Characteristics of the substance

Propylene glycol is a dihydric alcohol, usually a colorless viscous liquid. It has a faint smell and a sweetish taste.

Propylene glycol, unlike its closest analogue, ethylene glycol, is considered a non-toxic substance, it is widely used in the perfumery and even in the food industry - in this case it is designated as E-1520.

The chemical formula of propylene glycol is C3H6 (OH) 2. The substance is extremely fluid in structure and can slowly seep through micro-holes and cracks. The ignition temperature is quite high, it is + 421 ° С.

Why DO NOT use a GLYCERINE mixture - antifreeze in the heating system ??

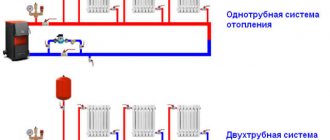

Let's consider, with specific examples, what is better to fill in the installed heating system in your house or in the air conditioning and ventilation system, for example, in a shopping mall.

In order for these systems to work flawlessly at any time of the year, it is necessary to use such coolants that would not only provide heating of the room, but also have such properties as a low freezing point, because no one has canceled frosts in Russia. When choosing a coolant, one must also not forget about such indicators as high thermal conductivity and heat capacity, corrosion protection of all construction materials, the ability to work without the formation of scale, inertness with respect to seal materials, and finally, stability and long service life during the operation of your heating system. What is better to fill in the heating system depends on the specific operating conditions, your boiler equipment, heat exchangers, pumping equipment, etc.

For any heating system, water or a special low-freezing liquid - heat carrier (household antifreeze) can be used as a heat carrier.

Water is the cheapest, most affordable and environmentally friendly heat carrier, but it also has a number of disadvantages, since the heating system, which is operated on water, must constantly be in a state of heating in the zone of positive temperatures so as not to defrost the system. The chemical composition of water contains many different impurities of iron, chlorine, salts, and therefore, when heated, these impurities are deposited on the walls of pipes, on the surfaces of heat exchangers, heating elements, which causes a deterioration in heat transfer, and heating elements can fail due to overheating ...

And one more very important argument, in case of an emergency power or gas outage in the autumn-winter period, the system must be drained in order to prevent its defrosting.

Advantages and Disadvantages of Propylene Glycol as a Heat Transfer Fluid

You can clearly identify the advantages and disadvantages of propylene glycol by comparing it with water (which is also a heat transfer fluid in some heating systems):

- the density of dihydric alcohol is 1037 kg / m³, which is more than that of water (1000 kg / m³): the difference is 3.7%;

- the substance begins to boil at +187 ° С, and water at +100 ° С, the difference is 87%;

- alcohol freezes at -60 ° C, water already at 0 ° C;

- the specific heat capacity is equal to 2483 J / (kg · K), almost 2 times lower than that of water (4.187 J / (kg · K));

- thermal conductivity - 0.218 W / (m · K), which is three times lower than that of water 0.6 W / (m · K);

- dynamic viscosity of alcohol - 56 mPa · s, eight hundred times more than that of water (0.894 mPa · s).

Several conclusions can be drawn from this list.

- The density of propylene glycol is higher than that of water, so the static load and pressure in the heating system will also increase.

- The high boiling point of +187 ° C is not such an advantage. The specific heat of propylene glycol is two times lower than that of water. This means that you can bring these two liquids to a boil with the same amount of heat. Their temperature will reach its extreme point almost simultaneously, only water will boil at +100 ° C, and alcohol at +187 ° C.

- The freezing point of propylene glycol is noticeably lower. In addition, it practically does not expand during cooling, and this does not damage the heating system.

- A low specific heat capacity is a clear advantage, hence the rapid heating of the heating system, however, propylene glycol is able to accumulate little heat - and this is already a disadvantage.

- High dynamic viscosity will add a load to the circulation pump, which moves the coolant through pipes and radiators.

However, in some situations propylene glycol will do its job better than water:

- if you do not use the water heating system in winter and do not drain the water, the system may fail (even after complete draining, the water will still remain in the pipes, causing corrosion) - and propylene glycol can be used all year round and not drained in winter;

- antifreeze, which is based on propylene glycol, does not cause corrosion and does not form scale.

Such antifreezes also have disadvantages:

- the cost is higher than that of water;

- a complete fluid change is required every five years;

- the heating system should not have parts that contain zinc - propylene glycol quickly dissolves them;

- Propylene glycol is extremely fluid and can penetrate through small joints in the heating system.

Many manufacturers dilute antifreeze with water to correct some of the disadvantages of propylene glycol. What will it give:

- the cost of antifreeze will become noticeably lower;

- the viscosity will decrease;

- the heat capacity will increase;

- the heat transfer rate will increase;

- the boiling point will drop, but most boilers are still not designed for 160 ° C;

- freezing point is from -30 to -40 ° C degrees;

- antifreeze based on propylene glycol with water expands slightly, so the destruction of the heating system will not occur.

Using glycerin as a heat carrier

H2_2

To obtain a glycerin-based coolant, the pure substance is mixed with various impurities that allow it to remain liquid when used in cold conditions. The resulting composition is chemically inert, and chemical processes do not take place inside, which can have a detrimental effect on the elements of the entire system.

The ability to maintain a liquid state at subzero temperatures and absolute safety for humans makes it possible to use the coolant for heating systems in residential buildings, including for floor heating.

The operation of this heating system is based on one principle: there is a heater, heating elements and a coolant. In this case, the main characteristics of the coolant will affect the overall heating efficiency.

Important! It is necessary to decide which coolant will be used in the underfloor heating system at the stage of its design. This will affect the choice of equipment, pipe diameter and the length of the circuits.

Advantages of glycerin coolant

Compared to propylene glycol or ethylene glycol formulations, this antifreeze has the following advantages:

- It can be used in a wide temperature range from -30 to +105 ° C. Even when the substance is completely frozen, it does not expand and does not damage the pipes. After thawing, all its original properties are restored.

- The coolant is sold ready-made and does not require additional dilution with water.Glycol formulations must be diluted;

- Antifreeze does not cause corrosion or other damage to floor heating elements, including galvanized pipes and rubber gaskets;

- The substance is absolutely safe for human health and the environment, which is very important in the event of leaks or damage to the system as a whole;

- At a relatively high price, the composition has a long term of use up to 8 years. Another type of antifreeze has been used for about 5 years;

- The coolant can be poured into the pipes after any other type of antifreeze; flushing is not required;

- Antifreeze is made only from high quality raw materials, which are also used in the food and cosmetic industries;

- Belongs to the class of non-flammable substances.

Advice! When filling the pipes, you can add some fluorescent dye to the antifreeze. In the event of a leak in the system, the dye will help to quickly locate the leak.

Disadvantages of a glycerin composition

A glycerin-based coolant has its drawbacks, which must be taken into account when designing a warm floor:

- Freezing increases the density and viscosity of the glycerin composition, which leads to a decrease in its heat capacity. In a heating system project, pipes of a larger diameter will have to be used than when using ordinary water;

- The high viscosity of the composition will require the installation of a more powerful circulation pump in the heating system;

- Glycerin-based antifreeze requires the use of reliable and expensive gaskets and seals during the heating installation process. Teflon or paronite gaskets are recommended;

- Antifreeze tends to foam, which can cause the warm floor to air out. Special additives help to partially reduce foaming;

- The composition based on glycerin has a density and mass greater than that of glycolic. The use of a glycerin composition in the underfloor heating system will increase the load on the floors and foundation of the building.

How to use propylene glycol fluids correctly

Propylene glycol based heat transfer fluids have a similar chemical composition, which differs in the percentage of alcohol. Most often, such compositions are named by the manufacturer's name.

If propylene glycol antifreeze contains about 30%, it freezes at -13 ° C, 35% alcohol solution crystallizes at -20 ° C, 40% at -25 ° C, 75% solution at -65 ° FROM.

When replacing water with a propylene glycol-based composition, it is necessary to take into account some of the properties of antifreeze.

- Lower heat capacity and thermal conductivity. It is worth increasing the number of radiators, as well as purchasing a more powerful boiler. Heating systems are often installed in private houses that operate at half their capacity - in this case, you can do without replacing the boiler.

- High viscosity. Make sure the pipes have an inner diameter of at least 25 mm and install a larger circulation pump.

- Greater expansion ratio. If the expansion tank is less than 10 liters, then a larger one will need to be replaced.

- High fluidity. It is worth reducing the number of threaded connections, tie-ins and squeegees, and also provide free access to existing connections in case of leaks.

If the technical parameters of the existing heating meet the new requirements, you can proceed to the preparatory work:

- to seal squeegees, connections, tie-ins;

- completely drain the water from the heating system and rinse with caustic soda, it will remove rust and scale;

- remove all zinc parts;

- additives can be added to antifreeze that will protect copper parts;

- check the dirt trap twice as often;

- check the solution every two years for alcohol concentration;

- complete change of antifreeze every five years.

It is always worth flushing the system thoroughly if you are going to switch to another coolant.

Glycerin based antifreeze

- protect the system

heating and all its elements from corrosion; - safe to use

coolant without damaging the elements of the system; - Non-toxic and non-flammable

; - efficiently and reliably

use heating at temperatures in the system from -30 C to +105 C; - heat carrier based on glycerin Teplokom ready to use;

- service life 8 years

subject to the temperature regime; - Thanks to high quality product

, Heat carrier based on glycerin, brand Teplokom, recommended for use with floor convectors with copper-aluminum heat exchangers;

When it comes to heating systems, it is antifreeze that acts as a coolant that is the key component. The quality of antifreeze directly affects the service life of other elements, from boilers to radiators. takes into account the peculiarities of the functioning of engineering systems and offers the consumer a high-quality product created specifically for autonomous heating networks.

Advantages of Teplocom branded antifreeze for heating systems

Antifreeze for use in heating systems presented is an excellent choice that allows you to solve problems that you had to deal with earlier. Antifreeze for autonomous heating systems is characterized by a number of advantages that distinguish it favorably from other options:

- Antifreeze for a modern heating system protects the network and individual elements from corrosion using the used coolant additives.

- Antifreeze for modern heating systems guarantees safe use without damaging seals and gaskets, zinc-coated pipes, aluminum radiators and so on.

- Antifreeze for a modern heating system allows the network to operate in a wide temperature range - from -30 to + 105 degrees - due to the properties of the coolant.

- For the manufacture of antifreeze, poured into an autonomous heating system, food glycerin is used. Glycerin in the basis of the coolant is absolutely inert and does not harm the elements of the system. Glycerin in the heating medium in systems and heating using glycerin heating medium are safe for people and animals. Such a coolant does not belong to the category of flammable and poisonous.

- Antifreeze for a modern heating system can be used without first mixing the heat carrier and water. It is very easy to fill in the system and use the coolant.

- It is realistic to use antifreeze as a coolant for a long period of time without replacement. Antifreeze for autonomous heating systems has a service life of 8 years, subject to the recommended temperature regime. Working with a coolant in systems during heating does not require regular flushing after other coolants have been poured into the system. The heating medium is suitable for systems with zinc coated pipes, aluminum batteries, etc., while other ethylene glycol based heating fluids destroy these elements.

- Antifreeze for heating systems and operating air conditioning systems presented is unique. Even if the coolant inside the system is completely frozen due to a drop in temperature below the critical level, the equipment is not defrosting, and the system is not damaged by the coolant. The coolant inside the system can thaw out, after which it completely restores its original properties.

Antifreeze "Teplocom" - high-quality heat carrier for comfortable use

The high quality of the coolant in the form of antifreeze for use in the heating system determines that this particular type of coolant is recommended for use in floor convectors with copper and aluminum heat exchangers.Even manufacturers of electric heated towel rails prefer a proprietary type of coolant for pouring into devices.

Nothing threatens the system and heating with the coolant. You do not have to "get used" to antifreeze in heating systems. Heat carriers in the form of antifreeze when used in a heating system do not cause the slightest problems and difficulties. Using antifreeze for heating is even easier than you might imagine.

Recommendations for the purchase and use of Teplocom heat carrier

We recommend that you carefully calculate the heating medium before pouring it into the heating network. Under such conditions, the system will function as correctly as possible. If the object of filling is a system with a volume of 100 liters, then the optimal amount of antifreeze in such a heating system will be 115 kilograms.

We have made sure that its use in modern heating is as comfortable as possible. Anyone can use a heat carrier in the form of antifreeze for heat supply systems. The supply of heat carriers provides for their packaging in a convenient container. Antifreeze for the heating network can be supplied in a 10 or 20 kilogram canister, as well as in a 50 kilogram barrel with antifreeze for heating applications.

You can find out more about heat carriers and the use of glycerin heat carriers in heating before buying a product directly on the website. In addition, specialists who know everything about coolants are ready to help the buyers and will help to buy the best option.

You can get advice on the product and order a coolant with delivery - by calling our phones. You can also arrange the delivery of the heat carrier by Teplokom to any of the regions of Russia!

Antifreezes for heating systems can be produced on the basis of different components. One of the most popular is propylene glycol.

Water

Benefits:

- environmentally friendly substance;

- sufficiently high heat capacity;

- circulates freely through the system;

- always at hand;

- extremely low cost.

Disadvantages:

- freezes at temperatures below 0 ° С;

- lack of operation in winter requires draining the system, which leads to corrosion;

- water hardness manifests itself at temperatures above 80 ° C, then decomposition of carbonate salts begins and scale deposits on the walls of the system, which reduces heat transfer and can break the system due to overheating.

The antifreeze market is seriously ill

What do you think is the main problem of the Russian antifreeze market now?

Our market is seriously ill. He is struck by a "cancerous tumor" - a massive replacement of the basic component of coolants - monoethylene glycol (MEG) - with glycerol-methanol mixtures. Such a replacement leads to a significant reduction in the cost of the coolant, but at the same time its quality drops catastrophically. Today this is the key topic of anti-freeze problems. Now even issues such as tolerances from car manufacturers or the culture of antifreeze production (despite the fact that all this is very important) are fading into the background. Every car owner should understand that our market is flooded with SURROGATES.

Until recently, the range of many manufacturers included inexpensive coolants of the so-called traditional, or antifreeze, level. These compositions, subject to the original recipe, cannot be called bad, they coped with their task for a number of brands of cars. They just have a small mileage before replacement. Nevertheless, there is a certain category of car owners focused on this type of coolant. But now there are practically no such liquids on the market, since only the cost of raw materials from which they can be produced is already significantly higher than the retail price of surrogate mixtures. their products to the price of the market, or leave it.A normal (honest) manufacturer lost this market sector one and a half to two years ago, since buyers in this segment are primarily focused on a low price. Therefore, we can say with confidence that there are practically no normal coolants in the lower price segment, this entire segment has been “eaten up” by a glycerine-methanol mixture. Similar "compositions" appear in the middle and even in the upper price segment.

How does this threaten the car?

First, overheating, which can occur in traffic jams in the heat or under difficult road conditions. The reason is simple - the boiling point of glycerol-methanol antifreezes is 90–97 degrees with a minimum rate of 108 ° C (according to a study conducted by the magazine "Avtomir"). This is the operating temperature for most engines.

Secondly, higher corrosivity, which is better called corrosiveness. The glycerine-methanol mixture corrodes cylinder blocks, engine plugs, and especially quickly destroys parts made of aluminum alloys: pump impeller and radiators ...

Thirdly, the low boiling point of antifreeze in combination with corrosive aggressiveness leads to accelerated cavitation destruction of the pump, and in trucks - to cavitation destruction of "wet" liners.

When did this problem occur?

Glycerine-methanol mixtures became noticeable on the market 3-4 years ago. Since then, the volume of deliveries of such "trains" to the market has grown like an avalanche. Our neighbors, Ukraine and Kazakhstan, were the first to face this problem. Since then, cars have been boiling there in the summer heat.

Car owners change pumps and radiators, but the problem is not at all with them. They just fill in a coolant that cannot work normally in the cooling system.

Don't we have some kind of control?

There are about 200 manufacturers of coolants in Russia. Large ones can be counted on one hand. Some of them have been tested and approved for use by car manufacturers. The products of other manufacturers are not controlled by anyone, and no one knows what kind of liquids they are. It is quite easy to determine the presence of methanol in a mixture - it is just that no one is doing it. Alas, the Russian antifreeze market does not know how to protect itself from counterfeits.

The results of recent tests can be cited as confirmation of the current situation. For example, a study conducted last year by specialists from the 25th State Research Institute of the Ministry of Defense of the Russian Federation (the result was published in the journal Avtomir, No. 23, 2014) confirms that 50% of the samples taken for testing (of different price categories) contain methanol, which completely reveals their surrogate composition.

What do surrogate manufacturers say in their defense?

First, few people ask them.

Secondly, they are very fond of referring to the Volkswagen concern, which really allows the presence of glycerin in the coolant. (This refers to the specification G13: VW TL 774-G.) However, they slyly "forget" to say that Volkswagen severely limits the glycerin content in the mixture: a maximum of 20% per concentrate or 10% in the finished coolant, the rest is ethylene glycol. They also forget that G13 antifreeze (not according to the label, but in essence) has a special, different from ethylene glycol, additive package and has passed a full cycle of tests at Volkswagen.

Third, they recall Fleetguard ES Compleat Glycerin glycerin-based antifreeze, which is part of the Cummins line of antifreezes. But again, they forget to say that this is a one-of-a-kind antifreeze with a special additive package, and there are 7 other ethylene glycol antifreezes in the Cummins lineup. This antifreeze does not meet any of the American standards (ASTM D3306, D4985, D6210), it cannot be used in heavily loaded engines, its freezing point is only -32 ° C, and its service life is 2 times less than that of the ethylene glycol "branded" Fleetguard ES Compleat OAT.Its only declared merit is the use of glycerin, a by-product of the production of biodiesel fuel, which otherwise would simply have to be disposed of. In our practice, we have not met a single Cummins truck that would drive this antifreeze, at least in Russia.

Actually, on these two examples, the argument in favor of glycerin coolants is built.

This means that 10% of glycerin can be added. Is there more? Can I get 30%? Or 50%? Can the entire MEG be exchanged for glycerin?

It is impossible, because, firstly, a completely different additive package is needed for glycerin, otherwise there will be frenzied corrosion, which we have already seen in numerous examples. Secondly, glycerin has a different viscosity, and the standard coolant on glycerin becomes one and a half times more viscous than on ethylene glycol. The load on the pump exceeds the permissible values, and its failure becomes only a matter of a very short time. Thirdly, glycerin has a higher freezing point, and instead of the standard –40 ° С, we get only –32 ° С.

To adjust the viscosity and freezing point to acceptable values, glycerin is diluted with methanol (methyl alcohol). But methanol is poison. Its use in household chemicals or in automotive fluids is prohibited by the order of Rospotrebnadzor. That is, the use of glycerol-methanol coolants is a clear violation of the law and the conditions in which the coolant must work. The addition of methanol allows the surrogate coolant to adjust parameters such as density and crystallization onset temperature to the required antifreeze values. But these values do not last long. During operation, alcohols evaporate from the mixture (even in a closed system) and the viscosity of the surrogate coolant increases. However, the state of the cooling system of cars of manufacturers of surrogates is not at all interested.

What to do?

The dominance of surrogates is so alarming that not only journalists are asking this question. It is also set by the largest players in the industry - coolant manufacturers. As a collective response, the Coolant Manufacturers Association is currently being formed. The goal of the association is to create a regulation that the coolant must comply with and make it so that the consumer knows that everything that complies with this regulation (and has some kind of confirmation of this) is included in the pool of "good products". That is, it's not about lobbying someone's interests. The association is created by competing companies with different interests. They are united by one common desire - to clear the market of surrogates. Such things are not done quickly. The transition period, according to our estimates, may last two years. Representatives of the parties have already met more than once in order to compare their positions. Now the base of characteristics that need to be included in the future regulations is being developed.

I think this is a workable project that will allow production to adhere to some single standard or amount of requirements.

In addition to creating its own regulations, work is underway in other areas. For example, now there is a technical regulation of the Customs Union. In fact, it concerns fuels and lubricants (fuels and lubricants), but contains a section on coolant. Unfortunately, this section does not fully reflect the real state of affairs. Our task is, through the Association or in some other way, to try to modify that part of the regulation that relates to coolant (ideally) to a single regulatory document for the entire industry, for all those who wish to call their product "antifreeze".

Why do we need new regulations, are there not enough existing regulatory documents (for example, GOST 28084-89)?

This GOST (State Standard of the USSR) 1989 release.He regulated the quality characteristics of the coolant, relevant for that time. At present, GOST is morally outdated, the best examples of modern antifreezes do not correspond to it.

In addition, GOST has long been unnecessary. It is possible to produce products that comply with GOST, or not. All release their products according to the technical specifications, which they themselves have developed.

Does this mean that with all the problems of the market, the consumer is the most unprotected link?

Exactly. The choice of antifreeze today is very difficult due to the lack of any starting points for the consumer from which to build. These starting points can only be found armed with knowledge gleaned from serious publications.

A person cannot comprehend the problem of surrogates from what is written on the label, since none of the manufacturers indicates on the label that glycerin-methanol mixture is used instead of MEG. Some openly lie, others mislead the consumer, fogging up with complex formulations. Everything that is written on the label usually does not correspond to realities. If it is written that antifreeze is "recommended" for cars of such and such car brands, then the answer to the question: "Recommended by whom?" - can not found. They did it themselves, they recommend it themselves.

The world's leading manufacturers of antifreezes have research units that have been developing and adapting coolant formulations to the requirements of car manufacturers for years. Even more time and effort needs to be spent on testing the obtained antifreezes and obtaining approvals from automakers. The output is antifreeze that meets all the requirements of a modern car.

At the same time, on the shelves of domestic stores, you will find a wide range of liquids, which can be conditionally divided into two categories: verified (with the approval of the automaker) and all the others, the quality of which is unknown. The latter are the overwhelming majority, and it is not worth looking among them for a product for your own car, even a used one.

Antifreeze color selection system is thriving among sales consultants. Although any color can be made, it is determined only by the dye and in no way reflects the composition and properties of the product.

Quality packaging cannot serve as a selection criterion either. The form does not always correspond to the content, but the content to the form.

Often, good sales statistics are demonstrated by antifreezes that have entered the market long ago and have beautiful packaging. However, brand awareness is also not always a guarantee of quality. Because under it (not at all embarrassed) surrogates can be supplied in huge quantities.

The only correct line of behavior for the car owner today is to ask the question of which antifreezes are approved for use for cars of the brand of interest to the consumer. Then go to the website of the coolant manufacturer and check the availability of documents (read them carefully) confirming this admission. All normal manufacturers have a hotline telephone, a "box" for sending a request, a list of authorized sellers.

Summarizing what has been said, we would like to note once again.

There is a difference between antifreezes, and it is significant. With an abundance of surrogates flooding the market, consider carefully the choice of coolant, if your car is really dear to you.

Glycerin-based heat carrier

Benefits:

- environmentally friendly;

- not dangerous by inhalation of vapors;

- does not cause poisoning if accidentally ingested;

- inert to galvanized parts;

- cheaper than propylene glycol-based coolant.

Disadvantages:

- the mass of the glycerin coolant gives an additional load on the equipment;

- the viscosity is higher than that of glycol solutions;

- thermally unstable;

- foams strongly, the risk of airing the system increases;

- when used, the requirements for gaskets (seals) and parts are increased.

What kind of liquid "GLYCERINE" is this ???

Glycerin is 1,2,3-trihydroxypropane, 1,2,3-propanetriol, Latin versions of the names: Propantriol, Glycerol, Glycerin organic compound, representative of saturated trihydric alcohols. The chemical formula of glycerin is C3H5 (OH) 3. The molar mass of glycerin is 92.10. A colorless, very viscous liquid of sweet taste, the melting point of glycerin is 7.9 ° C, and the boiling point is 245 ° C. The density of glycerin is 1.26 g / cm3. Autoignition temperature 362 ° C. Soluble in water and organic solvents.

Only in our country can homegrown inventors invent and impose on us something that the whole world has long since refused and proved that it is bad. But we, in pursuit of cheap antifreeze, do not notice that we are throwing money away, buying this Russian miracle "New - invention" based on GLYCERINE for expensive heating and air conditioning systems... Our Russian "grief - inventors" opened our eyes to the fact that antifreeze-coolants based on glycerin are the best that exists in nature, the most ecological and reliable liquid, but let's turn to facts and common sense.

Ethylene glycol heat transfer fluid

Benefits:

- the system is not defrosting;

- good thermophysical properties;

- slight deposits of salts and scale;

- average cost.

Disadvantages:

- belongs to the third class of danger, has a narcotic effect on the body, is toxic;

- quickly absorbed into the body, is able to penetrate the skin and by inhalation;

- does not have an unpleasant odor;

- poses an environmental hazard;

2.2 Glycerin as an antifreeze for the climate system

The first low-freezing coolant for engineering systems appeared almost 100 years ago and was made precisely on the basis of glycerin, a trihydric alcohol. The then antifreezes were an aqueous solution of glycerin with a concentration of about 65%. Such a working fluid had a freezing point of 40 degrees below zero and a boiling point of + 280 degrees. Almost from the beginning of the use of antifreeze, some drawbacks appeared - insufficient fluidity of the composition, they tried to correct this drawback by introducing salts, methanol and ethanol into the solution. Already in the 30s of the last century, an alternative to glycerin appeared - a water-glycol mixture based on ethylene glycol. In the USSR and other developed countries of the world, glycerin antifreezes were almost everywhere replaced by ethylene glycol. Despite this fact, some manufacturers are still trying to prove the exclusivity of glycerin and continue to release compositions for climate systems based on it.

If we analyze the properties of glycerol, or trihydroxypropane, or propanetriol, then this is a representative of saturated trihydric alcohols. Physical properties: colorless viscous liquid with a sweetish taste, melting point 7.9 degrees, boiling point 245 degrees and density 1.26 grams per cubic centimeter. The liquid dissolves in both organic solvents and water.

A thorough study of the shortcomings of glycerin shows that, despite the admissibility of their use in technology, the use of such antifreezes can be detrimental to expensive climatic equipment, and also poses a serious danger to human health and the environment. The facts speak in favor of this opinion.

Propylene glycol based heat carrier

Benefits:

- insures the system against rupture;

- the volume during freezing increases by only 0.1%;

- provides the highest level of safety after water;

- not dangerous even with prolonged inhalation of vapors;

- non-corrosive;

- good thermophysical properties;

- possesses bactericidal and sterilizing properties.

Disadvantages:

- high cost (pays off with minimal repair costs, safety and the ability not to connect to central heating systems).