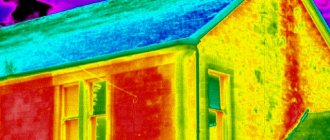

Developers and manufacturers of double-glazed windows strive to improve their products and actively use modern technological advances. About a third of all heat generated by appliances and heating systems goes through the window openings from the premises to the street.

Energy saving windows are a new generation of glazing. The products are designed to reduce heat loss through window openings and create more comfortable conditions in the living space.

How Energy Saving Windows Work

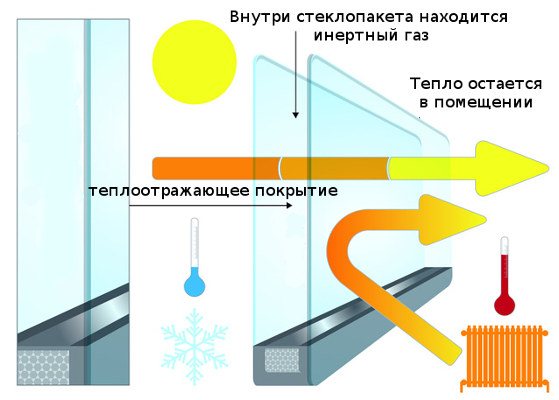

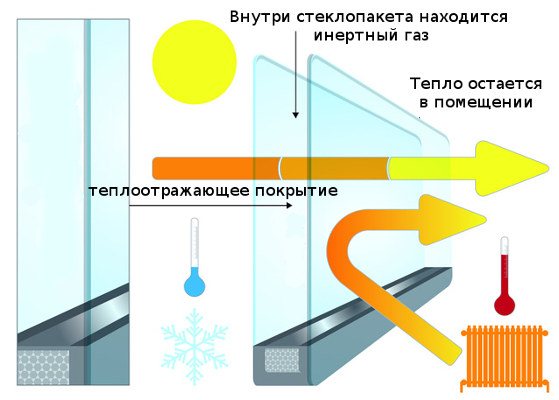

An energy-saving window is

- double-glazed window,

- in the inner cavity of which there is an inert gas,

- and a heat-reflecting coating is applied to the inner surface of the glass.

Now in more detail.

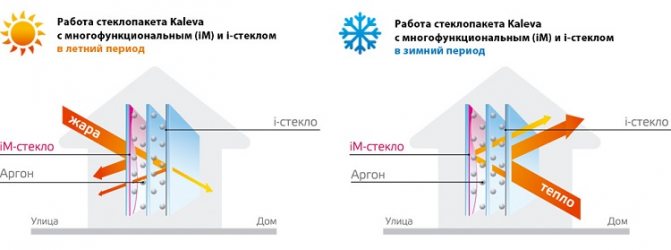

The most important energy saving technology in energy efficient windows is silver oxide coating.

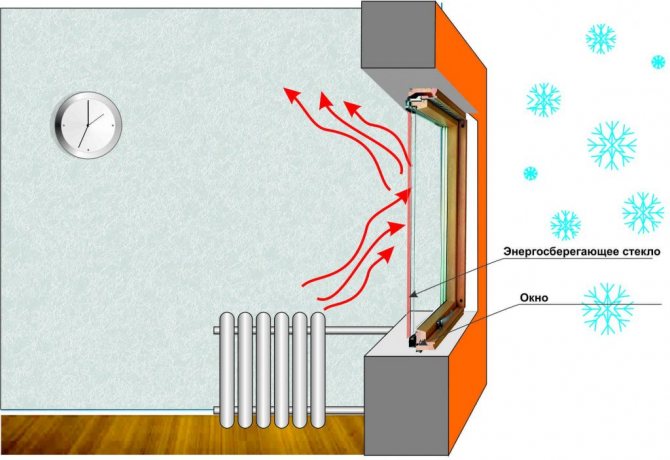

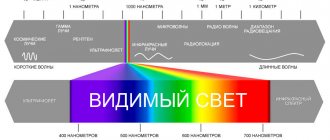

The coating reflects infrared radiation back into the room.

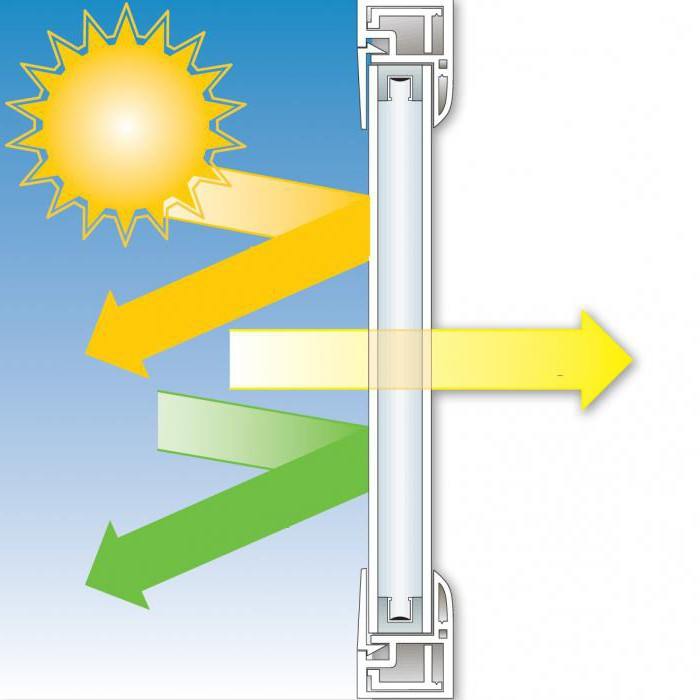

Keeps you warm in cold seasons and protects against solar radiation in summer.

The cover of the energy-saving window reflects the heat that comes from the heating devices into the room.

The energy saving window works like a thermos.

In the cold season, the inner glass of the energy-saving window is 5-7 degrees warmer.

Heat loss through windows is reduced.

According to our energy surveys, heat losses through glazing can be as high as 40% of the total.

In hot summer, such a window allows you to save on air conditioning.

Summer heat protection

What are

Poor thermal insulation of apartments is a fairly common problem. Experts have proven that about 35% of the room heat goes through the windows. Heat loss almost doubles the cost of heating. Thanks to the peculiarities of technology, energy-saving windows help keep warm in the house.

Products consist of:

- Low thermal conductivity polymer frames;

- Glass unit with spraying, heat-reflecting film or inert gas;

- High quality fittings.

Each component part of the block: fittings, double-glazed windows, frame - are energy efficient. All together represent a new generation of high-tech products.

Why do you need gas inside a glass unit

Now about the gas inside the glass unit.

Inert gases have a lower thermal conductivity than air.

There are no water molecules in this gas, and water is a good conductor of heat.

An inert gas increases the thermal insulation properties of an energy-saving window, but this is only a small part of the total savings.

Argon is most commonly used.

You can determine that the glass unit is intended for gas as follows: in one of the corners you can see the filling valve.

But whether it is filled with gas cannot be determined - only the reputation of the manufacturer can serve as a guarantee.

Energy saving window frame

The frame of the energy-saving window is made of a material of low thermal conductivity - polymer.

A high-quality polymer has low thermal conductivity and is resistant to external influences.

Wooden frames of double-glazed windows are also used.

Such frames have nothing to do with the old windows that were installed in the last century.

Now this processed wood, which serves as a good heat insulator, does not dry out, it well ensures the tightness of the window opening.

Pros of energy-efficient windows

What energy-saving windows give:

- low thermal conductivity of windows (protection from heat in summer and heat preservation in winter);

- preservation of heat in the room (due to the coating reflecting the infrared spectrum);

- lack of moisture condensation on the inner surface of the energy-saving window (the temperature of the glass is higher, the room air does not pass the dew point on contact with the glass - moisture does not condense).

- less weight - for effective energy saving, one or two cameras are enough for a new glass unit.

The energy-saving window will not freeze on the inside in cold weather.

The savings in space heating with energy-saving windows depend on the total glazing area.

Heating multi-storey glass towers (there are already quite a few such business centers) can save more than 20%.

Characteristics

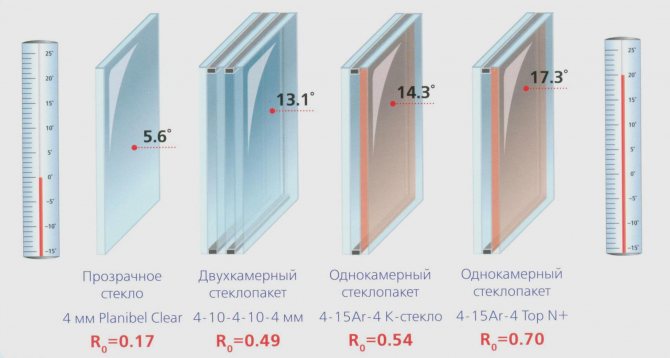

An energy-saving design can have one or several air chambers, there are also those that are filled not with air, but with argon - which better protect against cold penetration.

But the packages themselves are characterized by the composition of the spraying:

- I - with completely transparent glass, which is obtained as a result of applying a silver composition from the smallest particles of only a few microns;

- K - with a darkened thinnest film coating in hundredths of a micron. The film consists of oxidized metal spraying, they are much higher in cost, but they have less ability to reflect the heat flux.

In one word, their heat-shielding characteristics are much higher than that of ordinary glass by about 2 times.

Cons of energy efficient windows

Energy efficient windows are the next step in the evolution of windows.

The massive use of conventional metal-plastic insulating glass units in the 90s and 2000s seriously changed the situation with heat losses.

When replacing a traditional glass unit with an energy-saving one, the result will no longer be so noticeable.

New windows are not a breakthrough, they are the next step towards energy efficiency.

There are some disadvantages of energy-saving windows, but not a lot:

- energy-saving windows are more expensive than ordinary ones;

- installation is advisable in buildings of high energy efficiency class (B + and higher);

- the heat-reflecting coating gradually loses its properties over time.

Our suggestions

We order one- and two-chamber double-glazed windows from our reliable partners - manufacturers of high-quality, sealed products Mascoglass, RSK and others. uses the following types of glass structures in the production of windows:

- Energy saving;

- Multifunctional;

- Sunscreen;

- Soundproofing;

- Shockproof;

- Armored and others.

At the request of the customer, we can produce window structures with tinted glass. This type of processing is carried out by spraying or using a film.

Price comparison: energy efficient windows vs conventional windows

We will tell you more about the cost.

If we compare two double-glazed windows (identical, 2-chamber), only one with a coating, and the second without.

The difference in price will be - the coverage is more expensive.

But, this cannot be compared, it is necessary to compare in terms of thermal conductivity.

An interesting result is obtained: a single-chamber, energy-saving, coated window shows the same result as a 2-chamber ordinary double-glazed window.

The cost of the extra glass offset the cost of applying the reflective layer.

So it turns out that prices are proportional, and the energy-saving window is lighter.

Less weight means less stress on hinges and fittings.

Such fittings are cheaper and require less adjustment.

An alternative to installing energy-saving windows is the installation of high-quality multi-chamber double-glazed windows with low thermal conductivity frames.

Multi-chamber double-glazed windows are quite energy efficient, but they are heavy and distort visibility.

Installed windows cannot be coated; such coating is applied only in the factory.

You can stick a heat-reflecting film on the inner glass.

Such a film will not turn the window into an energy-saving one and it will slightly worsen the light transmission, but will increase the glass temperature by 1-2 degrees in the cold season.

The film is not protected by anything and is subject to mechanical damage.

Our advantages

:

- It guarantees the production of windows with double-glazed windows of any type and size, as well as door blocks, exactly on the time specified in the contract.

- At the request of the customer, it performs turnkey work (including delivery in Moscow and the region) and installation.

- Provides a long product warranty (5 years) and installation (3 years).

- Offers favorable terms of cooperation to regular customers and large customers.

For more information about the cost of a window structure with a certain type of glass unit, services, payment methods, options for filing an application, you can contact our company's consultant.

Recommendations for the installation of energy-efficient windows

Installation of energy saving windows

A building or room must meet the following parameters:

- large glazing area (more than 40%),

- high energy efficiency class of the building.

- a properly configured ventilation system that provides the necessary air exchange (the windows are sealed and do not let outside air into the room).

In order to check if the building is suitable for installing energy-efficient windows, it is necessary to carry out an energy survey of the building and check the ventilation system.

What other windows are there? What are their main differences?

Let's figure it out now.

Soviet windows

Soviet windows, wooden, no insulation

"Old" wooden windows, no insulation.

In houses and buildings that were built before 2000, such windows were installed.

Let's talk about their device.

Frame made of solid pine wood, painted with white paint, the same window profile.

Installed two glasses and provided the ability to open the sash to wash the glass from the inside.

The windows were not sealed, dust got inside.

Glasses were inserted into a wooden frame simply in a groove and fastened with a wooden lath.

Such a window retained heat poorly.

Before each winter, the windows had to be insulated with a foam sealant and the joints had to be sealed with paper.

Than sprayed

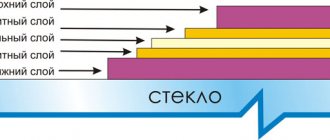

Spraying is done on one glass and on one side, regardless of the amount in the chamber. To preserve the layer, the glass is placed inside the first chamber from the outside.

Varieties of layers:

- K-coating. It is characterized by increased hardness, strength, and is not subject to scratches. Composition: metal oxides. Apply to a heated surface. In order to reduce resource costs, cost, they are sprayed during the manufacture of a double-glazed window.

- I-cover. Two-layer. Soft. The first layer is applied in a vacuum - a layer of silver is sprayed. The second layer is titanium oxide.

Modern wooden windows

This whole story is almost a thing of the past.

Now wood is also used for the production of modern windows, only the technology has changed.

For the manufacture of frames and sashes, pine, larch, oak are often used.

Now they are made not from solid wood, but from prepared laminated veneer lumber.

Such a profile is not afraid of moisture, does not bend, retains heat perfectly.

Double-glazed windows are used in such windows, more on this below, in the section on PVC windows.

The cost

The cost of a double-glazed window depends directly on the constituent elements. Due to the complexity of the production process, a multifunctional energy-saving glass unit is more expensive than a heat-saving one.

| Glass unit Thickness / exact formula of a glass unit in accordance with GOST | The cost |

| Single-chamber heat-saving double-glazed window with argon 24 mm / 4M1-16Ar-I4 | 2480 rubles / square meter |

| Two-chamber heat-saving glass unit with argon 42 mm / 4M1-16Ar-4M1-14Ar-I4 | 3940 rubles / square meter |

| Two-chamber energy-saving multifunctional glass unit with argon 44 mm / 6CGSolar-16Ar-4M1-14Ar-I4 | 4370 rubles / square meter |

Detailed price list in the price section for double-glazed windows.

You can order the production of a heat-saving or energy-saving glass unit according to your size by contacting Business-M.

PVC profile windows with double-glazed windows

PVC is polyvinyl chloride, a safe, durable, damage and temperature resistant plastic.

PVC is a good heat insulator, the profile for the window frame and sashes is made multi-chamber.

Double-glazed windows are used for such windows.

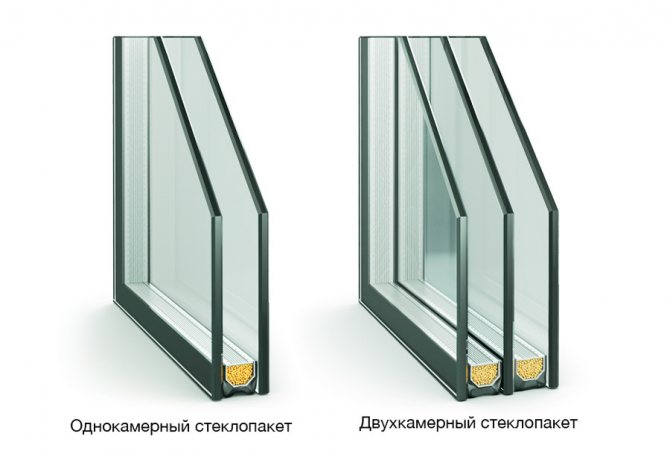

Double-glazed windows are two or more glasses, which are connected with an interval of 6-10 mm into a single sealed unit.

The bag is sealed, dust will not get inside.

The more glasses in the package, the higher the energy-saving properties of the package.

Unfortunately, the weight of such a package grows with each glass.

There are single-chamber double-glazed windows (only two glasses), but up to seven.

PVC windows with multi-chamber bags retain heat well.

The main thing is that the window is assembled with high quality and installed in the window opening.

Modern wooden windows and PVC windows are also energy-saving windows, they keep the warmth of the premises.

Old and new

Until recently, it seemed that metal-plastic is the best, most technologically advanced, efficient windows. They did not hold out in the first place for long: less than five years later, new, energy-saving plastic structures began to displace them from the market. Manufacturers pay attention to the fact that such windows let in more light, retain heat better, which means that you only need to install them, and it's time to urgently change the old ones. Of course, replacing windows is a good idea, but it's not cheap, so a reasonable person will think twice about how justified such a waste of money is.

The main idea of the novelty among window technologies is to effectively prevent heat loss through the window opening. Studies show that, on average, almost half of all heat lost by the dwelling goes into the environment through this site. As the manufacturers assure, and this is also indicated in some reviews, energy-saving windows are one-third more efficient than metal-plastic - which means they are incomparably better than old wooden structures.

Metal-plastic windows

Now about the metal-plastic windows.

Metal-plastic windows

Everything is simple here, it is a PVC double-glazed unit, but an additional metal profile is installed in the frame for reinforcement.

The construction of such a window is more rigid.

Such windows should be installed where deforming loads on the frame are possible.

There are also aluminum windows.

The profile and frame of such a window is made of aluminum alloy.

Such a profile is the most durable, the window will last one and a half times longer than PVC.

Manufacturers claim a service life of almost 100 years.

The price of an aluminum profile is higher, the manufacturing technology is more complicated.

The profile is durable, aesthetic.

There are also disadvantages to such windows.

Metal is a good heat conductor.

To insulate the aluminum profile, which is also multi-chamber (like PVC), the cavity is filled with insulation.

Only insulated aluminum profiles can be classified as energy-saving windows.

If we compare all these technologies, the most energy-efficient are PVC windows and modern wooden windows with installed multi-chamber double-glazed windows.

That is why energy-saving glasses began to be used on such structures.

Where are energy-efficient windows produced?

Who produces energy saving windows

There are many manufacturers of energy-saving windows in Russia and around the world.

The responsible manufacturer indicates in the product documentation the type of coating, which gas is used in the inner cavity and the material of the window profile.

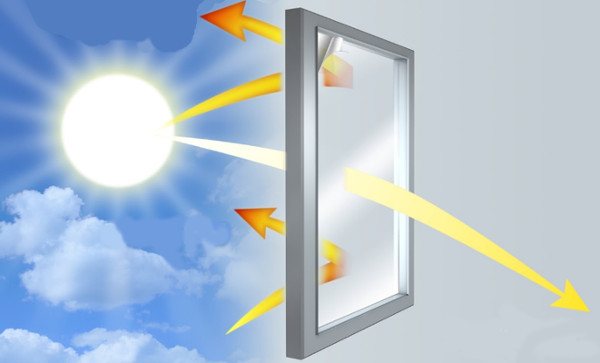

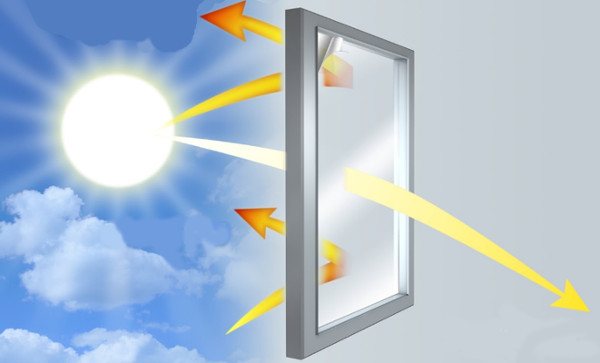

Features of glasses

Solar control glass units have a special structure, so they either reflect light or absorb it. Such characteristics are achieved due to the fact that the composition of the spraying contains oxides, metal nitrites, which are applied in a thin layer in the form of spraying to the glass surface. Modern PVC windows are processed in different ways: using spraying, energy efficient or tinted coatings.

Mirror coating is good in that it helps to absorb some of the solar energy and reflect the other part, so the light intensity is reduced by 30%. The properties of the deposition and its composition directly affect the amount of reflected and absorbed light energy. The design of the window is such that the glass with a mirror effect is visible from the outside, but from the inside it is transparent. And this makes it possible to protect personal space from prying eyes and prevent excessive heating of rooms, protecting interior items from fading. The benefits of using mirror glass include:

- One-way visibility while maintaining natural light.

- Reflection of thermal solar energy, which creates a favorable indoor climate.

- Prevent sun glare.

- High strength of the glass itself.

- The full value of the protection of premises from radiation harmful to our health.

- A wide range of color solutions, which makes it possible to implement different design ideas.

Spraying for the treatment of insulating glass is applied in a thin layer, therefore it facilitates light transmission, in contrast to the thicker coating on the back wall of a conventional mirror. The same light transmission and reflectivity is possessed by a translucent film, which is applied to a glass unit.

It turns out that glass with one-sided specularity is created either by spraying the composition onto the surface, or by mounting a mirror film. And the current trend is the use of a mirror coating for processing glass on balconies and loggias or when decorating doors inside rooms, which makes the interior original.