Nowadays, almost every apartment or private house has plastic windows. This greatly simplifies people's lives, because metal-plastic structures are very durable, they are more convenient to use, they are more reliable, and the service life is much longer than that of wooden ones. But these advantages do not negate the need for special care, which will extend the operating time... PVC structures need to be cleaned, insulated, repaired, etc. Preparing plastic windows for winter is an important point of operation.

When it gets colder outside, it is important to think about how to adjust the plastic windows for the winter. Proper preparation is not difficult at all, but very important. If you do not make a few simple manipulations, then the euro windows will not perform the functions declared by the manufacturer.

Removing dirt and rinsing PVC profiles

Checking the condition of the windows and preparing them for the cold season begins with cleaning and rinsing the profile. Dust and dirt left for the winter not only spoil the appearance of the structure, but also cause a reduction in its service life (aggressive substances, fungi and microorganisms actively destroy the outer layer and the inner structure of the profile). The PVC frame can be washed with ordinary household products that do not contain aggressive components and particles that can damage the surface. Do not use cleaning powders or products with a discoloration effect. The ideal remedy is professional care solutions offered by window companies.

How to close plastic windows for the winter

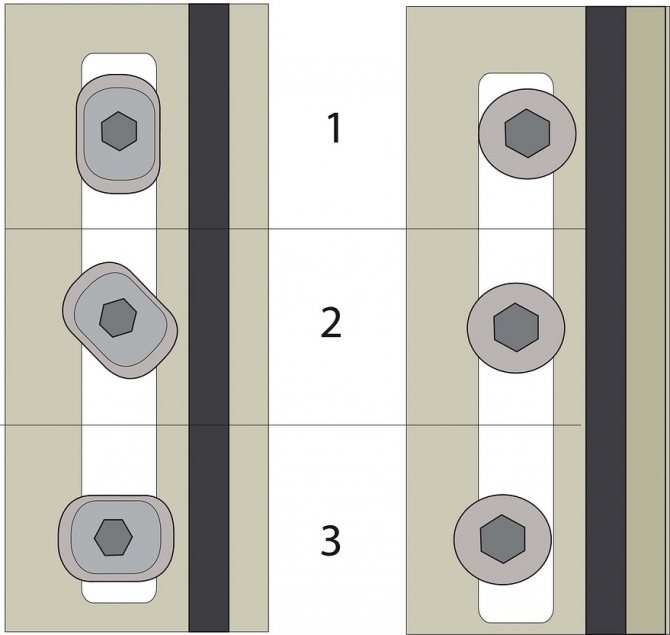

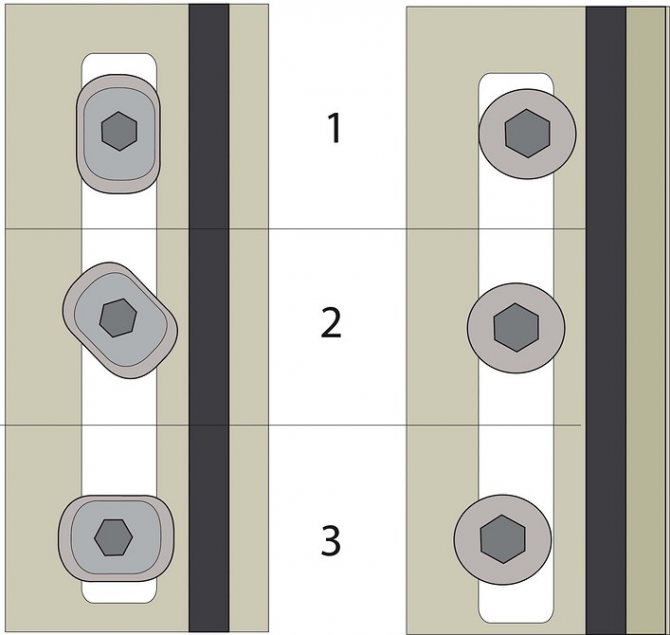

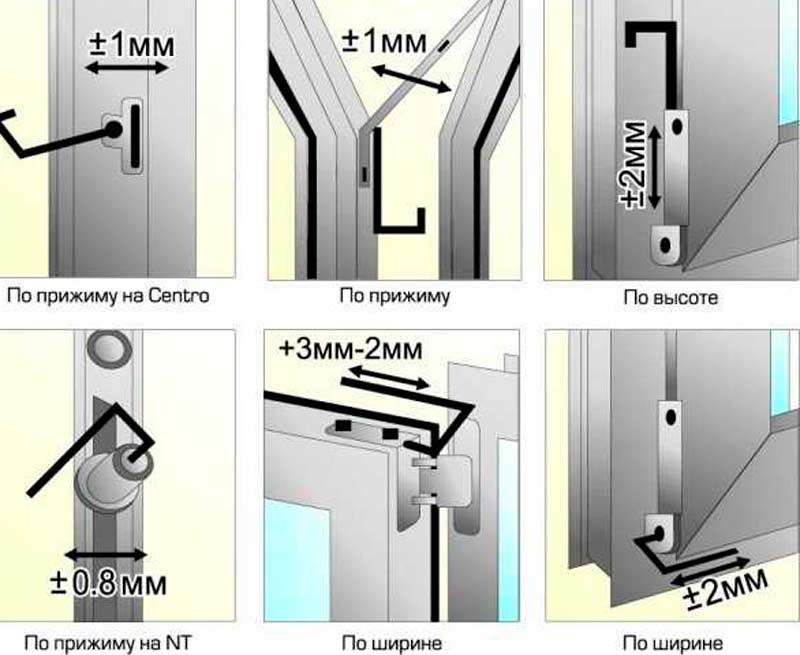

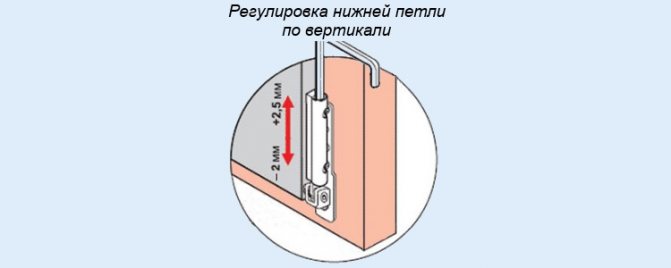

If PVC is classified as regulated, that is, the trunnion has hexagon entry

- which means you can switch to winter mode. It's easy to close for the winter:

- Raise the hardware roller.

- Adjust the pressure with a hexagon.

- Lower the roller into place.

- Turn the roller with a notch to the side of the offset.

- This should be done with each video.

Sometimes, after carrying out manipulations, the fastening of the handle of the structure weakens. To eliminate this problem, rotate the plastic plate next to the handle 90 degrees, then tighten the screws.

If the handle is difficult to turn, you need lubricate the mechanism

special oil.

Glass unit washing

Double-glazed windows are washed with glass cleaner or ordinary soapy water, cloth rags or paper napkins (towels). The rags should be soft, fluffy and free from hard, scratch-causing seams. Glass units should be washed and wiped carefully, keeping in mind the fragility of glass and its vulnerability to mechanical damage.

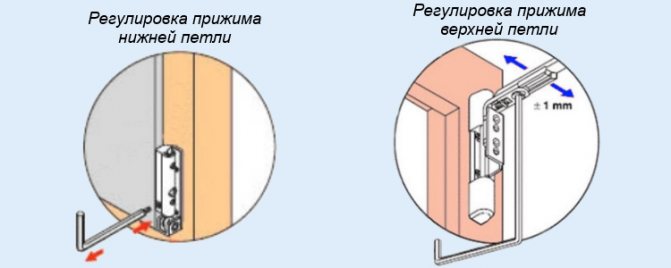

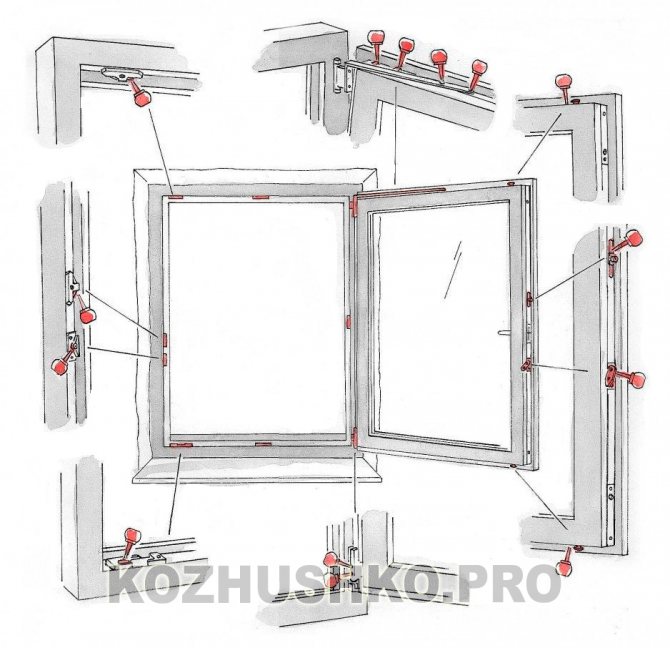

Work with fittings

Checking the condition and performance of the fittings is the next important stage in preparing PVC windows for winter. The first step is to inspect all the elements, make sure that they are intact and have no external damage. Next, you should see how each unit works: whether the doors close / open well, whether they are tightly pressed against the frame. In case of detection of individual problems, it is necessary to adjust the fittings. You can do this yourself (if you have professional skills and experience) or call a window company specialist.

The adjusted fittings are lubricated from the outside and from the inside in the locations of the moving elements. Lubricants are sold by PVC window manufacturers or suppliers and can be ordered with window systems or purchased separately.It is recommended to process fittings with special compounds at least twice a year: when preparing plastic windows for winter and before starting operation in summer mode.

Before lubricating the fittings, you need to remove dirt and dust from the working parts. This can be done with an ordinary brush or a vacuum cleaner in combination with a brush - most of the dirt is removed so quickly and effectively.

If the fittings are adjusted by a specialist of the window company, ask him to also check the condition of the other elements of your window.

Checking windows for serviceability and eliminating errors

It is better to detect and fix any problems during the warmer months.

Rubber window seal

First, be sure to check the condition of the seals. In fact, this can be called a key moment, since it depends on them how the winter will pass.

Old and worn out seals will be much less effective, they can allow cold air to pass through and create unwanted drafts.

Installing a new seal on the window

It is necessary to carefully examine the gum for cracks, dents or tears, and if any, be sure to replace it with a new one. Do not try to fix it yourself or repair cracks.

A new seal is not too expensive, and the desire to save money can only aggravate the situation.

Universal seal in a plastic window

Preparing the seal

The window seal is hardly noticeable against the background of other structural elements, but it plays one of the main roles in providing thermal insulation. It is he who does not allow cold air currents, moisture, dirt into the room and reduces the volume of street noise. Seals are made from different polymers and therefore react differently to UV exposure, precipitation and temperature fluctuations. Caring for seals of plastic windows consists in cleaning and processing them with special compounds that prevent cracking and rupture of the material.

The minimum period for processing the seal is 1 year. It is advisable to carry out work during the independent preparation of PVC windows for winter, as this can affect the frost resistance of the entire structure.

Before lubrication, the sealing contours are cleaned of dirt and wiped with a damp cloth or sponge. Use of soapy water is allowed. Processing is carried out with silicone-based solutions and sprays, or with ordinary glycerin. The listed substances allow the material to maintain elasticity, not to crack or tear, even in severe frost. It is not recommended to use machine oil, talc, petroleum jelly and cosmetics containing glycerin.

Sections of the sealant with identified cracks and ruptures should be replaced before the onset of frost. If, upon visual inspection, the seal has fallen out of the groove, you need to fill it back with your own hands or contact a specialist.

Save as much daylight as possible

As you know, in winter the days become shorter, and letting in as much daylight as possible into the house, which is so scarce in the cold season, is one of the main tasks that a homeowner faces. Today it has become the norm to install mosquito nets, but if in the summer it is a very useful accessory, then with the onset of cold weather it loses its functionality. Therefore, before proceeding with other procedures, it must be removed - the mosquito net can be easily dismantled. This measure also prolongs its life, since under the influence of atmospheric precipitation in low temperatures, the structure of the mosquito net can be damaged.

The removed mesh should be vacuumed, washed with warm soapy water, dried and put into the closet before the onset of warm days.Pay special attention that the storage area of the removed mosquito net is free of rodents, since in the spring there is a possibility of encountering an annoying nuisance - the net can be damaged by cunning mice.

Cleaning the drainage system

The window drainage system is a combination of small holes and channels in the PVC profile, the main purpose of which is to remove the resulting condensate outside. Before the onset of frost, you need to check how the entire system is functioning, whether the holes and passages are clogged. Inoperative drainage can lead to icing of windows in winter and the appearance of mold or mildew. Drainage holes and channels can be cleaned with wire of the required flexibility and rigidity.

Mosquito nets in winter - should they be removed or left?

Despite the fact that modern mosquito nets are made of materials resistant to negative factors, experts still recommend removing them before the onset of winter. Why do you need to do this?

- Firstly, synthetics (from which most nets are made) tend to stretch and the size of the cells can increase significantly due to the regularly formed ice. The mesh with large cells will protect from fewer insects and allow midges and other small insects into the room;

- Secondly, ice or icicles can break the canvas, and the mesh will have to be completely pulled;

- Thirdly, under the influence of negative weather factors, the mesh frame will lose its attractive appearance faster (the paint will crack, the base will fade, etc.).

The removed nets do not take up much space - they can be stored behind cabinets, on the mezzanine, on a glazed balcony. Before cleaning for storage, the nets are washed in water with non-aggressive household products using a sponge or a soft-bristled brush.

In autumn and spring, dirt and external fasteners for the mesh should be cleaned - this prolongs their service life and preserves aesthetics longer.

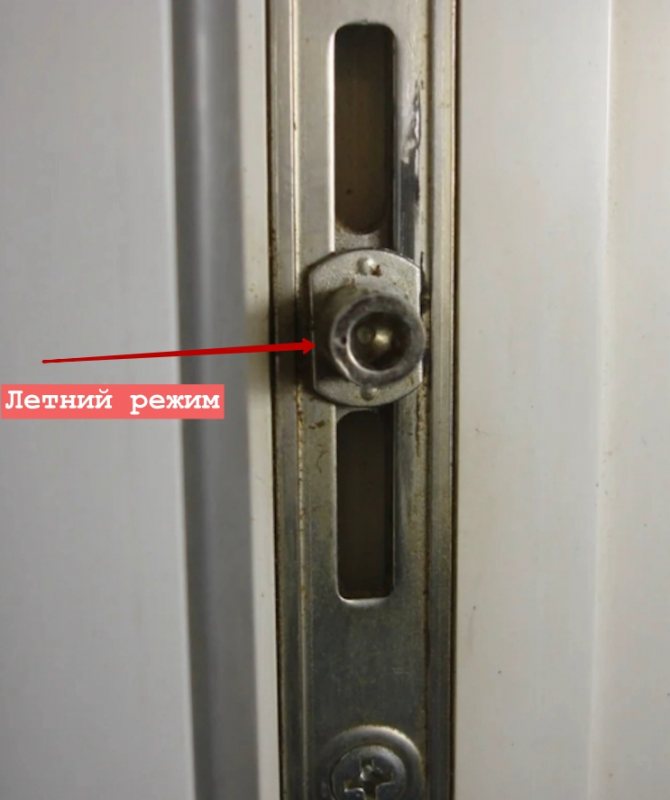

Difference between summer and winter mode

During the first years after the installation of windows, home owners enjoy a comfortable microclimate, coziness and sound insulation. However, during operation and under the influence of subzero temperatures, the closed doors begin to let heat through. Failure to do the right thing will exacerbate the problem, making your home cold. To eliminate the trouble, many people decide to seal the cracks with a strip of paper, but this is the wrong decision.

Manufacturers of window products have provided for the function of adjusting plastic windows for the winter, with which you can tightly press the sash and frame to each other. However, it cannot be carried out immediately after the installation of the structures, since this will reduce the tightness of the sealing gum and lead to a loss of its elasticity.

Further, the seal will begin to wear out, which will cause voids to appear. Experienced experts recommend adjusting the window only after feeling a draft. They also offer services for the maintenance of window systems, but for such a procedure you will have to pay a rather large amount.

If you understand the specifics of adjusting windows and read the step-by-step instructions, you can set up summer and winter modes yourself.

Preparation of wooden windows for use in winter

In general, preparation for wintering for wooden windows differs little in the care process for their PVC counterparts. A significant difference is observed only in relation to wooden frames, which are more sensitive to maintenance and require special preventive procedures:

- Identification and elimination of cracks and other surface defects - the wood's susceptibility to decay requires prompt elimination of problems (application of protective compounds, coatings, "patches");

- Thorough cleaning of the joints and areas where the profile adjoins the glass unit - the maximum amount of dirt and moisture accumulates in the joint zones, due to which decay processes develop rapidly.

Wood profiles should be regularly cleaned with dry cloths, paper towels or paper towels. Both during the preparation of wooden windows for winter and in other seasons, wet cleaning is recommended with products intended for the care of wood. It is necessary to select a product, taking into account the type of paintwork.

In principle, these are the main stages of how to prepare plastic windows for winter without significant material costs in a short time. If the above list seems too long, and the upcoming implementation of all stages does not arouse enthusiasm, turn to the financial side of the issue. High-quality preparation of windows for the season will significantly save on heating and spend money on other important (or pleasant) purposes.