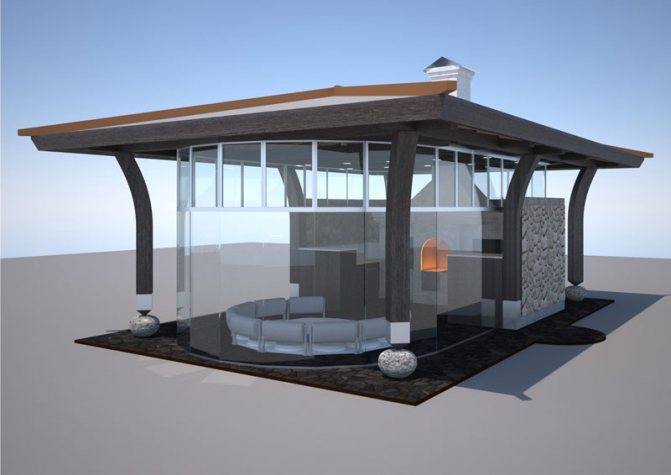

Glazing is an essential element in the construction of closed gazebos. There are two main types of windows - hinged and sliding. Sliding gazebo windows are the perfect solution. Such designs allow you to create panoramic glazing.

Plastic windows in the gazebo will become reliable protection from wind or precipitation. They will not let dust inside, and will also serve for sound insulation.

Glazed gazebos for summer cottages: features

Dignity

glazed gazebos for summer cottages:

- variability of forms and models;

- glass construction will fit into any architecture of the site;

- not devoid of grace in appearance;

- warm and comfortable without additional thermal insulation.

disadvantages:

- requires glass care;

- the structure is susceptible to damage: repair is not cheap and quick;

- construction is expensive.

Glazing and installation, despite the seeming difficulties, are within the power of a beginner. Exists two approaches to glazing: by method and by material... Let's consider both options and analyze the correct installation methods.

List of materials and tools

To perform self-assembly from materials, you will need the polycarbonate plates themselves, profiles for the ends, self-tapping screws, washers for the seal, protective self-adhesive tapes, and sealant for the gaps.

The list of instruments will consist of

- puncher; pliers, a screwdriver, a clerical knife for cutting off excess sealant; building level; hacksaws; roulette; electric saw for cutting polycarbonate sheet.

Classification by glazing method

Before installing the structure, decide on the method of its glazing. There are many options for glazing a gazebo for a summer residence, each has its own characteristics. Within the framework of the material, the following are considered:

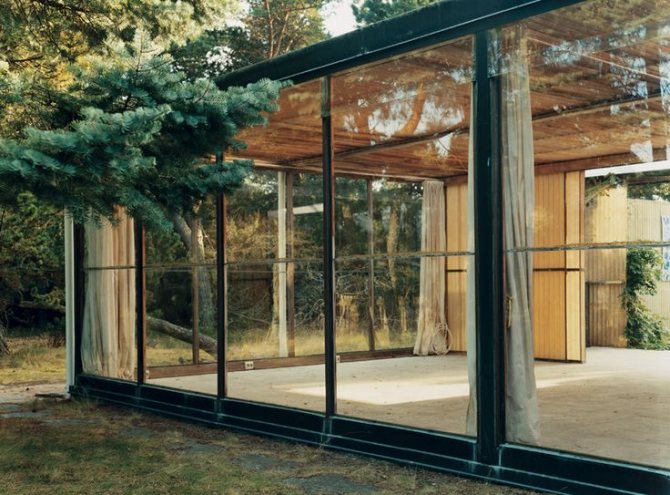

Frameless glazing of arbors

Attractive in terms of design, it is used both for verandas and for gazebos with panoramic glazing. The glass follows the contours of the facade - the windows are large, which allows you to enjoy incredible panoramic views. Among the minuses, we note the unreliability of the glass - it is easy to break it, and replacing it with a new one is troublesome and costly, especially if you do the frameless glazing of the gazebo with your own hands.

To put the method into practice, use a special material - triplex, which is connected to each other using mounting brackets.

It is advisable to use not ordinary glass, but tempered glass - the likelihood of the durability of the structure will increase. The peculiarity lies in the fact that in case of damage, the probability of injury is small, since the glass crumbles into rounded granules, and not into pointed fragments.

If you are suddenly interested in the frameless glazing of the veranda and terrace, we recommend that you familiarize yourself with a useful article on the topic.

Soft glazing of arbors

The essence of soft glazing of gazebos is to use flexible PVC film instead of ordinary glass - an advantageous option in terms of price and quality... It is more difficult to damage the film than glass. Protects from bad weather with the same success, and you can approach the design with a film with originality, using multi-colored palettes.

Essential minus soft glazing is the non-environmental friendliness of the material - not everyone likes to breathe PVC while being in nature. On the other hand, it is impossible not to estimate the budget - soft windows can be made by yourself. The buildings are cozy and warm.

To glaze the frame with a soft film, you, in addition to the film itself, will need special belts with a zipper - they attract the windows to the frame.

Cold glazed gazebo

It is unlikely that glazed structures in this way will allow you to enjoy the rest of the cold winter, but for summer evenings, albeit rainy, it will do. They use an aluminum profile or frameless structures - of your choice. Of uncompromising pluses - the ability to make a gazebo with your own hands. It is possible to make the windows removable - for this, threaded rods are screwed into the frames.

Cold glazing is not suitable if you plan to relax during the cold season (the temperature in the room will be 5-8 degrees higher than outside). If you want to create something like a heated house, buy warm windows.

Facade glazing

Facade glazing will appeal to fans of illuminated panoramic structures. A feature of the design is a glazed roof - light enters the gazebo from virtually every corner. As in frameless glazing, we are talking about the use of tempered glass - otherwise there is a risk of seeing your building destroyed after a few weeks of operation.

Polycarbonate is used as a roof for the front glazing of the gazebo - it is as reliable as possible. The tightness of a gazebo with a glass roof can be considered both a plus and a minus: on the one hand, it can be used as a winter house, on the other hand, it is hot inside in summer, and it will be possible to ventilate the room if there is a window in the roof.

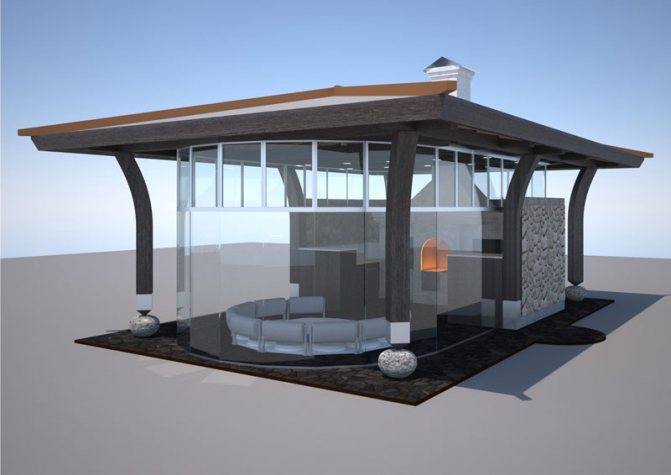

Gazebos with sliding glass walls

The structure allows you to rationally use the space. Metal-plastic structures are used during installation, therefore it is always cool inside in summer and warm in winter. Differs in panorama. Buy designs with glass doors and windows - their installation is less problematic.

Polycarbonate windows: cheap and practical

Polycarbonate has distinctive features, thanks to which it can be used for the manufacture of windows. This material is capable of transmitting light through its surface, blocking the flow of ultraviolet radiation and withstanding onslaught and impacts of various strengths. Moreover, its cost is quite low.

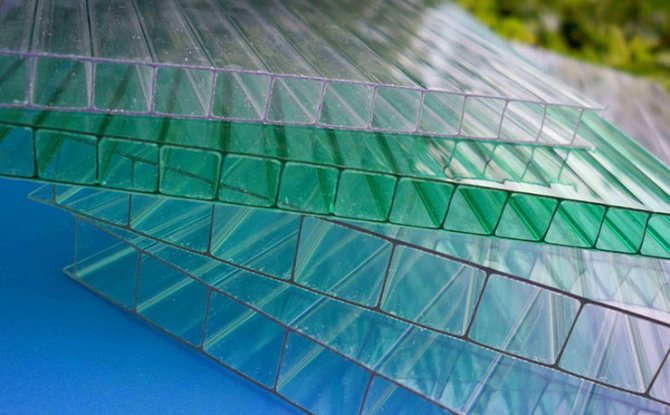

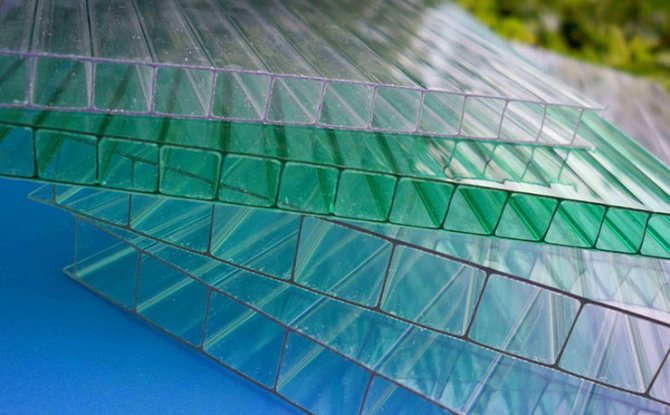

Cellular polycarbonate windows

Do-it-yourself constructions for a gazebo or veranda made of this material can have an arbitrary appearance or be placed in a metal-plastic, wooden or metal frame. Frameless structures can be easily bent, which allows for curved shapes.

What are the different types of polycarbonate for windows? Allocate:

- cellular polycarbonate,

- monolithic systems.

The first type, shown in the photo, has a high level of noise and heat insulation. It has a high density, due to which the room can be very dark. Due to its attractive appearance, this material will harmoniously suit any interior, and you will have the opportunity to create new design ideas. With the help of cellular polycarbonate, you can decorate an office, a balcony, and also form canopies and roofs for a gazebo or veranda.

A monolithic block, as in the photo, has a higher cost, but it stands out for its great strength, low weight, safe operation and high ability to transmit sunlight.

Polycarbonate facade

To make polycarbonate windows with your own hands, you need to take care of the availability of such consumables:

- polycarbonate sheets of the required color, size and type;

- protective tape;

- several end and connecting profiles;

- a sufficient number of screws, anchors and self-tapping screws;

- sealing washers for sealing;

Also, the following tools should be available:

- puncher, which is necessary for drilling holes;

- pliers - will be needed during installation;

- screwdrivers, screwdrivers - will be needed to screw in anchors and screws;

- a clerical knife - will be needed during the execution of installation work, as well as to eliminate excess foam after it has hardened;

- building level - it is necessary to correctly set the location of the windows during their installation;

- nail puller, scrap - will be used when removing old frames;

- saw - needed to align the edges of the frame;

- a tape measure will allow you to correctly take all measurements for the frame;

- polyurethane foam will be used to seal the structure;

- circular saw - to cut polycarbonate blades.

Glass gazebo with barbecue

You can cook food in any open glass gazebo with barbecue, observing fire safety rules. If the construction is closed type no chimney, barbecue is contraindicated due to the appearance of soot - the walls will turn black over time, there is little beauty in this.

The chimney pipe is placed on the side opposite to the direction of the prevailing winds. If you are drawing a wind rose, install the pipe from the side of the shortest rose petals.

Do not forget about basic fire safety rules: install glazed gazebos with barbecue and barbecue not too far from the house, next to water sources. Polycarbonate, despite its heat resistance, is subject to combustion (it burns in consistency like plastic). How to build a brazier with your own hands with a chimney step by step with a photo, see our other articles.

Types of material

The polycarbonate structure can be monolithic or honeycomb. The latter is often used precisely for decorative purposes, for example, for arranging a visor, a canopy, and decorative decoration of a veranda.

Monolithic is more durable and safer, therefore it is used for glazing purposes.

A honeycomb has in its structure air pores - honeycombs - which are too large to retain heat inside the room. Monolithic ones, in turn, represent a cast plate with micropores, therefore, its insulating characteristics are much higher.

Both honeycomb and monolithic sheets have a wide range of different colors, if you want to install a colored structure - red, green, blue and others.

Features of plastic arbors

PVC - polyvinyl chloride obtained from oil waste. To make the chemical composition of the thematic product environmentally friendly, stabilizers are added to it. The end result is a hard plastic that can be combined with metal for hardening.

Therefore, modern plastic looks like a profile with metal reinforcement. Many people so often confuse the finished profile with PVC that it has already become the norm.

As a result, a thematic abbreviation is attached by default to all structures made of a metal-plastic profile. Pvc gazebos are no exception.

The main thing is that the features of the metal-plastic profile, regardless of its application, always remain the same:

- A light weight;

- Suitability for assembly and disassembly;

- Neutrality to the environment.

The last point implies the ability of plastic to serve for many years without decay, fading, damage from insects. Moreover, such a reliable structure does not require a lot of construction time.

It is assembled from a group of elements in which holes for fasteners are provided in advance. Also, fittings are responsible for the latter and the operation of the profile (opening-closing).

Externally, the plastic is an even white product. But if you want to make the gazebo dark or wood-like, the artificial profile can be laminated. To do this, you just need to make the appropriate order - PVC profile for wood

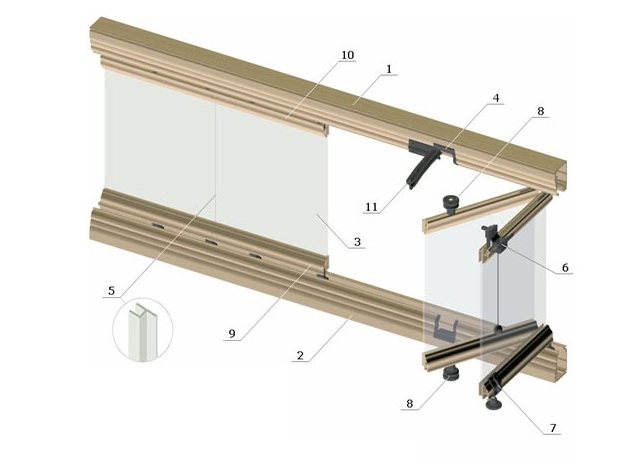

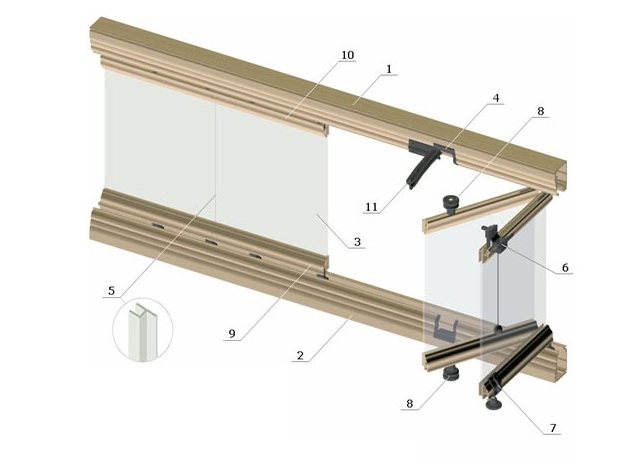

Installation of a sliding structure

During the installation of the window profile and its glazing, the following materials, tools and working accessories will be needed:

- polycarbonate sheets;

- protective perforated tape and end profiles;

- detachable connecting profiles;

- self-tapping screws with thermal washers, roofing screws, screws and anchors;

- insulation, polyurethane foam;

- construction tape, level, marker;

- circular saw, electric jigsaw or wood saw with fine teeth for cutting material;

- drill with drills of various diameters, perforator;

- screwdriver, screwdrivers, pliers;

- saw, edger knife, sandpaper;

- silicone glue and a gun for applying it.

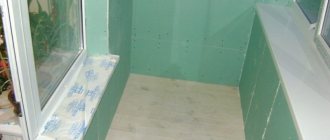

For the installation of a parallel-sliding window system, it is recommended to make a drawing. The presence of a detailed diagram will help to avoid common mistakes in construction. The drawing is made on the basis of the measurements made and taking into account the design features of the sliding system.

Now let's move on to the algorithm for installing polycarbonate sliding windows:

- Clean the work surface from dust and debris. Make a cutting of the polymer web, taking into account the tendency of the material to thermal expansion.

- Then clean the embedded structure to install the window frame. Treat the surface with special protective agents.

- Using anchors, attach the profile to the frame and install the window frame on it. Using a spirit level, level the structure horizontally and vertically.

- Install a window sill that is fixed under the bottom of the frame. Attach the window sill with metal anchors.

- Fit individual elements. Recheck the horizontal and vertical lines. Fill the gaps between the gazebo frame and the window frame with polyurethane foam.

- Process the ends of the plastic with perforated tape and end profiles.

- Install the split profile base. Install polycarbonate, fix the canvas with self-tapping screws with thermal washers.

- Close the profile with a protective cover.

The polycarbonate glazing of the gazebo requires minimal maintenance. Timely cleaning of panels from dust, debris and various kinds of contamination will significantly extend the life of the window. The warranty period for polycarbonate glazing of garden pavilion windows is 10-15 years.

Assembling plastic arbors

What certainly pleases the plastic gazebos is the ease of assembly. The corresponding event does not require the construction of an expensive foundation, cement mixing, caulking, shrinkage, etc.

The process is divided into the following stages:

- Choosing a picturesque place for assembling a gazebo;

- Acquisition of the desired design (standard or with six walls, fully or half transparent, multi-chamber or summer);

- Leveling the ground;

- Laying a 5-10 cm layer of crushed stone, gravel and sand, which will serve as a protective substrate;

- Creation of the bottom rail for the floor covering;

- Assembling the entire frame, starting from the bottom strapping and ending with roof rafters;

- Installation of roofing material on the crate;

- Installation of double-glazed windows in empty openings;

- Sealing joints with rubber seals.

If the structure will be used in winter and will require the installation of many furniture products with a heater, then it is better to arrange a columnar or pile foundation for it. In this case, there should be a little support - 4-6 pcs.

I am doubly pleased with the opportunity to purchase a plastic gazebo, which provides for strapping and lathing under the roof. By the way, the latter can also be included in the kit and represent triangular double-glazed windows.

The plastic gazebo can be assembled in winter. In this case, it is important to use so-called soft vinyl windows as temporary glazing. And if there is no money for a PVC profile, then a round or profile pipe will fit instead.It goes without reinforcement, but it is still connected by means of adapters

Materials used

Unlike an open or semi-closed canopy, a closed garden gazebo can be used at any time of the year. Such buildings combine the functions of a summer kitchen and a platform for recreation and pleasant pastime with the family, therefore, the choice of glazing of the object plays an important role.

Polycarbonate sheets are a synthetic thermoplastic polymer made by organic synthesis of carbonic acid. Polycarbonate is environmentally friendly. Due to its safety and environmental friendliness, polymer plastic is used in the construction industry, the national economy, instrument making and medicine.

There are two types of polymer plastic: monolithic and honeycomb.

Monolithic polycarbonate is a solid sheet, the main technical characteristics of which are called high impact resistance, resistance to temperature extremes and maximum light transmittance.

Cellular, or cellular polymer plastic consists of two panels connected by perpendicular bridges. The degree of flexibility of a material, its strength and endurance is determined by the number of internal ribs.

When choosing a material for glazing, it is recommended to take into account its technical characteristics and features. So, for regions with severe frosts and gusty winds, a monolithic canvas is suitable. Cellular polycarbonate keeps heat better and has high noise insulation performance.

In this video you will learn how to install polycarbonate windows:

Options for plastic arbors

Plastic gazebos are a rather broad concept, because there are many varieties of this material.

Most suitable for construction:

Light summer gazebo

- PVC (polyvinyl chloride) - This is a popular cheap material that is easy to cut, is not afraid of moisture and does not fade in the sun. However, it is not suitable for outdoor conditions, since it has little strength and begins to emit harmful substances from the sun.

- Polypropylene Is an opaque matte plastic. It does not emit toxic substances when heated in the sun, but it is also not strong enough for outdoor use. Can only be used for temporary coverage.

- Polycarbonate - the most popular material for decorating gazebos and greenhouses. It can be completely transparent or multi-colored, so it transmits the sun's rays well. Durable material that is not afraid of heat or frost.

- Special PVC curtains... Vinyl curtains are often used in outdoor cafes to block the wind from the walls.

- Gazebos made of plastic windows - made only to order. The walls are made of sliding segments, which are similar to the design of sliding wardrobes. The roof is covered with shingles or any other roofing material. The price for the simplest quadrangular structure of 8 square meters will cost you 200 thousand rubles.

Walls from plastic windows

- A gazebo made of plastic boxes is a good option for building from scrap materials. The boxes themselves will not look beautiful, but if you plant plants in them, you get a real living gazebo.

- Plastic bottles - Another material from which you can make economical wall cladding.

- Another economical option for a summer cottage is the manufacture of a frame from PVC drain pipes and fittings. They are installed in small steps, and a wicker from the garden border is made between them.

Selection of polypropylene pipes

For simple plastic buildings, pipes made of polypropylene, metal-plastic, PVC are used. Their diameter and density depend on the final design. Pipes are a flexible material that gives room for creativity, the gazebo can be made in the form:

- trapezoid;

- ball;

- semicircular.

The parts are connected together with a soldering iron or fittings.

Metal-plastic has the highest strength in comparison with analogues.

On a note!

Thanks to the aluminum interlayer, the pipes do not expand, do not deform from high temperatures, which increases their service life.

Details connect:

- press;

- crimp fitting method.

But this material is much more expensive than PVC pipes.

To create a gazebo made of PVC pipes with your own hands, you will need:

- polypropylene pipes;

- scissors for cutting material (precision);

- soldering iron;

- cladding material for walls, roofs;

- fittings of different sizes (angular, tees, extension);

- shovel;

- fittings or metal tubes.

During construction, combinations of different materials are often used - a frame made of durable types of plastic, for decoration - soft.

Polycarbonate veranda windows

Since the veranda is attached to the house and, in fact, is its addition, it must be warm enough, and the glazing must be airtight and heat-insulating. Therefore, the polymer is perfectly suited for these purposes. Among the advantages of such a window for a gazebo, in addition to its insulating properties, weight also stands out - such a system will weigh much less than a metal-plastic or glass one, therefore the load on the structure is reduced.

When purchasing polymer for future glazing, the seller will pack the material in the form of a roll. You cannot store the purchased material in this form for more than a day - the material is flexible enough and can take shape. Therefore, at home, the sheets are laid out on a flat surface, one by one, it is desirable that the surface with a protective film is on top, even if sunlight does not enter the storage room. It is impossible to store polycarbonate vertically - a crack may appear along the entire length of the sheet.

DIY window making instructions

For flexible window products, a film with a thickness of 500 to 800 microns is used. Experts believe that the best option is 700 microns. On sale there is a roll of film, the width of which is 140 cm. If the opening is wider than this range, the material will need to be soldered using a construction hair dryer, leaving about 3-4 cm on the seams.

Reinforce fastenings with edging. For it, they take a dense polyester fabric Oxford 600 PVC with a width of about 5 cm. Making flexible window products with your own hands is accompanied by mandatory actions.

Did you know? ID cards, credit cards and even hotel room keys are made of PVC.

They include:

- Measurements... With a flat surface, the opening is measured taking into account the seams and edging. If there are protrusions, it is worth contacting a measurement specialist.

- Purchase of film and edging... The film material is cut to size.

- Purchase of fasteners... You will need metal clasps of any color. The staples can be swivel (located along the perimeter of the window, which, thanks to this mechanism, is well fixed in the desired position and has a high-quality tension) or simple, with silicone / fabric straps (an accurate calculation of the distribution of staples is important in order to obtain the ideal tension of the canvas).

- The film is cut to size, taking into account the seams... They put a transparent material into the grooves of the edging, level them so that there are no folds.

- Warm air flow you need to serve not from above, but into the groove itself, pushing the upper part with a special device (spoon). It is better to start work from the middle, moving to the edges. Soldering must be accompanied by a rolling roller. After the structure is "sewn" on one side, it will be necessary to turn it over and repeat the manipulation again. If the PVC film is thick, it is better to take a powerful soldering iron for soldering.

- Purchased fasteners are mounted around the perimeter of the frame.

Video: Installation of PVC curtains on the terrace

Benefits of PVC

Traditional materials for the construction of a capital gazebo are wood, metal, brick. In small summer cottages with temporary residence, plastic gazebos are increasingly being built. Mostly used are pipes made for the installation of water supply systems.

Advantages of PVC:

- long service life;

- simplicity and speed of installation work;

- the ability to quickly disassemble and move the structure;

- resistance to environmental influences;

- low cost.

PVC gazebos are most often used only in summer. At subzero temperatures, this material deforms.

For construction, it is better to buy square pipes. They are stiffer and easier to work with, since fittings are used to connect the segments. This allows you to save money, as it eliminates the need to buy a welding machine.