Today, there is no person who has not heard of PVC doors, also called metal-plastic or simply plastic. Using them in everyday life, how often have we wondered what it is?

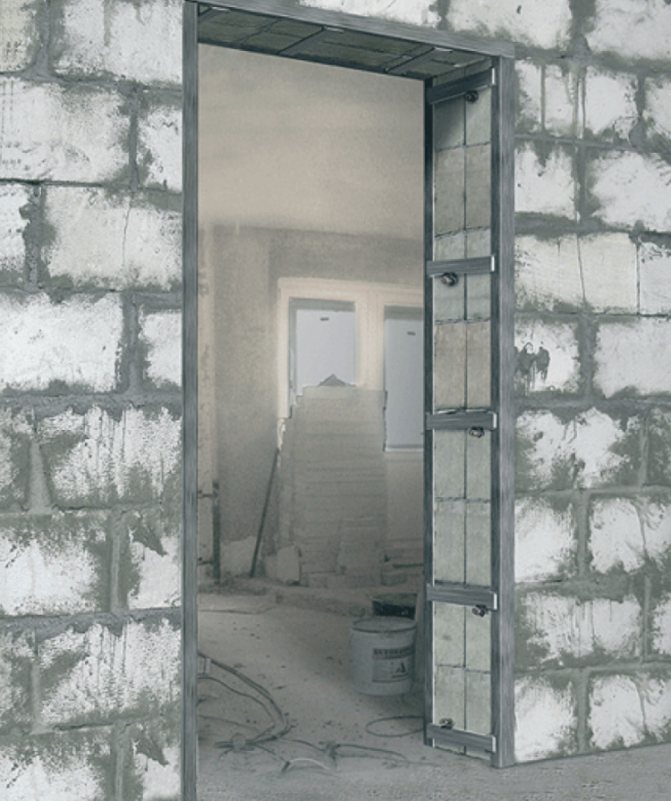

Bathroom door

Usually such doors are made of polyvinyl chloride (PVC) material reinforced inside with aluminum structures. Hence the name - metal-plastic. PVC is hardly flammable and self-extinguishing material, resistant to atmospheric influences, as well as the destructive action of alkalis and acids, not subject to rapid wear. It is these characteristics that make it possible to use it for the manufacture of door frames. Also, a PVC door is much cheaper and often more beautiful, as indicated by customer reviews.

Anyone buying a PVC door should know that the opportunity to choose a really high-quality product is regulated by law. Since 2002, the State Standard for metal-plastic doors has been used. It is called "Door blocks made of PVC profiles" (GOST 30970-2002).

This standard describes the main types of metal-plastic doors and their technical characteristics that require production. GOST obliges manufacturers to adhere to all quality standards described in it. Therefore, when purchasing a metal-plastic door, in order not to blindly trust the seller, it is important to understand the basic concepts of GOST.

Description

PVC, or as it is also called polyvinyl chloride, is a polymer film that is wrapped around the canvas in order to give an aesthetic appearance. In addition to attractiveness, the material improves the technical and operational characteristics of the base. So, a little more on that.

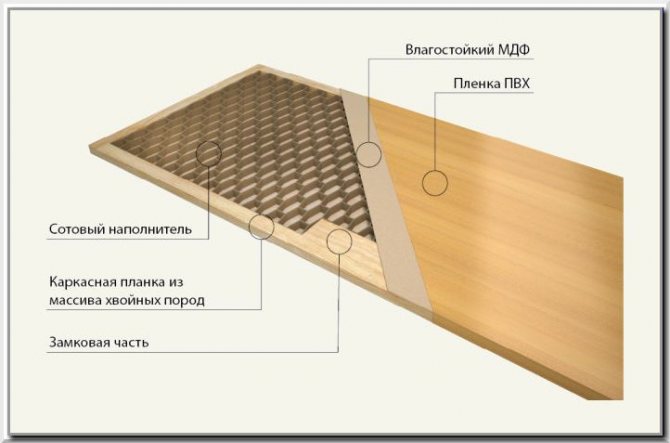

Standard PVC interior doors are a canvas on a frame, which is covered with a film on top. Sheets of MDF or fiberboard are fixed on the frame. And inside the structure is filled with honeycomb cardboard.

One of the main advantages of PVC is its moisture resistance. This is achieved by hot pressing the material.

Attention! It should be noted that the entire film application process requires sterility. There should be no dust particles, sand or traces of grease on the canvas.

This method is often used in furniture making. For example, kitchen facades.

Door leaf passport

The buyer has the right to demand, and the seller (manufacturer) is obliged to provide the buyer with a passport, from which it is possible to obtain comprehensive information about the product, to check the conformity of the delivery.

In the first section of the document, indicate the name and details of the manufacturer and then describe:

- type of door leaf;

- filling the canvas;

- design feature of the box;

- opening method and number of canvases;

- dimensions with indication of height, width, including the box;

- completeness of delivery (web filler, quantity and quality of hinges, locking devices, seals, additional equipment in the form of door handles and the like);

- the results of the tests carried out are given, up to the guaranteed opening (locking) cycles of the curtain;

- stipulate the warranty period for the product as a whole;

- indicate the number of the batch, order, date of manufacture with the signature of the responsible person who made the acceptance of the product.

As can be seen from the above, the passport contains comprehensive information about the purchased product.

Important! If the seller cannot or does not want to provide such a passport, then there is a high probability that the product was manufactured with violations of technological cycles and assembly procedure, is in the nature of short-lived and, possibly, traumatic equipment.

Pros and cons

PVC interior doors are the most popular type of doors. They are practical, attractive and are the leaders in demand among buyers. PVC doors have many advantages.

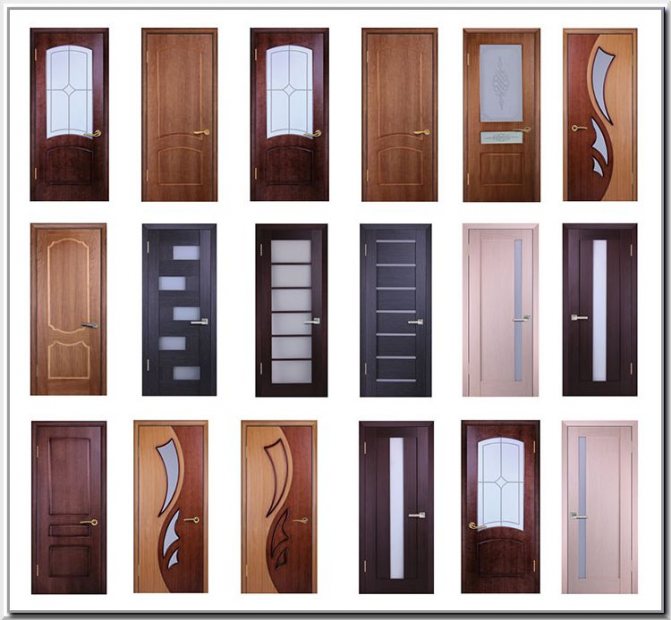

PVC door models

- The appearance of PVC doors is not much different from the material of valuable tree species. Only a professional can distinguish between the two.

- Low cost of doors.

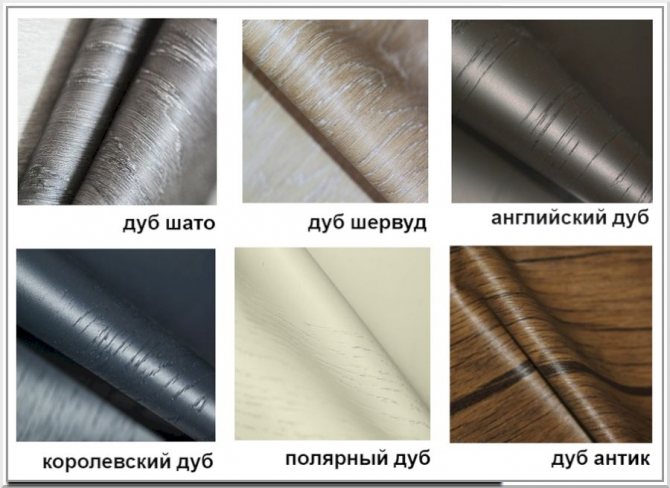

- A variety of colors and patterns will help meet the design ambitions of any buyer.

- Easy to care for.

Advice. PVC interior doors do not need chemical maintenance.

- Non-toxic (check the environmental certification before purchasing).

- Good heat and sound insulation.

- Strength.

- Safety.

- Resistant to moisture.

- Non-flammability.

- Long service life.

There are much fewer drawbacks, more precisely, it is one. The low elasticity of PVC can lead to deformation due to physical force. Scratches and abrasions are visible on the glossy surface.

What do customer reviews say?

Judging by the reviews of those who purchased such products, it can be understood that they are most popular among buyers with a not very high level of income who do not have the ability or desire to purchase more expensive doors. But among those on sale, you can always choose your best option - high-quality, durable and affordable.

Interior doors with PVC coating are perfect for middle-class people. They are especially good for bathrooms or other rooms with a fairly high humidity. A variety of product designs and a large color palette will help you find your exact option. If there are difficulties when choosing the texture of the surface of the material, you can always first look at the photo to see which one looks like.

Specifications

The purchase of a PVC interior door is protected at the legislative level. This means that for a low-quality product, you have the right to demand a refund of the money spent. They have the following types of technical characteristics:

When choosing a door, ask the seller for a quality certificate

- tensile strength;

- softening threshold;

- resistance to very high temperatures for a long period of time;

- shape change due to heating;

- shock resistance at low temperatures;

- departure from white as a result of exposure to UV rays;

- welding strength factor;

- the stability of the joints of the film with the base;

- duration of use;

- resistance to low temperatures;

- resistance to chemicals.

Attention! This standard describes the types of doors and their technical characteristics.

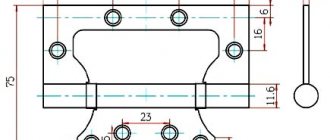

Interior fittings

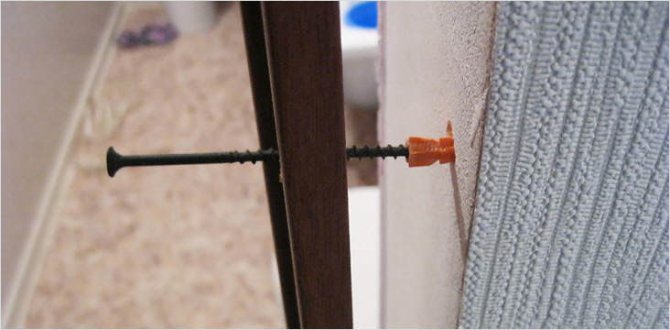

All steel structural elements are treated with protective materials for high-quality resistance to corrosive phenomena. When using aluminum, its nominal strength must correspond to the required parameters of the door block. The insert must be fixed with a pair of screws or self-tapping screws. The mounting pitch cannot exceed 40 cm. When using colored profiles, this distance is reduced to 30 cm. Installation of amplifiers does not require the use of special tools. The inserts are installed manually.

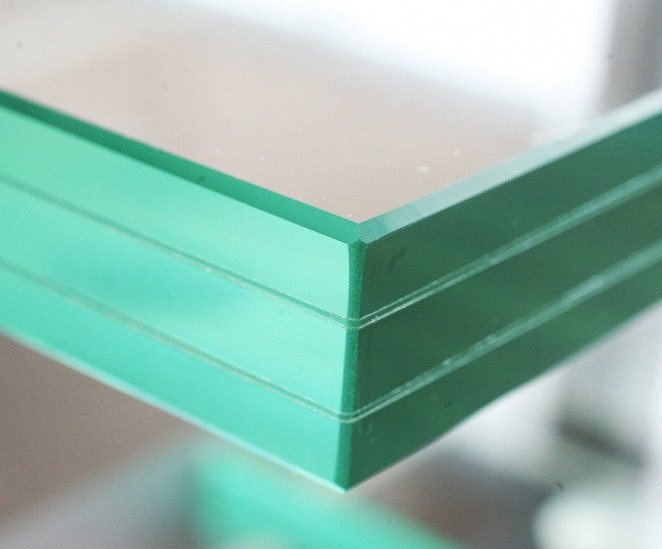

In the manufacture of blocks without transparent inserts, a three-layer foam PVC filling is used. The use of various finishing materials is permissible.

In the case of adding glass inserts to the structure, an anti-splinter coating is mandatory. The glass itself is made by bonding it in several layers.

Typology of PVC doors according to GOST

In accordance with the standard, doors are subdivided as follows:

By appointment - external or internal. The latter, in turn, are divided into interroom, entrance or for a plumbing unit.

Depending on the internal filling of the frame doors:

- glazed - a PVC door in which a double-glazed window or ordinary glass is installed;

- blind - door of an opaque modification. It can be light or decorative.

Depending on the constructions:

- with one or more canvases;

- with a fixed or opening sash;

- with or without a threshold;

- with or without a box.

Depending on the variety PVC profile.

Doors with glass inserts

Features of production technology

PVC interior doors are a frame structure covered with a decorative foil. In fact, this is a standard product that is no different from wooden counterparts. On a frame made of bars, sheets of MDF or fiberboard are fixed. Inside the resulting voids, there is a cardboard with many honeycombs. Main a special feature of such doors is the external PVC coating... protecting the base from moisture and mechanical damage.

To ensure reliable adhesion of the film to the base, special equipment is used. Before PVC production, the film is cleaned and degreased with high quality. The door leaf together with the film is placed in a special chamber. After that, the temperature in the chamber begins to increase, under the influence of which the PVC coating becomes soft, assuming any shape. The film is pressed thanks to the pressure created in the vacuum... due to which the polyvinyl chloride is qualitatively fixed on the product.

The main characteristics of using a plastic door

Before purchasing a door, you need to pay attention to its characteristics. These include:

- Insulation thickness in the range of 0.8-1.2 m2xC / W.

- Air permeability up to 3.5 m³ / (h x m2).

- Sound insulation not less than 26 dBA.

- The operation of PVC doors is at least 40 years, for a model with a double-glazed window - at least 20 years, and for a sealing material - at least 10 years. The number of door openings and closings can be at least half a million times.

Installation procedures

Installation work can be performed in several ways: by fastening directly to the plane of the wall through special holes, or using special mounting iron plates.

The plate mounting method is more popular and easier to use. For its implementation, a frame is inserted into a previously prepared opening. The fixation is carried out with a wedge lining. The alignment procedure is mandatory and is carried out from the side of the future location of the hinge mechanisms. After that, the pre-prepared metal plates are fixed. They are fixed on the surface of the adjacent wall.

Before fastening, the metal rack is level-locked under the lock. In this case, it is necessary to maintain a gap of 2 mm from the surface of the frame. The retaining wedges are not retracted until the final stage.

According to SNiP, the final assembly procedures of the structure are performed with the door leaf closed. Such measures are necessary to avoid distortions of the frame and fabric of the product. In the course of work, the supports can be removed, however, if desired, it is enough to simply cut them off during leveling, after blowing in the voids with polyurethane foam.

Door strength groups

In total, three groups of strength are divided: A, B and C. The first group is considered the most durable, from the point of view of GOST.

Deviations that should be considered a marriage:

- The difference between the finished product and what is declared in the project should not exceed 0.2 cm or be less than 0.1 cm.Likewise, diagonally, the difference should not be more than 0.2 cm for a canvas of 1.5 square meters and 0.3 cm for large doors.

- Scratches and various deformations that are visible to the naked eye.

- Problems opening and closing the door (requires exertion).

- Deviation from technical specifications.

- Deviations from the requirements specified by GOST during installation.

The main advantage of PVC doors is their appearance. A variety of shades will help you easily find the right option. The use of glass and various elements can be an addition to the design. The technology of gluing the film on the canvas ensures its full adherence.

Can be installed in a bathroom or other wet rooms

Yes, PVC coated doors are the first candidates for use in rooms with “walking” humidity.

Door with PVC foil installed in the bathroom

You should focus on one point. We have already said that the upper and lower ends of the canvases are sold unprocessed. In these places, the internal elements of the structure are open, freely in contact with the atmosphere, therefore they become conductors of dust and moisture. Before installing, try to cover these surfaces - grease them with a primer, varnish, paint.

The same should be done with the places where the hinges and handles will be installed. Of course, the recommendation applies to doors purchased without fittings.

Doors with PVC finishing for bathroom and toilet 137 series

Choosing a door: what to look for?

- Dimensions. For door openings from 80 to 90 cm, a standard single-leaf door is suitable. A sliding or swing two-leaf door is installed for openings with a width of 1.1 m. It is not difficult to choose a door of a non-standard size or make it to order.

Choose a door according to the style of your interior

- Budget. Initially, you need to decide how much you are counting on. It is advisable to purchase all interior doors at the same time. This will protect you from the risk of inability to purchase an existing model for other rooms due to the product being discontinued or out of stock.

- "All inclusive". When buying doors, remember that the door, as a rule, is sold complete with a frame, threshold, trims and accessories.

- Quality certificate. The presence of a certificate is a guarantor of product quality. All self-respecting manufacturers carry out mandatory product certification.

- Feel free to ask the seller questions.

PVC interior doors are a good inexpensive option for interior decoration and home decoration in any style. Non-flammability, environmental friendliness, price component and a variety of colors are the main advantages of the design. The presence of a certificate is a guarantor of quality.

Fitting a non-standard opening

If the established parameters indicated in SNiP do not match with the existing dimensions of the doorway, it is necessary to adjust it to the appropriate dimensions. These measures must be carried out until the completion of the finishing work on the walls. It is worth remembering that the maximum gap overlap with platbands is 3 cm.

The width of the opening must be reduced evenly on both sides. However, the narrowing can be made no more than 3 cm from each side. A wider door block must be used to extend the walls of an acceptable size.

Interior PVC doors: photo