Using modern technologies, manufacturers of double-glazed windows are trying to improve the quality of products.

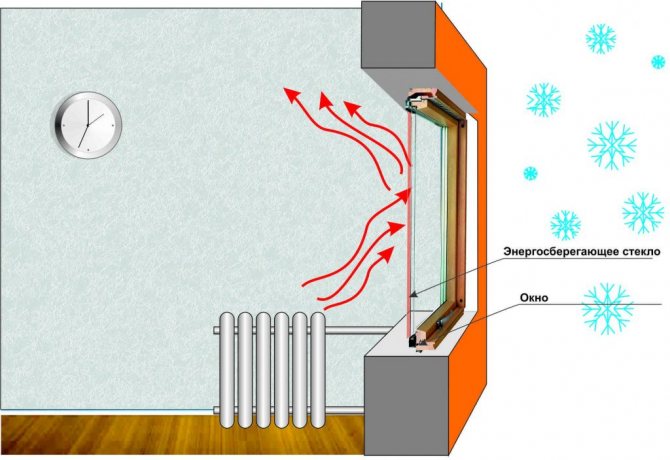

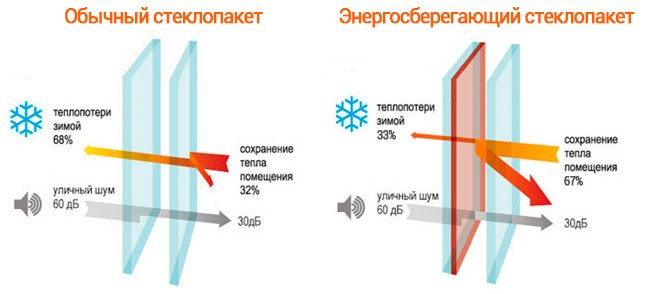

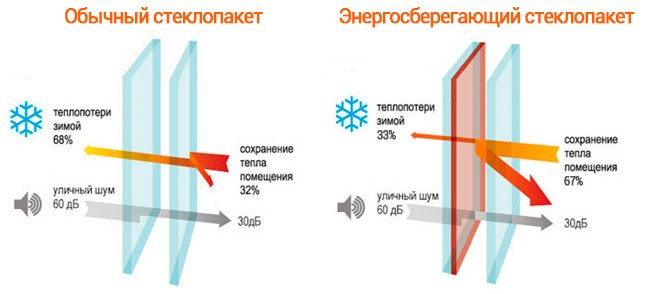

It is known that a large amount of heat loss occurs through the windows in the house, therefore, manufacturers today offer modern energy-efficient double-glazed windows. They significantly reduce the percentage of heat loss in the room, creating an optimal microclimate inside. Before ordering windows in Kharkov, we will consider the main characteristics of energy-saving windows and the rules for their installation.

Energy-efficient windows: myths and reality

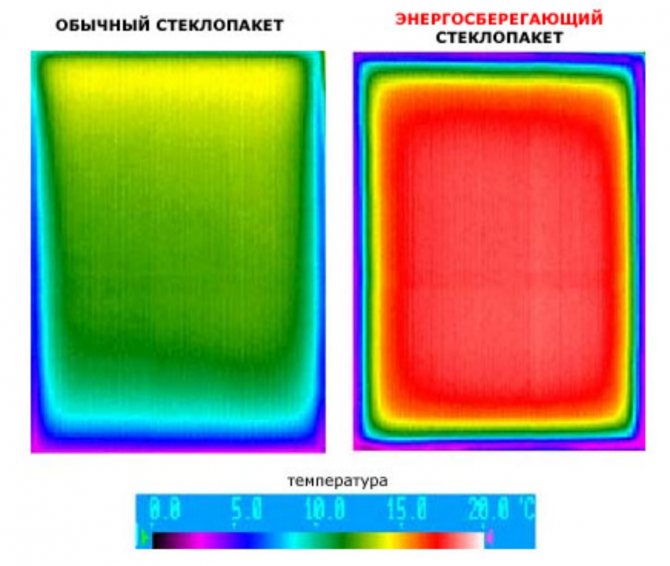

Despite the popularity of energy-efficient windows, there is also a skepticism about them. However, in practice it has already been proven that they are very effective in keeping the normal temperature in the house. The high cost is offset by savings in heating costs. According to numerous customer reviews, it is known that in addition to saving energy resources, “warm” windows save you from other problems.

Benefits of energy-efficient insulating glass units:

- preservation of heat in the room during the heating season;

- providing coolness in the room during the summer heat;

- protection against condensation;

- UV protection;

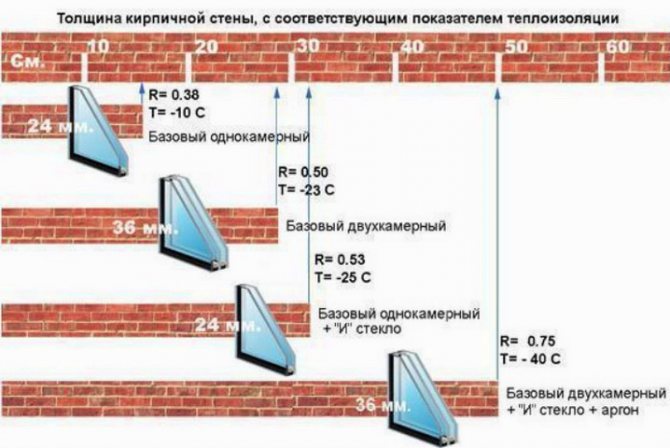

- it is possible to install lighter single-chamber double-glazed windows, which are not inferior to conventional two-chamber products in terms of their heat preservation properties.

Energy-saving windows have plastic double-glazed windows with a special modification, which prevent heat exchange between the street and the room. This helps to spend less money on heating during the cold season. This is especially important for owners of private houses. In multi-apartment buildings, where the heat supply is not regulated, the benefits include keeping warm in winter, as well as being cool in summer heat. After all, such windows do not allow the air in the room to heat up, even when the temperature outside the window is very high.

Another great advantage of such windows is the reduced likelihood of condensation. Indeed, for the formation of drops on the glass, 2 factors contribute - high humidity and a cold surface. Energy-efficient double-glazed windows allow to maintain a higher glass temperature from the side of the room. Therefore, condensation can very rarely appear on it.

These windows also protect indoor surfaces from fading when exposed to sunlight. Furniture, textiles, paintings and other interior items retain their original color for a long time, even if the room is located on the sunny side.

A protective barrier limits the penetration of ultraviolet rays from outside into the house. But this does not in any way affect the growth and development of indoor plants, because the flowers receive a sufficient level of 35% of UV radiation.

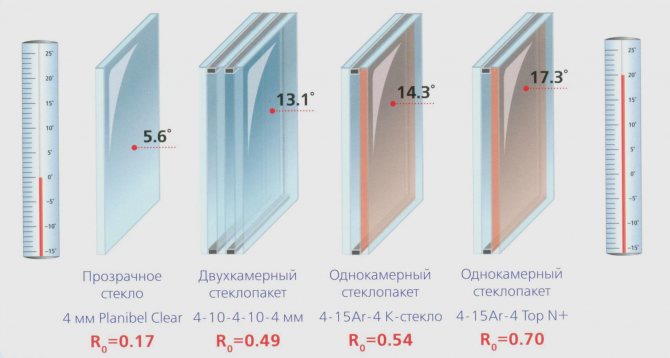

Single-chamber energy-saving double-glazed windows can be 20% more efficient than conventional two-chamber ones. Even greater thermal insulation properties are possessed by two-chamber and three-chamber, manufactured using a new improved technology.

But the advantages and use of such single-chamber windows are indispensable where the construction of the house does not significantly increase the weight load. In such cases, lightweight single-chamber products fully replace ordinary PVC windows with multi-chamber double-glazed windows.

The most common myths about energy-efficient windows and their refutation:

- The inert gas argon, which is used to fill the hermetic spaces inside the glass units, quickly evaporates. This myth is spread by competitors.This is done to promote their products on the market.

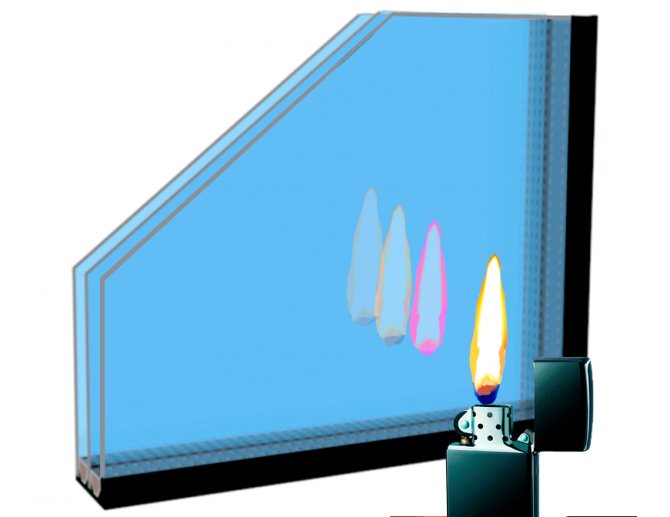

- There is no argon inside the double-glazed windows - this is a publicity stunt. The presence of this gas cannot be visually identified, because it is invisible and odorless. But testing methods are used to check for the presence of argon. For example, if you bring a lighted match close to the glass, then if there is argon inside, the color of the match flame and its reflection will be different.

- Plants die in a room with such windows. In practice, it has already been proven that plants grow well in such rooms. They receive a sufficient dose of ultraviolet light necessary for growth and development. And also, reliably protected from the cold in winter. When simple PVC windows are installed, the flowers freeze on the windowsills.

- Energy efficient insulating glass does not exist. But these products are being produced. Their thermal insulation properties have been tested during operation.

Functions

- What is energy-saving glass and why is it needed?

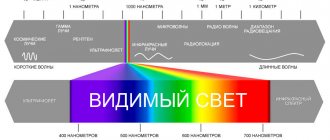

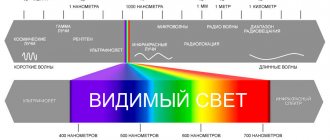

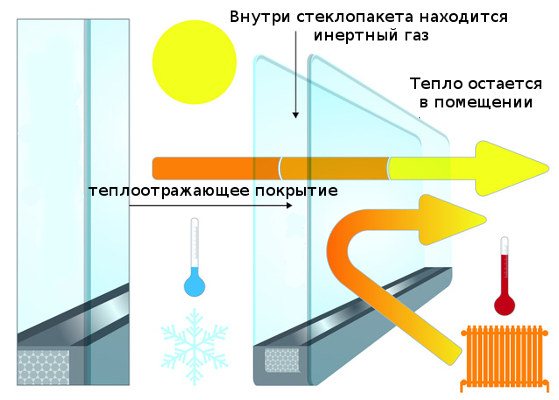

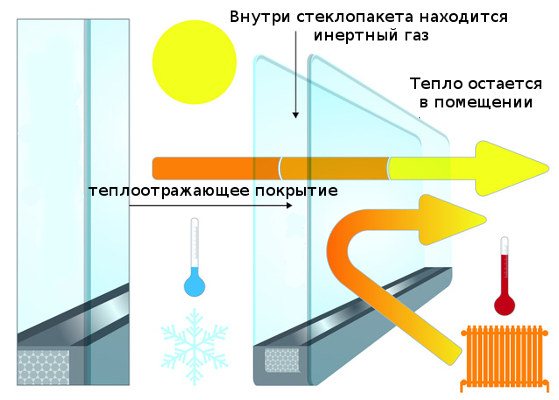

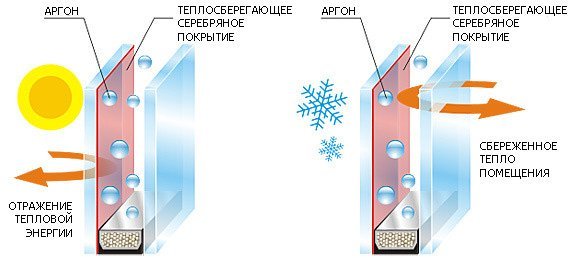

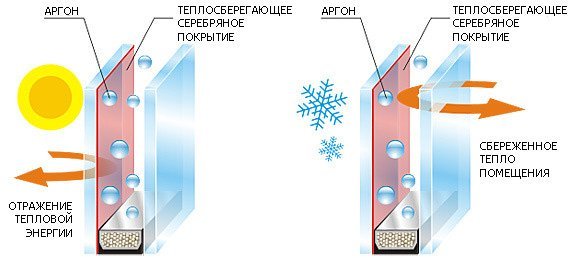

This is a common thin-sprayed glass with limited transparency in the infrared part of the spectrum (corresponding to thermal radiation). Reflection of infrared rays can significantly reduce heat loss in winter and heating of the room through windows in summer.

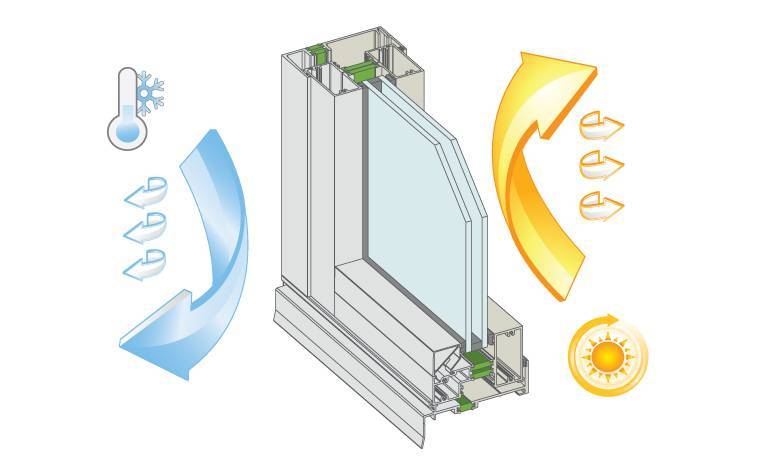

- Does the energy-saving layer affect heat transfer by convection?

Spraying has no effect on convection. But filling the cavity between the glasses with argon, which is practiced in the assembly of energy-saving glass units, reduces heat loss due to convection by 10-12%. The effect is associated with the higher viscosity of argon compared to air, as well as its lower thermal conductivity.

Argon significantly reduces heat loss due to convection.

Energy-saving glass in a double-glazed unit

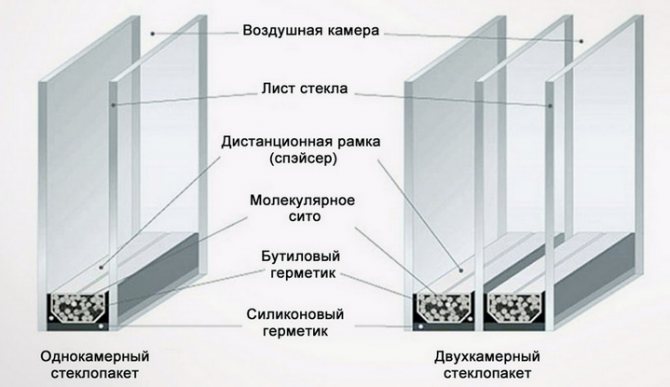

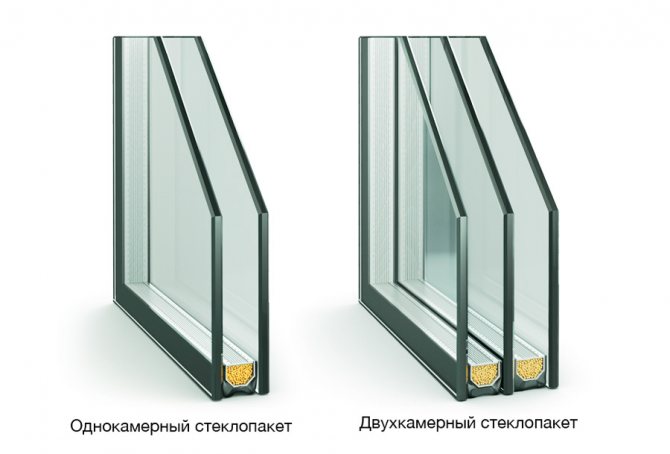

In appearance, they do not differ from ordinary PVC windows. They are single-chamber or multi-chamber bags with several glass surfaces and connecting baffles with seals. Inside the chambers, the space is filled with an inert gas, usually argon. This improves thermal insulation properties and additionally soundproofing.

The surfaces of the glasses inside the chambers are coated with a special layer of silver ions or indium and tin oxides before being assembled into packages. The technology of a two-layer coating of silver and titanium is also used. Depending on the type of spraying on the windows, the technical characteristics of the surface resistance to chemical and physical influences differ.

Sprayed coatings are applied in the thinnest layer (0.08-0.12 microns thick), which is invisible to the human eye. If the manufacturer has not done such a spraying, then they acquire a special protective film and apply it already from both outer sides to the glass. Transparent and tinted protective films are commercially available.

This technology made it possible to embody the following properties in one material:

- energy saving;

- heat-saving;

- shockproof;

- protective from ultraviolet radiation outside and infrared rays from inside the room;

- self-cleaning surfaces.

Their manufacturing technology is complex. It requires the use of expensive modern equipment. Such acquisitions are available only to large manufacturing companies. Strict adherence to all stages of the technological process is necessary. It is impossible to make these products in handicraft conditions.

It is difficult for an untrained person to visually distinguish a glass unit with energy-saving properties from a usual one. It is better to choose the products of well-known large companies.

It is imperative to check the corresponding markings. This will allow you to purchase a quality product with a guarantee.

My experience

Background: four years ago, shortly after moving to Sevastopol, I was puzzled by the construction of an attic instead of a low cold attic. A beautiful view of the sea disposed to a large area of windows.

From the usual in the Far East, where I lived before, two-chamber double-glazed windows dissuaded me in favor of single-chamber energy-saving windows installer company manager. The total glazing area was 26 square meters - 2 glass gables, 13 m2 each.

Device: windows represent a compromise between the desire to save budget and the requirements for reliability.

| Picture | Glazing element |

| Profile: Chinese Hautek. It is noticeably cheaper than the German Rehau and KBE, while it has sufficient rigidity and reliable UV protection. |

| Fittings: Siegenia-Aubi. The period of trouble-free operation of windows depends on the fittings, so it is unreasonable to save on it. |

| Double-glazed windows: 4-16-4i. With a translucency of about 90%, they provide very little dimming. On the left in the photo - a view through an open balcony door, on the right - through a double-glazed window. |

Impression: generally positive.

- An inverter air conditioner with a thermal power of 4.1 kW is enough for heating an attic measuring 5x12 meters with a glazing of 26 squares. Small heat losses indicate high-quality thermal insulation of the roof and windows;

- In summer, when the window sash or balcony door is open, it is easy to notice uneven heating of the floor. Where it is illuminated through glazing, the surface is colder; under the open sash, the laminate is heated to a higher temperature. IR filtering makes itself felt;

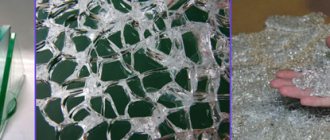

- The light weight of the insulating glass makes them easy to dismantle and install.

The lighter the glass unit, the easier it is to remove and install it.

The only problem with large windows is that they provide excessive insolation in the attic: on a summer day, it is so light in it that you have to keep the curtains closed for most of the day. That is why my immediate plans include pasting the glass with a light-protective film.

Light-protective film limits the transparency of glasses in the visible spectrum. It is useful where in summer the illumination of the house is higher than comfortable.

Disadvantages of energy saving packages

There are pros and cons to these products. The biggest disadvantage is the high cost. Because the manufacturing process is complex. But as a result, over the course of operation, such costs are justified by saving energy resources, creating more comfortable conditions in the room.

In some cases, when a poor-quality spraying of a protective layer was made during the production process or the sealing of a glass unit was broken, then its energy-saving properties are lost. When buying, it is difficult to immediately determine their quality. But well-known manufacturing firms value their reputation. They check their products for defects. Therefore, their products can be bought without fear and with a guarantee.

If heat-shielding windows are installed on the sunny side, then this significantly reduces their service life with high-quality protective properties. The PVC windows themselves will last a long time, but their thermal insulation properties will be much reduced. The lowest service life is when using a protective film - after 10 years it will lose its useful functions.

Films

- How effective is energy saving window film?

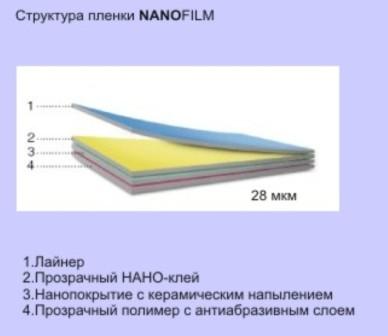

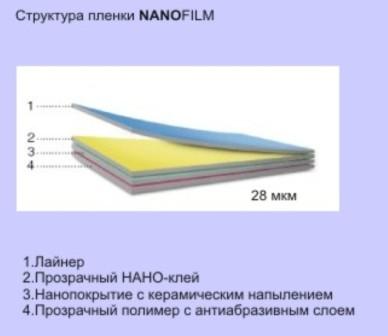

High-quality film from renowned manufacturers (for example, Nanofilm) really provides filtering in the infrared part of the spectrum and approaches the efficiency of i-glass. At the same time, it practically does not darken the room.

The structure of the Nanofilm energy-saving film.

In addition to energy-saving, there are mirror and colored light-protective films. They are useful on the south side of the house to protect the building from heating in sunny weather and from excessive light.

- How to properly glue such a film with your own hands?

To apply the film, I strongly advise you to remove the glass unit from the frame. There are two reasons for this:

- When cutting it along the contour of the glass unit installed in the frame, it is very easy to damage the rubber seal;

- Inevitable gaps around the edges will look untidy and collect dirt.

To remove the glass unit from the frame, you need:

- Pry the middle of one of the glazing beads (longer) with a knife blade or a thin steel trowel and pull it out of the frame. Do not be afraid of bending the glazing bead, it will not break;

- Repeat the operation one by one with the remaining glazing beads. The top one is removed last: until the last moment it will hold the glass unit in the frame.

Dismantling of double-glazed windows begins with the removal of glazing beads.

The released glass unit is placed on a table covered with a cloth and thoroughly washed from any contamination - first with water and any detergent, then with a glass cleaner.

By the time the film is applied, the glass must be clean, transparent and dry.

The film together with the base (the so-called liner) is cut to the size of the glass unit with ordinary scissors. You can not cut the film after sticking with a clerical knife. It is easier, but this way there is a great risk of breaking the sealing of the glass unit along the perimeter of the glass.

Then the glass lying on the table is abundantly moistened with soapy water. It will avoid the formation of air bubbles under the film.

The next stage: the film is peeled off from the liner (it is better to do this together), after which its adhesive surface is also moistened with soapy water. Then the film is placed with the adhesive side on the glass. It remains only to drive out the water from under it; this is done by sliding a dry cloth or plastic card from the center to the outside.

If there are water bubbles under the film, do not worry about it. It will evaporate quickly.

It remains only to install a double-glazed window. It is exposed on plastic spacers with a small gap between the bottom edge and the frame; then glazing beads are installed into the frame one by one, starting from the top, and hammered (with a rubber mallet or a hammer through a block).

How to distinguish an energy saving package from a regular one

It is visually difficult to distinguish between conventional and energy-saving double-glazed windows. Therefore, it is necessary to check the labeling of the goods when choosing. For example, for an ordinary similar product, it will be 4-16-3, and for the same heat-shielding product with the presence of argon in the chambers, it will be 4-16-Ar-4I.

The decoding of the labeling of the energy-saving package in this example means that it is two-chamber with a sheet thickness of 4 mm, inside the chambers there is argon gas, on one of the glasses an energy-saving I-coating is applied.

Special devices are able to accurately determine the properties of energy-saving glass units - the thickness of the glass, the type of protective coating, they can even deduce the product's formula. But such devices are not widely available to anyone. They are commonly used by large construction companies to monitor the quality of materials and the glazing work performed on objects.

Available verification methods:

- Going to the store you need to take a lighter or matches with you. If you bring a flame close to the glass, then its reflection in an ordinary glass unit will not change, and if there is argon gas inside, then the reflection of the flame will be more reddish.

- Another way to check energy-saving glass in double-glazed windows is the “glare method”. If you look at the glass from an angle, then on its surface, if it is an energy-saving product, you can see a bluish-purple tint.

Thermal conductivity characteristic

How to identify an energy efficient glass unit:

One of the characteristics of a glass unit is (k) thermal conductivity coefficient... This characteristic is equal to the amount of heat (in W) that passes over 1 sq. m., and the temperature difference in both environments will be with a difference of 1 degree on the Kelvin scale (A), measured in W / (m K) in the SI system.

A small value of "k" indicates a low heat transfer, and, consequently, small losses through the packet. At the same time, if we talk about the thermal insulation properties of the structure, then they are quite high. It is known that metals have high thermal conductivity, low - air. Therefore, if there are several air chambers, the structure will have a low thermal conductivity and will be the optimal value in such packages.

It can be concluded that the more cameras in the set, the higher the heat saving. In order to achieve higher values of heat saving, the chambers are filled with inert gases, as well as by applying a low-emission coating to the glass.

Within Russia, the same product costs differently. Here, not only the manufacturer, prices for materials, but also the region play a role. It all depends on how far it is from the manufacturer, the firm.

What does it depend on:

- The type of premises.

- Block size.

- Product quality.

- The constituent parts of the block.

- Window configurations.

- The number of components.

If we consider the capital prices, then the price of the simplest single-chamber double-glazed unit, with a glass thickness of 4 mm, varies from 1300 rubles. per sq. m. Thicker glass in a bag (5 mm) - 1450 rubles, 6 - 1600 rubles. Glass covered with an impact-resistant base will add another 600 rubles to the total price. per sq. m. Triplex glass with tempering will cost the buyer 3,500 rubles.

Which side to put an energy-saving double-glazed window

For the correct functioning of the glass unit, the installation rules must be observed. Then the protective films will fulfill their purpose. Most of these are applied inside the chambers to protect these coatings from oxidation and damage.

Surfaces with a self-cleaning effect, hard k-glass, multifunctional and designed to reflect the sun's rays from the surface are always placed on the street side.

Low-emission coatings should be located either inside the chambers or on the side of the room. Because their main function is to store long-wave infrared radiation, to prevent heat leakage from the room.

Energy efficiency class of windows

Everyone is accustomed to the fact that household appliances are labeled with a scale of their energy efficiency indicators. This information also applies to insulating glass units. They mean how much of the product of this marking allows you to save on heating and cooling (air conditioning) of the room.

Many countries have adopted standards that summarize the two types of energy savings. Demand rates are different in cold climates or hot countries. Energy efficiency class scale has been created.

In Russia, the following classification is used:

- E - low class;

- D - lowered;

- C - normal;

- B - high;

- A is the highest.

There are many different climatic regions in Russia and in each of them the requirements for double-glazed windows are different. For example, from the Moscow region, where the average heat and cold, they include the highest energy efficiency class for both the hot season and the winter.