Foam consumption factors

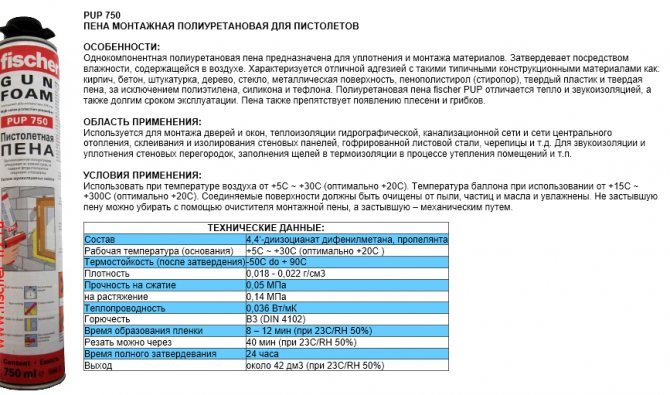

It is possible to calculate the consumption of polyurethane foam per meter with maximum accuracy, but only knowing enough information about the material and the upcoming work. The information on the label will be correct under certain conditions, including optimum temperature and humidity. But often the specified volume differs from the theoretical one, because you have to work in a variety of conditions.

Each polyurethane foam has its own expansion coefficient. Domestic foam usually has a small magnification factor and is suitable for small seams. In this case, the consumption will be less. Expandable ones are suitable for large seams, and a little more of these mixtures are needed.

Factors directly affecting how much foam will be consumed per meter:

- Components included in the polyurethane foam.

- Temperature regime, humidity level.

- Expansion factor of an individual train.

- Mass distribution rate.

- Application in the process of applying a gun or factory tube.

- Seam depth.

- Professionalism of the master.

The standard flow rate indicated on the package is a reference, based on certain conditions and strict sequence of work. At the same time, in order for the numbers to match, you need to follow a number of application rules. They relate to the regular shaking of the cylinder, one speed of the mixture output, moistening the joints before work.

The depth and width of the opening are of great importance. If large seams are not additionally sealed, material consumption can increase several times.

90 ° bend seam

A special technique is needed when processing horizontal seams that rest against the vertical corner of the wall. The spatula is applied to the seam at an angle of 70 ° -80 ° so that the special cut (or edge) on the surface of the spatula is not visible to you. In this case, the side of the spatula hidden from you should not touch the surface of the seam.

The movement is performed towards the vertical corner smoothly in the direction where the side of the spatula is looking without a cut. When the vertical angle is reached, we simply continue to move along the perpendicular wall, smoothly leveling the angle of the spatula to the seam to a value of 90 °.

Foam consumption per meter

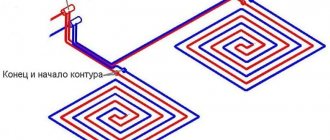

Consider the consumption of material using the example of installing window blocks. If the thickness of the joint is 35-40 cm, and the area is 3 meters, then the amount of foam spent will be 1.25 cylinders per 0.75 liters.

In the case of laying thermal blocks, 10 liters of foam will go per square meter. Specific norms are established at each enterprise. The company can change the standard indicators. There is no exact figure for the consumption in any documentation, you can only calculate approximately, and set your own rate after testing a separate polyurethane foam.

With a cylinder volume of 65 liters, the flow rate will be 70-80%. With a depth of 5 cm, a width of 2 cm per 1 meter, a fifth of the cylinder is required. However, these figures vary significantly depending on the specific scope of work.

Reference! The formula for calculating the approximate output of the material is DxW + OxW, where D is the depth, W is the width, O is the indent.

Measurement accuracy

A common mistake that negates further "scientific" calculations of the consumption of raw materials is negligent or "by eye" measurements of the PPU sprayed object. First, it is necessary to use special measuring instruments - laser rangefinders, tape measures, level meters. The more accurate the measurements, the smaller the final error.Secondly, when measuring insufficiently simple geometric calculations of areas, it is necessary to inspect the object for the presence of voids, cracks, beams and complex building units that are subject to foaming.

I will give a simple example, the hangar is subject to insulation along the entire contour, a rectangular beam of 20x40 cm with a length of 12 m runs under the ceiling. It would seem an insignificant nuance. And now let's calculate that we have a relatively flat ceiling, two additional faces of 40 cm each and 12 m long - this is 9.6 additional square meters or about 24 kg of raw materials with a layer of 5 cm. Not to mention the complication of the surface, which gives an additional overrun. And if there are several of these beams? Or is it not a beam, but a channel with an even larger surface area? All this must be taken into account and strictly considered.

Varieties of polyurethane foam

The consumption of the composition is largely determined by its variety, that is, the components in the composition and technical characteristics. Consider the main types of polyurethane foam that craftsmen and amateurs have to deal with.

All types of polyurethane foam have the following characteristics:

- Output volume - the value indicated on the bottle corresponds to the volume of the already hardened product. At the same time, the numbers indicated on the label will never coincide with the actual yield of the composition, because it is impossible to carry out the work in ideal conditions. Masters note that with an output value of 65 liters, you need to be ready for 35 liters.

- Primary expansion - corresponds to the amount of material that is obtained immediately at the exit from the cylinder.

- Secondary expansion - the value of the amount of the mixture after drying. If you need to fill small gaps up to 1 cm, then it is better to choose compositions with a slight expansion, and then the final yield of the mixture will reach 100%. Expanding foam has a higher consumption.

- Viscosity - the foam must be viscous and never drip over a vertical surface.

- Adhesion - the ability to adhere to different surfaces is of great importance, but this has a negligible effect on material consumption.

To calculate the yield of polyurethane foam, it is important that it meets all the required characteristics. Spoiled, unusable, poor-quality composition is not suitable for work. It makes no sense to calculate its output, primary and secondary expansion. You need to buy original formulations from trusted manufacturers.

What quality criteria should the polyurethane foam meet:

- Heat insulation and sound insulation.

- High resistance to moisture.

- The ability to use as an adhesive for connecting different elements.

- Ability to fill a wide variety of gaps.

- Suitable for various surfaces - smooth and porous.

- Safety for humans and the environment.

- Ease of use of the balloon.

- Resistant to open fire.

- Low electrical conductivity.

Such qualities are possessed by household and professional foam. The first is used at home for various jobs. It is easy to deal with, it is sold in cylinders with an already built-in mixture supply system. After reading the instructions, everyone can start work.

Professional formulations are used in conjunction with a pistol. It allows you to accurately dose the material and deliver it to the most difficult-to-reach areas. This type of foam has a high expansion coefficient. Best suited for large jobs.

There are also summer and winter mixtures, depending on the period of work. The former can be used at temperatures from -18 to +30 degrees. Summer type is used in conditions from +5 to +35 degrees. There are also all-season compounds that can withstand temperatures from -100 to +350 degrees.

Depending on the production technology, there are one-component and two-component foams. The former are aerosol formulations.

Two-component consists of main components and catalysts. In order for the components to mix, the container must be shaken well.The chemical reaction in such formulations occurs later, which means that the service life is longer.

Variations

Selection foam for mounting

depends on the tasks set. For convenient application, saving money and your time, use a specialized design - an assembly gun. It allows you to manually adjust the required strip thickness and apply the volume of the balloon to the end. If a spacious work front is foreseen, then it is more correct to purchase qualified foam for installation work. Its main difference is the non-standard mount for the pistol with which the cylinder is equipped.

Types of foam for installation

For the purpose of carrying out work of a small volume, homemade or semi-professional foam is suitable. Balloons are equipped with a tube, thanks to which they fill inaccessible places.

There are such types:

- Multipurpose. It is possible to use at - 10 ° C without warming up the cylinder in advance. Differs in fast polymerization process and high material yield;

- Winter. It is applied on surfaces cooled down to -18 ° C;

- Summer. The characteristics of the material make it possible to apply it on heated surfaces, up to +35 ° C.

The foam is able to reduce the level of vibration, noise, rattling.

Application features

The following recommendations will help to make the foam yield close to ideal:

- Before work, the container is shaken well to mix the components. If this is not done, not the required foam will come out of the cylinder, but a thick mass and air. After mixing, a homogeneous consistency is obtained, which comes out at the same speed.

- Before applying the polyurethane foam, moisten the surface for better adhesion and hardening. This is a mandatory measure when using one-component mixtures.

- During application, the balloon must be kept upright at all times. Insulation should start from the bottom. The first layer can be up to 3 cm, then the composition can be applied again, but only after complete hardening, after about 8 hours.

- Only after hardening, you can cut off the remnants of the material, touch it with your hands, paint, load, plaster. If you do this earlier, the polyurethane foam will lose its properties.

It is important to learn how to use a pistol, otherwise you can waste a lot more material. You need to take the cylinder, shake it, remove the cap, turn it over and screw it into the thread of the gun. Then you need to conduct a test. If done correctly, the foam will come out evenly. Before inserting a new cylinder, you need to rinse all the parts well so that there are no residues of polyurethane foam. This should be done with a special cleaning liquid.

So that the polyurethane foam does not deteriorate ahead of time, it must be properly stored. You cannot heat the composition to +50 degrees, and also keep the container near the fire, because this can cause an explosion. Before use, you can slightly warm up the composition. The balloon is kept in warm water at a temperature of no more than 20 degrees. Store the formulations in a place protected from sunlight at temperatures from -5 to +25 degrees.

In the video: Instructions for using polyurethane foam.

We calculate the optimal amount of material

It is not an easy task to correctly calculate the amount of building materials that you will need to perform one or another type of construction and repair work. We all know that wallpaper, tiles, glue, and everything else is usually purchased with a certain margin. But what about sealants? It would seem, why calculate the exact consumption of the sealing compound, because you can always go to the hardware store and buy the missing material. But there are times when it is better to calculate in advance at least an approximate amount of sealant. For example, you order a material of a certain color, which will be made to order for you (the so-called tinting of the sealant in bulk). In order not to be mistaken and not to buy too much, it is worth using some calculations and formulas.

Recommendations for economical consumption

Such advice of masters will help to achieve a good result and save material, such as:

- Do not touch the foam during the polymerization process.

- Use a professional pistol.

- Check the integrity of the cylinder and the serviceability of the foam feeding mechanisms.

- Choose materials only from trusted manufacturers.

- Protect the mixture from exposure to sunlight by painting or plastering.

- Follow the instructions on the packaging of each composition.

Non-expanding, medium and highly expanding formulations give significant differences in the filled volume. Some increase by no more than one and a half times, others acquire a volume 6-8 times larger than the original. Products from different companies have a different consumption. From all it can be concluded that the calculations are only approximate and relative. It is better to consult with a master who has dealt with a specific polyurethane foam, and knows for sure how much of it is required for each meter.

Polyurethane foam consumption: recommendations from the masters (2 videos)

Polyurethane foam consumption (17 photos)

Types of silicone sealants

Silicone sealant, the consumption per running meter of which should be calculated by the master, is of two main types. These are neutral and acetate varieties. In the latter case, the sealant is applied to smooth surfaces such as glass. But this kind of silicone is not suitable for metal. The glue contains acid. It has a negative effect on metal. Use acetate silicone only in well-ventilated areas.

A neutral sealant can be used on all porous surfaces. It has a high level of adhesion. These silicones are temperature resistant.

Another type of the presented agent is a silicone sealant, which includes a fungicide. This prevents the development of fungus on the seams. This is necessary when using sealant in the bathroom or when doing outdoor work.

Additional terms

The width and depth of the assembly joint have a huge impact on the consumption of polyurethane foam. Approximate calculations for different indicators can give significant differences in numbers. For example, if the gap in the joint width is 3.5 times, and in the length - 2.5 times, the consumption of the sealant can increase (or decrease) by 8 times. But only if additional materials will not be used to fill the joint.

None of the documentation and instructions for use provide accurate data on the consumption of polyurethane foam. All figures are averaged and adjusted for optimal conditions. But they make it possible to find out at least the approximate number of cylinders required to perform work on sealing joints. An individual approach to calculations helps construction organizations to lay down figures in the estimate that are most close to specific conditions, and home craftsmen - to estimate the possible costs.

Professionals recommend purchasing polyurethane foam with a certain margin, since it is impossible to take into account the parameter of its expansion in certain temperature and humidity conditions.

Weak, medium and highly expanding foam based sealants can exhibit significant fill variations. Some of them have a tendency to increase during polymerization only two to three times, others expand almost six times. A can of one manufacturer may be enough to seal the entire window, and the same volume of packaging for another company's products will not fill even half of the identical joints. As a result, it can be concluded that the calculations of the consumption of polyurethane foam are made only relatively.

How to clean surfaces?

Chemicals will help to clean the contaminated surfaces from the sealant:

- Foam cleaners - are produced in the same line with sealants and are suitable for both cleaning the gun and cleaning surfaces.

- Solvents - "Acetone", White Spirit, "Thinner 646" effectively deal with fresh dirt.

- Dimexide - a pharmaceutical product destroys the structure of polyurethane, removing it from different materials

To soften the dried layer, it is allowed to use vegetable oil, water and vinegar. As soon as the sealant layer becomes pliable, it is scraped off with a spatula or wiped off with a rag.

Important! Test the chemical on an inconspicuous area to be cleaned. If the surface is not damaged or discolored, you can safely use the product.

Wood surfaces that are not coated with paint or varnish can be cleaned with a solvent. From the lacquered door, the sealant is carefully scraped off with a knife and polished with sandpaper. Then the product is re-painted and varnished.

Foam is removed from linoleum, laminate and parquet with a sharp object and the remains are removed with a special cleaner. The product must not contain acetone, otherwise matt marks will remain on the flooring.

Result

- illbruck FM070 290 ₽

- Construction foam Soudal Professional 60, winter 280 ₽

- Polyurethane foam Profil, winter 210 ₽

- Construction foam Soudal DIY 200 ₽

- Self-expanding anchor bolts 10mm × 72mm 7 ₽

- Self-expanding anchor bolts 10mm × 112mm 9 ₽

- Self-expanding anchor bolts 10mm × 132mm 10 ₽

- Self-expanding anchor bolts 10mm × 152mm 11 ₽

- Self-expanding anchor bolts 10mm × 182mm 12 ₽

- Self-expanding anchor bolts 10mm × 202mm 13 ₽

- Assembly wedge, 143 * 43 * 22 mm 6.5 ₽

With the help of polyurethane foam, you can close up cracks and voids, increase the sound and heat insulation of the room, insulate and strengthen the window structure. Foam is widely popular due to its versatility, ease of use and quick drying.

Silicone sealant is used for internal and external work when sealing joints, filling cracks and joining surfaces. It is very elastic, resistant to temperature changes and other influences, does not allow moisture to pass through. The consumption of silicone sealant depends on the thickness, depth and length of the joint; accordingly, calculations are made according to the size of the cavity to be filled.

The consumption of polyurethane foam depends not only on the brand of the product, but also on the temperature conditions, the thickness of the seam, the material of the working surface, and the peculiarities of the work of the master. The average flow rate is always written on the cylinders, in addition, polyurethane foam has the ability to expand during polymerization, therefore it is recommended to test the foam in a small area separately in advance.

Pistol selection

The foam of the professional segment can only be used with a pistol. This is a special nozzle that helps to fill gaps and voids after installing an interior door.

What criteria to rely on when choosing a pistol:

- Material (metal or plastic). Plastic nozzles are cheaper, but metal ones are considered more durable and easier to clean from the remains of the foam.

- Design... Reusable collapsible models are valued higher. Disposable nozzles cannot be effectively cleaned of foam, so they are immediately disposed of after use.

- Nozzle size... It is selected in accordance with the volume of the cavities to be blown out.The smaller the gap, the smaller the “caliber” of the pistol should be.

At the time of purchase, it is necessary to evaluate how comfortable it is to hold the nozzle in your hand, whether it is easy to adjust the supply of sealant.

How do you define a quality product?

You can understand that you have a cylinder with high quality polyurethane foam by the following signs:

- Packing condition... The cylinder must be intact, free of dents and visible damage. Only integral packaging guarantees the preservation of the high chemical and operational properties of the mixture.

- Shelf life... It is not recommended to buy an expiring sealant. There should be at least 2-3 months until the end date - the fresher the foam, the more reliable the installation.

- Uniform composition... To check, it is enough to turn the container upside down and shake it several times. Its contents should flow smoothly, without sharp blows typical for dried sealant.

- Color... Can be determined only after opening the package. A quality product has a light beige tint, and a dark color is a sign of polymerization of the composition.

The average weight of a can, which contains a quality undiluted mixture, should be about 910 g. This corresponds to 750 ml of a foaming agent.

Pricing reform in construction was to be completed

Dear estimators! Can you please tell me the consumption of polyurethane foam when installing plastic window and door blocks for 1m2? "Stroyzakazchik" says: "0.2 cylinders per 1m2"

MAN72, see the relevant material consumption rates in HESN 81-02-10-2001

Specifically, mounting foam is included in the following standards: Table HESN 10-01-047 Installation of PVC blocks in external and internal doorways Table HESN 10-01-035 Installation of PVC window sills Table HESN 10-01-047 Installation of PVC blocks in external and internal doorways

slavalit, Thanks for the answer!

Here in my price TEP 10-01-030-02 A - there is a red line of foam - as you said at the GESN - I don't have such a raccoon there. Can someone tell me how much you need to take this foam ?!

there it shouldn't be .. replace resources at a price with foam-windows, PVC doors ..

38qwer, in my resources TEP10-01-047-1 (with an opening area of up to 3m2) foam consumption per 100m2 of the opening = 123.5 cans with a capacity of 0.75l each.

From the area of the opening depends up to 3m2-926.25ml., More than 3m2-527.25ml., Per 1m2 for outdoor use, the wall is concrete.

Only now I did not understand why, with an opening area of more than 3m2 (TEP10-01-047-2), the consumption is already 70.3 pcs of spray cans That is why so: the larger the opening, the less foam is needed?

SMETANKA53, according to the norms, although in fact it is not.

SMETANKA53, The larger the opening, the lower the ratio of the perimeter to the area, and the expense goes to processing the perimeter of the window block, something like this. For example 1x1 - perimeter 4m, area 1m2, - 4: 1 2x2 - perimeter 8m, area 4m2, - 2: 1.

In practice, the gap is minimal, the consumption depends on many factors, and not only on the size of the opening.

from what is IT? -from the handlessness of measurers and installers?

encoder, all the same did not understand. If the unit of measurement was in meters or pieces, otherwise, meters are square, well, that is, 100m2! In general, the foam consumption should be the same.

vladnik, the degree of expansion of the polyurethane foam depends on the humidity of the temperature, and its consumption also depends on the quality of the preparation of the opening, the exposure of the frame to the draft. - these are already production costs

SMETANKA53, the window is not covered with foam. They are processed only along the perimeter of the window block.

gelo, - nonsense .. you DO NOT apply paint at sub-zero temperatures and in the rain .. current according to TU on it .. = the same, yes .. NOT connected with the production NORM

encoder, I forgot that we are talking about 100m2 of the opening, and not the surface to be sealed (narrow specialization affects)

vladnik, under the influence of air humidity and temperature, the foam increases in its volume by 50-250%. The type of foam also affects the degree of its expansion. Normally, the average consumption is taken under optimal conditions for the production of work.

gelo, Duc the conversation was about the NORM .. or about HOW the foam foams.

If the design dimensions of the openings are observed, then the consumption of 2 cylinders of 750 ml per window is 1.8 * 1.35 m. In general, according to the standards, the mounting gap is 20 mm.

Hello, can you tell me the consumption of foam when facing window slopes?

11.3 balloons per 1 perimeter for a double-leaf window.

for sticking plastic on slopes.

but there could be cavities.

tulenin, yes you are right. they need to be repaired - otherwise cockroaches will crawl in, but they will not be able to get out and will die

tulenin, thanks. veronika, well, for sealing, as I understand it Added (04/01/2011, 13:34) ——————————————— First said thank you, then realized that I did not understand) on the perimeter of the window, how is it?

tatjana__s, And message # 21 does not suit you?

tatjana__s, well, there is no such norm! Don't you understand the jokes?

Sandronik, no time for jokes to be honest Added (04/01/2011, 14:55) ———————————————— penr, as I understand it, message 21 is for setting the window. I have slope filling

tatjana__s, even more so there can be no norm - what is the depth of the slope (wall thickness). What a perimeter. What is the gap between the starting profile and the wall of the opening. This is all that determines the expense.

still to know. okay thank you.

tatjana__s, yes, take a quote for facing slopes with plastic on glue

veronika, the question is about the expense, not about the price.

tatjana__s, The use of polyurethane foam is described here and, in fact, coincides with the message of the Kazakh colleague bravas

tatjana__s, talking to a Sandronik colleague again, or or

tulenin, Duc, it was not a joke !? And what do you say, colleague, that all openings are the same !? And give a reference to the studio about the rate "11.3". And it's okay that the cylinders are different in weight (the amount of foam) - 250g., 500g., 750 - all the same, 11.3 pcs.

certainly not a joke, but a JOKE. for reproducing - YES

Good day! I ask for help on this issue - the inspection organization does not miss the price 10-01-047-01 Installation of PVC blocks in external and internal doorways in stone walls with an opening area of up to 3 m2, justifying this by the fact that the price is very "expensive" and the consumption of foam "very big". However, I was unable to find any regulatory documents that would give grounds to consider this rate to be incorrect. The representative of the inspection organization refers to the article of the magazine "Consultations and explanations on practical issues of estimated pricing in construction" No. 4 (32) 2003. The magazine indicates the consumption of foam 2 cylinders of 750 ml per 100 m2 of the opening for a price of 10-01-034. But the magazine is still 2003 and the price for windows, and the price we apply is from GESN 81-02-10-2001 as amended in 2009. The arguments that the norm is state and approved by the ministry do not have any impact. Maybe you have met adjustments to the consumption of polyurethane foam for the 10th collector? In the meantime, there is no need to know about it. ”

Florimel7584, the main document of the HESN. Ask the reviewers to correct it .. If they have such a right. The second main one is MDS. PS Foam is still not enough .. so agree to a stupid wishlist / correction and buy in addition at the expense of HP. cheaper bu.

Thanks for the advice, vladnik. Nerves will be more intact. But we write off the material according to the norms, and the write-off is also checked. What to write off the foam based on the proposed rate, I need to overestimate the volumes, firstly, the customer may not miss it, secondly, an increase in volumes will lead to an increase in labor costs, and they are also checked according to the standards of the HPPN, thirdly, an increase in labor costs will pull payroll along and it, as you probably already guessed, is also checked. It is impossible to buy foam at the expense of HP, because we are an internal contractor and operate at cost, we have no contingency costs. It is somehow strange to me to set labor costs for the HPES, and the consumption of foam for the "Wishlist", and what are my reasons for this, if there is a state norm.

Your stupid inspector, tell him so. Compares an awl with soap - federal SNB with individual (Goryachinsk new technologies), windows (10-01-034) with doors (10-01-047). Does he himself leave the room through the door or through the window? Although in certain situations it is possible. Before that, I was probably in charge of culture.

Well, then you have the last opportunity .. to change the inspectors (Don't ask how better.)

You need to do sports, for example, American rounders - sports equipment there can convince anyone.

Regulatory prescriptions

The Internet made it possible to perform calculations on the consumption of polyurethane foam in the online mode. Calculators can be found on various sites, but they are only available to confident users of the worldwide network. DIYers can also use the instructions of the manufacturers indicated on the packaging, or the regulated norms, if any. But in both cases, it is recommended to increase the result obtained in order to prevent the situation of emptying the cylinder at the most inopportune moment.

It should be noted that different polyurethane foams have different consumption per square meter or running meter.

Sealant consumption depends on a number of factors:

- the qualitative composition of the polyurethane foam;

- the required depth of the filled slots, joints, abutments and other recesses;

- use when applying a plastic tube or a special gun;

- the presence of a dispenser;

- professionalism of the master;

- uniformity of mass distribution;

- percentage increase in volume;

- temperature and humidity conditions accompanying the work process.

The consumption of polyurethane foam in the standards used by the estimators is calculated based on the performance of work in optimal conditions, using a professional assembly gun. At the same time, attention is paid to the mandatory moistening of the surfaces before applying the sealant, periodic shaking of the cylinder, and uniform distribution of the mass in the direction from bottom to top.

The calculation of the required amount of foam per square meter when installing window blocks is made taking into account the thickness of the seam 35-40 mm and its location along the entire perimeter of the opening. For example, if the window has an area of up to 3 square meters, then the consumption of the assembly sealant will be 1.24 cylinders with a capacity of 0.75 liters. If the opening turns out to be more than 3 square meters, then 0.7 part of the cylinder of the same volume will be spent on its square meter.

In the case of laying heat-efficient blocks, about ten liters of foam will be needed per square meter. But this normative figure is not final. Any construction company has the right to change the figure upwards, justifying the amendment by the circumstances that have arisen. Individual norms are approved in accordance with the established procedure at the enterprise.

In the accepted state prices, there is another indicator of the consumption of polyurethane foam - per 100 running meters of the seam. An example is the renovation of balconies. In this case, you will need four cylinders of sealant with a capacity of 0.85 liters. Many professionals proceed from a different, fairly simple formula. For four linear meters of a gap of a typical size, they "take" a liter of expanding volume of polyurethane foam. As a rule, this number is present on the cylinder. In other words, approximately the following correspondence is written on it - 900ml = 65l.