the surface, and this is very important in work. Steel door canopies are attached to the body by welding, and then the doors themselves are hung on them.

Here it is imperative to provide a locking device, which can be made like a guillotine valve or bolt.

The optimal openings for the firebox are 250 × 250 mm, for the blower - 100 mm high and 250 mm wide. The awnings are installed on the same vertical axis. A distance of approximately 10 centimeters is maintained between the openings. To prevent coals from falling out through the door, the opening of the furnace is placed slightly above the level of the grate.

A steel pipe with a diameter of 100–150 mm is used to remove flue gases in a stove.The pipe itself is not insulated - it serves as an additional source of heat. And for better heat transfer, it is located at the outlet with inclined or horizontal sections, thereby increasing the path of warm gases.

The outlet for connecting the chimney is placed on top or better on the side. The latter option slows down the evacuation of gases, leaving room for the cooking zone.

Note! In the chimney, to regulate the intensity of the removal of hot gases, it is advisable to use a rotary or directional valve

Modern charcoal stoves for home description, types

A charcoal stove for home has many advantages. The main ones among them are ease of operation and maintenance, the possibility of using another type of solid fuel instead of coal, and a large heat capacity. And besides, such a coal-fired stove for a country house can be made of different materials.

A coal-fired stove has high efficiency rates (about 60 percent, which corresponds to boilers for heating systems that use liquid fuel). Modern models allow you to control the combustion of coal in the furnace, regulate this process for a more rational use of fuel and heat.

Modern coal-fired stoves are of several types, depending on their purpose:

- heating stoves;

- heating and cooking ovens;

- household;

- fireplace stoves.

Modern furnaces are produced from different materials: refractory bricks, cast iron, steel, talc magnesite, etc.

What stoves are designed for kindling coal

Furnaces that run on coal have a special design. The main factor affecting the structure of the heating device is the high temperature during fuel combustion. In household stoves, depending on the type of coal, the temperature regime can rise up to 1000 degrees. In industrial equipment, this value often exceeds 2000 degrees.

In household ovens, the temperature regime can rise up to 1000 degrees

In this regard, the firebox must be sufficiently strengthened and made of thick-walled metal or cast iron with high heat-resistant properties. To maintain a constant intensity of fuel combustion in coal-fired furnaces, a special system is installed that supplies oxygen to the furnace. Grids are also used. They are usually made from a strong cast iron alloy.

Is it possible to heat with coal

Many owners of houses with stove heating are wondering: is it possible to use coal instead of firewood in a brick stove? Will it burn as efficiently as in industrial boilers?

The process of coal combustion occurs with the release of a large amount of heat, the temperature in the furnace is significantly higher than when burning wood. At the same time, the smoke coming out of the firebox is less hot than when burning with wood.

For this reason, a conventional stove with long smoke channels cannot be fired with coal: the smoke entering the chimney will have a too low temperature, which will lead to the formation of condensation and soot. When they interact, they form carbonic acid, which destroys bricks, which can eventually cause a fire.

In addition, the high temperature in the firebox can cause its destruction. The firebox for a coal furnace made of bricks must be made only of fireclay bricks, and the walls of the furnace in this place must be thicker for high-quality removal and accumulation of heat.

It is not recommended to heat an ordinary Russian stove with coal. having a non-lined firebox and extended smoke channels! This will lead to the gradual destruction of the furnace elements!

In which furnaces can coal be fired

Since as a result of combustion, coal gives a higher temperature than wood fuel, stoves for combustible stone (black gold) are slightly different from wood-burning structures.

Although, it is possible to heat with coal, using an ordinary brick oven for this, but only with the presence of thickened walls and a 2-row grate. Plus, such a heating structure must be equipped with an additional hood that would not be connected to other channels.

There are designs with the presence of 2 water boilers in the furnace, with the help of which not only the room is heated, but also the brickwork is significantly cooled. Such devices require special supervision, since they must constantly contain water.

Plus, the dimensions of the grate and the ash pan must be identical, otherwise there may be significant heat losses.

It will be interesting! Instructions on how to make a bell-top oven.

Other fuels for the boiler

Alternative fuels can be used to operate a solid fuel boiler.

Coal briquettes. The fuel is produced by pressing fine coal and coal dust fractions. Mineral substances or coal tar are used as a binder. The advantages of this type of fuel are ease of stacking and kindling, high heating values and excellent flammability.

Pressed peat or wooden Euro briquettes. Fuel briquettes made on the basis of peat have a small area, while they are capable of smoldering for a long time, maintaining the phase of active combustion.

Pellets. It is a biofuel made in the form of pellets. For the production of peat, wood and agricultural waste are used. It is an environmentally friendly and energy efficient material that is preferable to use in boilers, the design of which is adapted to pellets.

How to choose

Advantages of long-burning steel boilers:

- one-piece welded construction that is not subject to leaks;

- fast heating and cooling of the walls of the boiler and heat exchanger;

- full automation is possible due to low inertia;

- less weight;

- reasonable price.

Disadvantages of steel models:

- susceptibility to corrosion, especially in welding areas;

- steel boilers cannot be repaired; in case of perforating corrosion and leaks, the unit is replaced with a new one.

The advantages of long-burning cast iron boilers include:

- resistance of cast iron to corrosion;

- the design of the heat exchanger from separate sections allows for partial replacement in case of damage;

- cast iron is a brittle and non-plastic material, in the event of a sharp change in temperature, cracks and destruction are possible;

- higher price than steel models;

- cast iron boilers are much heavier - 1.5-2.5 times.

Loading volume and automation The frequency of filling the combustion chamber with coal depends on this characteristic. It is worth analyzing whether it will be convenient to load coal several times a day, or whether it is better to give preference to models with a large load volume. Records in terms of the duration of operation are mine-type boilers of the upper combustion. They occupy a small area, while their loading chamber is quite large, and some models can heat a house on one load for 5 days on anthracite and 3 days on brown coal. Mine boilers are usually equipped with microcontrollers to automate the entire process and keep maintenance to a minimum. Bottom loading boilers are usually smaller, much cheaper than mine boilers and easier to handle. Such boilers usually do not have a blower fan, and the air intake is due to the draft. The chimney for such a boiler should be as simple as possible and have a total length of no more than 5 meters. The advantages of boilers without traction are independence from electricity and a low price. Cons - a low level of automation. The least attention and maintenance are required by fully automated models with a loading bunker that can hold a multi-day rate of fuel. Their price, of course, is high, but they have a number of advantages that provide worry-free heating during the season:

- a fuel feed mechanism equipped with a turner;

- built-in and remote sensors that control the combustion process;

- emergency valves to prevent boiling;

- SMS alarm mode;

- function of maintaining combustion and standby mode;

- DHW circuit.

Boiler maintenance is reduced to loading the bunker at the beginning of the season and setting the parameters of the required mode.

Video: automated boiler with a hopper

The choice and purchase of a boiler is not an easy matter, and given the cost of modern models, it is also costly. Therefore, for small private or country houses, you can evaluate your strength and make a coal stove with your own hands.

Advantages and disadvantages

The following advantages of coal stoves can be distinguished:

- High power - is achieved due to the higher combustion temperature of the fuel.

- High efficiency - up to 60% with a conventional firebox (in a brick oven) and up to 90% in a long-burning brick oven.

There are also disadvantages, but they can be effectively dealt with:

- Coal stains everything around... The problem is solved by equipping the firebox in a separate room.

- Formation of dust, soot and soot. You will have to regularly (at least twice a year) clean the chimney. Combustion products from the ashtray must be removed before each new furnace. All joints must be hermetically sealed with fireclay clay.

- Coal is picky about storage conditions... This should be a separate dry area, protected from wind and precipitation. It is not worth storing coal for more than a season. It clogs and lumps are obtained, which are not very pleasant to hammer every time.

- High price.This issue is highly region-specific. Somewhere coal is a rarity, its use is economically inexpedient. Elsewhere, it is the main fuel. Compared to wood, the higher price is offset by a longer combustion time and greater heat dissipation (fuel economy).

Preparatory stage for kindling the furnace

If you are going to start kindling the furnace of a furnace that has not been used for a long time, a number of preparatory measures should be taken. This procedure must be carried out in order to ensure the trouble-free operation of the furnace, as well as to avoid unpleasant situations that sometimes lead to fires or harm to human health and life.

• Inspect for cracks. Their presence can contribute to the penetration of smoke and even carbon monoxide into the room. If any are found, minor repairs should be carried out immediately using a mixture of clay and sand. • Clean out soot from all gas ducts and chimney. Wipe off dust from the inner walls with a dry cloth, so as not to feel a bad aroma when kindling. In general, it is advisable to perform this procedure 2-3 times a month.

• Pay attention to the doors, especially to their fit, the functionality of the locking mechanisms, in order to avoid the appearance of smoke. • Select fuel of the proper quality, suitable for your particular type of stove

• Properly equip solid fuel storage areas.

During further operation, you should also follow a number of simple rules. The use of plastic, construction and household waste for kindling will lead to severe contamination of the stove. It is wrong to open the blower and the oven door at the same time. It should be heated several times a day for one and a half to two hours to avoid overheating. Dry, medium-sized, dust-free charcoal will provide excellent functionality.

Avoid storing flammable objects near hot walls. Do not leave the stove unattended during kindling, especially in houses where there are children.