Aluminum profile: types

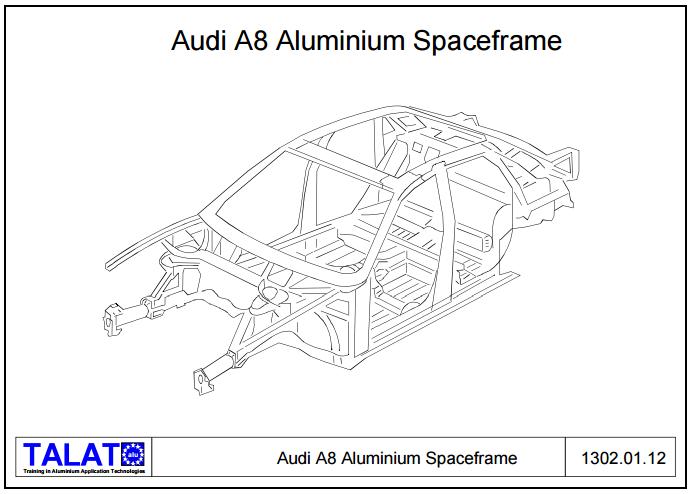

Among the variety of building materials that exist today, aluminum products are especially popular. Their light weight, corrosion resistance and durability have made it possible to create reliable structures that are used in many fields of activity.

One of these materials is an aluminum profile. It is actively used today in construction, in the manufacture of furniture, in aircraft construction and in heavy industry. This aluminum product comes in many different shapes and configurations.

Aluminum profile application and types

Companies that sell aluminum profiles in Moscow today have quite a lot of competition. Therefore, buying this material is not a problem. But often, after purchase, during operation, you can encounter a low quality of the product. To avoid such consequences, it is better to approach the purchase responsibly, and then it will last for many years.

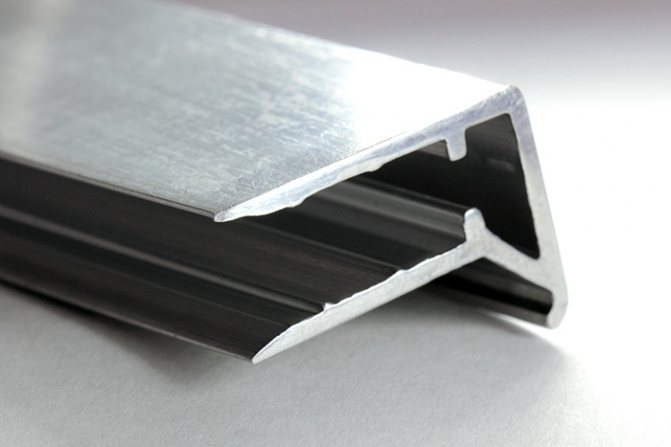

The modern market of the city of Moscow, the aluminum profile is represented by such types as: extruded, bent, rolled.

Each of these species has its own characteristics and has its own properties and purpose. For a decorative profile, the most important characteristic is to have an excellent surface, so that during operation it would please the eyes of others.

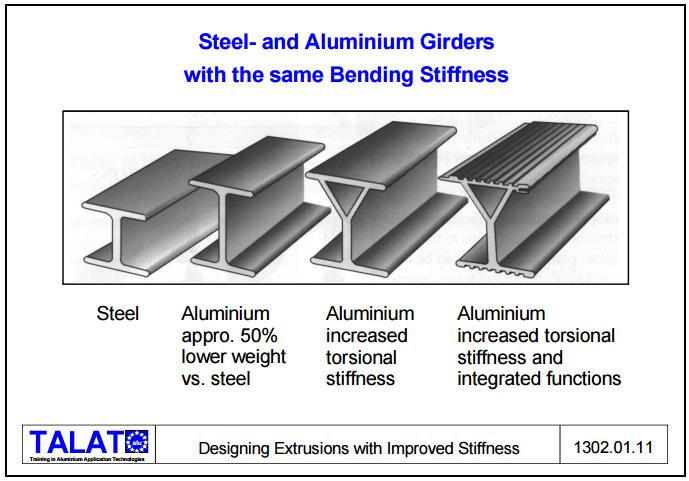

A profile from aluminum is used, as a rule, in elements of various designs. Therefore, during the selection, one must take into account the presence in the material of such characteristics as strength and flexibility.

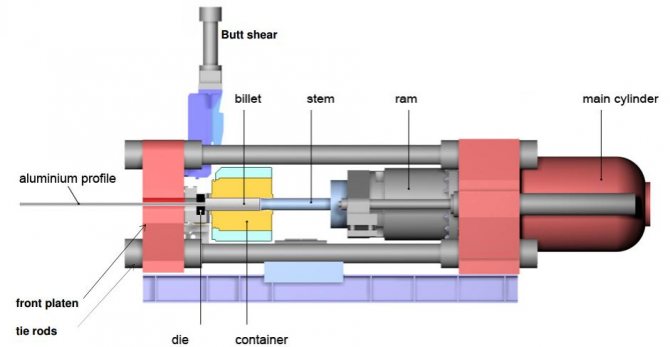

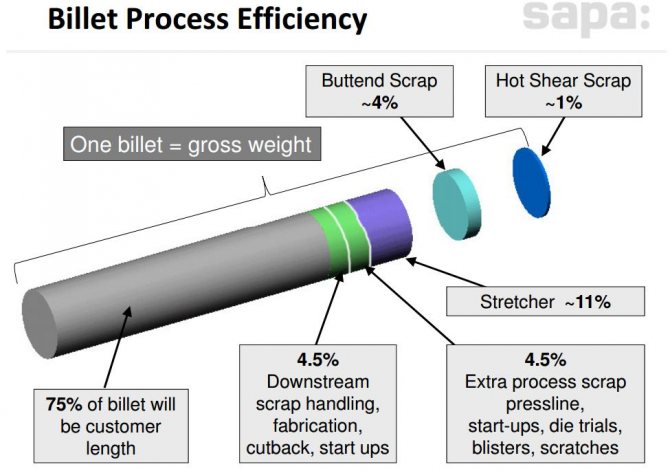

Almost all types of these products are manufactured by the method. This is due to the fact that would satisfy the needs of all kinds of spheres of human life, starting with their use from household products and ending in the space industry.

Depending on the degree of complexity of manufacturing, the product can be made into such categories as rods, standard profiles and simple solid profiles, semi-closed, with complex matrix tongues, pipes, simple, complex and wide hollow profiles.

- products that meet all norms and standards;

- profile of the required size and delivery;

- conditions of cooperation, which are difficult to refuse;

- attractive price;

- obtaining complete information from consultants on issues of interest.

Our pricing policy is aimed at making high quality products at the most affordable cost for the consumer, you get the best quality and price. If necessary, we provide a delivery service to the regions of our entire country.

Aluminum window production technology

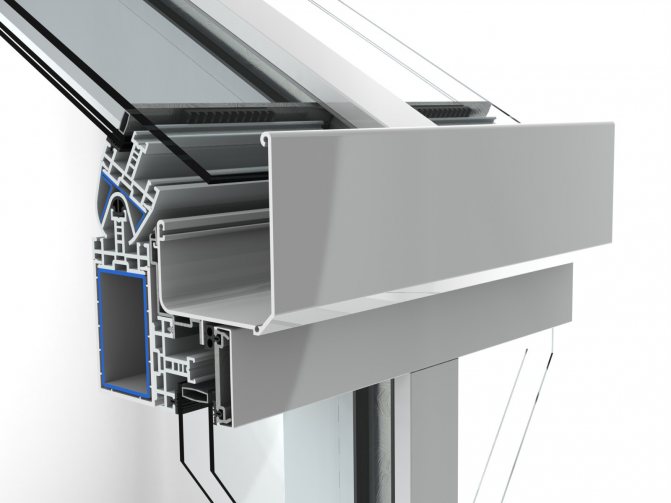

Fig. 11. Window production.

Aluminum windows have a higher price in comparison with PVC profiles due, first of all, to the labor intensity of their production. We will not consider the entire procedure in great detail and technologically meticulously - we will only note its most important stages:

- Aluminum casts are heated in a special oven in order to facilitate work with them;

- A metal profile is cut according to the required dimensions of the customer;

- Milling of the ends of the impost (parts responsible for holding the leaves in the frame) is performed on a special machine;

- All the necessary holes are punched for the fittings and the functioning of the window;

- Special holes are drilled for specific locks and accessories;

- The prepared frame is blown with compressed air to get rid of metal chips and dust;

- The sealant, fittings, handle, fasteners and hinges are installed;

- The corners of the profile are clamped, the seal in the corners is glued;

- The frame and sashes of the window are connected;

- Installation of double-glazed windows is in progress.

If all the characteristics of an aluminum window suit you, and you decide to buy it, in addition to carefully choosing a company, be sure to pay attention to the fact that the price of the profile will depend on:

- Thickness (additional heat and sound absorption comes with additional thickness);

- Components (the window itself will serve you all your life, from time to time you only need to replace the fittings, so it is preferable to immediately choose a high-quality one);

- The number of chambers in a double-glazed window (the more - the quieter and warmer, therefore, choose designs with 4-5 chambers for rooms).

All types of aluminum profiles and their purpose.

Aluminum profiles can have not only a bright glossy, almost mirror-like appearance, but also matte. To provide a profile with a certain type, it is necessary to create a special alloy for each material and actually process it using various methods. The alloy must be processed in a certain way and actually coated with one or another mixture, which emphasizes the matte or gloss.

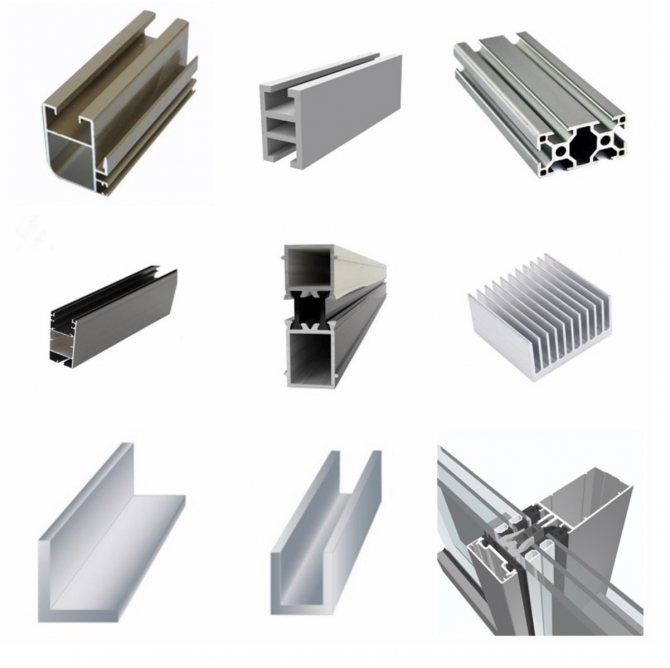

Aluminum profiles in Moscow usually serve as some kind of elements in the construction industry. It may be some kind of material that helps to build supporting structures, while such a material does not require special attention to strength, ductility and others, since it is itself a strong, ductile and stable element. There are several types of aluminum profiles, of which the following stand out:

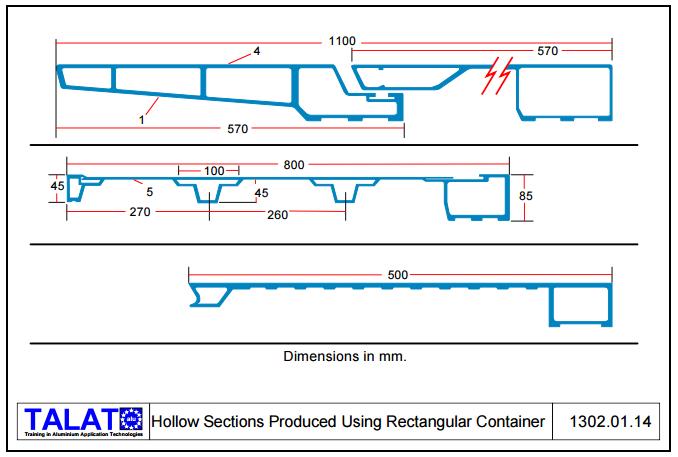

- Hollow profile;

- Solid;

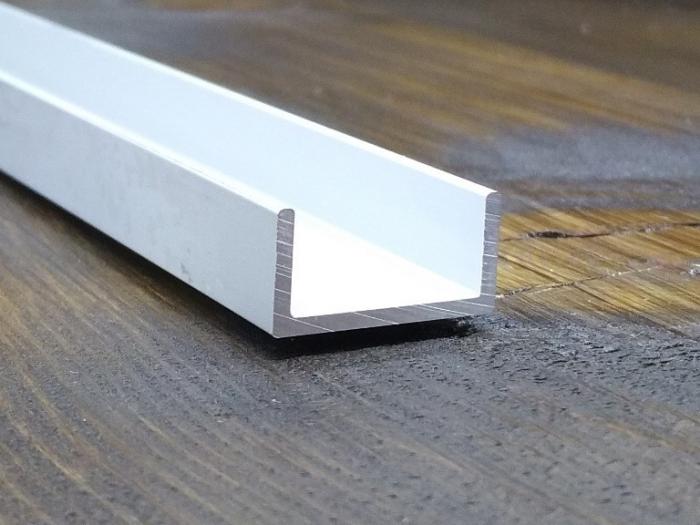

- U-shaped;

- H-shaped;

- w-shaped.

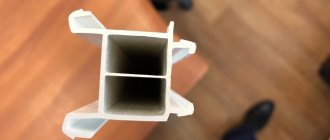

Hollow profiles can be called those materials that have one closed plane in cross-section. Those materials that cannot or do not have a closed plane are highlighted with solid materials. The U-shaped profile has a cross-section and, at a certain angle, forms the letter n. The H-shaped profile is used mainly in the construction industry for the design of facades. Such material helps to create a stable balance and actually give rigidity to the facade. The W-shaped profile can most often be found in furniture production, while the W-shaped shape helps to make wardrobes and many other types of furniture.

The role of aluminum in creating a modern interior

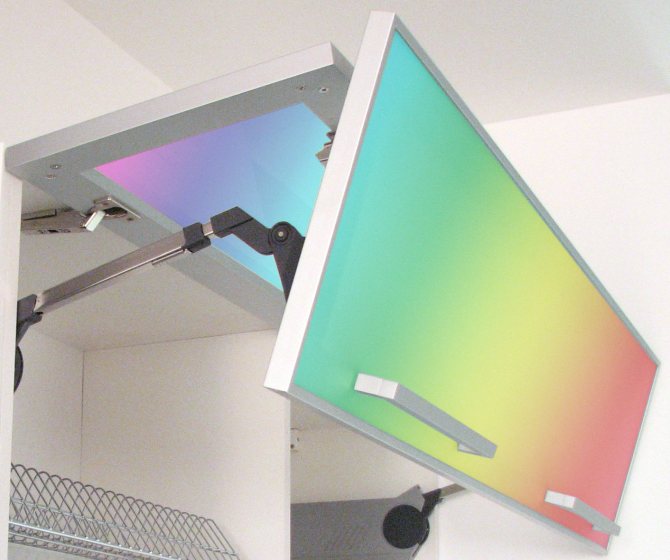

For the kitchen, aluminum facades are a godsend of designers and designers of furniture sets. Fashionable styles minimalism, loft and techno give preference to materials with a silver and mirrored surface. The kitchens have a small area, cluttered with furniture and equipment. Such facades can be easily washed, do not change color when hot fat and steam get in. Resistant to moisture and acid, metal is indispensable for creating kitchen hoods, fittings and frames for shower doors. Sliding wardrobes with aluminum facades look great and are comfortable. The frame profile holds the canvas. The H-shaped dividing element stiffens the door and allows you to combine materials.

Furniture design increasingly uses a combination of aluminum and glass

Furniture design is increasingly using a combination of aluminum and glass. This is not only a setting for the kitchen, but also a stylish table in the hall, shelves for decorative decoration and a bedside table for books, a mirror frame in the hallway and bathroom. The interior is a continuation of the building's facade. He must be in harmony with him. Therefore, an office located behind a beautiful facade should look modern. This requires an aluminum profile.

Related article: What does the roof truss system look like with a valley?

The best posts

- Fascinating female hobby

- Girlish grapes on the balcony: growing technology (photo)

- Elastic band on a bunch of kanzashi: a master class with photos and videos

- Screed thickness for a water-heated floor: how to fill a warm water floor with your own hands

- Decorating interior doors with your own hands: coating options

- Interior of an American Art Nouveau house in the USA

- [Plants in the house] Gemantus: growing secrets

- Stained glass (drawing): how to draw on glass and on paper in stages from a photo

Advantages of aluminum facade structures

Among the most important advantages of aluminum facade structures, it should be noted:

Dynamic façade created by aluminum construction

- absolute safety, realized in practice due to the unique properties of the aluminum edge, which has left far behind all its "competitors";

- Versatility of use. Thanks to technological innovations underlying the production of aluminum facades, structures can be used in the implementation of any architectural solution;

- The aluminum profile can be made in any color scheme. The same applies to glass tinting. This state of affairs gives a lot of scope for the implementation of the most intricate design ideas and fantasies;

- A pleasant bonus to the aluminum facade will be the possibility of applying various technical innovations. We are talking about the possibility of installing swing windows and doors, sliding window sashes with an electric motor, opening and closing mechanisms, etc.

- A variety of technological solutions (the choice of the type of structures or their combination is possible: post-transom, semi-structural or structural facades).

Read more about the types of stained glass systems for the facade and find answers to your questions.

Dynamic façade in action

What is an aluminum profile. specialized aluminum profile

5.32.3 specialized aluminum profile: Architectural aluminum profile reinforced with alloy steel inserts and used for the manufacture of window and door protective structures

Dictionary-reference book of terms of normative and technical documentation. academic.ru. 2015.

- MPEG Profile -2

- archive profile

normative_reference_dictionary.academic.ru

an aluminum profile is ... What is an aluminum profile?

aluminum pishin

Russian-Kazakh terminological dictionary "Architecture and construction". - Academy of Pedagogical Sciences of Kazakhstan .. 2014.

- profile

- city profile

See what "aluminum profile" is in other dictionaries:

building_rus_kaz.academic.ru

specialized aluminum profile Architectural aluminum profile, reinforced with alloy steel inserts and used for the manufacture of window and door protective structures.

Topics

facility security and safety systems

Technical translator's guide. - Intent. 2009-2013.

- subscriber profile when roaming

- burner embrasure profile (boiler furnace)

What other varieties exist

Among other things, the aluminum profile can differ in the following indicators:

- Sectional shape. Profiles are either hollow or solid.

- By the correctness of the geometric dimensions. In this regard, products are distinguished with normal, increased and special accuracy.

- In terms of quality indicators. In construction and in the creation of various kinds of architectural elements, both cold and warm aluminum profiles can be used.

Aluminum facades of Elion

Since 2006, Elion LLC has been introducing bent aluminum facade profiles (or) to the customer's size into the serial flow.

The radius of aluminum facades has three main standards.

Products can be narrow and wide aluminum profiles for different inserts of 4 mm.

Aluminum facades "Elion" can be used in sliding doors both in furniture and in stained glass, door structures, doors of sliding wardrobes, including monolithic, interior partitions.

According to our experts, a sliding door from "Elion" saves the manufacturer up to $ 45 per item per square meter. Thus, our new aluminum facades and structures represent a broad competition for manufacturers of facades for sliding wardrobes.

But really - why pay more if the door of the same size can be assembled by paying less money, lightening weight and saving time, which is becoming more and more precious these days.

Recently, aluminum interior doors and office partition structures have been very popular. The aluminum facades of our company can also show themselves here on a full scale solely because of their technological and decorative advantages over their counterparts.

Aluminum facades are becoming simply an indispensable element of the interior today, which is appreciated by our customers, among which, unfortunately, foreign capital firms, joint ventures and foreign companies prevail.

Obviously, a lot more time must pass to change the views of Russian furniture makers on stained glass structures and facade execution on the domestic market in parallel with the products used by foreign companies.

At the moment, profiles for facades have become especially in demand on the part of firms engaged in shop structures, commercial equipment and display panels, which especially emphasizes versatility

of our

aluminum facades

.

Particularly interesting is the variant of using an aluminum facade profile in the "Spider system" of stained glass partitions.

Aluminum facades can also be widely used in advertising activities and profiles for advertising screens and partitions.

The quality of the facade aluminum coating is guaranteed by certificates and 15-micron anodizing capable of hiding light scratches and mechanical damage.

Up to 14 types of glass and more than 18 types of colored poly-glass are offered as a front insert, it is possible to insert 4-mm MDF or plastic.

Aluminum facade profiles "Elion" are subdivided into three main types according to their varieties:

- Wide

- Narrow or square

- Clip system or DIY system

Wide aluminum fronts are used from complex and large structures to ordinary kitchen fronts, their standard size is 20 * 45. Their shape allows you to attach almost all types of handles through the profile, without damaging the glass. The used connecting angle is 7019.

Narrow aluminum facades are limited by the strict use of special hinges and have a size of 20 * 20.

The clip system includes both narrow and wide profiles, combining them through a structural innovation - the absence of a back wall, which makes it possible to connect profiles without milling for hinges. But here it is necessary to remember that this convenience entails the need to purchase special hinges, a special seal and possibly special adapters for additional closers.

In a word, everything that you can find in "Elion" on aluminum facades you cannot find in a separate organization, and everything that you can find in one of the existing specialized companies you can also find in our company.

The most popular fillers for kitchen facades

- Glass, and most often a special tempered version is used. Tempered glass can withstand a fairly strong direct impact and has excellent performance characteristics.

- Plastic, despite the seeming impracticality. Such facades are easy to clean and can withstand a long service life without significant losses. A significant advantage of plastic is its affordable cost.

- Fiber boards: chipboard, laminated chipboard and MDF.The last variety is characterized by maximum strength and quality of the coating. You can make such facades with your own hands, and only then make a frame from an aluminum profile fixed along the edge.

Wide range of aluminum fronts

An important component will also be high-quality fasteners for the door opening mechanism. By the type of device, there are hinge hinges, closers-shock absorbers and roller guides

Each of these mounts has both advantages and disadvantages in use.

How is it used

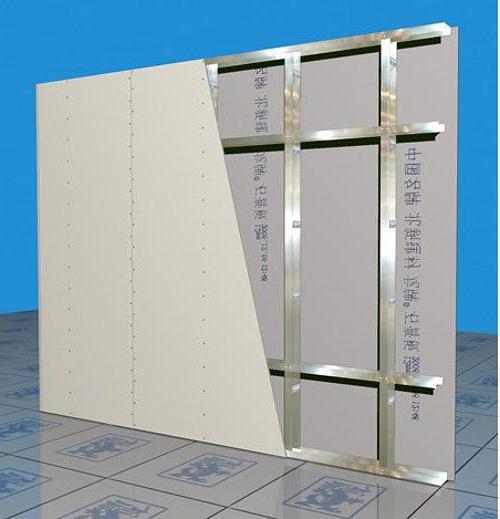

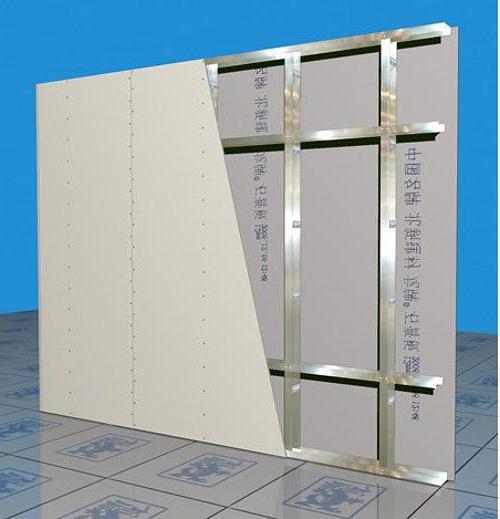

Thus, a wide range of applications is what characterizes the aluminum profile. All types of profiles of this type, as already mentioned, are distinguished by a rather high degree of strength. Therefore, this material is most often used for the assembly of load-bearing frames, which are subsequently sheathed with not particularly heavy materials. For the installation of all kinds of critical structures, steel products of this group are most often used. In most cases, an aluminum profile frame is used to support sheets of drywall, plywood, siding and plastic panels.

Facade structures made of aluminum profile typology and design features

Facade aluminum structures are very diverse. Let's consider the main ones:

Post-transom and semi-structural facades

- The post-transom facade is rightfully considered the most durable and reliable among other types of aluminum facades. However, it also has its own rather significant drawback: a rather laconic appearance. The facade of this type has the appearance of a glass cube, because the design features of the profile allow glass only in the shape of a rectangle and nothing else.

- The semi-structural facade has structural differences from the post-transom aluminum facade. With this type of construction, all bearing racks are located inside the building, outside there is only a clamping mechanism that holds the glass unit. Such a design is somewhat more expensive than a post-transom facade, however, due to the variety of design options, its aesthetic properties exceed their "competitor" by an order of magnitude.

- The structural façade is structurally similar to the semi-structural façade type. The main difference from the latter is the method of fastening the glass unit. The glass is not attached to a special metal element, but with a special sealant. In terms of its strength characteristics, it is in no way inferior to a semi-structural facade, and in aesthetics it wins significantly.

Appointment

Various systems of aluminum profiles are used for the manufacture of translucent structures, external and internal fences, partitions in public, residential and industrial buildings, as well as in the construction of industrial enterprises, shopping malls. Windows of various configurations, balcony glazing, entrance groups for external / internal opening, pendulum or revolving type, facade structural or semi-structural glazing - these are the main areas of application of various systems of aluminum profiles

Steel profiles for ventilated facades

Ventilated facades have recently attracted more and more attention from manufacturers of curtain walls and trade and exhibition structures. Modern slabs, as well as panels of different materials, which are fixed to steel profiles for ventilated facades, make it possible to give the building an original and attractive look with the help of external finishing.

A variety of textures, ergonomics and ease of installation allow finishing work in the shortest possible time. To get a venfasad, you need to select and install the elements of the substructure, which is the basis.The aesthetics, durability and reliability of the building depend on its components. The profiles for the ventilation façade already mounted on the wall of the building are called substructures. Considering the state of the environment and the required service life, profiles, in addition to galvanized steel, are also produced from aluminum alloys, stainless steel, as well as steel, which is powder-coated.

Modern slabs and panels made of different materials, which are fixed to steel profiles for ventilated facades, make it possible to give the building an original and attractive look with the help of external finishing. A variety of textures, ergonomics and ease of installation allow finishing work in the shortest possible time. To get a venfasad, you need to select and install the elements of the substructure, which is the basis. The aesthetics, durability and reliability of the building depend on its components. The profiles for the ventilation façade already mounted on the wall of the building are called substructures. Taking into account the state of the environment and the required service life, profiles, in addition to galvanized steel, are also produced from aluminum alloys, stainless steel, as well as steel, which is powder-coated.

The main purpose that the profile for the ventilation facade must fulfill is to reliably hold the facade slabs and thermal insulation, while ensuring normal natural ventilation. For fastening plates, in addition to profiles, additional fixtures are also used: brackets, clamps and fastening hardware. All of them must have sufficient bearing capacity that would allow them to withstand dynamic and static loads for a long time, not corrode and eliminate the detected irregularities of the facade walls. Steel profiles for ventilated facades https://veknew.ru/ventiliruemye-fasady.html are selected depending on the types of facing materials. For the profile, we mainly use galvanized steel grade 08ps with different methods of finishing in accordance with GOST 14918-80.

Substructures are divided into three types according to the method of positioning the profiles:

- vertical. They are T-shaped profiles that are attached to the load-bearing walls in a vertical position. Facade cassettes, ceramic stone, siding and corrugated board are attached to the walls with the help of such structures;

- horizontal. In this case, U-, L- and Z-shaped profiles are used that are located on the walls in a horizontal position. Profiled sheeting or linear panels are attached to these horizontal elements;

- combined (cross). These profiles have a Z-, L-, U- and T-shape and are attached to the walls so that square gratings are formed on them. With the help of combined structures, facades are clad with facade cassettes or porcelain stoneware.

Consumer opinion

Good reviews from the owners of houses and apartments are rightfully deserved by such material as an aluminum profile. All types of profiles are extremely popular with consumers. Ease of installation, excellent performance, low cost - these are the main reasons for the demand for such products. Most often, the profile is used when performing repair work. As a basis for internal and external wall cladding, according to most owners of houses and apartments, the aluminum profile is just perfect.

Aluminum profile advantages and types of Electrician, Plumbing

Introduction

The aluminum profile is considered the most modern, demanded and multifunctional building material. It is used to produce durable, lightweight structures. The aluminum profile is used for building facades, balconies, doors, windows, railings, gates, glazing, partitions, trade equipment, etc.

Aluminum profile, advantages

Among the advantages of this building material, it is worth noting:

- Ease. Since the production uses aluminum and aluminum alloys.

- Strength. The aluminum profile is many times stronger than PVC and wood.

- Resistant to fire, twisting, oxidation.

- Resistant to temperature extremes.

- The material does not crack.

- The aluminum profile is environmentally friendly and completely harmless to health.

- Installing it is easy enough. It is also easy to maintain.

- Resistance to negative environmental influences.

- Since the facade profile is covered with a special paint, the material is not subject to corrosion.

- Reliability, withstands heavy loads.

- High quality.

- Affordable price.

Types of aluminum profiles

Today there are different types of aluminum profiles. There are systems that are characterized by high resistance to heat transfer. And there are fire-resistant profiles for expansion joints. There is also a frame aluminum profile for glass on the market. Primary aluminum alloy is used in its production. And the addition of magnesium and silicon improves the performance of the structure. There is a profile for expansion joints.

Aluminum profile for building facades can be painted in any color. It is produced as a standard white color, and can have an anodic coating or decoration, painting according to the RAL table. Together with the aluminum profile for glass, you can purchase the necessary fittings and components. For example, hinges, locks, seals, tilt-and-turn mechanisms, handles, corner joints, etc.

With the help of an aluminum profile, walls can be finished with stone, porcelain stoneware, panels. For cladding of any level of complexity, an aluminum profile for glass facades with triplex or tempered heavy-duty glass is used. Such material is not only unpretentious and durable, but also attractive in appearance. Profile aluminum systems make it possible to dispense with standard windows and walls. Therefore, it is better to give preference to the aluminum profile. For an affordable cost, you get high quality products.

Interregional aluminum company translucent structures for various purposes with a guarantee

We carry out glazing of facades of shops, supermarkets, banks, business centers and other structures, as well as manufacture various translucent structures: vestibules, showcases, rotundas, bay windows, office partitions and much more. In the production and installation of translucent structures, we use high-quality building materials, as well as high-tech Italian and German equipment.

The main metal used for glazing is aluminum. Glazing of facades using PVC profiles is permissible only for structures with a height of no more than 2,500 mm. In all other cases, the advantages of using aluminum to create translucent structures are obvious: this metal is durable, strong and fireproof. In addition to excellent technical characteristics, aluminum facades are distinguished by ease of assembly and excellent appearance.

Interregional Aluminum Company performs facade glazing using the following profile systems: Reynaers (Belgium), Newtec (Italy), Tatprof and AGS (Russia).

The accumulated work experience allows us to give the following production assessment to some systems: Tatprof TP-50300 is a high-quality system with which it is possible to glaze both vertical and inclined facades. It is also used to create single and gable roofs. It is equipped with a drainage system to remove moisture to the outside, which prevents the formation of ice and, as a result, increases the service life of the structure. Translucent structures of the Tatprof system are recognized as the best aluminum facade system in Russia, which is confirmed by the certificate of the State Construction Committee of the Russian Federation No. 00018040.AGS-500 is a new promising facade system that allows to erect structures of any complexity with the ability to install infills with a thickness of 4 to 46 mm. The system uses a three-level system for draining condensate and moisture penetrating from the seam area of the double-glazed window. The system is designed for the manufacture of curtain wall enclosures of buildings, vertical and inclined translucent facades. Various opening elements can be inserted into the facade structures: doors, windows, smoke exhaust systems, etc. Reynaers CW-50 is an elite Belgian facade system. Here you can find a solution to almost all problems arising in the design of translucent facades. A large selection of front posts with a depth from 60 to 316 mm allows the manufacture of structures with a maximum horizontal step, and the availability of accessories for relieving the load from the crossbar from the weight of the glass unit makes it possible to install large dimensions in the filling system. Also in the arsenal of the system there are racks and transoms Slim (with a narrow body), which can be used to improve the appearance of the interior decoration of the abutments. With the CW-50 it is possible to produce structural and semi-structural translucent facades with integrated windows and recessed doors. A special feature is parallel-sliding windows (the leaf of the sash extends outward parallel to the facade line).

The professionalism and high level of knowledge of our specialists, as well as the use of modern software systems Auto CAD, Sheet Metal Design, ProfStroy and Win Frame 3D, allow us to design translucent structures of any complexity. We provide a guarantee for all aluminum facades and translucent structures, as well as provide post-warranty service.

Energy-saving and soundproofing capabilities of insulating glass units with various insulation options

Applicability of double-glazed windows in facade structures:

| ENERGY SAVING AND SOUND INSULATION CAPABILITIES OF GLASS PANELS WITH DIFFERENT INSULATION OPTIONS | |||

| Glass unit type | Condensation temperature (dew point) | Sound insulation class | Scope of application |

| Simple single chamber | - 8 ° C | 2 | Standard thermal insulation properties |

| Simple two-chamber | - 18 ° C | 3 | Houses on a busy city highway, good thermal insulation properties |

| Double chamber + krypton | - 29 ° C | 4 | Houses located in areas of high background noise (near airports, etc.), in cold areas |

| Single chamber + K-glass | - 30 ° C | 2 | Open location of residential buildings in cold areas |

| Double chamber + K-glass | - 39 ° C | 3 | Houses on a busy city highway, increased thermal insulation properties. |

| Double chamber + K-glass + argon | - 112 ° C | 4 | Houses in extreme climatic conditions, with an increased background noise (for example, near the Plisetsk cosmodrome) |