Plastic window painting and lamination: 2 ways to change the look of frames

Table of Contents

Of course, you can order new windows or hire a special team, but both of these options are expensive, and not always and not everyone has the money for this. Therefore, more and more craftsmen are looking for ways to change the color of the windows on their own, without involving specialists.

There are 2 ways to change the appearance of frames:

- lamination, that is, a special film is applied to the profile that imitates any texture (most often a tree);

- painting - 1-2 layers of paint are applied to the frames.

Lamination

For this procedure, laminated film is used. It is glued onto a special glue. At first glance, everything is simple: you need to glue the film onto the frames. However, the glue requires certain conditions and heating. In order for the film to adhere tightly to the profile, it is necessary to press and smooth it well. In production, a machine with pressure rollers is used for this. At home, it is unlikely that you will be able to glue the film on plastic with high quality on your own. Again, the frames need to be removed for lamination. It is still possible with sashes, but the frames themselves will remain white.

An alternative is to use a self-adhesive tape. Of course, it is difficult to call this a full-fledged process. But it will be quite possible to change the appearance of the windows. This work is also not easy and will require considerable restraint and accuracy.

Painting windows

It is much easier and cheaper to paint windows. This process is much faster. However, everything needs to be done correctly. For painting plastic windows, simple oil, acrylic or other paint is not suitable: it will drain, as a result, you will get an ugly coating. You only need to use a plastic agent: special substances have been added to them that provide high adhesion, protection from solar radiation and resistance to precipitation. As a rule, such paint is sold in cans.

First, the windows must be cleaned of dirt, if necessary, washed and dried. Double-glazed windows must be protected in some way from the ingress of coloring compounds on them. The simplest thing is to seal it with paper or masking tape. Then the profiles are treated with a plastic primer. The composition allows the product to adhere to the PVC surface (including vertical). The primer is also often sold as an aerosol. This is the most convenient format for working with windows.

After the primer has dried, the frames are painted with spray paint. The composition is applied in 2 layers. First one. They dry it well, and then the second one. Otherwise, the old color will show through the new one. Unfortunately, after a few years the paint will fade and you will have to repeat the procedure again. This is a natural aging process for paint.

Therefore, before proceeding with painting or lamination, you must first consider the degree of need for such changes, since both paint and film begin to fly over time. And they will have to be changed and refreshed over and over again.

Adhesive systems

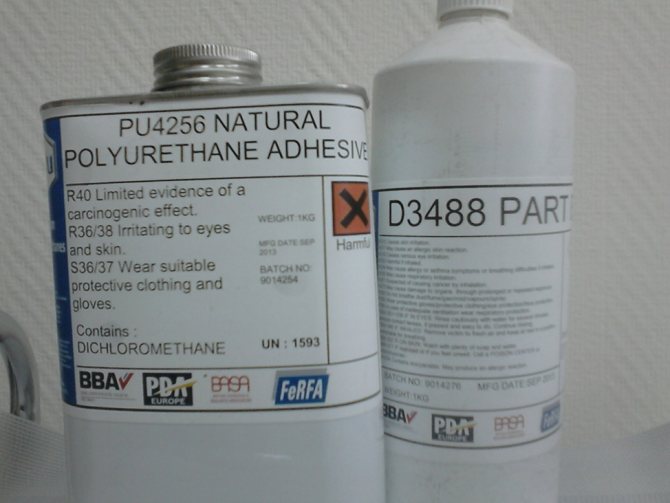

For lamination on PVC surfaces, 2 adhesive structures are usually used.

- Adhesive "Augsklei 60" brand based on polyurethane. Used together with hardener “Augsklei Hardener 60” by mixing in a ratio of 1:25. Glue - hot melt is an adhesive system and in its composition has a dry residue of 100%.

As a result of cooling, the glue quickly sets and forms a strong polymer network with moisture resistant properties.

The technology of lamination of window sills with the use of polyurethane glue contains certain terms:

- exposure until the material melts - 45 hours;

- the time required for ripening in winter conditions –70 hours;

- readiness before the bending of the window sill profile –13 days;

- the time required for the final hardening of the product is 60 days.

Fig. 3. Adhesive system for lamination

The product is distinguished by excellent adhesion, neutrality to ultraviolet rays, and besides, it tolerates plus and minus temperatures well.

Due to its performance, it is possible to glue both the inner surface of the window sill and the outer plane. Solvent-free adhesives have become increasingly popular in recent years and are rapidly gaining access to the market.

2. Polyester based adhesive. This bustilate has been a leader in this technology for about 25 years. The gluing of the film on the surface of PVC is successfully carried out with liquefied glue based on polyester.

2-7% of the hardener and binders are added to it. This mixture is vigorously mixed, while preventing the ingress of foreign particles. Then adhere to the time specified by the manufacturer in the recipe.

The container with the glue must be kept closed, and if the bustilate remains, it must be destroyed in accordance with the rules for the ecology of the environment. Short-term storage up to a day in a refrigerator at a temperature of 4 - 7˚С is allowed.

Fig. 4. Adhesive lamination system for window sills

Advantages and disadvantages of adhesive systems

Each composition has pros and cons, therefore, their properties must be considered separately.

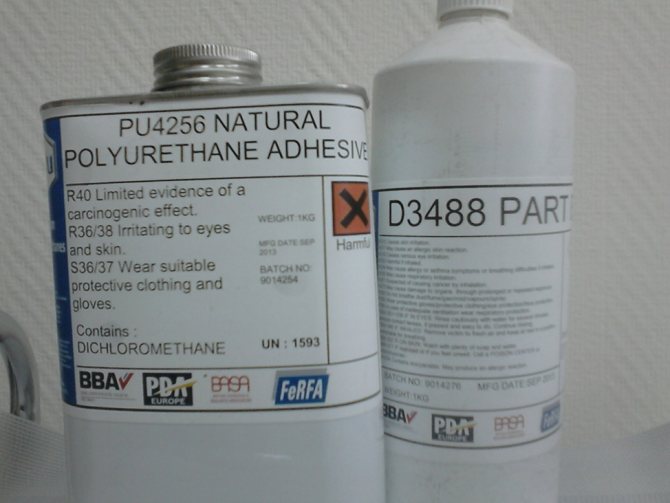

Two-component polyurethane based adhesive

This bustilate has certain benefits:

- Versatility. With such an adhesive composition, up to 90% of the components of a solid material can be connected;

- Strength. Jointed parts can be machined as one piece;

- No joining seam after gluing;

- Budget cost. The price of the glue is quite reasonable.

The disadvantages include its one-time use. After mixing the components, the glue retains its qualities for a short time from one to six hours. And also when working with this glue, you need to follow safety measures, wear gloves and use a respirator.

Fig. 5. Polyurethane adhesive

Polyester based adhesive

Resin of this content is formed during the distillation of alcoholic liquids for special purposes. The glue is sourced from polyester. For faster hardening, different brands of solvents are used.

Depending on the area of application of the material, it has a different structure and quality. The main advantage of this glue is its ability to transmit ultraviolet rays (up to 90%).

Connections of this kind form high-strength materials and are used in the production of window sills, shower cubicles, and various partitions.

For the hardening of polyester resin, special temperature conditions are not required, the cost of this adhesive is less than its counterparts, for example, epoxy resin.

Fig. 6. Polyester glue

What is lamination?

Wooden windows made by highly qualified specialists look respectable. It is immediately evident that the owner of the house is a solid person. And if it didn't work out wooden, but you really want it to be solid? This is where a process like lamination comes in handy. In short:

- a layer of glue heated to a high temperature is applied to the window profile, and on top of it is a multilayer acrylic film.Then, on special equipment with special rollers that repeat the profile of the window, the film is pressed against the surface to be coated. This requires a lot of effort. When the glue cools down, the film cannot be separated from the profile. It lasts long enough, up to 20 years;

- the film reproduces both the shades and the structure of the wood;

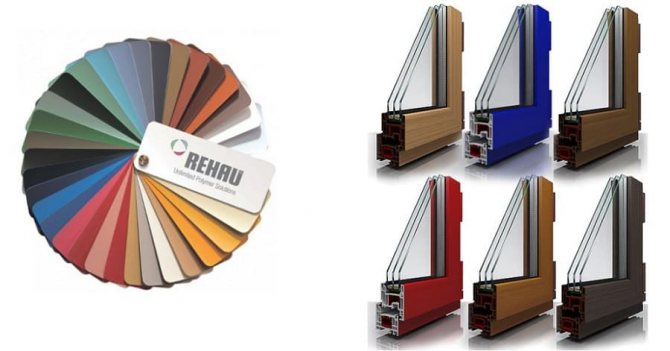

- in addition, films are available in a wide variety of other colors. This is especially true for a nursery, because the window there can be made blue, red, green or other bright cheerful color.

Equipment for the procedure

If you are interested in DIY lamination of plastic windows, acrylic film of the selected color in the right amount is not the only thing worth purchasing. The procedure requires the use of special equipment. To fasten the film and profile, you will need a tool with rollers that repeat the shape of the surface. Using it, you will need to forcefully press the acrylic to the frame with glue.

In general, do-it-yourself lamination of plastic windows requires care and a serious approach. It is better to start it with experience, or at least after reading the detailed visual master classes on gluing the film and profile. And keep in mind that laminating an already installed window is an impossible mission. If you do not order products with an already finished surface, then you can perform the procedure only until you have assembled the products.

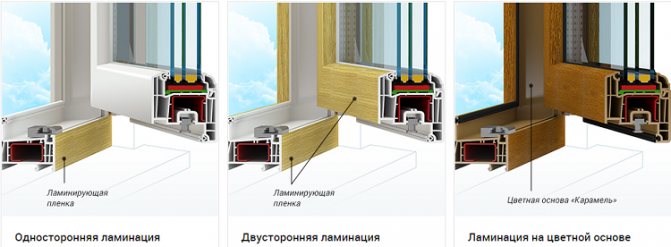

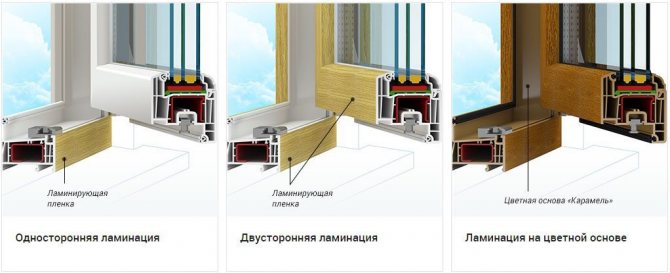

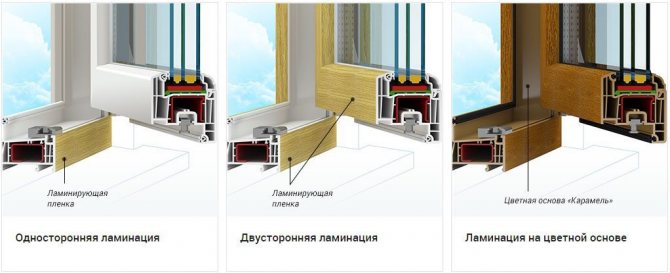

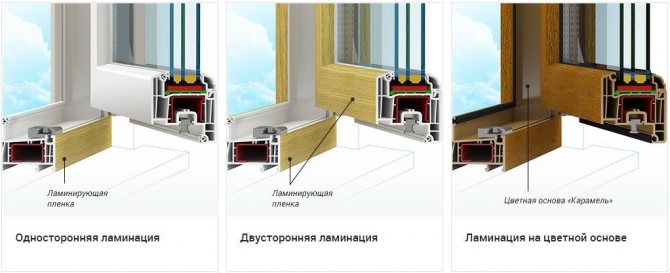

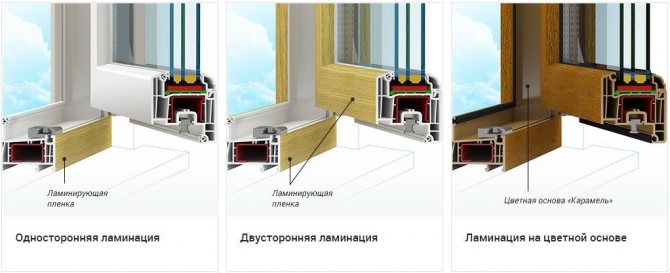

Types of lamination

Windows are laminated in several ways:

- just outside. Inside the window is white or in a different color, but from the street, for example, a tree. Most often, such windows are installed in country houses and cottages;

- lamination on one side, but inside. In order not to violate the general style solution of the facade of an apartment building, the window remains in its original form from the outside, and from the inside any color you wish;

- lamination on both sides. Such windows in offices, but not only - they are often ordered by the owners of cottages, private houses.

The film for laminating windows has a number of advantages:

it is almost impossible to separate it from the surface on which it is applied, as well as scratch or otherwise damage it mechanically;

- having high resistance to temperature influences, it also protects the window profile from them;

- has a high moisture resistance;

- not affected by ultraviolet rays;

- has a wide range of colors, so you can choose any colors for lamination of windows;

- gives windows an exclusive, aesthetic look.

Related article: How to screw a comb to a plastic window

Film composition

The window lamination film has the following structure:

- it contains several layers. They are so thin that their total thickness is only 0.2 mm;

- its tone depends on the color of the base, i.e. acrylic substance. In addition to decorative purpose, this base protects the window profile from overheating;

- the top layer of the film is transparent. It contains synthetic crystalline polymers polymer polymethyl acrylate and polyvinylidene fluoride. It is this layer that creates gloss and withstands adverse weather conditions;

- the image of wood on the film looks very natural down to the smallest veins. It is difficult to distinguish from the real one not only visually, but also by touch.

Renolit film, which is produced in Germany, is distinguished by its high reliability:

- has embossed layers, where the lower semi-solid consists of a 2-component polyurethane adhesive. Includes a layer with permanent pigments;

- it is applied to the PVC profile at a temperature not lower than 125 degrees C, which ensures the fusion of the film with the window surface at the molecular level;

- imitates the natural structure of wood. It comes in green, red, blue and other colors;

- a few years ago, the company began to produce self-adhesive films, with the help of which damaged laminated surfaces are repaired.

- contact with organic solvents is contraindicated.

How is laminated chipboard made?

Laminated particle boards are common products that have been faced with decorative coatings. It can be plain and smooth, multi-colored, or imitate the texture of wood. Such an improved material is produced in those factories where conventional chipboard is made. This is possible in enterprises where the lamination line was launched.

For coating conventional chipboards, 3 technologies are used: lamination, laminating and smooth lamination. To understand the difference between the methods, they must be considered in detail.

Lamination

In this operation, first, 2 layers of special paper are glued onto the base. The first of them is made as thick as possible in order to be able to push the drawing in the future. The thickness of this layer can be either 0.5 or 1 mm. The second, decorative, is much thinner: its thickness is only tenths or hundredths of a millimeter.

Another layer is laid on them. It consists of transparent paper and resins, which, when heated, become the most durable film that protects the decorative surface of the board from damage. All operations are carried out sequentially:

- First, a thick base layer is laid on the chipboard, then it is pressed down with a hot stamp having some kind of pattern. Its surface temperature is 150-220 °. Thanks to her, chipboard and paper become one.

- Then, in the same way, a decorative layer with a certain pattern is glued (pressed, heated), followed by a protective layer. The result is durable protection, which becomes an integral part of the board.

This is the first option. At some enterprises, the lamination technology is different. First, all the layers of the coating are connected together, then the resulting film is dried, then glued to the board with a hot press. Such a coating is a tape. To apply the pattern, a cylinder is used, on which the matrix is installed.

Lamination

The steps in this process vary from manufacturer to manufacturer. Some factories have their own workshops (lines) for laminating. Others, for reasons of economy, prefer not to spend money on the purchase of additional, expensive equipment for the manufacture of coatings. They buy materials made by others. In general, lamination is the pressing of a finished (roll) film to a chipboard using glue.

This operation differs from lamination in the absence of high temperature. All layers of the future coating are laid in order, and then connected, the pattern is printed using a warm (hot, cold) press. The resin of the layers is blended to form a tough film tape.

The finished product is sent to the dryer, after drying, the film is wound into rolls and transported to the laminating area. Here the coating is cut to the size of the slabs. Special glue is applied to the chipboard sheets, a film is laid on top, heated with a press until both elements become one.

This technology makes it possible to avoid wasting time, since the coating does not have to be heated in layers. Thus, the plant is able to produce more products. But the minus is also significant: such a cladding can hold on worse than what is made using lamination technology.

The main difference between lamination and lamination is softer, sparing production conditions: at the first, lower temperatures and pressures are used. The difference in temperature conditions and technologies, in particular, is the reason for the higher cost of laminated products.

Smooth lamination

This method is similar to lamination, however, it is a real lamination, since there is only one difference from it: due to the lack of relief in the products, the stamp is not used. To create a smooth lamination, "only" 2 layers are laid on the chipboard.The first is traditional (thick) paper, the second is made of protective film-paper. As in the lamination process, both layers are separately (sequentially) pressed and heated at a high temperature.

Which is better: laminating or laminating?

To understand the difference between them, you need to understand what are the features of both technologies. The use of finished film is not the only difference between laminating. A short description of the methods and a few numbers are enough.

- Lamination is a physical and chemical process of lining with paper-resin films. Temperature - 150-220 °, pressure - 25-28 MPa.

- Lamination is the physical process of lining with finished paper-resin films using an adhesive. Temperature - 20-150 °, pressure - 5-7 MPa.

Thus, during lamination, the coating is created precisely during heating and pressing, and during lamination, the completely finished decorative material is only glued.

The quality of laminated products depends only on the manufacturer. It is believed that, due to the budgetary production and, naturally, the lower price, laminated chipboards lose in quality. This is not necessarily the case. The material is also able to withstand moisture with dignity, it has a good degree of wear resistance.

In this case, we are talking about the characteristics of the decorative film itself, as well as the adhesive composition used in the production. It is believed that laminated boards made of high-quality materials are practically not inferior to the classics - laminated products.

Lamination of installed windows

Any specialist will say that it is impossible to laminate installed windows. Unless someone wants to dismantle the window, subject it to the lamination procedure, and then reinstall it. This is hardly possible, because it will be cheaper to order a ready-made laminated plastic window. But still there is a way out even with such a situation.

Self-adhesive film oracal

The German company ORACAL produces a self-adhesive film under the same name. It is mainly used to decorate shop windows, decorate stands at exhibitions, cars. Some craftsmen use this film to laminate PVC windows with their own hands. This can be called lamination only conditionally, but as an option, in the absence of another possibility, it can be applied. So, you need a tool:

- squeegee or suitable tool at hand;

- spray. You can replace it with an empty detergent bottle;

- sharp office knife;

- metal ruler;

- hairdryer.

- oracal film with textured surface of the desired color;

- liquid soap.

You can get to work:

- let's prepare the surface. We will remove dirt using special detergents. Degrease with alcohol. We make sure that there are no villi left anywhere;

- preparing a soapy solution. Dissolve liquid soap in water in a ratio of 1:10. If there is an incomplete bottle of "Mister Muscle", then just add water to it - you will not need to pour it into the spray bottle;

- mark up the material;

- attaching a metal ruler to the marking, cut off the film with a sharp knife, leaving a margin of 20-30 mm;

- moisten the profile abundantly with the prepared soapy solution;

- it is difficult to work on your own, you definitely need an assistant in order to simultaneously peel off the backing and wet the adhesive base of the film;

- in order to avoid adhesion of the material to each other, one person holds the film without a backing, and with the other left hand pulls out the lining, and with his right hand wets the base that will be glued;

- press the film down to the surface. Avoid creases and ensure that the overlap is evenly distributed on both sides. Now you can move it as you like, and if you need to correct it, then detach it;

- now one holds the material, and the second drives the liquid from the center to the edges with a squeegee;

- bend the self-adhesive on the sides, and carefully cut at the corners and also bend it;

- folds do not stick well, so take a hair dryer and warm them up;

- one side of the profile is framed, we do the same with the other.

Note: this technology can be used to laminate wood windows. Just do not forget to putty them first, walk over the surface with emery and prime.

How to laminate a pvc window with your own hands

Laminated windows allow you to give your home an individual, unique look. This way of decorating is convenient and practical. There are many companies offering their services in this direction. Is it possible to laminate windows with your own hands? The article is devoted to this topic.

Wooden windows made by highly qualified specialists look respectable. It is immediately evident that the owner of the house is a solid person. And if it didn't work out wooden, but you really want it to be solid? This is where a process like lamination comes in handy. In short:

- a layer of glue heated to a high temperature is applied to the window profile, and on top of it is a multilayer acrylic film. Then, on special equipment with special rollers that repeat the profile of the window, the film is pressed against the surface to be coated. This requires a lot of effort. When the glue cools down, the film cannot be separated from the profile. It lasts long enough, up to 20 years;

- the film reproduces both the shades and the structure of the wood;

- in addition, films are available in a wide variety of other colors. This is especially true for a nursery, because the window there can be made blue, red, green or other bright cheerful color.

Windows are laminated in several ways:

- just outside. Inside the window is white or in a different color, but from the street, for example, a tree. Most often, such windows are installed in country houses and cottages;

- lamination on one side, but inside. In order not to violate the general style solution of the facade of an apartment building, the window remains in its original form from the outside, and from the inside any color you wish;

- lamination on both sides. Such windows in offices, but not only - they are often ordered by the owners of cottages, private houses.

The film for laminating windows has a number of advantages:

it is almost impossible to separate it from the surface on which it is applied, as well as scratch or otherwise damage it mechanically;

- having high resistance to temperature influences, it also protects the window profile from them;

- has a high moisture resistance;

- not affected by ultraviolet rays;

- has a wide range of colors, so you can choose any colors for lamination of windows;

- gives windows an exclusive, aesthetic look.

The window lamination film has the following structure:

- it contains several layers. They are so thin that their total thickness is only 0.2 mm;

- its tone depends on the color of the base, i.e. acrylic substance. In addition to decorative purpose, this base protects the window profile from overheating;

- the top layer of the film is transparent. It contains synthetic crystalline polymers polymer polymethyl acrylate and polyvinylidene fluoride. It is this layer that creates gloss and withstands adverse weather conditions;

- the image of wood on the film looks very natural down to the smallest veins. It is difficult to distinguish from the real one not only visually, but also by touch.

Renolit film, which is produced in Germany, is distinguished by its high reliability:

- has embossed layers, where the lower semi-solid consists of a 2-component polyurethane adhesive. Includes a layer with permanent pigments;

- it is applied to the PVC profile at a temperature not lower than 125 degrees C, which ensures the fusion of the film with the window surface at the molecular level;

- imitates the natural structure of wood. It comes in green, red, blue and other colors;

- a few years ago, the company began to produce self-adhesive films, with the help of which damaged laminated surfaces are repaired.

- contact with organic solvents is contraindicated.

Any specialist will say that it is impossible to laminate installed windows. Unless someone wants to dismantle the window, subject it to the lamination procedure, and then reinstall it. This is hardly possible, because it will be cheaper to order a ready-made laminated plastic window. But still there is a way out even with such a situation.

The German company ORACAL produces a self-adhesive film under the same name. It is mainly used to decorate shop windows, decorate stands at exhibitions, cars. Some craftsmen use this film to laminate PVC windows with their own hands. This can be called lamination only conditionally, but as an option, in the absence of another possibility, it can be applied. So, you need a tool:

- squeegee or suitable tool at hand;

- spray. You can replace it with an empty detergent bottle;

- sharp office knife;

- metal ruler;

- hairdryer.

- oracal film with textured surface of the desired color;

- liquid soap.

You can get to work:

- let's prepare the surface. We will remove dirt using special detergents. Degrease with alcohol. We make sure that there are no villi left anywhere;

- preparing a soapy solution. Dissolve liquid soap in water in a ratio of 1:10. If there is an incomplete bottle of "Mister Muscle", then just add water to it - you will not need to pour it into the spray bottle;

- mark up the material;

- attaching a metal ruler to the marking, cut off the film with a sharp knife, leaving a margin of 20-30 mm;

- moisten the profile abundantly with the prepared soapy solution;

- it is difficult to work on your own, you definitely need an assistant in order to simultaneously peel off the backing and wet the adhesive base of the film;

- in order to avoid adhesion of the material to each other, one person holds the film without a backing, and with the other left hand pulls out the lining, and with his right hand wets the base that will be glued;

- press the film down to the surface. Avoid creases and ensure that the overlap is evenly distributed on both sides. Now you can move it as you like, and if you need to correct it, then detach it;

- now one holds the material, and the second drives the liquid from the center to the edges with a squeegee;

- bend the self-adhesive on the sides, and carefully cut at the corners and also bend it;

- folds do not stick well, so take a hair dryer and warm them up;

- one side of the profile is framed, we do the same with the other.

Note: this technology can be used to laminate wood windows. Just do not forget to putty them first, walk over the surface with emery and prime.

When they talk about laminating windows with their own hands, they mean not only profiles, but also glass improvement:

- by gluing a sun-protective film on the glass, they protect the room from ultraviolet radiation. If you take a mirror film, then through the window from the street you can not see anything in the room, but from the room you can see everything perfectly;

- by laminating the glass with an energy-saving film, we will prevent heat leakage in winter, and in summer, hot air from the street will not enter the room;

- by gluing a vandal-proof film, we will make the glass resistant to impacts, which means we will protect ourselves from thieves.

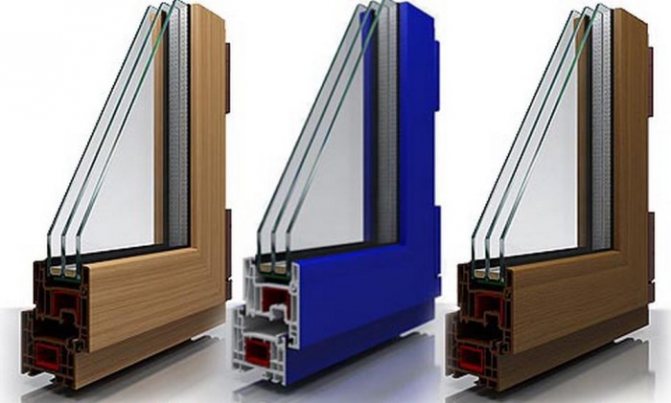

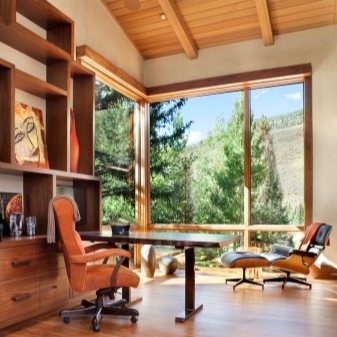

Plastic windows have won their leading position in the market deservedly. However, most plastic systems are standard white and may not match the interior. The situation can be corrected by making plastic windows under a tree. You can, of course, order and natural wooden double-glazed windows, but this will cost much more. So how do you make your window profiles look like a tree?

Plastic windows, laminated under a tree, do not differ in their properties from the standard profile.They are also airtight and retain heat well.

The properties of a laminated wood-like window are the same as those of a conventional

The only difference is the appearance: styling like a tree by applying a special film to the surface. What does it give at the output?

- Laminated windows simplify the design of the room, as you can choose the color and texture for the overall style of the rooms.

- The natural look of window frames is very difficult to distinguish from more expensive natural counterparts. Moreover, all properties are preserved without any changes.

- Laminating film will provide additional protection for window profiles. It perfectly resists many influences (sunlight, temperature, humidity, and others).

- Long service life: the film will not crack and will not lose its appearance even after many years. Moreover, unlike the white profile, which can turn yellow, such a coating retains its color.

- The material used for lamination of window profiles does not emit toxic substances that can harm the health of others.

The laminated profile is available in a wide range of wood-like shades

By placing an order for modern plastic windows with wood-like lamination, you save money, while getting a quality product with imitation of natural material.

There are several types of window lamination, the classification of which depends on the degree of profile coverage, and this also affects the cost.

One-sided lamination. Most often used to style a window. The inner side of the glass unit is made out under the wooden profile to create the overall design of the room. The outside street side remains white. This type of lamination makes sense to use in multi-storey buildings, when the design of the facade at a height is not so important.

Street one-sided lamination. It is also a one-sided type of design. When plastic windows under a tree are made from the side of the street. This type of lamination can be used in a private house, which will simplify the design of the facade of the house.

One-sided lamination is used in multi-storey buildings, two-sided - in private

Double lamination. This is a more expensive type of decoration, as it requires the application of a wooden texture on both sides. Also, you can order lamination that differs from different sides (for example, on the street under an oak, and in the house - under a mahogany).

Colored profile. This type of window frame design has no texture structure. But at the same time, from a distance, such windows will look like wooden ones.

An order for windows styled like a tree will cost more than ordinary white windows, as the production process becomes more complicated. The finished frame looks very natural, while retaining all the properties of a plastic window.

Laminated PVC windows are more expensive than conventional ones

When ordering lamination with a wooden texture, it is important to achieve the integrity of the entire structure: all fittings and handles must also be painted in the same style.

There are many options for the film that can be used to decorate wood-like surfaces. But, unfortunately, it will not be possible to implement such technology independently in everyday conditions. Perhaps something will come out, but how high-quality this type of lamination will be is a rather controversial issue. How is the technological process of giving a wooden texture to a plastic window frame carried out?

To increase adhesion, the surface of the profile is first primed

Initially, the entire surface to be coated is treated with a special primer mixture, which will ensure reliable adhesion of the plastic with the laminating film.

The next step is the direct coating of the profile surface using industrial equipment. In this case, two types of adhesives are used: polyester and polyurethane.

After that, the frames are rolled on special shafts, which smooth and level the surfaces.

The consequence of this technology is a high-quality product made of firmly glued film, which will ensure a long service life.

It is not possible to laminate the window profile on your own.

But what if the windows are already installed and you want to change the style? To do this, you can use the technology of painting profiles, which is quite accessible to everyone.

First, paint is selected for plastic surfaces. Four types of color scheme are best suited for these purposes:

- Paints for plastic surfaces.

- Acrylic varnishes.

- Automotive enamels.

- Nitro paints.

The first three options are best suited, such dyes are designed for various effects and do not require constant updating.

It should be borne in mind that most modern paints on sale come in one color - white. The desired shade is obtained by adding a special dye... For the required color, the paint is diluted by mixing with the color scheme. How it will look can be checked empirically by making a smear on any surface.

For uniform application, use a spray gun or spray gun, the painting material in this case lays down evenly without any special smudges and changes in shade.

To ensure uniform color, you must use a spray bottle

Painting begins with preparatory work. It is best to remove the window sashes from the frames; this is done by knocking out the pin from the upper hinge and removing the vents from the structure.

The surfaces must be thoroughly cleaned of dirt, and the protective film must also be removed (if it remains on the frame). The entire area must be degreased using a solvent.

In order not to dismantle the double-glazed windows, the glass must be covered with a protective film, which is fixed with masking tape.

After that, they start painting. If the windows are painted by hand with brushes, you need to do several approaches. And it is imperative to even out the color, avoiding smudges on the surface.

Imitation of a PVC window under a tree using paint will be much cheaper than installing laminated structures

To quickly remove unwanted stains, you need to have a solvent and a rag on hand.

Be sure to observe temperature conditions when painting windows. In most cases, they are indicated on the color package. Modern paints, as a rule, are based on water and their use at low temperatures will lead to rapid deterioration of the surface.

Such windows will dry out for several hours, after which all dismantled sashes are returned to their place.

Painting windows will make plastic window systems stylish and unusual, but it will not be possible to achieve full resemblance to a wooden surface. The best way out for imitating wood would be to order laminated surfaces.

Lamination of window glass

When they talk about laminating windows with their own hands, they mean not only profiles, but also glass improvement:

- by gluing a sun-protective film on the glass, they protect the room from ultraviolet radiation. If you take a mirror film, then through the window from the street you can not see anything in the room, but from the room you can see everything perfectly;

- by laminating the glass with an energy-saving film, we will prevent heat leakage in winter, and in summer, hot air from the street will not enter the room;

- by gluing a vandal-proof film, we will make the glass resistant to impacts, which means we will protect ourselves from thieves.

Color solutions in lamination

To ennoble the window, customers often choose options with imitation of wood textures. This approach will look great in a room where a lot of wood is used in the interior. And in general, the timber profile fits well into any room.In the event that self-lamination of windows is done from the outside, then such a frame will look especially good in a wooden house and a cottage. But don't be afraid to experiment with other options. Do-it-yourself lamination of plastic windows will refresh the brick structure.

- Acrylic film buyers are often offered imitation oak among wood shades - it can be light, dark, rustic, golden, natural.

- Mountain pine, black cherry, brown chestnut are also reproduced from woody textures.

- There may be more exotic options, such as makore or shogun.

Lamination is an inexpensive way to decorate windows

Lamination technology has solved many problems and made beautiful windows more accessible to a wide range of buyers. Lamination of windows with PVC films is allowed in the manufacture of all popular models, including structures with a radius shape. Thanks to the huge number of decorative films that are used as a topcoat, the design capabilities of interior decorators have significantly expanded. At the same time, laminated windows are in no way inferior to similar models made of white or mass-painted profiles.

Repair needs to be done in order to live, not live in order to make repairs

Forget about excuses about the "curvature" of the hands and total ignorance in this area. Our portal exists just to close the blank spots in your knowledge and make you a real home master. With us you can not only renovate a city apartment, but also build a whole house with your own hands - and here, you must agree, there is something to be proud of.

The main thing that is necessary for the successful promotion and completion of construction and repair is motivation, which is important to successfully maintain at all stages of action. In order to bring your ideas to life, you need to determine your desires, needs and capabilities. This will be the first step on a difficult but exciting path. We are ready to provide you with the most interesting videos, articles, practical advice on interior design, the specifics of certain building materials and tools used.

We will help you with useful advice in finding fresh ideas and original solutions. All texts posted on our website were written with the support of the most experienced builders and repairmen, who have more than one successful project behind them. To keep up with the times, we offer you information about the latest developments in the construction industry, which make it possible to significantly facilitate the process during apartment renovation, house construction, the choice of materials and tools.

If you decide to build a house or renovate your home with your own hands, then you've come to the right place. We hope that this visit will help to replenish knowledge in this area, and the time spent visiting our site will not be useless.

Pros and cons of window lamination

The main advantage that window laminating provides is the ability to create a reliable imitation of natural wood products. Since the film can be applied to profiles both from the street or rooms, and simultaneously to both surfaces, customers optimize their costs and easily choose the most suitable design option for sashes and frames.

An important advantage is the ability to adapt windows to any facade finish and individual style of interior interiors. The laminated profile looks incredibly impressive together with the colored sloping systems, which are discussed in a separate review on OknaTrade.

The disadvantages of this technology sometimes include the rise in the cost of the profile after applying a decorative film. However, this is a conditional drawback, since in such a situation the cost of lamination is the lowest possible price for solving serious problems. The real disadvantages include:

- the appearance of white areas when the valves are opened on their inner edges, if the profile is not painted in the mass;

- increase in the production time of products;

- the existence of a minimal probability of a violation of the technology of applying the film, which will manifest itself only a few months / years after the installation of windows.

When cutting a laminated profile, white stripes appear at the corner joints of frames and sashes, to mask which special markers are used. This phenomenon can be avoided by using the profile dyed in the mass as close as possible in color. However, this method leads to a significant increase in the cost of products. In addition, the limited number of colors of these profiles forces you to still use markers when combined with many films.

Double-sided and single-sided lamination

The choice of the scheme for applying acrylic film of the desired shade depends on the budget and design tasks.

- One-sided lamination allows for a uniform style of window decoration throughout the entire facade. It can only be used to change the view from the inside. In any case, the cost of such a profile will be cheaper than with the decor of all its parts.

- Double-sided lamination provides higher rates of aesthetic appeal, but leads to an increase in the cost of the profile by 50% compared to the price of a conventional white PVC window. With this solution, you can provide a different style of exterior and interior design.

White stripes may form at the joints of sashes and corner frames during installation. To ensure high attractiveness of the exterior and interior, special markers are used that correspond to the color of the profile color in the mass.

What is lamination technology

Lamination of windows in its essence is nothing more than the application of a decorative PVC film to the surface of the base profile. In order for this film to reliably hold the entire service life of plastic windows, the surface of the profile must be pre-cleaned and degreased, and then thoroughly dried. Only after that, a special composition is applied to the products - a primer, which is a mixture of a solvent and laminating glue. It is important to observe the proportion when mixing - it should be 1:11.

Related article: Sliding plastic windows for the veranda

The glue itself is applied to the inside of the decorative film. During this process, it is necessary to maintain the same thickness - it should not exceed 80 microns, the optimal range is 50-75 microns. Moreover, the maximum bond strength is ensured with a minimum thickness of the adhesive layer. The adhesive film is literally pressed into the profile surface by means of special pressure rollers in the machine under pressure. The high temperature at which the lamination procedure is performed improves the bond strength - for this, the profile and the film are preheated. The process of applying a decorative coating is completed with the procedure of cutting the film and cleaning its edges.

Types of films for window lamination

When laminating windows, the colors and textures of the films can be very different. Today, manufacturers are most actively using embossed wood-like coatings. Also, for finishing the profile, sometimes unicolor films or with fancy decors are chosen. In addition, there are a lot of price offers on the market at the moment. There are cheap and expensive decor, and such products are fundamentally different. Some manufacturers are saving on special stabilizing additives that allow the film to:

- maintain elasticity at low temperatures;

- reflect UF rays;

- do not melt in the sun;

- preserve the structure of the material and rich color.

These stabilizers are quite expensive, and an ordinary buyer will be able to discover their absence only during operation, when problems arise with the decorative layer.As a result, unscrupulous manufacturers are always tempted to save on quality when purchasing materials. It is due to this that they manage to attract customers at a lower cost compared to the price at which most responsible companies perform high-quality lamination of plastic windows. Find out how to avoid cooperation with such scammers in a special article on OknaTrade.

Tips from the masters: what we offer

Here you will find news in the field of construction, production of materials, tools, equipment, instructions from professional craftsmen. In their articles, they will share the subtleties and nuances in the questions that interest you.

Our information will be useful to those who:

- loves and knows how to work with the instrument;

- dreams of building a house with his own hands;

- plans to renovate housing;

- begins his career in construction.

The upcoming renovation of the apartment scares some, others are happy to take on it, and there are jokes among the people that it never ends, but only stops. But is it really so? No wonder they say, "fear has big eyes."

Preferring to leave everything at the mercy of professional builders, we unconditionally entrust them with our future housing. However, you need to understand that no matter how responsible and qualified the master is, he will not live in your house. The person becomes surprisingly diligent in doing things for themselves. That is why it is better to do such important work on your own. But not always a person, starting work on repair or construction, finds the necessary information or uses outdated methods that do not bring the desired results. Our website will help fill these gaps.

Recommendations for the care of laminated windows

Since the basis of decorative films is the same polyvinyl chloride that is used in the manufacture of white profiles, laminated windows are looked after according to the same rules as for standard models:

- cleaning is done with soft flannel napkins dipped in warm soapy water;

- in no case use abrasive powders and aggressive chemical compounds (solvents);

- they use a polish for plastic surfaces with an antistatic effect - it will not only clean the surface and prevent dust accumulation, but also give the profile an effective shine.

When using laminated models, it is recommended to always have a marker to match the film at hand. It is necessary to periodically "refresh" the camouflage at the joints. If all the technologies are followed when applying a high-quality film, the service life of such windows does not differ from the durability of the basic white models and, depending on the type of profile, is 30-50 years.

PVC film peels off from MDF kitchen facades! What to do?

It's no secret that the kitchen is the center of any home. And our task is not only to correctly plan it - in order to spend a minimum of effort and time when preparing food - but also to exploit it so that its presentation will please us and the household for many years. Most often, the consumer opts for chipboard furniture with MDF facades covered with PVC film. This choice is explained, first of all, by the relatively inexpensive price, as well as by the wide choice of configurations and colors. That is, there is an opportunity to satisfy almost any, even very demanding, taste.

Care rules

So, here your beloved and long-awaited kitchen was brought and installed, or you, after poring over the project for a long time, assembled it yourself. What to do or what not to do, so that in a couple of months you will not experience disappointment with the purchase. After all, the production technology of such facades, unfortunately, does not reflect in the best way on their wear resistance: the film can begin to peel off over time, especially around the perimeter.We will voice a few simple operating rules relating specifically to MDF facades covered with PVC film.

- The kitchen can only be washed with "mild" detergents. Never use scouring powders containing abrasive substances. Various surface sprays (maybe for glass) and a soft sponge, napkin are good for this.

- Avoid extreme temperature changes. Try to maintain +10 to +35 degrees. Lower or higher temperatures can cause the film to peel off. Sooner or later, an open oven, a nearby heated stove, too intense ventilation (especially in winter), and heaters will lead to the same result.

Features of operation

Think, after all, PVC film sticks at a temperature of 120 - 180 degrees, and if your oven gives out at least 60 -100 degrees, this already poses a threat to the closets nearby.

Install the thermal insulation strip. It protects the ends of the cabinet from heating by the stove and avoids delamination of the edge. It is mounted to the ends of the cabinet. It is very unpretentious to care for: it is recommended to wipe it with a damp cloth to remove dirt, however, it is not recommended to use any cleaning agents.

- Avoid high humidity. If you are still in doubt whether to install the hood or not, then I think now your choice is obvious. Steam from pots, grease from pans will also have a negative effect on your furniture.

- Water is the enemy of any furniture. Make sure that it does not fall on the facades.

- Close doors and slide drawers carefully, avoiding sudden movements. Do not expose them to mechanical stress (contact with sharp objects, friction, impact).

- The proximity of lighting fixtures can lead to excessive heating of the facade and, as a result, deformation of the film, as well as to a change in the color of the cladding. The luminaire and the facade should not be closer to each other than 15 cm.

Lamination and painting of plastic windows under a tree

Korovin Sergey Dmitrievich

Master of Architecture, graduated from the Samara State University of Architecture and Civil Engineering. 11 years of experience in design and construction.

Plastic windows have won their leading position in the market deservedly. However, most plastic systems are standard white and may not match the interior. The situation can be corrected by making plastic windows under a tree. You can, of course, order and natural wooden double-glazed windows, but this will cost much more. So how do you make your window profiles look like wood?

If not for the builders of the pyramids, who would have known the names of the pharaohs ...

Good day, dear visitor! You have entered a site where useful information is waiting for you. advice and recommendations from experienced craftsmen in the field of repair and housing construction sovety-stroy.ru. Experts will share their experience based on their practical knowledge, accumulated baggage of building skills.

We offer you a short excursion into the history of the construction industry. Since ancient times, the Stone Period, man has sought to provide his family with a roof over his head, strong walls to protect himself from bad weather and dangerous animals. Time does not stand still, with the evolutionary changes of society, the development of progress, the construction industry went ahead by leaps and bounds. Much attention has been paid to this area at all times. The latest technologies in the field of production of repair and construction processes, new items of construction equipment, equipment, tooling, tools, building materials were developed. Along with this, a rich experience of people of construction professions was accumulated, who were trained in advanced innovative methods of production.

Nowadays, many buildings perform not only protective functions, but are truly architectural monuments with elements of building art.People live in spacious comfortable apartments, cottages, use social and cultural facilities, beautiful streets, squares and squares delight the eye.

Not deprived of attention and ordinary consumers who need housing repair or the construction of new buildings. The construction industry now offers an extensive range of building materials, which is expanding every day. In order to unmistakably understand this variety of goods, to make the right choice, you need informative help. Stay tuned and you will get it!

What is a laminated profile

Plastic windows, laminated under a tree, do not differ in their properties from the standard profile. They are also airtight and retain heat well.

The properties of a laminated wood-like window are the same as those of a conventional

The only difference is the appearance: styling like a tree by applying a special film to the surface. What does it give at the output?

- Laminated windows simplify the design of the room, as you can choose the color and texture for the overall style of the rooms.

- The natural look of window frames is very difficult to distinguish from more expensive natural counterparts. Moreover, all properties are preserved without any changes.

- Laminating film will provide additional protection for window profiles. It perfectly resists many influences (sunlight, temperature, humidity, and others).

- Long service life: the film will not crack and will not lose its appearance even after many years. Moreover, unlike the white profile, which can turn yellow, such a coating retains its color.

- The material used for laminating window profiles does not emit toxic substances that can harm the health of others.

Related article: Protecting windows from the sun from outside

The laminated profile is available in a wide range of wood-like shades

By placing an order for modern plastic windows with wood-like lamination, you save money, while getting a quality product with imitation of natural material.

How to choose a color scheme for lamination

When determining the type of film used, it is necessary to take into account the general style of the interior or exterior, as well as the colors of the adjacent surfaces. So, to maintain a classic look, laminated plastic windows with imitation of natural materials in soothing shades (dark wood, light skin, etc.) are suitable. For the Art Nouveau style, decor is often used in brass, blackened gold.

Imitation of natural wood

This particular decor option deserves special attention, since environmentally friendly materials are again relevant in modern design. Unfortunately, few can afford solid wood windows due to their high cost. You can solve the problem by choosing brown lamination. At the same time, manufacturers offer a wide palette to simulate various breeds.

Wood-like window frames look especially good on wicker verandas. The same solution is harmoniously combined with false bindings and spros on the windows.

Types of window lamination

There are several types of window lamination, the classification of which depends on the degree of profile coverage, and this also affects the cost.

One-sided lamination. Most often used to style a window. The inner side of the glass unit is made out under the wooden profile to create the overall design of the room. The outside street side remains white. This type of lamination makes sense to use in multi-storey buildings, when the design of the facade at a height is not so important.

Street one-sided lamination. It is also a one-sided type of design. When plastic windows under a tree are made from the street side. This type of lamination can be used in a private house, which will simplify the design of the facade of the house.

One-sided lamination is used in multi-storey buildings, two-sided - in private

Double lamination. This is a more expensive type of decoration, as it requires the application of a wooden texture on both sides. Also, you can order lamination that differs from different sides (for example, on the street under an oak, and in the house - under a mahogany).

Colored profile. This type of window frame design has no texture structure. But at the same time, from a distance, such windows will look like wooden ones.

An order for windows styled like a tree will cost more than ordinary white windows, as the production process becomes more complicated. The finished frame looks very natural, while retaining all the properties of a plastic window.

Laminated PVC windows are more expensive than conventional ones

When ordering lamination with a wooden texture, it is important to achieve the integrity of the entire structure: all fittings and handles must also be painted in the same style.

Combination of color and style

Manufacturers of PVC windows have long achieved that lamination gives them the appearance of natural wood, and not only the appearance is similar, but also the texture of the product itself. Thanks to a wide range of coating shades, you can choose a color that will ideally suit any interior of an apartment or a country house. Currently, it is offered to choose not only imitation of various types of wood, but also the texture of the profile: smooth or rough.

Shades such as mahogany, golden oak, light oak, walnut are very popular. As a rule, the choice of the shade of the window frames is determined either by the color in the mass (for example, all the furniture in the room is made of walnut, respectively, and the window frame is chosen to match this tone), or the emphasis is on the little things, that is, the frame is matched to the color of other decorative elements ( photo frames, pillow cases, vases, etc.).

There is also an option when the window serves as a softening element, without participating in the whole interior design. An example of this is the shade of bleached old oak, which is not particularly striking and does not differ much from ordinary white plastic windows. Nevertheless, it brings a sense of coziness and sophisticated elegance, thanks to its warm rich color. This shade will look great in a classic or country style interior. But for the high-tech style, a colder shade of bleached oak will suit.

Walnut color gives the room nobility and unobtrusiveness. But it is only good in combination with other elements of the same shade. This color will look great in a French or English style interior. Extra bright lighting will accentuate the rich texture of this laminate.

Plastic windows for larch or pine have pleasant unobtrusive shades that will fit well into any interior, as they are perfectly combined with various styles and do not carry a special emotional message by themselves. Beech, on the other hand, gives the premises a joyful, positive look, creates harmony and comfort. A window for this type of wood can be perfectly fit into any interior, except for country and high-tech.

As you know, the dark color is very effective in itself, therefore, if you focus directly on the window frame, you should not overdo it with this shade in the rest of the decor. Light frames, on the contrary, look very advantageous in such a design, when you can enjoy all the beauty of the woody texture. The warm shade of wood on plastic windows enhances the feeling of good mood and, with the appropriate interior, creates an atmosphere of intimacy.

Whatever color of lamination the owner of the house chooses, the main thing is to understand that a plastic window under a tree already brings a large dose of warmth, style and nobility to the appearance of the room.

Lamination technique

There are many options for the film that can be used to decorate wood-like surfaces.But, unfortunately, it will not be possible to implement such technology independently in everyday conditions. Perhaps something will come out, but how high-quality this type of lamination will be is a rather controversial issue. How is the technological process of giving a wooden texture to a plastic window frame carried out?

To increase adhesion, the surface of the profile is first primed

Initially, the entire surface to be coated is treated with a special primer mixture, which will ensure reliable adhesion of the plastic with the laminating film.

The next step is the direct coating of the profile surface using industrial equipment. In this case, two types of adhesives are used: polyester and polyurethane.

After that, the frames are rolled on special shafts, which smooth and level the surfaces.

The consequence of this technology is a high-quality product made of firmly glued film, which will ensure a long service life.

It is impossible to self-laminate the window profile

But what if the windows are already installed and you want to change the style? To do this, you can use the technology of painting profiles, which is quite accessible to everyone.