Designing and thermal calculation of a heating system is an obligatory stage in the arrangement of heating a house. The main task of computing activities is to determine the optimal parameters of the boiler and the radiator system.

You must admit that at first glance it may seem that only an engineer can do a heat engineering calculation. However, not everything is so complicated. Knowing the algorithm of actions, it will turn out to independently perform the necessary calculations.

The article describes in detail the calculation procedure and provides all the necessary formulas. For a better understanding, we have prepared an example of thermal calculation for a private house.

Norms of temperature regimes of premises

Before carrying out any calculations of the parameters of the system, it is necessary, at a minimum, to know the order of the expected results, as well as to have available standardized characteristics of some tabular values that must be substituted in the formulas or be guided by them.

Having performed calculations of parameters with such constants, one can be sure of the reliability of the sought dynamic or constant parameter of the system.

For premises for various purposes, there are reference standards for the temperature regimes of residential and non-residential premises. These norms are enshrined in the so-called GOSTs.

For a heating system, one of these global parameters is the room temperature, which must be constant regardless of the season and ambient conditions.

According to the regulation of sanitary standards and rules, there are differences in temperature relative to the summer and winter seasons. The air conditioning system is responsible for the temperature regime of the room in the summer season, the principle of its calculation is described in detail in this article.

But the room temperature in winter is provided by the heating system. Therefore, we are interested in the temperature ranges and their tolerances for the deviations for the winter season.

Most regulatory documents stipulate the following temperature ranges that allow a person to be comfortable in a room.

For non-residential premises of an office type with an area of up to 100 m2:

- 22-24 ° C - optimal air temperature;

- 1 ° C - permissible fluctuation.

For office-type premises with an area of more than 100 m2, the temperature is 21-23 ° C. For non-residential premises of an industrial type, the temperature ranges differ greatly depending on the purpose of the premises and the established labor protection standards.

Each person has their own comfortable room temperature. Someone likes it to be very warm in the room, someone is comfortable when the room is cool - this is all quite individual

As for residential premises: apartments, private houses, estates, etc., there are certain temperature ranges that can be adjusted depending on the wishes of the residents.

And yet, for specific premises of an apartment and a house we have:

- 20-22 ° C - living room, including children's room, tolerance ± 2 ° С -

- 19-21 ° C - kitchen, toilet, tolerance ± 2 ° С;

- 24-26 ° C - bathroom, shower, swimming pool, tolerance ± 1 ° С;

- 16-18 ° C - corridors, hallways, staircases, storerooms, tolerance + 3 ° С

It is important to note that there are several more basic parameters that affect the temperature in the room and which you need to focus on when calculating the heating system: humidity (40-60%), the concentration of oxygen and carbon dioxide in the air (250: 1), the speed of movement of air mass (0.13-0.25 m / s), etc.

Calculation of heating devices

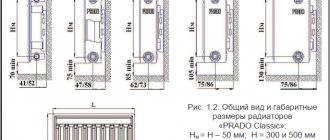

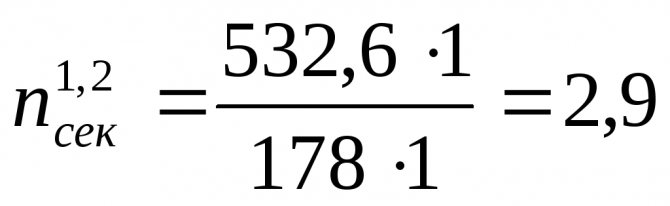

- Heater type - sectional cast iron radiator MS-140-AO;

Nominal conditional heat flux of one element of the device Qн.у. = 178 W;

Length of one device element l

= 96 mm.

St14

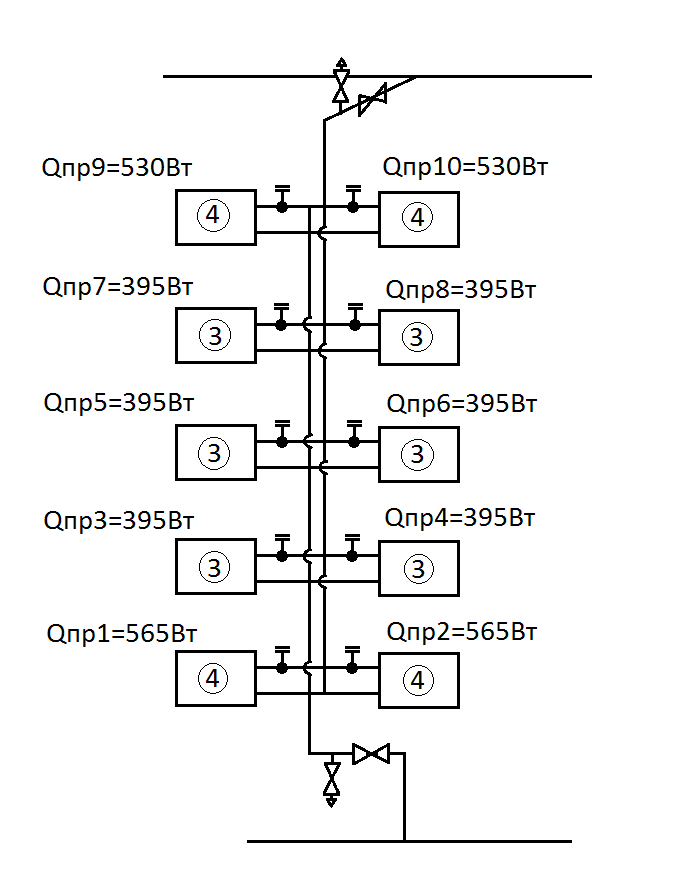

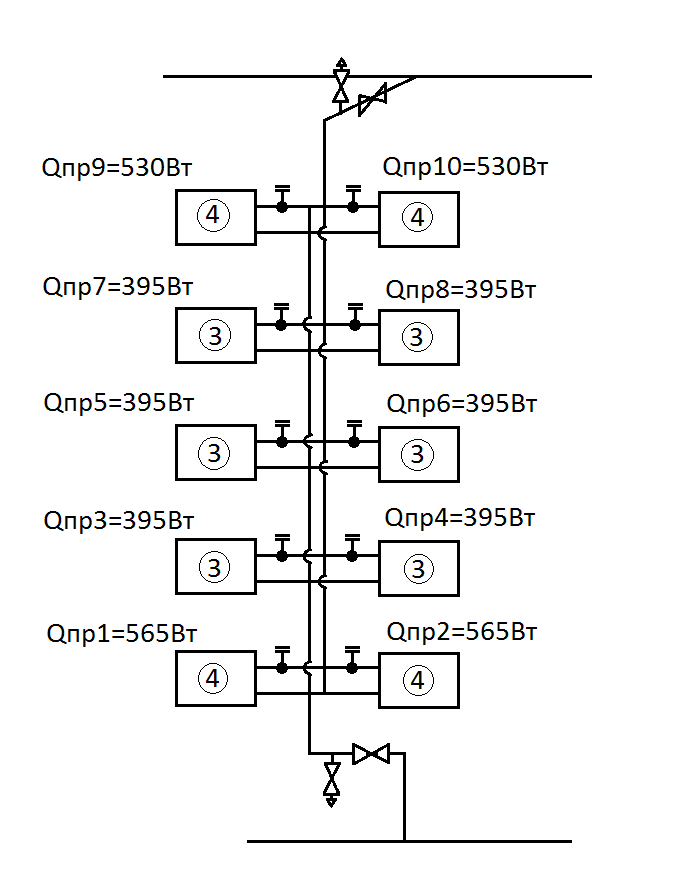

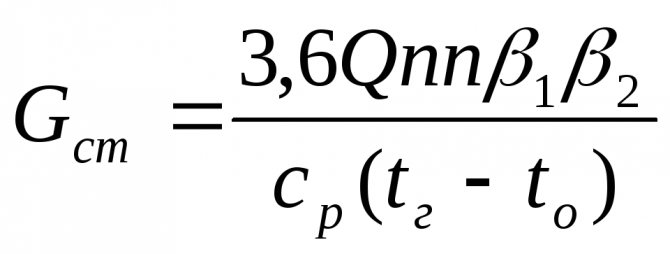

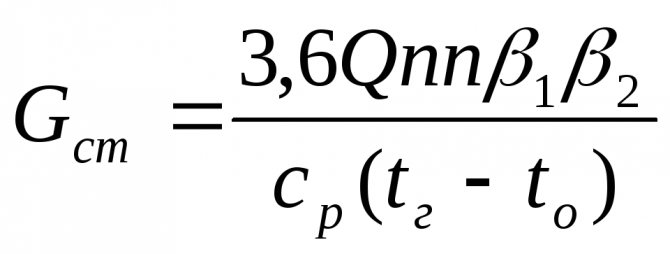

2) Mass water flow:

where cf is the specific heat capacity of water (= 4.19 kJ / kg ° C);

tg and to - water temperatures at the inlet to the riser and at the outlet from it;

β1 is the coefficient of accounting for the increase in the heat flow of installed heating devices as a result of rounding the calculated value upward;

β2 - coefficient of accounting for additional heat losses of heating devices at external fences.

- Average water temperature in each riser device:

tav = 0.5 *

=0,5* (105 + 70) = 87,5

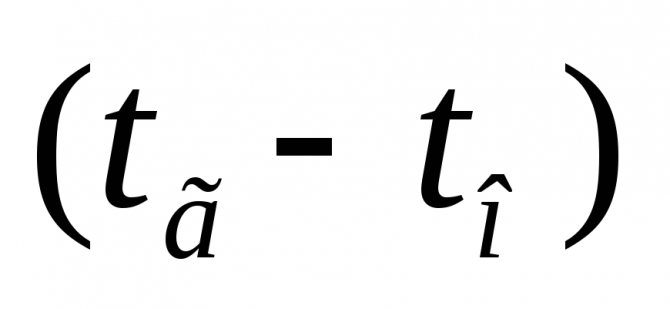

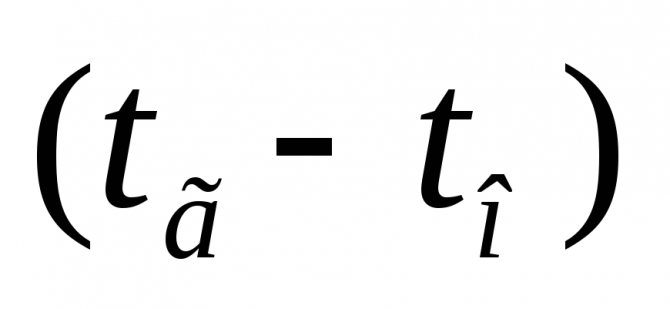

3) Difference between the average temperature of the water in the device and the air temperature in the room:

∆tav = tav - tint

∆tav = 87.5 - 23 = 64.5 ° C

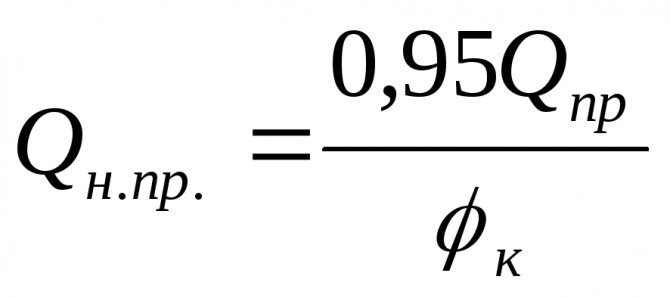

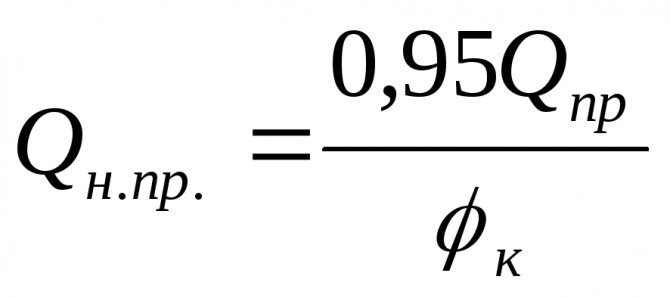

4) Required nominal heat flux

Where

to - complex coefficient of reduction Qn.pr. to design conditions

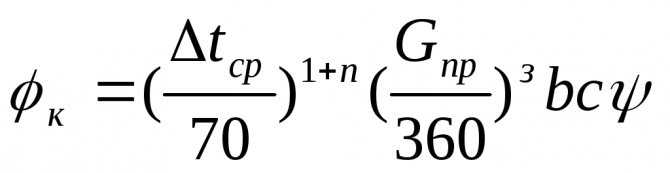

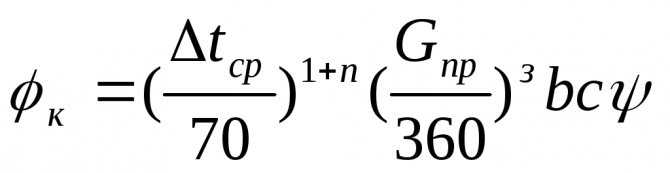

where n, p and c are values corresponding to a certain type of heating devices

b - coefficient of accounting for atmospheric pressure in a given area

ψ - coefficient of accounting for the direction of movement of the coolant in the device

For a one-pipe water heating system, the mass water flow passing through the calculated device Gpr, kg / h

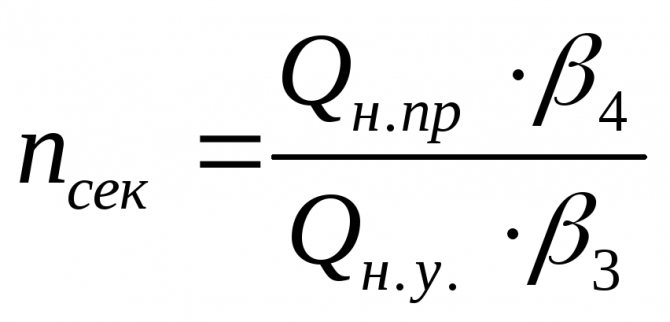

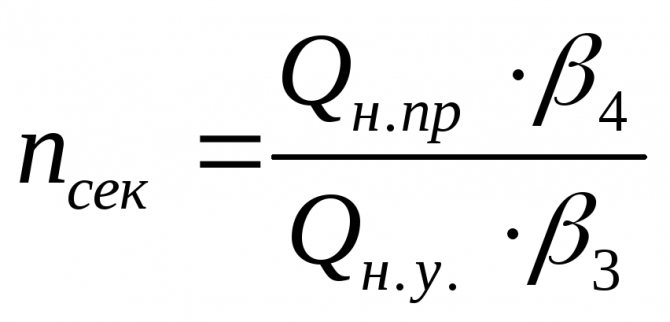

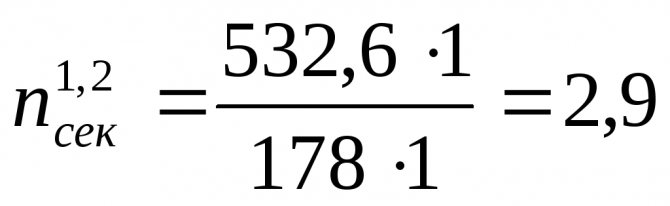

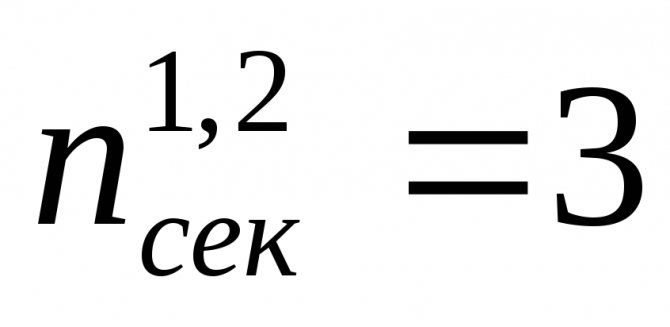

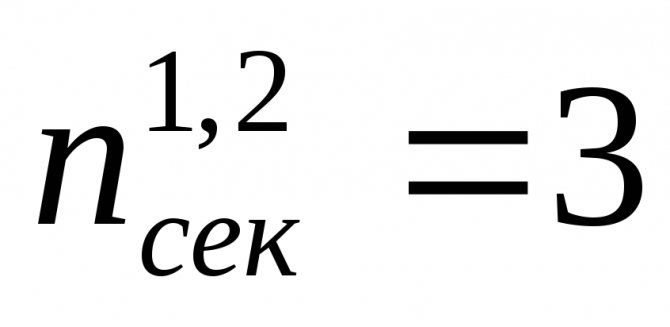

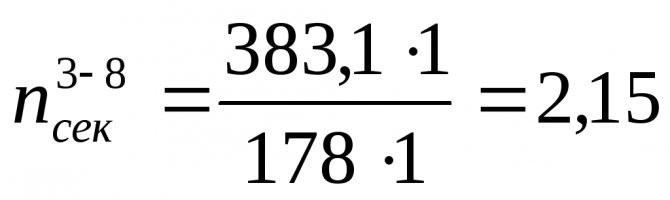

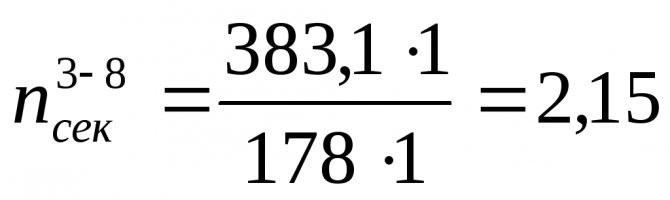

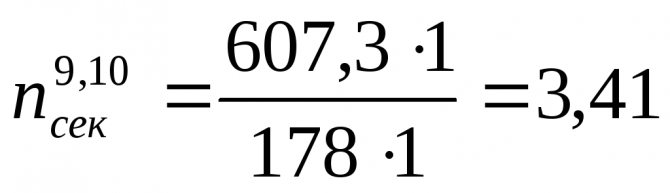

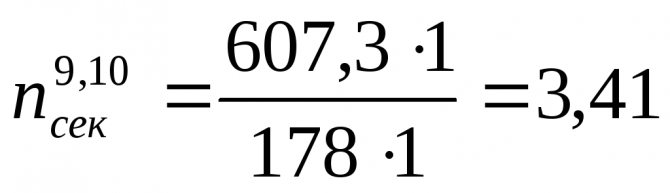

5) Minimum required number of heater sections:

where

4

- correction factor, taking into account the method of installation of the device, with an open installation of the device 4 = 1.0; 3 - correction factor taking into account the number of sections in the device, taken at an approximate value

(for nsec> 15).

,

;

,

;

,

.

Calculation of heat loss in the house

According to the second law of thermodynamics (school physics), there is no spontaneous transfer of energy from less heated to more heated mini- or macro-objects. A special case of this law is the “striving” to create temperature equilibrium between two thermodynamic systems.

For example, the first system is an environment with a temperature of -20 ° C, the second system is a building with an internal temperature of + 20 ° C. According to the above law, these two systems will strive to balance through the exchange of energy. This will happen with the help of heat losses from the second system and cooling in the first one.

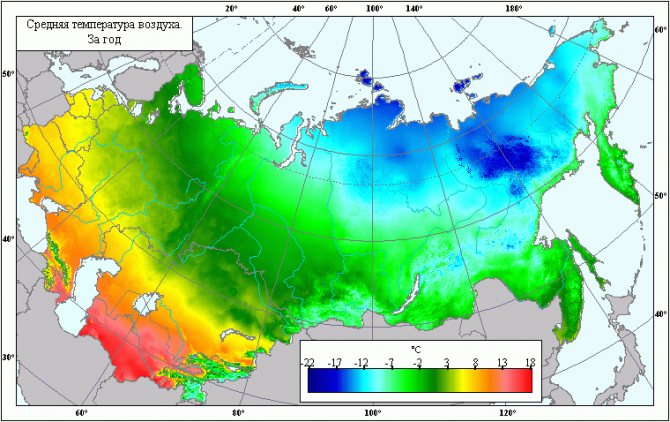

It can be said unambiguously that the ambient temperature depends on the latitude at which the private house is located. And the temperature difference affects the amount of heat leaks from the building (+)

Heat loss means the involuntary release of heat (energy) from some object (house, apartment). For an ordinary apartment, this process is not so "noticeable" in comparison with a private house, since the apartment is located inside the building and is "adjacent" to other apartments.

In a private house, heat “escapes” to one degree or another through the outer walls, floor, roof, windows and doors.

Knowing the amount of heat loss for the most unfavorable weather conditions and the characteristics of these conditions, it is possible to calculate with high accuracy the power of the heating system.

So, the volume of heat leaks from the building is calculated using the following formula:

Q = Qfloor + Qwall + Qwindow + Qroof + Qdoor +… + Qiwhere

Qi - the volume of heat loss from the uniform appearance of the building envelope.

Each component of the formula is calculated by the formula:

Q = S * ∆T / Rwhere

- Q - thermal leaks, V;

- S - area of a specific type of structure, sq. m;

- ∆T - temperature difference between ambient and indoor air, ° C;

- R - thermal resistance of a certain type of structure, m2 * ° C / W.

The very value of thermal resistance for actually existing materials is recommended to be taken from auxiliary tables.

In addition, thermal resistance can be obtained using the following ratio:

R = d / kwhere

- R - thermal resistance, (m2 * K) / W;

- k - coefficient of thermal conductivity of the material, W / (m2 * K);

- d Is the thickness of this material, m.

In older houses with a damp roof structure, heat leakage occurs through the top of the building, namely through the roof and attic. Carrying out measures for warming the ceiling or thermal insulation of the attic roof solve this problem.

If you insulate the attic space and the roof, then the total heat loss from the house can be significantly reduced.

There are several other types of heat loss in the house through cracks in structures, a ventilation system, a kitchen hood, opening windows and doors. But it makes no sense to take into account their volume, since they make up no more than 5% of the total number of main heat leaks.

Calculation formula

Heat energy consumption standards

Heat loads are calculated taking into account the power of the heating unit and the heat losses of the building. Therefore, in order to determine the power of the designed boiler, it is necessary to multiply the heat loss of the building by a multiplying factor of 1.2. This is a kind of reserve equal to 20%.

Why is such a coefficient necessary? With its help you can:

- Predict the drop in gas pressure in the pipeline. After all, in winter there are more consumers, and everyone tries to take more fuel than others.

- Vary the temperature regime inside the house.

We add that heat losses cannot be evenly distributed throughout the entire building structure. The difference in indicators can be quite large. Here are some examples:

- Up to 40% of the heat leaves the building through the outer walls.

- Through floors - up to 10%.

- The same is true for the roof.

- Through the ventilation system - up to 20%.

- Through doors and windows - 10%.

Materials (edit)

So, we figured out the structure of the building and made one very important conclusion that the heat losses that need to be compensated depend on the architecture of the house itself and its location. But much is also determined by the materials of the walls, roof and floor, as well as the presence or absence of thermal insulation.

This is an important factor.

For example, let's define the coefficients that reduce heat loss, depending on the window structures:

- Ordinary wooden windows with ordinary glass. To calculate heat energy in this case, a coefficient equal to 1.27 is used. That is, through this type of glazing, thermal energy leaks, equal to 27% of the total.

- If plastic windows with double-glazed windows are installed, a factor of 1.0 is used.

- If plastic windows are installed from a six-chamber profile and with a three-chamber double-glazed unit, then a coefficient of 0.85 is taken.

We go further, dealing with the windows. There is a definite connection between the area of the room and the area of the window glazing. The larger the second position, the higher the heat loss of the building. And here there is a certain ratio:

- If the area of the windows in relation to the floor area has only a 10% indicator, then a coefficient of 0.8 is used to calculate the heat output of the heating system.

- If the ratio is in the range of 10-19%, then a factor of 0.9 is applied.

- At 20% - 1.0.

- At 30% —2.

- At 40% - 1.4.

- At 50% - 1.5.

And that's just the windows. And there is also the influence of the materials used in the construction of the house on the thermal loads. We place them in the table, where the wall materials will be located with a decrease in heat losses, which means that their coefficient will also decrease:

| Type of building material | Coefficient |

| Concrete blocks or wall panels | 1.25 to 1.5 |

| Wooden blockhouse | 1,2 |

| One and a half brick wall | 1,5 |

| Two and a half bricks | 1,1 |

| Foam concrete blocks | 1,0 |

As you can see, the difference from the materials used is significant. Therefore, even at the design stage of a house, it is necessary to determine exactly what material it will be built from. Of course, many builders are building a home based on the construction budget. But with such layouts, it is worth revising it. Experts assure that it is better to invest initially in order to subsequently reap the benefits of savings from the operation of the house.Moreover, the heating system in winter is one of the main expense items.

Sizes of rooms and number of storeys of the building

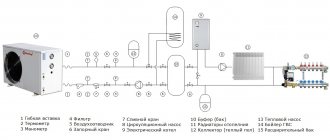

Heating system diagram

So, we continue to understand the coefficients that affect the heat calculation formula. How does the size of the room affect the heat load?

- If the height of the ceilings in your house does not exceed 2.5 meters, then a factor of 1.0 is taken into account in the calculation.

- At a height of 3 m, 1.05 is already taken. A slight difference, but it significantly affects heat losses if the total area of the house is large enough.

- At 3.5 m - 1.1.

- At 4.5 m –2.

But such an indicator as the number of storeys of a building affects the heat loss of a room in different ways. Here it is necessary to take into account not only the number of floors, but also the place of the room, that is, on which floor it is located. For example, if this is a room on the first floor, and the house itself has three to four floors, then a coefficient of 0.82 is used for the calculation.

As you can see, in order to accurately calculate the heat loss of a building, you need to decide on various factors. And all of them must be taken into account. By the way, we have not considered all the factors that reduce or increase heat losses. But the calculation formula itself will mainly depend on the area of the heated house and on the indicator, which is called the specific value of heat losses. By the way, in this formula it is standard and equal to 100 W / m². All other components of the formula are coefficients.

Determination of boiler output

To maintain the temperature difference between the environment and the temperature inside the house, an autonomous heating system is needed that maintains the desired temperature in every room of a private house.

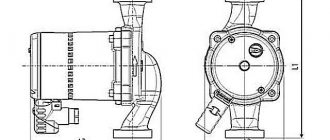

The basis of the heating system is different types of boilers: liquid or solid fuel, electric or gas.

The boiler is the central unit of the heating system that generates heat. The main characteristic of the boiler is its power, namely the rate of conversion of the amount of heat per unit of time.

Having made calculations of the heat load for heating, we will obtain the required rated power of the boiler.

For an ordinary multi-room apartment, the boiler power is calculated through the area and specific power:

Rboiler = (Sroom * Rudelnaya) / 10where

- S rooms- the total area of the heated room;

- Rudellnaya- power density relative to climatic conditions.

But this formula does not take into account heat losses, which are sufficient in a private house.

There is another relationship that takes this parameter into account:

Рboiler = (Qloss * S) / 100where

- Rkotla- boiler power;

- Qloss- heat loss;

- S - heated area.

The rated power of the boiler must be increased. The stock is necessary if you plan to use the boiler for heating water for the bathroom and kitchen.

In most heating systems for private houses, it is recommended to use an expansion tank in which a supply of coolant will be stored. Every private house needs hot water supply

In order to provide for the power reserve of the boiler, the safety factor K must be added to the last formula:

Рboiler = (Qloss * S * K) / 100where

TO - will be equal to 1.25, that is, the estimated boiler power will be increased by 25%.

Thus, the power of the boiler makes it possible to maintain the standard air temperature in the rooms of the building, as well as to have an initial and additional volume of hot water in the house.

Calculation method

To calculate heat energy for heating, it is necessary to take the heat demand indicators of a separate room. In this case, the heat transfer of the heat pipe, which is located in this room, should be subtracted from the data.

The area of the surface that gives off heat will depend on several factors - first of all, on the type of device used, on the principle of connecting it to pipes and on how it is located in the room. It should be noted that all these parameters also affect the density of the heat flux coming from the device.

Calculation of heaters in the heating system - the heat transfer of the heater Q can be determined using the following formula:

Qpr = qpr * Ap.

However, it can be used only if the indicator of the surface density of the heating device qpr (W / m2) is known.

From here, you can also calculate the calculated area Ap. It is important to understand that the estimated area of any heating device does not depend on the type of coolant.

Ap = Qnp / qnp,

in which Qnp is the level of heat transfer of the device required for a certain room.

The thermal calculation of heating takes into account that the formula is used to determine the heat transfer of the device for a specific room:

Qпр = Qп - µтр * Qпр

at the same time, the Qp indicator is the heat demand of the room, Qtr is the total heat transfer of all elements of the heating system located in the room. The calculation of the heat load on heating implies that this includes not only the radiator, but also the pipes that are connected to it, and the transit heat pipe (if any). In this formula, µtr is a correction factor that provides for partial heat transfer from the system, calculated to maintain a constant room temperature. In this case, the size of the correction may fluctuate depending on how exactly the pipes of the heating system were laid in the room. In particular - with the open method - 0.9; in the furrow of the wall - 0.5; embedded in a concrete wall - 1.8.

Calculation of the required heating power, that is, the total heat transfer (Qtr - W) of all elements of the heating system is determined using the following formula:

Qtr = µktr * µ * dn * l * (tg - tv)

In it, ktr is an indicator of the heat transfer coefficient of a certain section of the pipeline located in the room, dн is the outer diameter of the pipe, l is the length of the section. Indicators tg and tv show the temperature of the coolant and air in the room.

The formula Qtr = qw * lw + qg * lg is used to determine the level of heat transfer from the heat conductor present in the room. To determine the indicators, you should refer to the special reference literature. In it, you can find the definition of the thermal power of the heating system - the determination of heat transfer vertically (qw) and horizontally (qg) of the heat pipe laid in the room. The data found show the heat transfer of 1m of the pipe.

Before calculating gcal for heating, for many years the calculations made according to the formula Ap = Qnp / qnp and measurements of the heat-transfer surfaces of the heating system were carried out using a conventional unit - equivalent square meters. In this case, the ecm was conditionally equal to the surface of the heating device with a heat transfer of 435 kcal / h (506 W). Calculation of gcal for heating assumes that the temperature difference between the coolant and the air (tg - tw) in the room was 64.5 ° C, and the relative water consumption in the system was equal to Grel = l, 0.

Calculation of heat loads for heating implies that at the same time smooth-tube and panel heating devices, which had a higher heat transfer than the reference radiators of the times of the USSR, had an ECM area that significantly differed from the indicator of their physical area. Accordingly, the area of the ECM of less efficient heating devices was significantly lower than their physical area.

However, such a dual measurement of the area of heating devices in 1984 was simplified, and the ECM was canceled. Thus, from that moment on, the area of the heater was measured only in m2.

After the area of the heater required for the room has been calculated and the thermal power of the heating system is calculated, you can proceed to the selection of the required radiator from the catalog of heating elements.

In this case, it turns out that most often the area of the purchased item is slightly larger than that which was obtained by calculations. This is quite easy to explain - after all, such a correction is taken into account in advance by introducing a multiplying coefficient µ1 into the formulas.

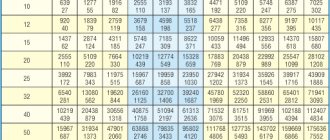

Sectional radiators are very common today.Their length directly depends on the number of sections used. In order to calculate the amount of heat for heating - that is, to calculate the optimal number of sections for a particular room, the formula is used:

N = (Ap / a1) (µ 4 / µ 3)

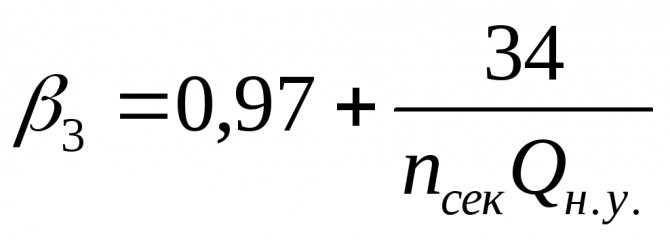

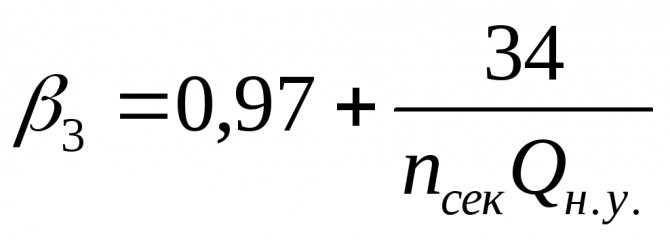

Here a1 is the area of one section of the radiator selected for indoor installation. Measured in m2. µ 4 is the correction factor that is introduced for the installation method of the heating radiator. µ 3 is a correction factor that indicates the actual number of sections in the radiator (µ3 - 1.0, provided that Ap = 2.0 m2). For standard radiators of the M-140 type, this parameter is determined by the formula:

μ 3 = 0.97 + 0.06 / Ap

In thermal tests, standard radiators are used, consisting of an average of 7-8 sections. That is, the calculation of heat consumption for heating, which we have determined - that is, the heat transfer coefficient, is real only for radiators of exactly this size.

It should be noted that when using radiators with fewer sections, a slight increase in the level of heat transfer is observed.

This is due to the fact that in the extreme sections the heat flow is somewhat more active. In addition, the open ends of the radiator contribute to greater heat transfer to the room air. If the number of sections is greater, there is a weakening of the current in the outer sections. Accordingly, in order to achieve the required level of heat transfer, it is most rational to slightly increase the length of the radiator by adding sections, which will not affect the power of the heating system.

For those radiators, the area of one section in which is 0.25 m2, there is a formula for determining the coefficient µ3:

μ3 = 0.92 + 0.16 / Ap

But it should be borne in mind that it is extremely rare when using this formula that an integer number of sections is obtained. Most often, the required quantity turns out to be fractional. The calculation of the heating devices of the heating system assumes that a slight (no more than 5%) decrease in the Ap coefficient is permissible to obtain a more accurate result. This action leads to limiting the level of deviation of the temperature indicator in the room. When the heat for heating the room has been calculated, after obtaining the result, a radiator is installed with the number of sections as close as possible to the obtained value.

The calculation of heating power by area assumes that the architecture of the house imposes certain conditions on the installation of radiators.

In particular, if there is an external niche under the window, then the length of the radiator should be less than the length of the niche - not less than 0.4 m. This condition is valid only for direct piping to the radiator. If a duck-pipe is used, the difference between the length of the niche and the radiator should be at least 0.6 m. In this case, the extra sections should be distinguished as a separate radiator.

For individual models of radiators, the formula for calculating heat for heating - that is, determining the length, does not apply, since this parameter is predetermined by the manufacturer. This fully applies to radiators of the RSV or RSG type. However, there are often cases when to increase the area of a heating device of this type, simply parallel installation of two panels side by side is used.

If a panel radiator is determined as the only one allowed for a given room, then to determine the number of required radiators, the following is used:

N = Ap / a1.

In this case, the area of the radiator is a well-known parameter. In the event that two parallel radiator blocks are installed, the Ap index is increased, determining the reduced heat transfer coefficient.

In the case of using convectors with a jacket, the calculation of the heating power takes into account that their length is also determined exclusively by the existing model range. In particular, the "Rhythm" floor convector is presented in two models with a casing length of 1 m and 1.5 m. Wall convectors may also differ slightly from each other.

In the case of using a convector without a casing, there is a formula that helps to determine the number of elements of the device, after which you can calculate the power of the heating system:

N = Ap / (n * a1)

Here n is the number of rows and tiers of elements that make up the convector's area. In this case, a1 is the area of one pipe or element. At the same time, when determining the calculated area of the convector, it is necessary to take into account not only the number of its elements, but also the method of their connection.

If a smooth pipe device is used in a heating system, the duration of its heating pipe is calculated as follows:

l = Ap * µ4 / (n * a1)

µ4 is a correction factor that is introduced in the presence of a decorative pipe cover; n is the number of rows or tiers of heating pipes; a1 is a parameter characterizing the area of one meter of a horizontal pipe at a predetermined diameter.

To obtain a more accurate (and not a fractional number), a slight (no more than 0.1 m2 or 5%) decrease in the A indicator is allowed.

Features of the selection of radiators

Radiators, panels, underfloor heating systems, convectors, etc. are standard components for providing heat in a room. The most common parts of a heating system are radiators.

The heat sink is a special hollow modular type structure made of high heat dissipation alloy. It is made from steel, aluminum, cast iron, ceramics and other alloys. The principle of operation of a heating radiator is reduced to the radiation of energy from the coolant into the space of the room through the “petals”.

An aluminum and bimetallic heating radiator has replaced massive cast-iron radiators. Ease of production, high heat dissipation, good construction and design have made this product a popular and widespread tool for radiating heat indoors.

There are several methods for calculating heating radiators in a room. The list of methods below is sorted in order of increasing computational accuracy.

Calculation options:

- By area... N = (S * 100) / C, where N is the number of sections, S is the area of the room (m2), C is the heat transfer of one section of the radiator (W, taken from those passport or product certificate), 100 W is the amount of heat flow, which is necessary for heating 1 m2 (empirical value). The question arises: how to take into account the height of the ceiling of the room?

- By volume... N = (S * H * 41) / C, where N, S, C - similarly. H is the height of the room, 41 W is the amount of heat flux required to heat 1 m3 (empirical value).

- By odds... N = (100 * S * k1 * k2 * k3 * k4 * k5 * k6 * k7) / C, where N, S, C and 100 are similar. k1 - taking into account the number of chambers in the glass unit of the window of the room, k2 - thermal insulation of the walls, k3 - the ratio of the area of windows to the area of the room, k4 - the average minus temperature in the coldest week of winter, k5 - the number of outer walls of the room (which “go out” to the street) k6 - type of room on top, k7 - ceiling height.

This is the most accurate way to calculate the number of sections. Naturally, fractional calculation results are always rounded to the next integer.

Hydraulic calculation of water supply

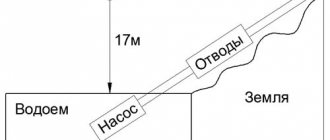

Of course, the “picture” of calculating heat for heating cannot be complete without calculating such characteristics as the volume and speed of the heat carrier. In most cases, the coolant is ordinary water in a liquid or gaseous state of aggregation.

It is recommended to calculate the real volume of the coolant by summing all the cavities in the heating system. When using a single-circuit boiler, this is the best option. When using double-circuit boilers in the heating system, it is necessary to take into account the consumption of hot water for hygienic and other domestic purposes.

The calculation of the volume of water heated by a double-circuit boiler to provide residents with hot water and heating the coolant is made by summing the internal volume of the heating circuit and the real needs of users in heated water.

The volume of hot water in the heating system is calculated using the formula:

W = k * Pwhere

- W - the volume of the heat carrier;

- P - heating boiler power;

- k - power factor (the number of liters per unit of power is 13.5, range - 10-15 liters).

As a result, the final formula looks like this:

W = 13.5 * P

The coolant velocity is the final dynamic assessment of the heating system, which characterizes the rate of circulation of the fluid in the system.

This value helps to estimate the type and diameter of the pipeline:

V = (0.86 * P * μ) / ∆Twhere

- P - boiler power;

- μ - boiler efficiency;

- ∆T - the temperature difference between the supply water and the return water.

Using the above methods of hydraulic calculation, it will be possible to obtain real parameters, which are the “foundation” of the future heating system.

Thermal design example

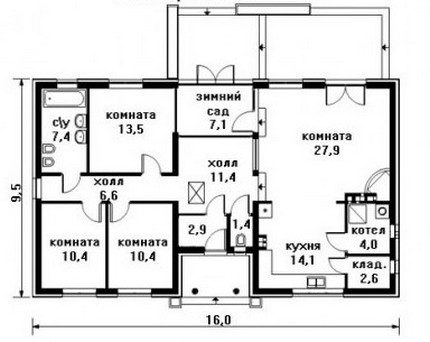

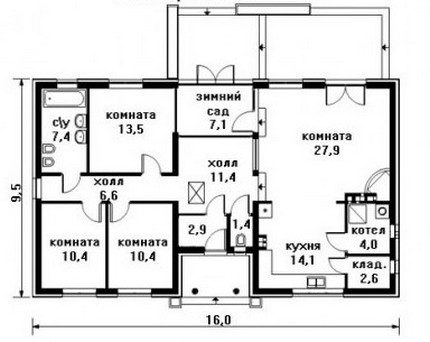

As an example of heat calculation, there is a regular 1-storey house with four living rooms, a kitchen, a bathroom, a “winter garden” and utility rooms.

The foundation is made of a monolithic reinforced concrete slab (20 cm), the outer walls are concrete (25 cm) with plaster, the roof is made of wooden beams, the roof is metal and mineral wool (10 cm)

Let's designate the initial parameters of the house, necessary for the calculations.

Building dimensions:

- floor height - 3 m;

- small window of the front and back of the building 1470 * 1420 mm;

- large facade window 2080 * 1420 mm;

- entrance doors 2000 * 900 mm;

- rear doors (exit to the terrace) 2000 * 1400 (700 + 700) mm.

The total width of the building is 9.5 m2, the length is 16 m2. Only living rooms (4 pcs.), A bathroom and a kitchen will be heated.

To accurately calculate the heat loss on the walls from the area of the external walls, you need to subtract the area of all windows and doors - this is a completely different type of material with its own thermal resistance

We start by calculating the areas of homogeneous materials:

- floor area - 152 m2;

- roof area - 180 m2, taking into account the attic height of 1.3 m and the width of the run - 4 m;

- window area - 3 * 1.47 * 1.42 + 2.08 * 1.42 = 9.22 m2;

- door area - 2 * 0.9 + 2 * 2 * 1.4 = 7.4 m2.

The area of the outer walls will be 51 * 3-9.22-7.4 = 136.38 m2.

Let's move on to calculating heat loss for each material:

- Qpol = S * ∆T * k / d = 152 * 20 * 0.2 / 1.7 = 357.65 W;

- Qroof = 180 * 40 * 0.1 / 0.05 = 14400 W;

- Qwindow = 9.22 * 40 * 0.36 / 0.5 = 265.54 W;

- Qdoor = 7.4 * 40 * 0.15 / 0.75 = 59.2 W;

And also Qwall is equivalent to 136.38 * 40 * 0.25 / 0.3 = 4546. The sum of all heat losses will be 19628.4 W.

As a result, we calculate the boiler power: Рboiler = Qloss * Sheat_room * К / 100 = 19628.4 * (10.4 + 10.4 + 13.5 + 27.9 + 14.1 + 7.4) * 1.25 / 100 = 19628.4 * 83.7 * 1.25 / 100 = 20536.2 = 21 kW.

We will calculate the number of radiator sections for one of the rooms. For everyone else, the calculations are the same. For example, a corner room (left, bottom corner of the diagram) is 10.4 m2.

Hence, N = (100 * k1 * k2 * k3 * k4 * k5 * k6 * k7) / C = (100 * 10.4 * 1.0 * 1.0 * 0.9 * 1.3 * 1.2 * 1.0 * 1.05) /180=8.5176=9.

This room requires 9 sections of a heating radiator with a heat output of 180 W.

We proceed to calculating the amount of coolant in the system - W = 13.5 * P = 13.5 * 21 = 283.5 liters. This means that the speed of the coolant will be: V = (0.86 * P * μ) / ∆T = (0.86 * 21000 * 0.9) /20=812.7 liters.

As a result, a complete turnover of the entire volume of the coolant in the system will be equivalent to 2.87 times per hour.

A selection of articles on thermal calculation will help determine the exact parameters of the elements of the heating system:

- Calculation of the heating system of a private house: rules and calculation examples

- Thermal calculation of a building: specifics and formulas for performing calculations + practical examples

Calculation of heat output

We will consider several calculation methods that take into account a different number of variables.

By area

The calculation by area is based on sanitary standards and rules, in which the Russians say in white: one kilowatt of thermal power should fall on 10 m2 of the area of the room (100 watts per m2).

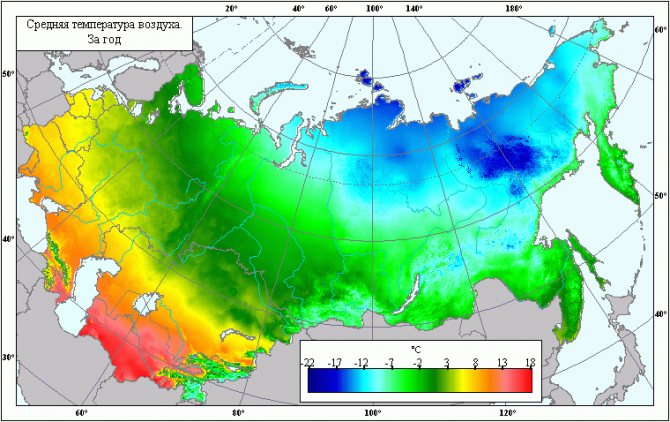

Clarification: the calculation uses a coefficient that depends on the region of the country. For the southern regions it is 0.7 - 0.9, for the Far East - 1.6, for Yakutia and Chukotka - 2.0.

The lower the outside temperature, the greater the heat loss.

It is clear that the method gives a very significant error:

- Panoramic glazing in one thread will clearly give greater heat loss compared to a solid wall.

- The location of the apartment inside the house is not taken into account, although it is clear that if there are warm walls of neighboring apartments nearby, with the same number of radiators it will be much warmer than in a corner room that has a common wall with the street.

- Finally, the main thing: the calculation is correct for the standard ceiling height in a Soviet-built house, equal to 2.5 - 2.7 meters. However, even at the beginning of the 20th century, houses with a ceiling height of 4 - 4.5 meters were being built, and stalinkas with three-meter ceilings would also require a more accurate calculation.

Let's still apply the method to calculate the number of cast-iron sections of heating radiators in a 3x4 meter room located in the Krasnodar Territory.

The area is 3x4 = 12 m2.

The required thermal power of heating is 12m2 x100W x0.7 regional coefficient = 840 watts.

With a power of one section of 180 watts, we need 840/180 = 4.66 sections. Of course, we will round the number up - up to five.

Advice: in the conditions of the Krasnodar Territory, a temperature delta between a room and a battery of 70C is unrealistic. It is better to install radiators with at least a 30% margin.

The thermal power reserve never hurts. If necessary, you can simply close the valves in front of the radiator.

Simple calculation by volume

Not our choice.

The calculation for the total volume of air in the room will clearly be more accurate, already because it takes into account the variation in the height of the ceilings. It is also very simple: for 1 m3 of volume, 40 watts of power of the heating system is needed.

Let's calculate the required power for our room near Krasnodar with a slight clarification: it is located in a stalinka built in 1960 with a ceiling height of 3.1 meters.

The volume of the room is 3x4x3.1 = 37.2 cubic meters.

Accordingly, the radiators must have a capacity of 37.2x40 = 1488 watts. Let's take into account the regional coefficient of 0.7: 1488x0.7 = 1041 watts, or six sections of cast-iron fierce horror under the window. Why horror? The appearance and constant leaks between the sections after several years of operation do not cause delight.

If we remember that the price of a cast-iron section is higher than that of an aluminum or bimetallic imported heating radiator, the idea of buying such a heating device really starts to cause slight panic.

Refined volume calculation

A more accurate calculation of heating systems is carried out taking into account a larger number of variables:

- The number of doors and windows. The average heat loss through a standard size window is 100 watts, through a door 200.

- The location of the room at the end or corner of the house will force us to use a coefficient of 1.1 - 1.3, depending on the material and thickness of the walls of the building.

- For private houses, a coefficient of 1.5 is used, since the heat loss through the floor and roof is much higher. Above and below, after all, not warm apartments, but the street ...

The base value is the same 40 watts per cubic meter and the same regional coefficients as when calculating the area of the room.

Let's calculate the thermal power of heating radiators for a room with the same dimensions as in the previous example, but mentally transfer it to the corner of a private house in Oymyakon (the average January temperature is -54C, at least during the observation period - 82). The situation is aggravated by the door to the street and the window from which the cheerful reindeer herders can be seen.

We have already achieved the basic power, taking into account only the volume of the room: 1488 watts.

The window and door add 300 watts. 1488 + 300 = 1788.

A private house. Cold floor and heat leakage through the roof. 1788x1.5 = 2682.

The angle of the house will force us to apply a factor of 1.3. 2682x1.3 = 3486.6 watts.

By the way, in corner rooms, heating devices should be mounted on both outer walls.

Finally, the warm and gentle climate of the Oymyakonsky ulus of Yakutia leads us to the idea that the result obtained can be multiplied by a regional coefficient of 2.0. 6973.2 watts is required to heat a small room!

We are already familiar with the calculation of the number of heating radiators. The total number of cast iron or aluminum sections will be 6973.2 / 180 = 39 rounded sections. With a section length of 93 mm, the accordion under the window will have a length of 3.6 meters, that is, it will barely fit along the longer of the walls ...

«>

“- Ten sections? A good start!" - with such a phrase a resident of Yakutia will comment on this photo.