From the outside, a standard plastic window seems, if not entirely light, then certainly not too heavy. It's all the fault of the white color. It creates the illusion of lightness, airiness of any object painted into it. Remember at least the pipes of cruise ships - almost all of them are painted white so as not to seem heavy ... And although the weight of a glass unit cannot be compared with the mass of a metal pipe of a sea vessel, the mass of a light-transmitting element, for at least one person, remains prohibitively large.

Like the pipes of ships double-glazed windows from each other may differ in weight... To understand what constitutes the weight of a double-glazed unit, it is necessary to clearly understand what components it includes in its design.

What depends on the mass?

It is most often used, therefore, the consumer will first of all be interested to know how much a plastic window with two glasses weighs. Most often, you can find out this parameter even before buying: the manufacturer indicates the weight of the product. In some cases, the window unit can be inserted without fear, in some it is necessary to reinforce the wall. The latter is especially true for houses of the old foundation.

The complexity of its maintenance also depends on the weight of the structure. The heavier the sash, the greater the risk of sagging. This means that you will have to more often. It is worth buying more powerful fittings, not to save on it, therefore, when choosing opening elements, you should also take into account how much the plastic window weighs.

If the weight of the window is large, you should not order a structure with an excessively long sash. Better to make two lighter ones.

And also in our material on the site there is information about standard

How to strengthen a large area stained-glass window

The weight of a stained-glass window and a frame for a large-sized product requires special design solutions. At the same time, attention is paid to the spatial arrangement (horizontal, vertical, inclined), stained glass technique (prefabricated / solid, transparent / opaque), as well as the operating conditions.

Spatial location:

| Location | Strengthening options |

| Vertical (stained glass panel, kitchen apron, etc.). |

|

| Horizontal (suspended ceiling, chandeliers, etc.). |

|

| Inclined stained glass |

|

Also, regardless of the location, you can give the following recommendations for all types of stained glass:

- all construction work (leveling walls, laying communications, etc.) must be completed before installing the stained glass;

- a seal on the ends of the stained glass is desirable, even if the stained glass has its own frame, like the Tiffany stained glass;

- opaque stained-glass windows can be strengthened using reinforced and tempered glass;

- to protect against the scattering of fragments, a transparent polymer film can be glued to one side of the stained-glass window;

- the weight of the stained glass and frame plays a secondary role when it comes to health and safety, so in children's rooms it is better to use durable glass and a reinforced profile.

Detailed information on the production of stained glass to order.

The cost of stained glass and frames

The cost of a stained-glass window is calculated individually based on various factors that form the price of a stained-glass window:

- the size of the stained-glass window;

- frame materials (profile, fittings, fasteners);

- type of glass and manufacturer (imported, domestic, tempered, reinforced, colored, embossed, etc.);

- the complexity of the installation;

- urgency of manufacturing.

Stained-glass windows and frames from our studio

Already at the stage of project development, we make the necessary strength calculations depending on the weight of the stained glass window and the frame. Thanks to this, it is possible to select the optimal materials so that the stained-glass structure will serve for a long time and reliably. This approach also minimizes the likelihood of complications during installation.

All work is carried out in-house and from our own materials, and in the stained glass workshop they also carry out carving, forging and other artwork. This allows not only to guarantee the high quality of stained-glass windows, but also to form reasonable prices, since from the development of the project to the installation we do everything ourselves.

Properties of individual structural elements

Fortune-telling is not worth it: two structures of the same size, produced by different manufacturers or made of different materials, may have different weights. The reason is as follows: different types of plastic or different glass can be used, which differ in thickness and weight, respectively.

The weight of 1m 2 PVC windows depends on the wall thickness. If for products belonging to class A this parameter is fixed at 3 mm, then for products of class C it is not regulated in any way. Class B has a wall width of 2.7 mm, respectively, the window will be slightly less durable and its weight will decrease.

It is important to know if there are internal baffles as they add weight too. The same parameter will increase with the number of air chambers. Each additional glass is additional kilograms.

Perhaps sliding windows will suit you, they are very space saving. Is a sliding profile made of economy class plastic.

Calculation of the weight of a PVC window 1m2

PVC windows have established themselves as strong, durable, practical products, characterized by excellent noise-suppressing and heat-insulating characteristics.

More accurately, specifically for your parameters, only a measurer can calculate the weight of a PVC window.

In our company you can

call a specialist free of charge

by measurements, who will make calculations and answer all your questions. Calling the measurer you

does not oblige to anything!

The sale of plastic windows is complemented by a range of related services. Experienced specialists carry out a huge range of construction and installation work, including the installation of ebb tides, slopes, window sills, and other accessories. We not only trade in window structures, we are able to create glazing of any level of complexity.

PVC profiles

PLASTIC PROFILE SYSTEMS

KBE

EXPROF

REHAU

PLASWIN

Pros of plastic windows with light weight

- Soundproofing. The window structures made by us will reliably protect you from extraneous noise and frost. Our products will take the hectic and loud metropolis beyond your home.

- Cool in the summer. Thanks to a special coating, the glass reflects 60% of infrared rays, which is several times more effective than ordinary glass, approximately as protection from heat with blinds.

- Warm in winter. In winter, PVC windows significantly reduce heat loss in the house. With them, the room does not cool down so quickly.

- High degree of safety. Our PVC windows are absolutely safe for the body. The special profile is hypoallergenic, and the children's fittings guarantee the safety of children.

The advantages of our company

WINDOWS DIRECT FROM THE FACTORY we have high-quality PVC windows without intermediaries and overpayments

A WIDE RANGE OF PVC, aluminum, different colors, selection of accessories

CONSTRUCTION OF ANY COMPLEXITY individual approach, production of windows of any complexity

FULL QUALITY CONTROL quality control at every stage of work

WARRANTY 5 YEARS we have the biggest guarantee on installations

MORE THAN 19 YEARS ON THE MARKET 100% quality, guarantees, vast experience

Ways to calculate the mass of a structure

We already know the weight. It is approximately 20 kg, respectively, the weight of a single-chamber double-glazed unit is half less and will be 10 kg. However, these are not final parameters; don't forget about the frame. The standard sash should not weigh more than 60 kg. This parameter is regulated by the standard. However, manufacturers often try to make the flaps lighter in order to increase their lifespan. On average, the figure drops to 50 kg.

The lighter the sash, the longer it will last. The average weight of a double-glazed unit with a frame is 35 kg per meter of structure, for a single-chamber unit - about 25 kg When ordering a window, it is better to ask the manufacturer in advance how much it will weigh.

You can calculate the weight using the following formula: you need to calculate the area of the structure, take into account how many chambers a glass unit has, then find out the average mass. The height is multiplied by the width and multiplied by the weight of the glass unit. If there are more chambers in the glass unit, it is easy to calculate the mass by adding the already known weight; one glass - +10 kg.

Glass unit weight –

more or less fixed value. The main difference lies in the mass of the frame, you can calculate the average mass of the window, if you got it ready-made, using the given formula.

Permissible loads

To perform accurate calculations, it is necessary to build on existing indicators. You can find out how much weight a kilogram of finishing or insulation can hold on the balcony, if, for the sake of order, take the carrying capacity of the loggia - 1770 kg. Distribute weight loads on several points:

- on average, three people weighing 80 kg is 240 kg;

- various devices and items - 175 kg;

- load of rainwater or snow - 200 kg.

It turns out that the non-glazed balcony receives a load - 615 kilos in our case. Given the indicator before glazing, the mass is 922.5 kilos. This means that for all materials in order to complete the decoration, 847.5 kilos are needed. For details of the competent finishing of the balcony, see this video:

What affects the weight of insulating glass

PVC plastic windows have many advantages, manufacturers do not forget to constantly remind us of them. But they have "problems", the list of shortcomings also does not consist of one item.

Let's choose only one of the shortcomings - the low indicators of plastic profiles in terms of resistance to dynamic (variable) and static forces.

Not every glass unit can withstand a standard profile, for some it is necessary to use special or reinforced models. Not only the plastic profile itself must be thick, but also the reinforcing metal elements mounted inside the profile cavity.

The use of a special profile increases the cost of the window, and this inevitably raises the selling price of the product.

we will call you back

Appearance

Anything that serves as decoration: various fences, water drains, and flower boxes must be periodically updated. It is worth painting them with paints that are resistant to atmospheric phenomena. The color of the paint must be selected so that it matches the shade of the facade. The shape, as well as the location of the flower grower, must correspond to the legalized architectural design of the building. They must be installed on special pallets, maintaining a gap from the wall of approximately 0.5 m.

In some apartment buildings, loggias have an external staircase that connects the balconies in stages and is an emergency loophole.

Doors leading to these stairs must not contain any latches on the outside. Loggias through which the evacuation will take place should not be glazed.

What determines the weight of double-glazed windows

There are several components that affect the weight of a glass unit. Let's consider each of them:

- Glass brand and dimensions. The mass of glass varies widely, these fluctuations are associated not only with the thickness and dimensions, but also with the peculiarities of the manufacture of glass and its physical properties.

- Additional components. This refers to spacers and sieves.

- Sealants. Different types of sealants with different specific gravity are used in different insulating glass units.

- Desiccants. There are double-glazed windows in which a fairly large amount of absorbent is used.

- Insulating glass unit. In most cases, a single-chamber glass unit is lighter than a two-chamber one, but not an axiom.

We will consider cases that fall under the "not always" category.

Each component affects the mass to varying degrees, let's start with the most important element - glass.

How to calculate the weight of 1 m² of glass

We have already mentioned that glasses are different, with different specific gravity and physical characteristics. First, let's talk about the most common conventional high quality transparent glasses of the M1 brand.

We find in the reference book the weight of 1 m² of this glass with a thickness of 1 mm, its weight is 2.5 kg / m². Next, we multiply the height and width of the glass (in meters) by its thickness (in millimeters) and by the specific gravity (from the reference book). Thus, we get a mass of single glass.

How to find out the weight of a single-chamber glass unit

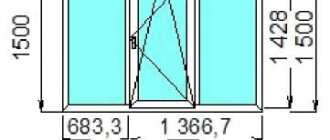

Very simple. Let's say the formula of a double-glazed unit is 4-16-4 (the most common option). Dimensions 1.8 m in length and 1.4 m in width. The calculation will need to be performed as follows: 2 × 1.8 × 1.4 × 3 × 2.5 = 37.8 kg.

- 2 - the number of glasses in the package

- 1.8 - package height

- 1.4 - package width

- 3 - thickness of each glass

- 2.5 - specific gravity of one square meter of glass (thickness 1 mm)

To find out the weight of 1 square meter of a glass unit, its total weight must be divided by the area.

Thermal insulation

For better thermal insulation of a glass unit, today special heat-reflecting glasses with low heat emission (Low E), low-emission ones, which we have already mentioned, are used. The most common type of low-emission glass is soft-sprayed silver. In the formula of a double-glazed unit, it is indicated by the letter "I". How to distinguish an energy-saving glass unit from a conventional one

According to GOST 30674-99, a double-glazed unit of two glasses, one of which is low-emission, is better than a double-glazed unit of three glasses in terms of the main parameter - heat transfer resistance. The higher the value, the better the structure protects from the cold.

The table below shows the thermal insulation characteristics of window blocks with a typical glass filling. You can familiarize yourself with the insulating properties of insulating glass units in detail at the link: insulating glass units.

| Glass unit formula | Heat transfer resistance m2 C / W |

| 4M1-16-4M1 | 0.35 (GOST) |

| 4M1-16-I4 | 0.58 (GOST) |

| 4M1-16Ar-I4 | 0.63 (GOST) |

| 4M1-10-4M1-10-4M1 | 0.51 (GOST) |

| 4M1-16Ar-4M1-14Ar-I4 | 0.95 (estimated) |

| 6CGSolar-16Ar-4M1-14Ar-I4 | 1.45 (estimated) |

Calculation of the mass of a double-glazed window

The calculation principle is very similar, only the number of glasses changes and their thickness can change. For example, the formula for your package is 4M1-8-6M1-10-4M1. Linear dimensions are the same with the first glass unit. The arithmetic is as follows: 2 × 4 × 1.8 × 1.4 × 2.5 and add 6 × 1.8 × 1.4 × 2.5 to the result. Amount 88.3 kg.

- 2 - two glasses of 4 mm thickness

- 6 - one glass 6 mm thick

- 1.8 - package height

- 1.4 - package width

- 2.5 - specific gravity of 1 m² of glass of millimeter thickness

What affects the weight of the glass unit

You can read on some sites that the thermal conductivity indicators depend on the weight of the glass unit, it is more profitable to buy a heavy glass unit, it saves a large amount of thermal energy. This is not entirely true, the thickness of the glass, of course, has an effect on thermal conductivity, but the difference in thickness in millimeters makes this influence extremely small.

The width of the air chamber is what affects the thermal conductivity. If you have a package with a thickness of 32 mm, then you can be sure that it is always "warmer" than a double-glazed window with a thickness of 24 mm.

How does the frame and sealant affect the weight of the glass unit

From the outside, a standard plastic window seems, if not entirely light, then certainly not too heavy. It's all the fault of the white color. It creates the illusion of lightness, airiness of any object painted into it. Remember at least the pipes of cruise ships - almost all of them are painted white so as not to seem heavy ... And although the weight of a glass unit cannot be compared with the mass of a metal pipe of a sea vessel, the mass of a light-transmitting element, for at least one person, remains prohibitively large.

Like the pipes of ships, glass units from each other can differ in weight. To understand what constitutes the weight of a double-glazed unit, it is necessary to clearly understand what components it includes in its design.

The profile of the insulating glass unit can be plastic, aluminum, or wood. In addition, the product consists of:

- (their number varies - 2 or 3), forming chambers into which dry air or inert gas is pumped to provide better heat and sound insulation;

- - mechanisms responsible for opening / closing the entire window structure.

In addition, a double-glazed window cannot do without spacers that fix the position of the glasses, as well as without a sealant serving as a means for treating seams. Thus, the weight of the glass unit is the sum of the masses of the glasses used, fittings, spacers and sealing compound.

Calculation of the weight of the structure.

Of course, glass has the greatest weight among all the above elements of a plastic window. As a percentage, their weight can reach up to 90% of the weight of the insulated glass structure.The weight of the glass itself depends on its type and thickness.

It is estimated that 1 m 2 of 1 mm glass has a weight of 2.5 kg. In most cases, 4 mm light-transmitting elements are used in a glass unit. Having done some simple calculations, we determine the weight of one square meter of glass (m 2) will be equal to 10 kg. (in a single-chamber double-glazed window - 20 kg, in a two-chamber - 30 kg - due to the number of glasses). The plastic profile, depending on the chamber, weighs at least 3 kilograms. , due to the fact that it is made with the use of steel components, weighs approximately at least 2 kg (depending on the manufacturer). The distance frame weight is equal to 0.5 kg.

By adding all the values, taking into account that the area of glass of a standard product is 1.8 (in height) * 1.4 (in width) = 2.52 m 2, we obtain that the minimum weight of a single-chamber glass unit is 20 * 2.52 + 3 + 2 + 0.5 = 55.9 kg., Two-chamber - already 81.1 kg.

Tinted glass and double-glazed windows

In the glazing of houses, shop windows, when installing office partitions inside the premises, tinted glass is also often used, as in the tinting of car windows. As a rule, one glass colored in the mass is used, less often two glasses as part of a one- and two-chamber glass unit. In this way, the required degree of decorative and protective design can be achieved.

For what purposes is tinted (painted) glass in double-glazed windows used:

- External glazing design in accordance with the architectural design;

- Protection from peeping;

- Indoor room shading.

The necessary color scheme, in addition to the glass colored in the mass, can be found by gluing a tint or mirror film.

| Advantages of tinted glass in bulk | Film advantages |

| The tinted glass unit includes mass-tinted glass. Peeling of the film and the appearance of air bubbles and other visually visible defects during operation are excluded. | The tint film serves as a reinforcing element and can be used to create safety glass without shattering. A tinted glass unit does not possess this property. |

An important difference between a tinted glass unit and a sunscreen unit is a significant reduction in the penetration of visible light. The light entering the room is indicated in the technical documentation as a percentage (according to GOST, it is indicated as τv (%)). With tinted glass, the light transmission is up to 20-30%, while with transparent transparent glass in a double-glazed window, the light transmission does not fall below 50%.

Non-standard double-glazed windows.

The term “non-standard” means a light-transmitting product that differs from the most common one in several components, namely, the thickness of the glass, the fittings used, etc. At the same time, with the same size with the usual, as a rule, they weigh more. From the standpoint of the weight of the glass unit, as a non-standard one, we will consider the sound-insulating version of the product.

So how much does a glass unit weigh? If we compare the soundproofing with the standard one, then the weight load of the glass used (1 m 2) will be about 5 kg more for the first one than for the second one. This is due to the fact that in the sound-proof version there are built-in glass with a thickness of 6 mm. Accordingly, the weight of 1 m 2 of double glazing will have a double (in comparison with the standard) weight equal to 10 kg.

An important point should be noted - with the additional weight of the structure itself, the pressure on individual elements of the window increases, which affects the duration of its trouble-free operation. For example, excessive structural weight affects:

- Fittings

... To avoid the appearance of defects in the operation of the hardware mechanisms, one should seriously be puzzled by the selection. The weight of the glass unit in this case plays a decisive role - the more chambers, the thicker the glass, the more reliable the hardware mechanism is required. - Installation production

... Since the mass of the sound-insulating glass unit is significantly greater than the mass of the standard one, the work associated with the installation is very specific and takes longer. - Operation

... It is no secret that with a high load on the glass unit, the period of trouble-free operation of the sash will be lower than the period of operation of the sash with a standard load. This is due, first of all, to the distribution of a greater load on the hinges and on the rubber seals. - The cost

... Additional glass thickness, the need to install special fittings designed for operation under conditions of additional weight load - all this affects both the weight and the cost of the final structure. Price for

Sun protection glasses and double-glazed windows

A sun-protection glass unit with the use of a thin layer of titanium oxide sputtering allows you to create an obstacle in the way of thermal solar waves. Outside, such a glass unit has a slight mirror gloss, and from the inside it is transparent like ordinary glass.

The key role of the solar control glass unit:

- Reduces heating of the room by the sun

- Reduces fading of furniture and interior

The solar protection properties of the glass unit are determined by glass with protection against solar energy, which reduces the "solar factor".

Solar factor (solar factor)

denoted in the documentation "g" and indicates the percentage of solar energy passing through the glass unit.

The lower the solar factor, the better sun protection the insulating glass will provide. For example, a solar factor of 40% indicates that only 40% of the solar energy is transmitted by an insulating glass unit.

The value of this parameter is directly related to the degree of protection against ultraviolet radiation. Low sun protection glasses are installed for art spaces to avoid UV fading. Unlike tinted glasses, new generation solar control glasses are transparent to visible light.