The glass industry, like any other that produces products in demand on the market, is developing at a very fast pace. As a result, the consumer is constantly offered new products.

The range of types and types of glass and glass units produced for both wooden and plastic and aluminum windows is very large. For companies engaged in the manufacture of glass units, there are no technological barriers to completing their products with certain types of glass. The choice remains with the customer, in connection with which he needs to understand this assortment. Let's consider the main distinguishing features of different types of glass.

Glass grades

Sometimes, when studying information, the varieties and types of glass for plastic windows are confused. In order not to be mistaken with the choice, you cannot substitute terms. A grade is actually a brand of glass used to denote the quality of a product. All the basic requirements that are used in classifying products and determining their quality are listed in GOST 111-90:

- optical distortion;

- deviations in sheet thickness;

- the presence of non-destructive defects;

- total deviation from the plane of the sheet.

In total, the state standard identifies 8 categories that determine the quality of glass. The marking is carried out as follows - from M0 to M7. Moreover, the extreme positions are not used in the manufacture of ordinary windows. Modern double-glazed windows are most often assembled using M4 glass, although in theory, M5-6 brands may be suitable. Polished M7 sheets are used to complete display cases, and M0 class products are intended for the manufacture of optics or measuring instruments.

You can also find the TC and XC markings. This means that the glasses are thermally or chemically resistant. The XC category is needed for the production of laboratory glassware, and with the use of TS, fire-prevention models of profile structures are assembled that can withstand the effects of flame for a long time.

Some impact-resistant glass for windows are also processed at high temperatures, but they should not be confused with products marked with TC - they are completely different products.

Advantages of PVC windows over alternative options

Plastic windows reliably protect the room from cold, precipitation, wind, dust and noise. They are durable and require minimal maintenance. Quality products from well-known brands do not lose their attractiveness for decades.

"Plastic" is safe for health - contrary to popular belief, it does not emit harmful substances. Polyvinyl chloride is fireproof - windows do not burn, but melt.

The designs are varied - it is easy to choose a window with the optimal configuration and is affordable. Modern products are also variable in terms of design - you can order a window of almost any shape and color.

VEKA windows are peace and safety, warmth and comfort. Against the background of the merits of German "plastic", ordinary windows seem inconvenient and impractical. And it is - after getting acquainted with technological systems, questions about their advantages no longer arise. The pros are obvious.

Glass properties

Different types of glass for windows have different properties. However, their base has common characteristics. After all, you need to separate the properties of the glasses themselves and the auxiliary elements that are used in the manufacture of different products. An exception can be made only by tempered or mass-tinted glass for window frames and active sashes.These products differ in thermal conductivity, fragility and bending strength.

Since the composition of window glass is approximately the same for different manufacturers (75-80% SiO2, 10-15% CaO and approximately 15% Na2O), it has generally similar properties:

- thermal conductivity ranges from 0.4 to 0.82 W / (m · ° С) - this means that the material conducts heat well and has low energy efficiency;

- light transmission capacity - up to 92%;

- chemical resistance - window panes are inert to household chemicals and airborne substances;

- refraction of light - from 1.46 to 1.53;

- impact bending strength is 0.2 MPa, which indicates the fragility of the material;

- electrical conductivity - depends on temperature and the presence of impurities, but in general, the material is safe to use.

Such properties today cannot be considered ideal for modern windows, therefore manufacturers use technologies and substances to improve performance. After all, safety, the level of energy saving, sun protection and aesthetics largely depend on what the window glass is made of. To improve the properties, different techniques are used - the necessary chemical compounds and substances are added to the mixture during the glass manufacturing process, or various coatings are applied to the surface of the finished sheets. Also, the technology of integrating other materials into the glass (reinforcement) is sometimes used.

Installation of PVC windows

In simple terms, a plastic window consists of three components:

- frame and sash made of PVC profile

- double-glazed window

- fittings.

PVC profile

The base of the window is a frame and a sash. They are made from PVC profiles. The service life and functionality of the entire window depend on their durability, which is why the choice of a window begins with the choice of a PVC profile.

PVC is the abbreviated name for polyvinyl chloride, the main substance from which the profile is made. To give the profile the necessary thermal stability and strength, steel reinforcement is used. Partitions divide the internal volume of the profile into isolated cavities, which are called chambers. They improve the thermal insulation characteristics of the window and increase the stiffness of the profile.

Depending on the wall thickness, the PVC profile is divided into three classes:

- class A: inner walls - 2.5 mm, outer - 2.8 mm; the best option for the manufacture of windows in residential buildings;

- class B: inner walls - 2 mm, outer - 2.5 mm; less strong and durable, used for glazing production and storage facilities

- class C: wall thickness not regulated, used for temporary structures.

Only a profile of class A has the necessary strength for long-term trouble-free operation - the sashes of such windows do not sag over time. Therefore, VEKA produces exclusively class A PVC profiles.

The wider the profile, the more chambers in it and the better its heat and sound insulation characteristics. In addition, the wide profile allows for a wider glass unit to be installed. By width, the profiles are divided into three main categories: 58–62 mm, 64–70 mm and 80–90 mm.

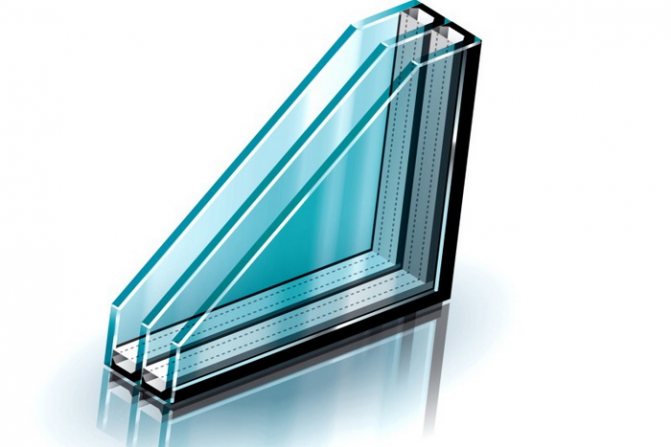

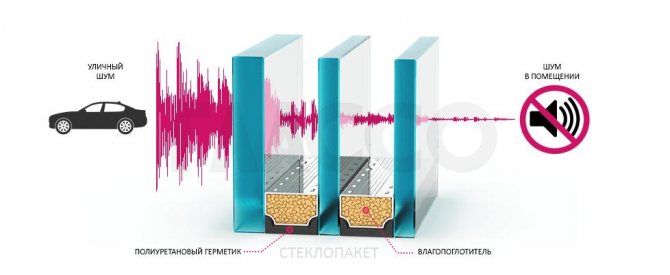

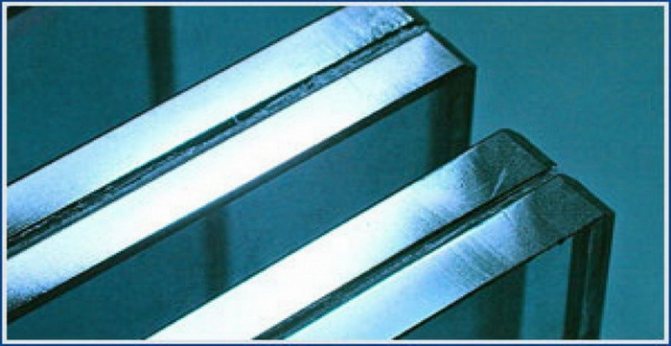

Glass unit

A double-glazed unit is a construction of two or more sheets of glass. The distance between the glasses is set by a spacer made of aluminum or plastic. There is an absorbent inside the frame - a moisture-absorbing material that prevents condensation from forming on the inner surface of the glass.

The chambers are filled with dry air. Sometimes argon or xenon is used instead, which have better thermal insulation properties.

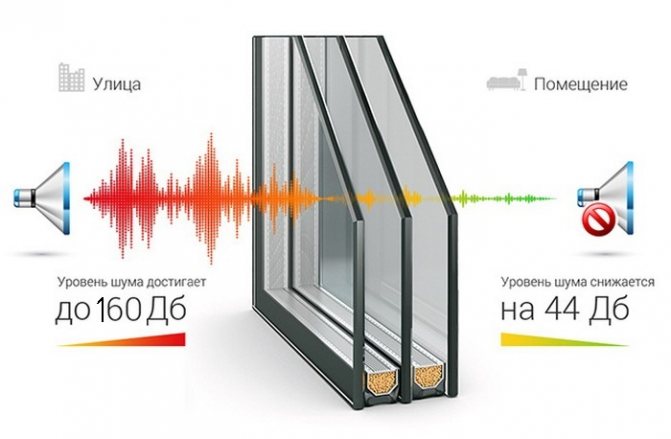

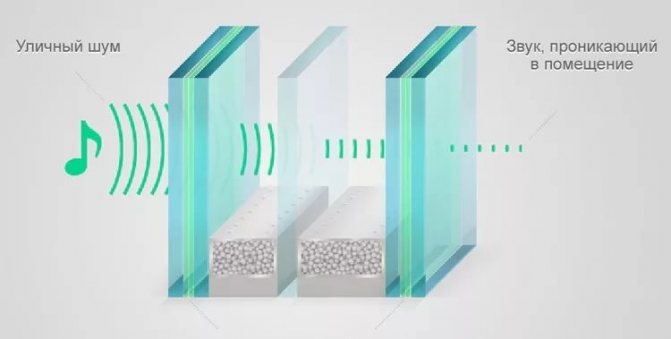

Single-chamber double-glazed windows provide satisfactory thermal insulation. Two-chamber - the best option for residential premises in central Russia. Three or more - a solution for regions with cold climates.

The increase in the number of glass has almost no effect on the light transmission of the glass unit, but it improves its energy efficiency and sound insulation. Unfortunately, such windows are not only more expensive, but also much heavier. In some cases, the weight of the window can be important.

Fittings

Competently selected fittings make the use of the window more convenient and increase its functionality.

Plastic window fittings include:

- handles, locks, blockers;

- hinges and hangers for sash;

- additional anti-burglary elements, child locks;

- sun blinds and micro-ventilation devices.

Also, the buyer can order the color of the profile, the finish of its surface and decorate the window with additional decorative elements, such as spros.

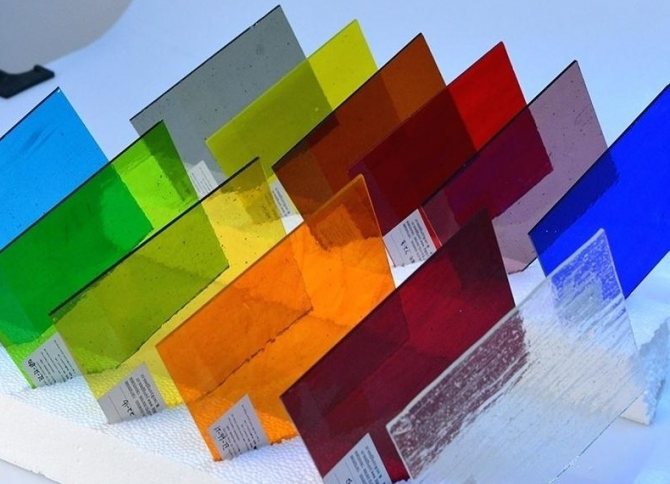

Float glass

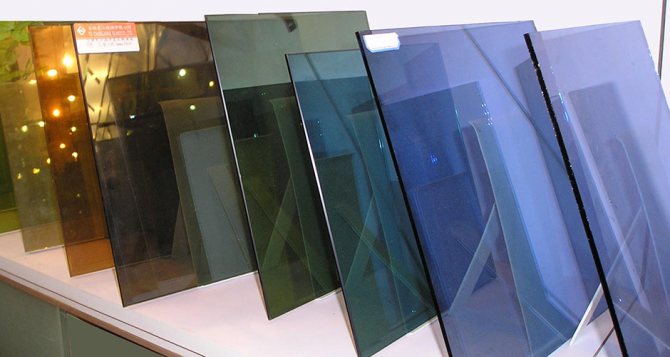

Today, this most common type of glass is made up of sheets with a thickness of 0.4 to 25 mm, which are formed on molten tin. This technology allows to provide glass with a smooth surface and reduce its cost, since the manufacturers no longer need to polish and grind the surface of the sheets. Float glass can be either transparent or tinted in bulk. In the second case, special mineral additives are added to the silicate mass, which give the sheets a blue, green, red or bronze color. For the manufacture of double-glazed windows, both types are actively used, but the most common is transparent float glass 4 mm thick.

The characteristics of float glass can be improved by gluing the windows with polymer films, which help to increase the level of heat and sound insulation.

Types of low-emission energy-saving glasses

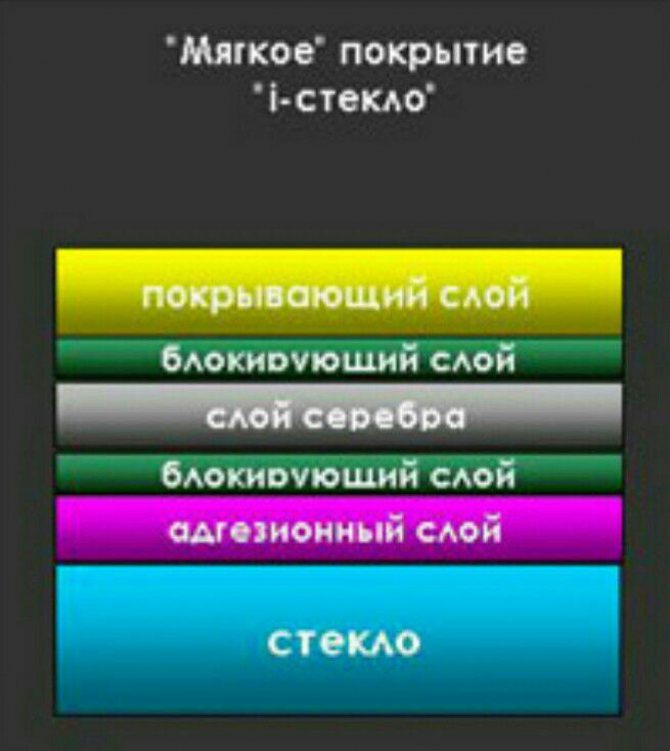

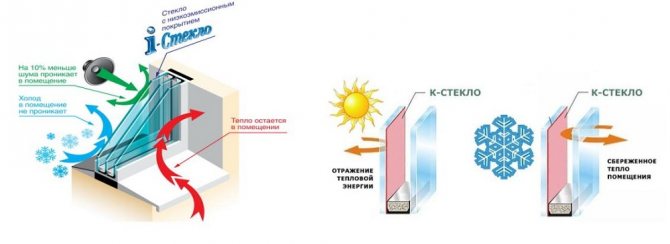

The "magic" coating of energy-saving glasses, selectively transmitting light and heat, is a metal film several microns thick, which is applied to the glass in different ways. A distinction is made between soft and hard coatings for low-emission glasses.

Hard coating, or (k-glass), is formed when the smallest film of metal is deposited on molten glass during its manufacture. It transmits light without obstacles and poorly - heat (the percentage of energy saving - up to 70). In addition, this coating is extremely durable. For their heat-saving properties and ease of operation, windows with k-glass are replacing conventional ones in Europe.

Soft coating, or (i-glass), applied under vacuum, without raising the temperature: a very thin film of silver is sprayed onto plain glass. In terms of technical properties, i-glass surpasses k-glass in the percentage of energy saving (up to 90). In countries with a harsh climate, only soft coating is mainly used, although in Russia practically nothing is known about it.

Due to the unique heat-saving properties of i-glass, you can significantly save on heating. Without a doubt, the future belongs to low-emission glasses, although the Russian market has yet to master this niche. The technology for the production of such glasses is complicated, and accordingly, the price is high. Even in the West, only very reputable firms were able to organize such a production.

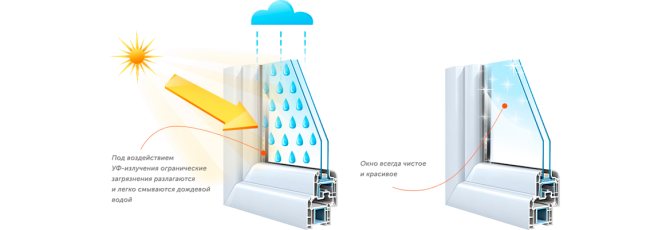

links to materials supplementing this article: Windows with self-cleaning glass - always light!

PVC windows with heated glass. How do they work?

Glazing with energy-saving glass - we make the house warmer!

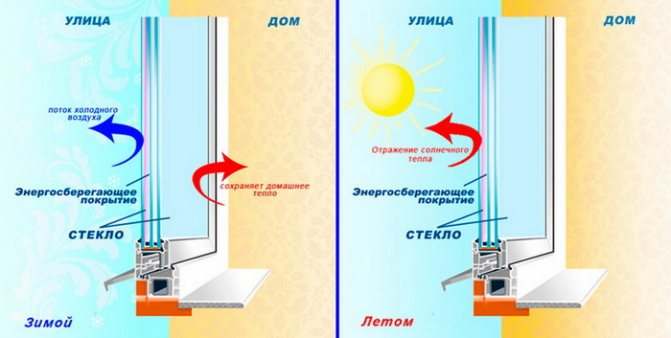

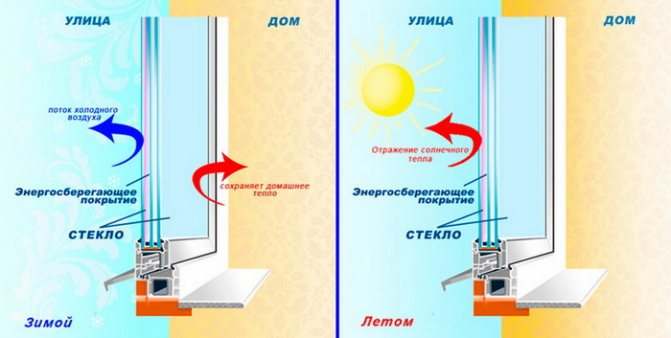

Energy efficient glass

For the manufacture of warm windows today, glass with a special selective coating is increasingly used. The metallized layer applied to the surface transmits visible rays of sunlight and retains heat. Thanks to this separation, it was possible to provide windows with high energy efficiency without reducing the light transmission capacity. Currently available:

- i-glass

- have a soft coating; - k-glass

- have a hard cover.

A detailed comparison of the characteristics of these two modifications is given in a special article on WindowsTrade. Energy-efficient glass for plastic windows allows not only to better keep warm in winter, but also to keep cool in summer - that is, it fully functions in 2 directions.

Energy efficient insulating glass units have approximately the same coefficient of resistance to heat transfer as conventional two-chamber models. An additional benefit from their use is that they can significantly reduce the weight of the windows and do not allow the interior rooms to warm up quickly in summer.

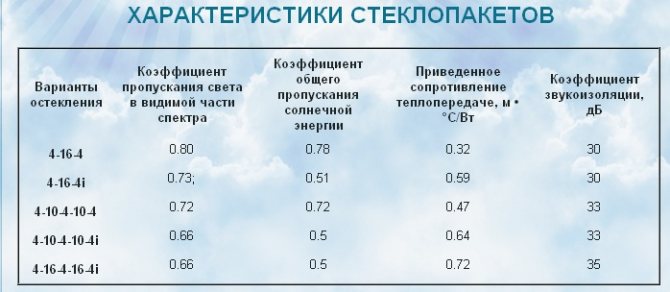

The choice of a double-glazed window.

When choosing a double-glazed window, as well as when choosing glasses for it, several factors should be taken into account. It must be remembered that the number of chambers in a glass unit is one of its main characteristics.

The layer of air between two adjacent glasses is called a chamber. Usually, in products for residential or office premises, there are from one to three. It is important to understand here that the heat-insulating properties directly depend not so much on the number of chambers as on their thickness. That is, the thicker the layer of air or inert gas between the glasses in the package, the higher its heat-saving properties.

Along with this, the weight of the glass unit is important, which is determined by the number and area of glass in it. Glass is a very heavy material, and neglect of this indicator, especially if the windows are large enough, will eventually lead to sagging of the opening sash and premature failure of window fittings.

Few people know, but with a two-chamber package, you can achieve higher sound insulation values than even with a three-chamber one. To do this, you just need to make a double-glazed window with cameras of different thicknesses.

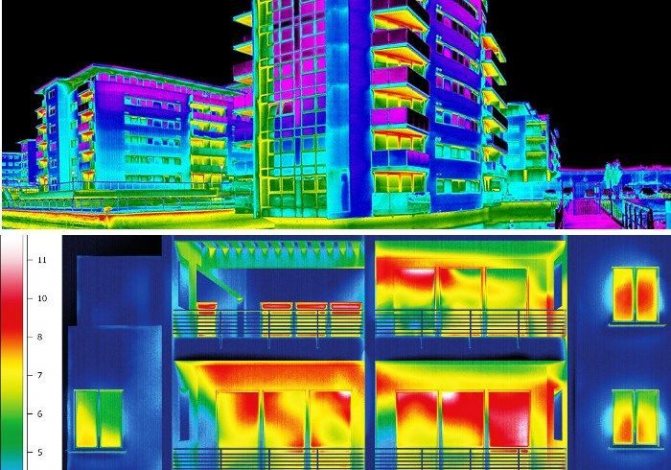

A double-glazed window is an important element in the construction of a house or apartment. The main loss of heat occurs through the windows in the room; they are, as it were, “cold spots”. Therefore, it is categorically not recommended to save on the quality of the glass and the insulating glass units themselves, because their subsequent replacement with more optimal ones can entail not only high costs, but also the possible need to change the entire window as a whole.

190

- Similar posts

- Energy saving glass

- What is PVC. Decoding and description of the material, its use in plastic windows

- Triplex glass. Description of the manufacturing technology. Application area

«Previous post

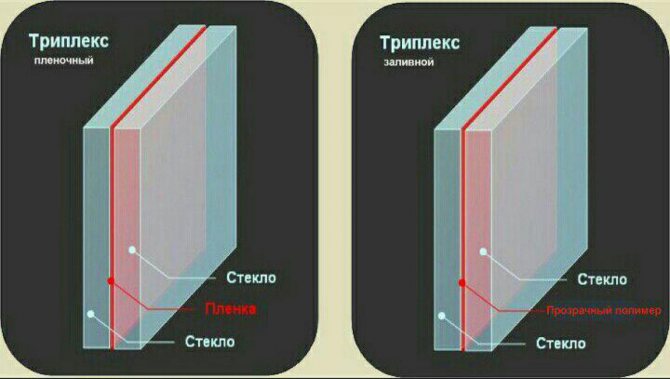

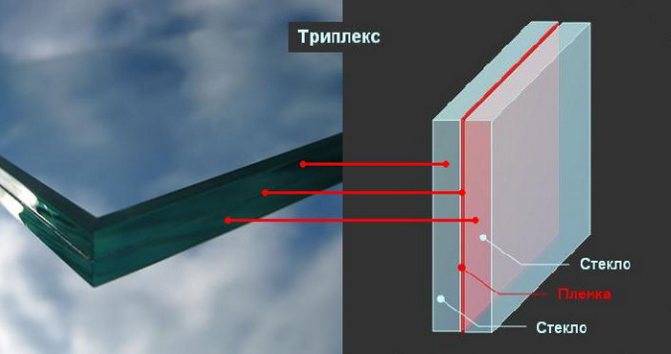

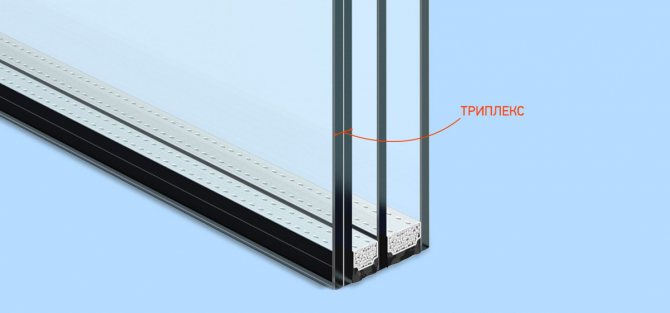

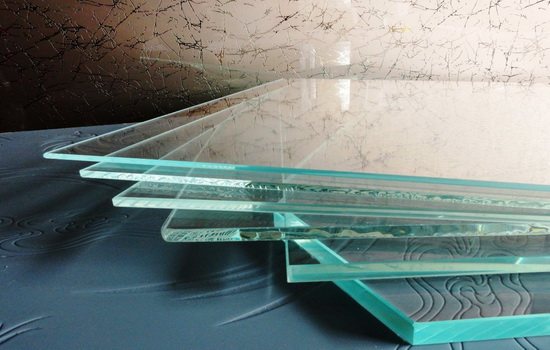

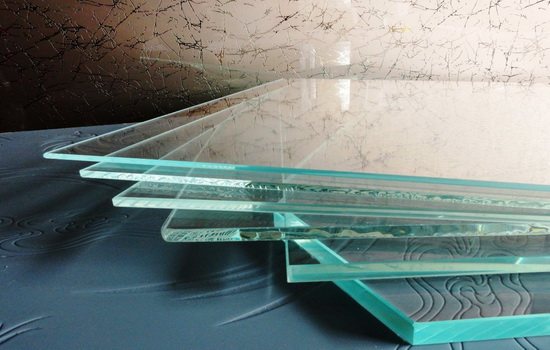

Triplex glass

Since ordinary float glass is easily shattered even by light impact, in the production of windows, a need arose for an impact-resistant material with good light transmission and a high level of safety. This is how the triplex appeared. It was obtained by combining ordinary glass and a polymer film, which is located between two sheets. This combination made it possible to simultaneously increase both the strength and the level of safety. Even if the triplex glass can be broken, thanks to the film, the fragments will not scatter throughout the room. In this case, the number of layers in a triplex can be more than three, which makes it possible to further increase the impact resistance of products. Today technologies make it possible to produce triplex with four layers of polymer film, the total thickness of which is 32 mm.

Reinforced glass

To strengthen the glass, a metal mesh can be used, which is placed in the body of a silicate mass during the casting of sheets. In the production of reinforced glass, 3 types of steel wire can be used:

- chrome-plated;

- nickel plated;

- annealed.

The mesh can be twisted or welded with a different area and shape of the cells and is located parallel to the surface of the sheets. It does not make the glass much stronger, but at the same time does not allow it to crumble when broken and becomes an additional obstacle on the way of intruders to the interior.Reinforced glass can be transparent, frosted and colored and at the same time has a smooth or embossed surface.

Strained glass

If ordinary float glass is subjected to heat treatment at a temperature of 650-680 ° C and simultaneously provide rapid two-sided cooling, it will become tempered. This means that such sheets will be much more difficult to break. Also, it has increased thermal resistance and increased safety - shards of tempered glass have blunt edges, making it almost impossible to get injured by them. Such products are most vulnerable to impacts to the end, and this should be taken into account when designing glass structures.

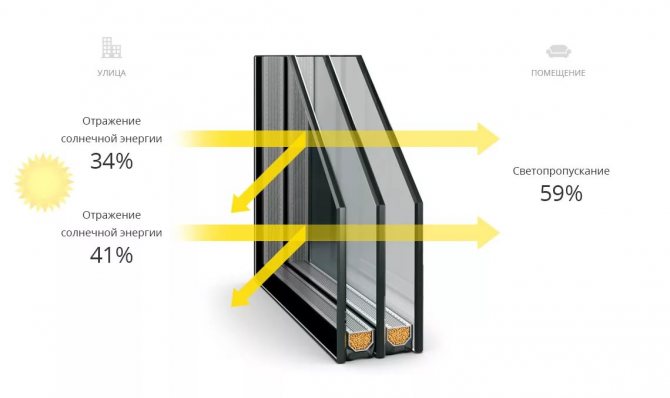

Reflective coated glass

These glasses are somewhat similar to energy efficient ones, but they are intended for different purposes - reflection or segregation of sunlight. The protective metallized coating can also be soft or hard and has a degree of resistance to external influences. Some types of reflective glass are able to protect against overheating while maintaining the high light transmittance of the windows.

The sun-protection reflective glasses have a mirrored surface, so that in some cases they can be used to ensure confidentiality.

Tinted glass

Tinting allows you to darken rooms, protect them from overheating and, in some cases, reduce heat loss. This type of glass is presented in 4 modifications:

- tinted in bulk;

- with pyrolysis coating;

- pasted over with polymer films;

- with a metal oxide coating applied in a vacuum chamber.

The characteristics of these products and the way of caring for us depend on the type of tinting. The most resistant to mechanical damage are considered to be tinted glass in the mass, but they themselves quickly heat up in the sun and begin to transfer heat to the interior. As a result, it is recommended to give preference to glasses with pyrolysis or vacuum coating.

White frosted glass for windows does not belong to tinted products, since they are made using other technologies - sandblasting or chemical etching.

Comparative characteristics of different types of glass - which glass will provide the best comfort

Each glass has a number of characteristics, based on which a glass unit is designed.

Characteristics of glasses with different functions compared to ordinary glass, double-glazed unit, 36 mm

| Glass type / function | Cold protection | Sun protection | Furniture burnout protection | Protection from prying eyes | Place of installation |

| Plain Float Glass Planibel Clear | low | low | low | — | everywhere |

| Heat-saving glass (i-glass) Top N + | 44% | 22% | 54% | — | inside or outside coated inside |

| Multifunctional glass Energy Light | 50% | 43% | 54% | — | outside coated inside |

| Stopsol Phoenix sun glass | = ** | 17% | 30% | + | outside coated inward or outward *** |

* The most common type of double-glazed unit is 2-chamber 3 glasses ** It is possible to enlarge if you put i-glass in a double-glazed unit *** Sun glass with a hard magnetron coating of class A

Analysis of the table shows that the use of different types of glass in the construction of an insulating glass unit significantly affects the basic properties of glazing.

Regular insulating glass unit with float glass

A double-glazed unit with ordinary glass (float glass) does an excellent job of protecting the house from rain and wind, but living behind such windows is not entirely comfortable. The disadvantage is the low heat and solar control properties of ordinary glass. From such windows blows cold in winter, and in summer the room heats up from the sun's rays.

Energy saving glass unit

Replacing one of the 3 glasses in a double-glazed unit for low-emission with i-glass significantly improves its thermal properties.Heat losses through a double-glazed unit with i-glass are reduced by 44% compared to conventional ones, and the protection against heating the room on a hot day is increased by 22% (the lower the solar factor, the higher the protection).

Protection against ultraviolet radiation - the reasons for the fading of interior items - is doubled. A double-glazed unit with i-glass will significantly reduce heating costs, minimize condensation (the effect of "crying" windows), partially protect from the sun and will perfectly cope with protecting furniture and wallpaper from fading. Glass is installed from the inside or outside of the room with a coating inside the glass unit. You can use two i-glasses in a double-glazed unit - external and internal, the coatings, and in this case, are facing the inside of the glass unit.

Multifunctional glass unit

Multifunctional glass* - the most advanced version of the new generation glass. Installed from the outside of the room with a coating inside the glass unit. The characteristics of the glass make it a favorite with buyers. It has more than 40% increased protection from the sun (solar factor) compared to a conventional glass unit, and the thermal performance increases by 50%. This glass is designed to be installed in almost all rooms. Multifunctional glass eliminates the need to stick on sunscreens or install blinds. A comfortable temperature in the house is provided both in winter and in summer. Glass 54% more than usual protects from ultraviolet radiation and fading of the original interior shades.

Photo: Energy Light - new generation multifunctional glass *

Sun protection mirror glass

Mirrored sun-protection glass will protect the property from prying eyes. Living with curtained windows or closed blinds is uncomfortable. Due to its high reflectivity, sun-protection glass will allow you to do without curtains during the daytime and enjoy the view from the window. But it must be remembered that "the carriage turns into a pumpkin" with the onset of dark and the lighting is turned on. Another advantage of this glass is the sun protection function.

Photo: private glass Reflective glass protects from the sun by 17%, and from ultraviolet radiation by 30% better than usual. This glass is especially loved by architects, because it allows you to embody different colors on the facades of buildings. In combination with i-glass, the glass unit acquires an additional energy saving function, comparable to the level of multifunctional glass.