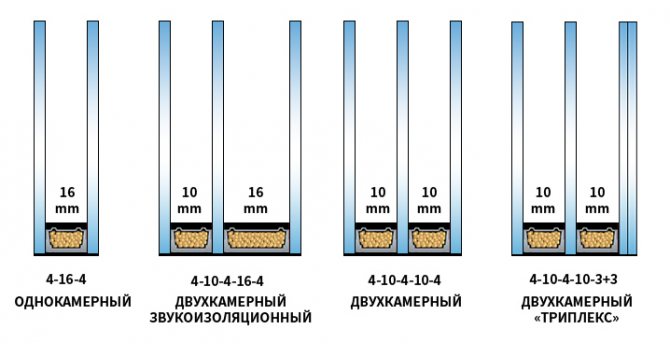

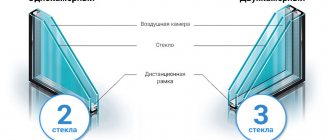

Most often, single-chamber or double-chamber double-glazed windows are installed in the window profile. The most budgetary solution is a single-chamber one. A two-chamber one is more expensive, but all other things being equal (glass characteristics, filling of chambers) surpasses a single-chamber one in a number of performance characteristics.

This is a more complex and more massive structure, more possibilities for various combinations of elements are available, and its thickness varies in a wider range.

What does a plastic double-glazed window look like?

Actually a blind PVC double-glazed window, not yet inserted into the profile, is a glass block, usually in the shape of a parallelepiped, the width and height of which significantly exceed the thickness. There are also more complex double-glazed windows.

Visually, the third glass, located in the middle of the glass unit, is practically indistinguishable. Therefore, a double-glazed unit from a distance gives the impression of an all-glass monolith inserted into a window block.

Close up, you can see that in this design there is glass in front and behind, spacers around the entire perimeter inside, and around the entire contour outside (from the ends, top, bottom) - a sealant.

If the glass unit is already installed in the sash, the sealant and the main part of the distance frame are hidden from view, only the glass and the side of the spacer (separating frame) facing the inside of the glass unit are visible, which is visually perceived as a metal (less often polymer) strip with small perforations - diffusion holes.

Without a profile, in the edge zone of the glass unit, the sides of the spacer are visible, glued to the glass with the thinnest layer of sealant.

The easiest way to visually distinguish a two-chamber glass unit from a single-chamber one is to turn off the overhead light in the evening and go to the window with a lighter or flashlight.

The number of reflections of the light in the glass unit must correspond to the number of glasses. That is, if you see 3 lights, your double-glazed window is really two-chamber.

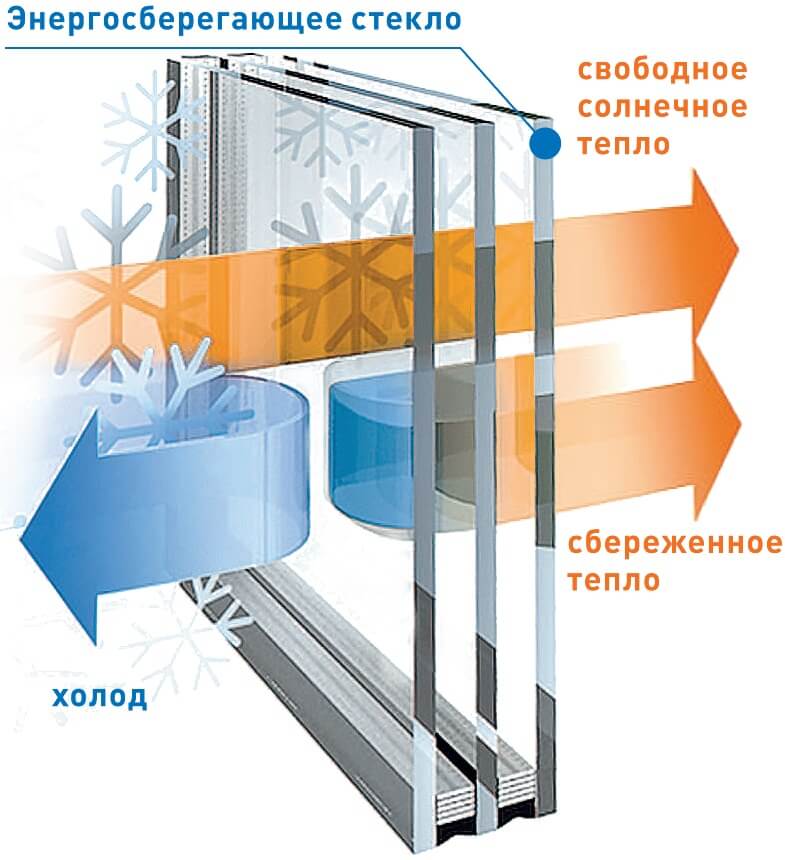

Energy saving glass unit with multifunctional glass

The next stage in the development of technology was the combination of two properties in spraying at once: heat saving and sun protection. The so-called multifunctional energy-saving double-glazed windows - transparent to light and impervious to heat and cold - have become a successful solution.

The presence of double deposition - titanium and silver - has a double effect: energy savings occur both in summer and winter:

- In summer there is no need for additional air conditioning.

- In winter, no money is spent on heating.

All properties of a multifunctional glass unit

Find out how much plastic windows with a multifunctional glass unit cost right now using the online plastic window calculator.

To calculate the exact price for the project, send a message through the "feedback" in the "Contacts" section. "

Construction of a double-glazed unit

Some elements of the glass unit are hidden from view. The structure of a double-glazed unit includes:

- glass - 3;

- chambers (inter-glass gaps) with air or gas filling - 2;

- distance (dividing) frames - 2;

- desiccant;

- internal (primary) sealant;

- external (secondary) sealant.

Glasses can differ in production and processing technology, PVC profile, composition, spraying, color, thickness, and it is on their characteristics that the properties of a glass unit largely depend.

It is also essential to fill the chamber between the glasses, ordinary humid air must be pumped out of it, a minimum of moisture must be contained inside the glass unit, otherwise the condensation will negate its heat-shielding properties.

The spacer is a nearly rectangular hollow tube, lightweight yet strong. Initially, spacer frames were made of aluminum, less often of steel; later, a technology for the production of frames from polymers with a lower thermal conductivity than metal was developed.

The frame can consist of four straight line segments connected by corners, or bend at the corners. In the second case, only one joint is formed in the structure and the likelihood of depressurization through the joints is significantly reduced.

The spacer is filled with a desiccant (absorbent, desiccant is a substance with a large number of pores), and small diffusion holes run along the top of the frame. Through them, moisture molecules from the air in the chamber penetrate into the frame and are absorbed by the absorbent. Used as a dehumidifier:

- molecular sieve;

- silica gel;

- their mixture.

Primary sealant - butyl mastic or tape that retains elasticity after hardening, is used to firmly join glasses and frames into a single structure and to protect against water vapor contained outside.

After gluing the glasses and frames, secondary, external sealing is carried out to give the structure additional strength and moisture vapor resistance. For external sealing, plastics are usually used based on:

- polysulfide;

- silicone;

- polyurethane.

Read: which double-glazed window is better: single-chamber or double-chamber.

Special properties of double-glazed windows

Glasses tightly connected in a double-glazed window make it possible to impart qualitatively new characteristics to the glazing. From a practical point of view, such a design is more convenient since there is no need to wash the glass from the inside - they remain clean during the entire service life of the products, which for modern plastic windows is about 60 years in a temperate climatic zone.

Modern glass production technologies allow the introduction of new types of glazing through the use of various decorative, protective and physical properties. In particular, the development of self-cleaning double-glazed windows is considered one of the most promising.

Self-cleaning double-glazed windows

- double-glazed windows with a hydrophobic coating, which, due to the property of repelling water molecules, keeps the glass clean for much longer than ordinary glass.

Heating double-glazed windows

or double-glazed windows with electrically heated glass - double-glazed windows in which a special laminated glass with a structured conductive layer is installed. When the current circulates through the conductor, the glass is capable of generating heat up to +50 0C. More details.

Fire-resistant double-glazed windows

- or fireproof double-glazed windows, are a structure with the participation of laminated glass and fireproof interlayers. At high temperatures, such a layer forms a dense solid foam that protects against flame propagation by holding the glass fragments in place and prevents heat radiation from the fire.

Decorative double-glazed windows

- inside the double-glazed window for visual division into sections, spros (layout) can be built in. For connoisseurs of patterned design, the glass unit can be decorated with an ornament, a stained glass pattern in the style of tiffany stained glass.

Double-glazed windows with built-in blinds

- especially in demand in medical institutions, where there are high requirements for hygiene due to sanitary standards. Conventional blinds are not suitable for equipping rooms with them - they are not protected from static dust in any way, unlike built-in ones.The sealed chamber in the glass unit serves as a reliable insulator against contamination, while the blinds are controlled outside.

Double-glazed window: formula, thickness and advantages

In comparison with a single-chamber glass unit, the formula for a two-chamber glass unit is more complicated, it consists of 5 elements, 1, 3 and 5 - glass characteristics (thickness, category), 2 and 4 - chambers (width, filling).

You can calculate the thickness of a double-glazed unit using this formula, adding up all the numbers - the thickness of the three glasses and the width of the two chambers. A two-chamber double-glazed window can be symmetrical and asymmetric, different design options for glazing are possible:

- all glasses are of the same thickness, and the cameras are of the same width;

- the width between the glasses is the same, but the thickness of one of the glasses differs from the thickness of the other two, or all three have different thicknesses;

- different thickness of glass and different width of the chambers.

Thicker glass not only absorbs noise better; if the thickness of the glass does not match, the resonance arising between them is extinguished in the composition of the double-glazed unit, so that the noise-insulating characteristics of the glass unit increase.

Different widths of the chambers also contribute to noise absorption, the best characteristics will be with an asymmetric glass unit with different thicknesses of all three glasses. The width of the chambers and the thickness of the glasses also affect the thermal insulation characteristics, but it is more effective to increase them by replacing standard glasses with low-emission glasses in combination with filling with argon.

The standard thickness of glasses used in double-glazed windows is 4 mm, to improve heat saving and noise protection, 1-2 glasses are replaced with thicker ones - 5 or 6 mm, glasses of smaller and larger thickness (3 or 7-8 mm) are used much less often, on request.

The width of chambers in double-glazed windows often varies in the range of 6-16 mm. Double-glazed windows with a width (mm) are present on the Russian market:

- 24, with chambers of 6 mm between glasses of 4 mm;

- 32, along with the formula (4-10-4-10-4), options (6-8-4-8-6), (4-10-4-8-6) are used;

- 36, 12 mm cameras, 4 glasses;

- 40, 14 mm chambers.

Double-chamber windows of greater width - 42, 44 mm - are still new, the standard formula of the latter (4-16-4-16-4), its sound insulation and resistance to heat transfer are the highest among all of the above, but the weight is also the largest.

The optimum in terms of performance, taking into account the price, is considered to be the thickness of a double-glazed unit of 40 mm, another popular solution is a double-glazed unit of 32 mm.

In theory, the thickness of a double-glazed unit can reach 72 mm if the inter-glass gaps are widened to 24 mm and thickened glasses of 8 mm are used. And the minimum width, based on technical conditions, is 24 mm.

Shockproof double-glazed windows

To ensure high safety performance: protection against impact, breakage, etc., special types of double-glazed windows are used - shockproof.

Impact resistance can be ensured by using one of the types of protective glasses as part of a glass unit:

- Tempered glass - glass with 2-3 times better impact resistance than ordinary glass;

- Laminated glass - glass with a shockproof film glued to one of the surfaces;

- Reinforced glass - glass inside which there is a steel mesh;

- Laminated glass triplex - several layers of sheet glass, glued together with a polyvinylbuteral film or resin (in the first case, we are talking about film lamination of triplex, in the second - liquid).

When talking about the differences in the production of triplex, the following should be considered:

- Since in the manufacture of laminated glass by film lamination one of the stages - heating to a temperature of 80-90 degrees Celsius, - the use of low-emission glasses in the composition of film laminated glass is not recommended (heating can damage the coating). Manufacturing of low-emission laminated glass using liquid lamination technology is possible.

Shockproof double-glazed windows more

Double-glazed windows 24 mm, 32 mm and 40 mm at low prices

What is the thickness of a glass unit, and what is it?The thickness of a double-glazed unit is the sum of all its chambers and glass. Simply put, if there was an opportunity to look at it "in section", then the two extreme glasses and everything in between would just make up this parameter. Thickness varies. It depends not only on how many cameras the future window consists of. A single-chamber double-glazed window may not differ much from a two-chamber one, if the first has this parameter high, and the second has small ones.

This value consists of:

The standard thickness of glass is 4 mm, it may differ slightly for some companies. But cameras are of different widths - from 6 mm to 24 mm. So it turns out that sometimes a single-chamber window can be thicker than a two-chamber one. The maximum thickness of a double-glazed window today is 44 mm (some manufacturers have 52 mm), but this size is used quite rarely and not all manufacturers have it. More often used 40 mm. It is clear that 40 mm is a rather thick layer of the structure. Nevertheless, it is successfully used by residents of the North or private houses, where this way you can significantly save on heating. Also available in 24mm and 32mm sizes. They are used more often, and you don't have to be a northerner anymore. You need to understand that the weight of the system also depends on the thickness, and therefore, too wide options are not recommended for balconies. In this case, it is better to use energy-saving double-glazed windows. What depends on the thickness of the glass unit?The choice of sizes is wide enough, while the larger the indicator (it is indicated in millimeters), the better the warm air is retained inside the house and the less cold air penetrates. It also affects how effective the sound insulation will be. But you need to understand that this is not the main parameter responsible for the warmth and the absence of unnecessary sounds in the apartment. Thermal insulation and sound insulation of housing using plastic windows is made up of many factors:

What is the thickness of the glass unit to choose?There is an opinion, which is confirmed by employees of some companies, that the optimal choice for double glass is a space of 16 mm, for triple glass - 10 mm. You can use this advice when purchasing. Not too wide and not too narrow. In general, the thickness parameter should be perceived by you as an additional factor to the already existing factors: whether energy-saving glasses were chosen, how many cameras will be supplied. If you have already taken everything into account, then a thin glass unit will do. If you doubt that the width will withstand the cold, take a warmer one, maybe not the maximum, but you should not be content with the minimum either. Since we pay for a window once, and for electricity - constantly, it is better to let the window be the cause of the heat in the house than the cold. If you get hot, you can always put it on air. In winter it will be very noticeable.

Glass unit thickness: little talked aboutWhen you order plastic windows, in addition to parameters such as color and number of cameras, you will most likely be asked about the desired thickness of the glass unit. This question usually baffles the buyer. How does he, ignorant of the issue of plastic windows, know the properties of each type? And how can you combine these properties with the heating quality of your home and the number of cameras in just a couple of minutes in order to make the right choice? Therefore, many clients cannot answer anything to this, but only ask questions, how they differ and what are the options. Employees who are asked this by several people every day do not describe everything in detail, but explain it literally in a nutshell. As a rule, they themselves, "by eye", advise what to choose.And yet: how to choose the optimum thickness of the glass unit for your case? Our company works from 9:00 to 22:00, seven days a week |

citiokna.ru