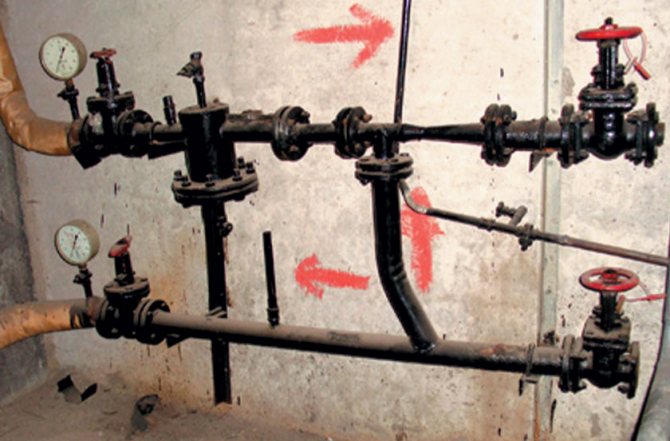

The heart of the heat supply system is the elevator unit

Today we have to find out how the water supply and heating of a residential building are arranged. The object of the study will be the most popular in Soviet-built houses, which make up more than 90% of the housing stock of our boundless and immense, open heat supply circuit with hot water withdrawal for households directly from the heating main.

How it works

First, some general information.

Hot water supply and heating of an apartment building begins with the introduction of the heating main into the house. Through the foundation, two lines are started from the nearest heat chamber - supply (through which industrial water, it is also a heat carrier, enters the building) and return (water, respectively, returns to the CHP or boiler house, giving off heat).

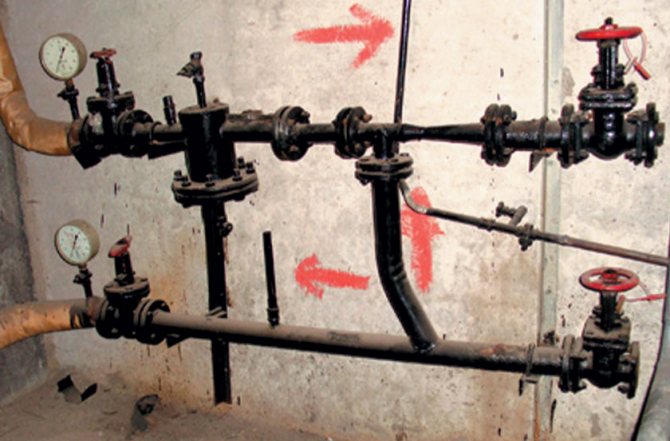

In the thermal chamber at the entrance to the house (as an option - at the group entrance to several houses located in close proximity to each other) there are cut-off valves or taps.

Heat chamber at the stage of installation

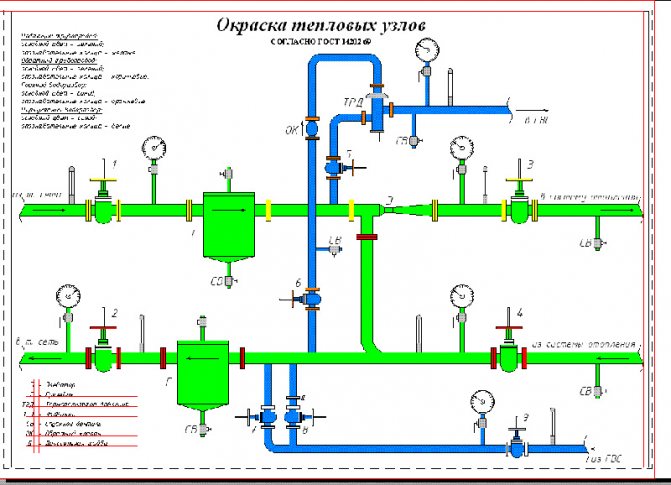

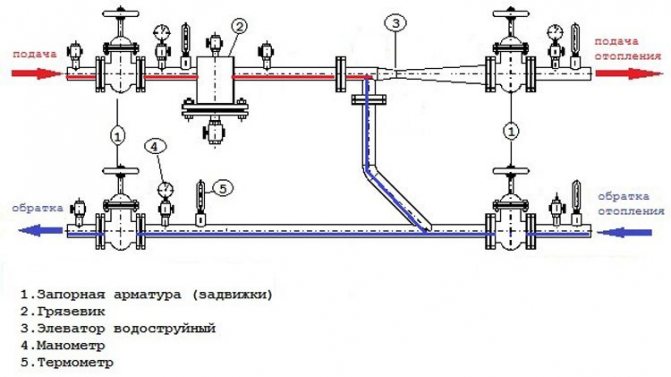

The heat point, also known as an elevator unit, combines several functions:

- Provides a minimum temperature difference between the supply and return of the heating system;

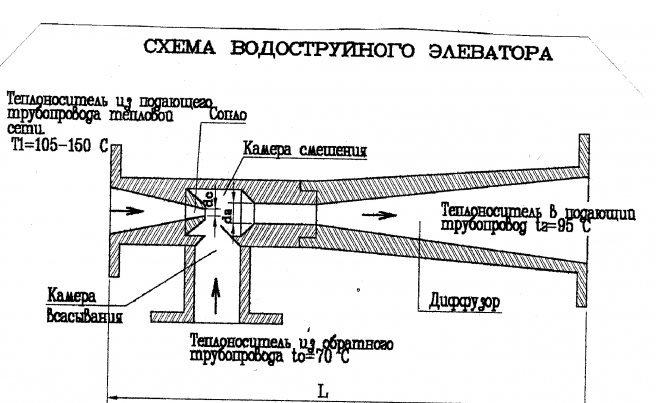

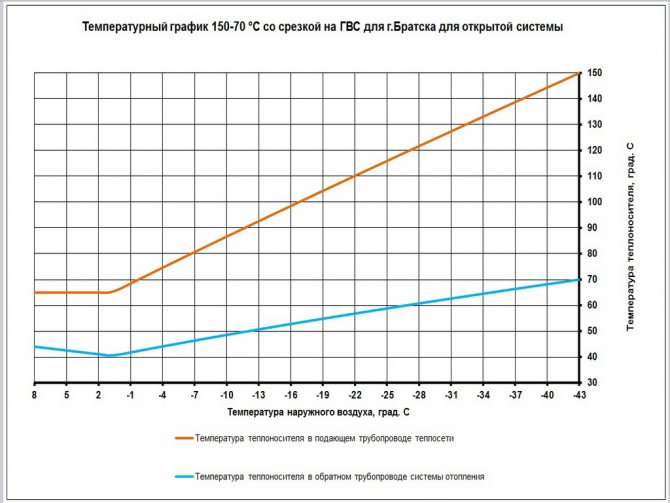

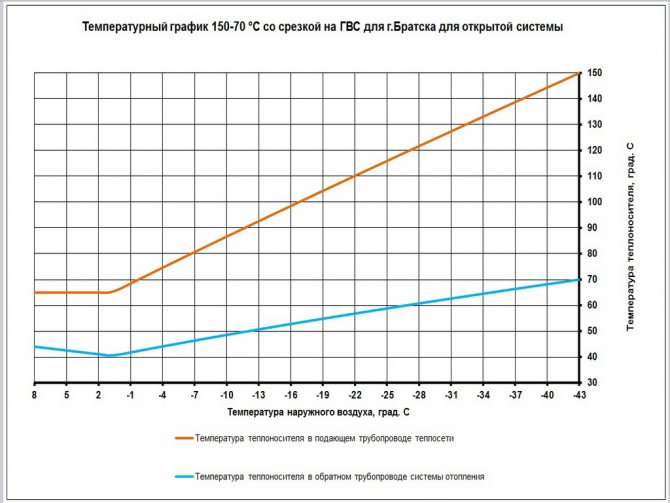

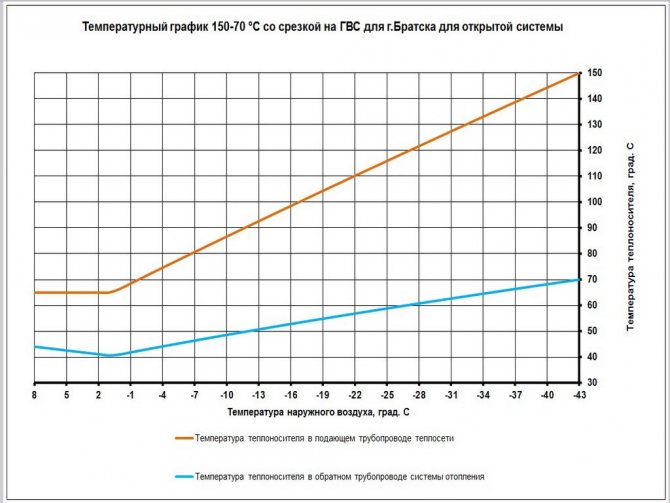

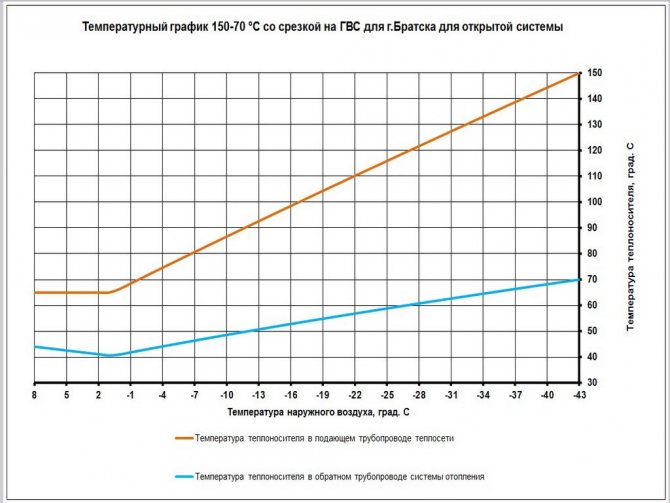

Reference: the upper peak of the supply temperature is 150 degrees, while, according to the temperature schedule, the return flow must return to the CHP plant cooled down to 70 ° С. However, such a difference would mean extremely uneven heating of heating devices, therefore, water from the elevator enters the heating circuit with a more modest temperature - up to 95 degrees.

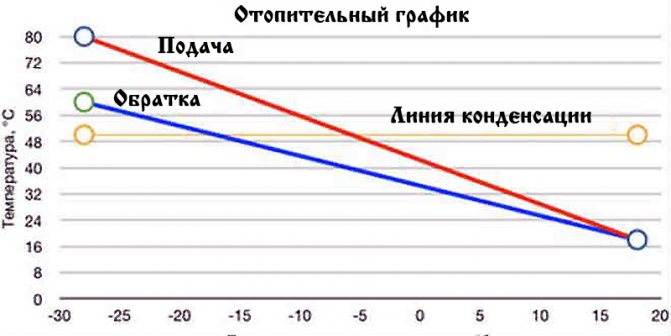

Temperature graph of the supply and return lines of the heating main depending on the outside temperature

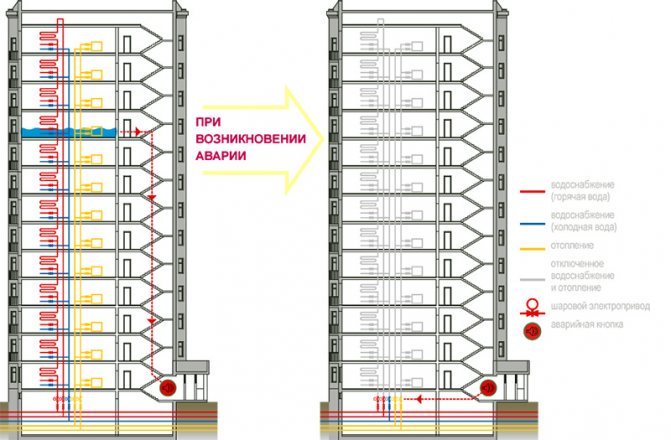

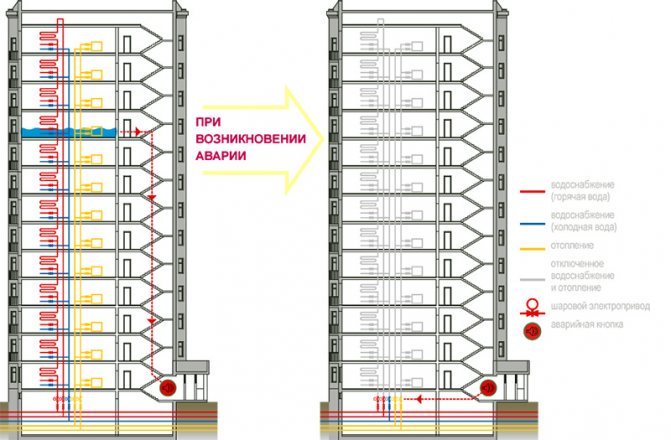

- Organizes the supply of hot water to the hot water supply system and its shutdown on a scale of the house in case of accidents and maintenance;

- It makes it possible to stop and reset the heating system;

- Allows you to take control measurements of temperature and pressure;

- Provides cleaning of the coolant and water for hot water supply from large contaminants.

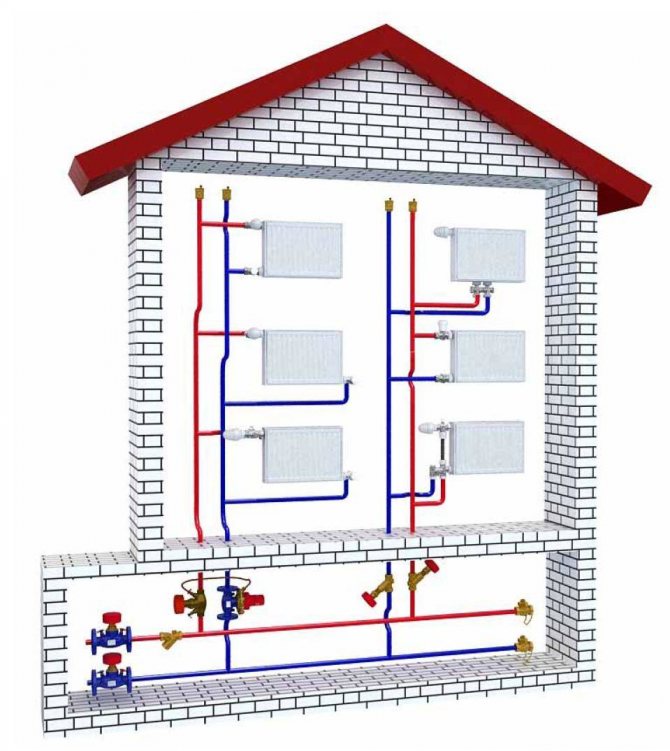

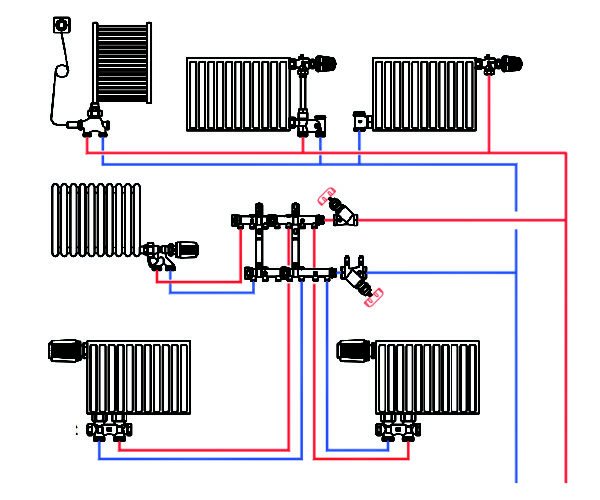

The heating system can be organized:

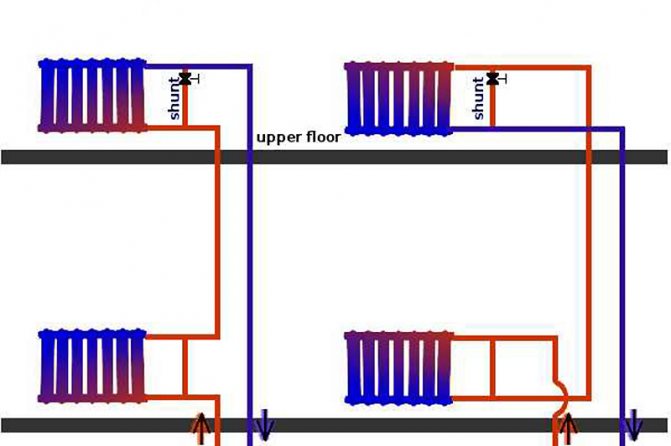

- With top filling: the filling of the supply takes place in the attic or technical floor under the roof of the house, and the filling of the return flow is located in the basement or underground. Each heating riser is disconnected independently of the others by two taps at the top and bottom of the house;

Top filling: heating supply is distributed in the attic

It is curious: there is also a reverse scheme - with feeding in the basement and pouring the return in the attic. However, it is much less popular and, as far as the author knows, is used mainly in small buildings with their own boiler rooms.

- With bottom filling: supply and return are bred in the basement; heating risers are connected to the filling in turn and are connected in pairs by jumpers on the top floor or attic. Each jumper is supplied with an air vent (Mayevsky valve or a conventional valve) to bleed the air lock.

The DHW system in buildings built in the 70s and in older houses is usually dead-end - completely identical to the cold water supply system. From a practical point of view, this means that hot water has to be drained for a long time during the drawdown before it is heated, and heated towel rails installed on the hot water supply pipes are heated only during the drawdown.

Dead-end DHW system: water needs to be drained for a long time before it heats up

In newer buildings, hot water supply and heating of a residential building function according to the general principle - water circulates continuously through the circuits, ensuring a constant temperature of heated towel rails and instantaneous heating of water during parsing.

To learn more about how the heating and water supply system of residential buildings is arranged, the video in this article will help you.

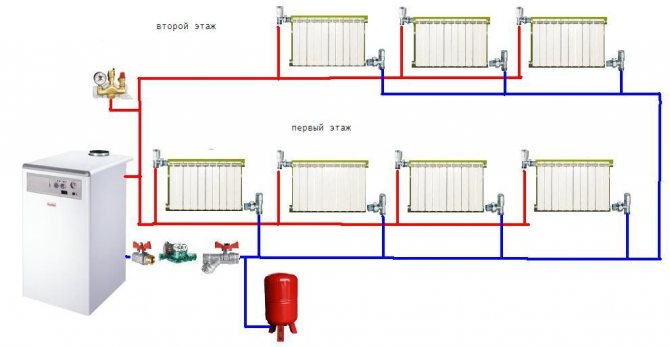

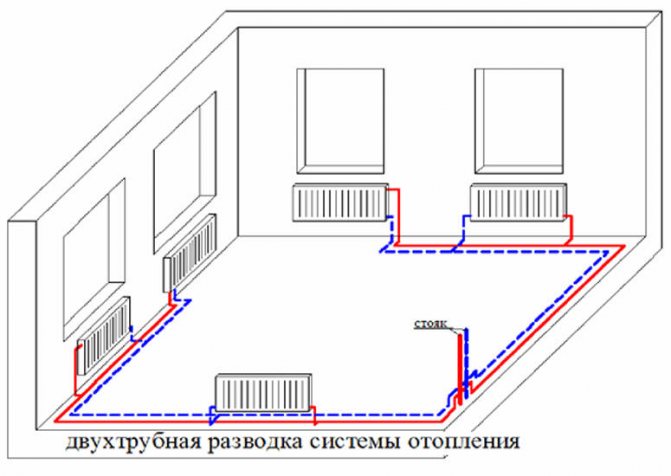

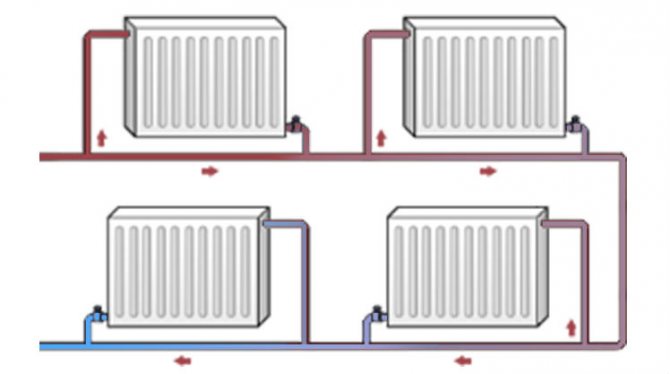

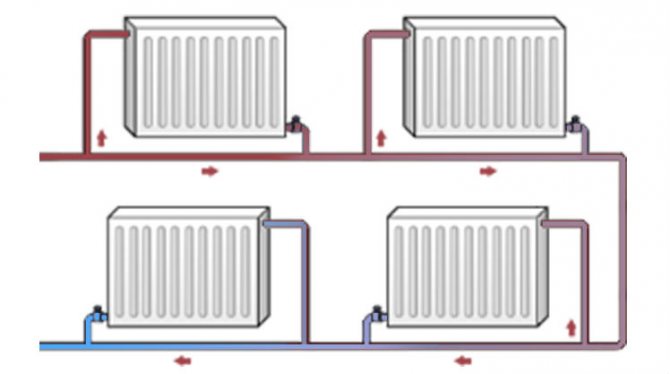

Top-piped two-pipe heating system

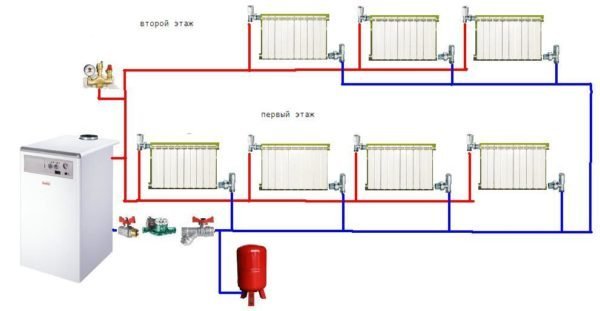

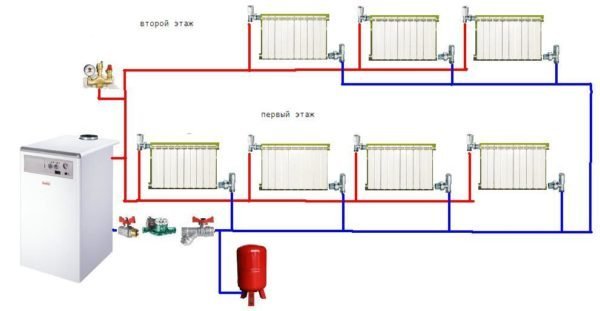

Installing a two-pipe top-wired heating system minimizes or eliminates many of the above disadvantages. In this case, the radiators are connected in parallel.

For its installation, much more materials are needed, since two parallel lines are installed. A hot coolant flows through one of them, and a cooled one flows through the other. Why is this top-drawer heating system preferred for private homes? One of the significant advantages is the relatively large area of the premises. The two-pipe system can effectively maintain a comfortable temperature level in houses with a total area of up to 400 m².

In addition to this factor, for a heating scheme with top filling, such important performance characteristics are noted:

- Uniform distribution of hot coolant over all installed radiators;

- The ability to install control valves not only on the piping of batteries, but also on separate heating circuits;

- Installation of a water-heated floor system. The hot water distribution manifold is only possible with two-pipe heating.

The optimum capacity of an open expansion tank is 5% of the total water volume in the system. Moreover, it should only be 1/3 full.

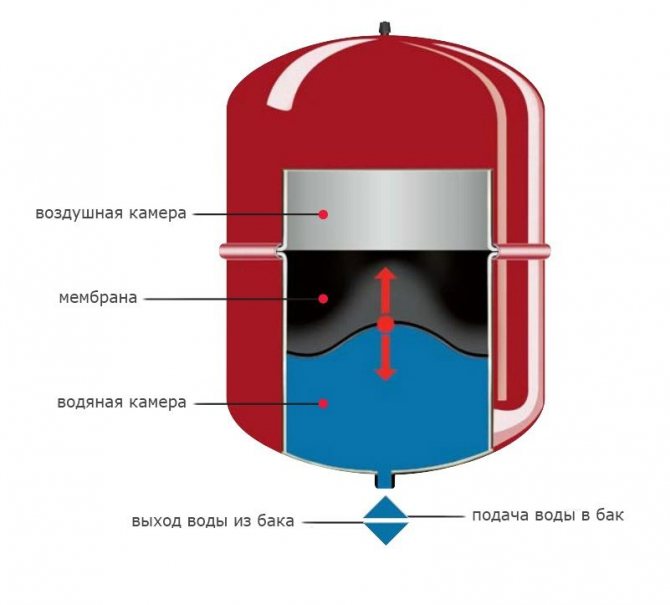

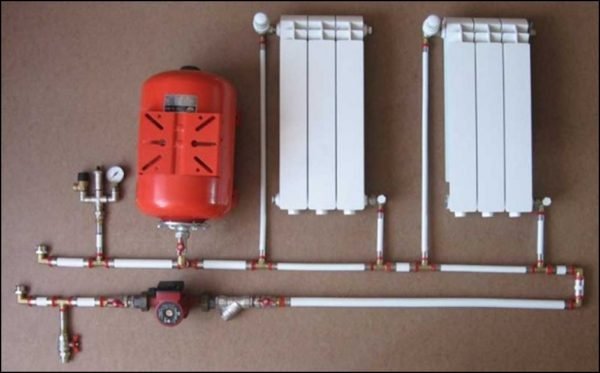

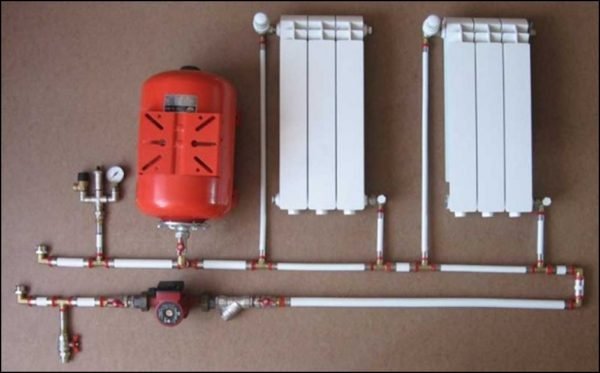

For the organization of forced top filling in the heating system, it is necessary to install additional units - a circulation pump and a membrane expansion tank. The latter will replace an open expansion tank. But the place of its installation will be different. Diaphragm sealed models are mounted on the return line and always in a straight section.

The advantage of such a scheme is the optional observance of the slope of the pipelines, which is characteristic of the upper and lower distribution of heating with natural circulation. The required head will be generated by a circulation pump.

But does a two-pipe forced heating system with an overhead wiring have any drawbacks? Yes, and one of them is dependence on electricity. During a power outage, the circulation pump stops working. With a large hydrodynamic resistance, the natural circulation of the coolant will be difficult. Therefore, when designing a single-pipe heating system with an upper wiring, all the required calculations must be performed.

You should also take into account the following features of installation and operation:

- When the pump stops, the reverse movement of the coolant is possible. Therefore, in critical areas, it is necessary to install a check valve;

- Excessive heating of the coolant can cause the critical pressure to be exceeded. In addition to the expansion tank, air vents are installed as an additional measure of protection;

- To increase the efficiency of the heating system with an upper piping, it is necessary to provide for automatic replenishment of the coolant. Even a slight decrease in pressure below normal can lead to a decrease in the heating of the radiators.

Regardless of the chosen scheme of the heating system with top filling, it is necessary to provide for two types of adjusting the degree of water heating - quantitative (using shut-off valves) and qualitative (changing the boiler power). Then the heating operation will be not only efficient, but also safe.

The video will help you to clearly see the difference for different heating schemes:

Central (or centralized) heating - heat supply system a large number of residential properties.

It is most often used for heating apartment buildings, office buildings, and industrial facilities.

Understand essence, device and principle of operation, as well as to understand the types of central heating system, this article will help.

The elements

Now let's move on to a detailed acquaintance with the nodes of systems that provide water supply and heating in apartments.

Elevator unit

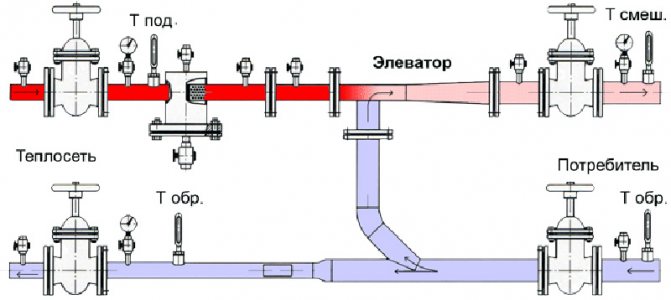

Its heart is a water-jet elevator, in the mixing chamber of which hotter and higher-pressure water from the supply is injected through a nozzle into the relatively cold water from the return. At the same time, it involves a part of the coolant from the return pipeline entering through the suction (jumper between the supply and return) into the re-circulation.

Direction of water circulation through the elevator unit

At the same time, the pressure at different points of the elevator unit is distributed like this:

- Feed to the elevator - 6-7 kgf / cm2;

- Return flow - 3-4 kgf / cm2;

- The mixture (on the supply line after the elevator) is 0.2 kgf / cm2 higher than on the return line.

Let us emphasize again: the entire coolant in the heating circuit sets in motion a difference of only 1/5 of the atmosphere, corresponding to a pressure (read — the height of the water column) of 2 meters. This explains the relatively slow circulation of the coolant, the absence of hydraulic noise in the radiators and the relatively large (15-25 degrees) temperature difference between the radiators in the house.

The mixture pressure is almost the same as the return pressure

There may be several elevator nodes in the house; however, usually only one of them is equipped with hot water connections. Tubes of the dead-end system are located on the supply and return to the elevator and suction and are connected to the general filling. At the same time, only one of the tie-ins is open: otherwise, the bypass created by them between the supply and return will extinguish the difference necessary for the operation of the elevator.

The simplest elevator with a dead-end DHW system

DHW with recirculation requires the wiring of two dispenses around the house.

In the elevator unit, they can be connected in three ways:

- From supply to return. The water flow through the hot water system is limited by a washer (steel pancake with a hole of a fixed diameter), installed on one of the flanges of the tie-in on the return line;

- From serve to serve. Two tie-ins are mounted on the supply line up to the elevator. Between them, a retaining washer is placed on the flange with a hole diameter 1 mm larger than the diameter of the elevator nozzle;

Note: the washer creates a minimum pressure drop between the tapping, with little or no effect on the operation of the water jet elevator.

- From return to return. The tie-in device and washers are the same as in the previous case, but on the return pipeline.

Please note: DHW switches to the return pipe when the flow temperature reaches 80 degrees Celsius. The current SNiP temperature of hot water supplied from an open heating system is limited to 75 ° C.

In addition to the elevator and hot water connections, the elevator unit includes:

- Mud traps (always at the supply inlet, optionally at the return) with flushing dumpers;

Sump on the feed of the elevator unit

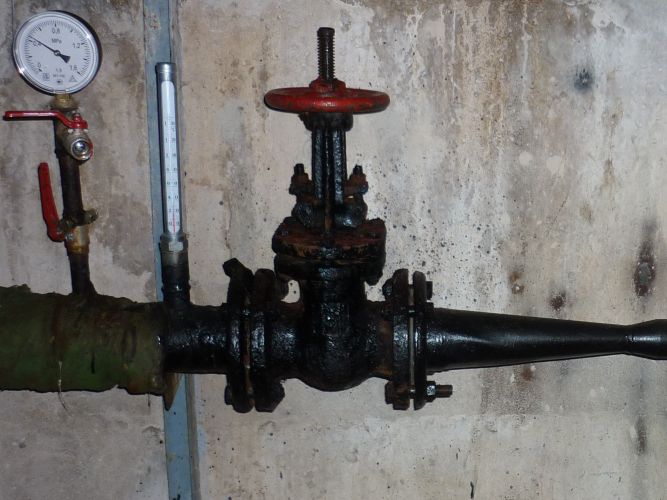

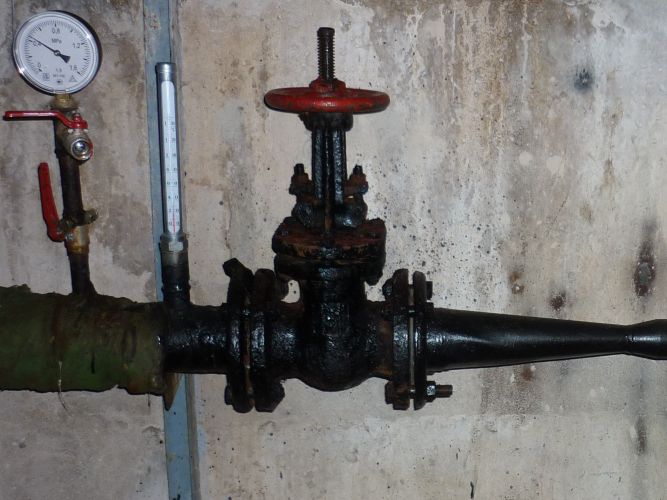

- Control valves for measuring pressure. They can be equipped with pressure gauges, but if the elevator unit is located in the basement of an economic purpose, the pressure gauges are often removed to avoid theft;

Permanently mounted pressure gauges

- Oil pockets for temperature measurement;

- Heating system discharges. They open to the floor of the substation or, which is much more reasonable, to the sewer. Discharges allow you to completely drain the heating and water supply systems of apartment buildings. In addition, they are used for annual hydropneumatic heating flushing;

Once a year, the heating system is flushed with a compressor

- Gate valves or ball valves at the inlet of the elevator unit, for heating after the elevator and at all hot water connections. Optionally, intermediate valves can be present in the substation, allowing, for example, to drain the elevator to dismantle the nozzle without turning off the hot water supply.

Heating spills

If the heating and water supply scheme for an apartment building is implemented with heating spouts in the basement, they are mounted horizontally, without slopes. Typical filling diameters are 32 - 50 mm. Risers are connected by welding, less often by threaded connections, on tees.

Bottom heating outlet: two pipes are laid around the perimeter of the house in the basement

It is curious: in the houses of the Stalinist construction, galvanizing was massively used for heating. Welding is contraindicated for galvanized steel, since the anti-corrosion coating inevitably burns out in the seam area. Therefore, all elements of the heating system were mounted only on the threads.

Heating in stalinka: all connections are threaded

In the case of top filling, the supply in the attic of the house is laid with a constant slope. An expansion tank with a relief valve is mounted at the upper filling point of the supply.

What is the difference in installation? With the order of starting heating systems.

In the first case, when the discarded circuit is started, it is distilled to a dump in order to expel the maximum amount of air from the risers; then air locks from the remaining cold risers are vented through the Mayevsky taps in each bulkhead. It is long, inconvenient and often associated with the search for the absent tenants of the upper floors.

To start heating, the air must be vented in each apartment on the top floor.

But the instructions for starting a top-filling house are much simpler than an example:

- Fill the heating circuit by slowly opening the house (heating) valves on the return and supply;

- Go up to the attic and bleed air through the expansion tank vent. Due to the slope of the filling of the supply, it will be displaced by water exactly there.

Expansion tank and air vent are located at the top filling point of the supply

Heating risers

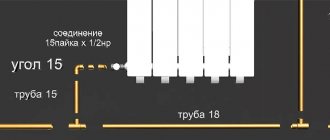

Typical diameter of heating pipes is 20-25 mm.

Steel heating pipes. Size - DN 20

Let's clarify: steel pipes, which are used to mount heating and hot water supply of apartment buildings, are designated by a conditional passage (DU, or DN). It indicates the possibility of connecting the pipeline to a pipe thread of the corresponding size and approximately corresponds to its inner diameter.

The risers go into the connections to the heating device; between the connections, a bypass jumper is usually mounted the same as the riser, or a step smaller. The bypass provides circulation in the riser with fully or partially closed shut-off and control valves on the connections (throttles, thermal heads, ball or three-way plug valves).

Three-way valve for adjusting the heat transfer of the cast iron battery

At bottom filling, a jumper is laid between the paired risers:

- At the level of the upper manifold of heating radiators;

Loopback of paired heating pipes on the upper floor

- Under the ceiling of the top floor apartment;

- In the attic.

Hot water filling

The diameter of hot water supply spouts varies from 25 to 100 mm. Fills with a cross section of 50 mm or more can be found mainly in houses built before the 80s of the last century: they were designed with an allowance for the overgrowth of steel water pipes with rust and lime deposits.

In later buildings, the diameters were selected without a reserve, taking into account the estimated service life of black steel on the water supply of 15 years.

Filling hot water and heated towel rails in the basement of the Khrushchev

Filling of water supply systems is laid only in the basement or subfloor.

The functionality of two hot water filling in a recirculation system can be:

- Identical (hot water risers with draw-off points and heated towel rails are attached to both bottlings);

Both draw-off points and heated towel rails are connected to the paired risers

- Separate (the filing of the supply is connected to the risers on which the points of water intake are mounted, and the risers with heated towel rails are connected to the pouring of the return). Less often, a group of risers with mixers and towel dryers is combined with a single idle (without attached devices) return riser.

Curious: up to 7 hot water risers can be combined into groups. In the author's practice, the risers were usually combined into groups common for a separate apartment or for an entrance.

DHW risers

Typical diameters (DU) of hot water risers are 20-32 mm.

They can be installed in apartments:

| Picture | Location of hot water risers |

| In the niche of the bathroom (open or closed). |

| At the entrance to the toilet or bathroom. |

| In a kitchen niche (kitchen hot water riser with apartment-based connection of risers in a circulation circuit). |

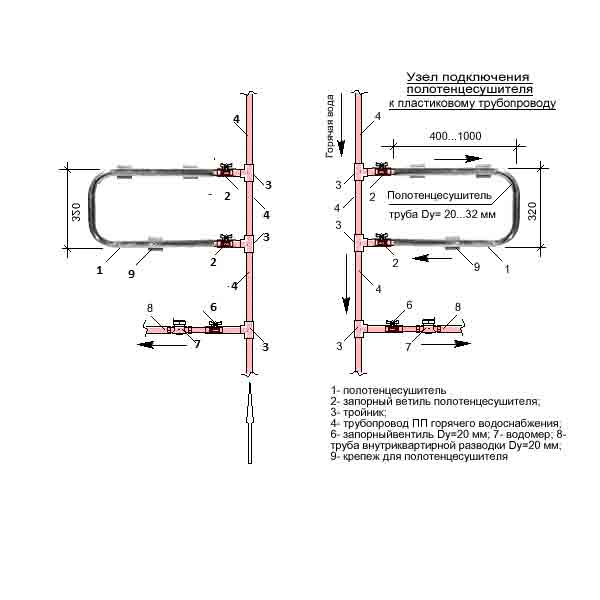

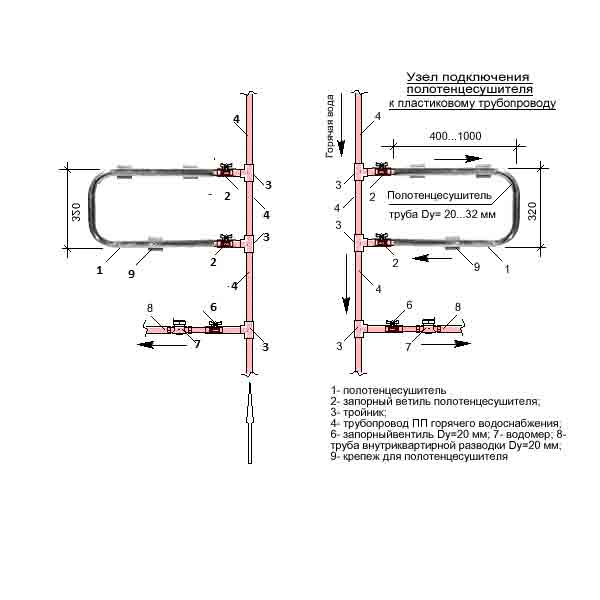

The connection of modern heated towel rails in the circulation circuits of hot water supply is carried out in the break of the riser and ensures their constant heating.

Useful: when installing a heated towel rail with your own hands, it is better to connect it not to the break in the riser, but parallel to it. Shut-off valves are installed at the inlet and outlet of the dryer. Such a scheme will help you turn off the heating in the summer heat.

Connecting a heated towel rail with shut-off taps and bypass

Private houses, apartments from the developer

The last remark, in fact, brings us very close to the next section of the article. Its theme is heating schemes for a private house: piping and heating appliances.

The schemes of the upper and lower filling described above are quite applicable for a two-three-storey cottage. However, they are not always optimal in terms of material savings, fault tolerance and temperature distribution. Well, let's explore the alternatives.

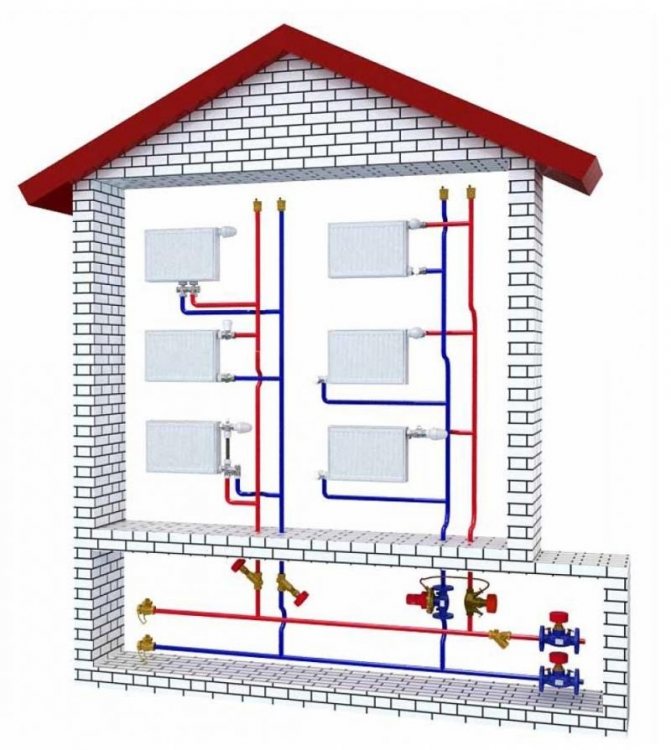

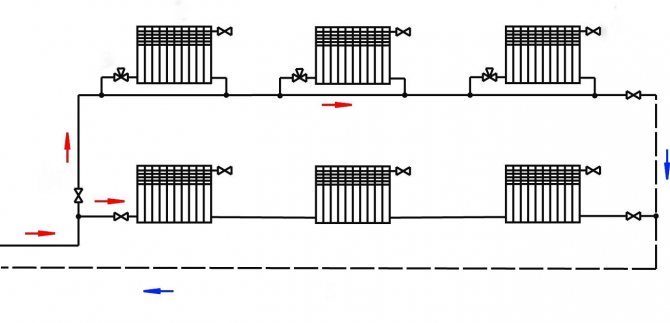

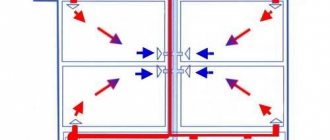

Horizontal routing differs from the standing (vertical) one in that heating devices located on the same level are interconnected. If there are two or more floors, the contour of each of them is horizontally divorced.

Horizontal routing for two floors.

Wiring from a boiler or other heat source can be:

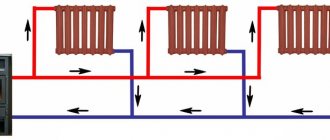

- Single pipe... All devices are connected to the gap of a single ring that encircles the room around the perimeter, or (which is much more reasonable) parallel to it. There can be several such rings - according to the number of rooms or floors;

The simplest one-pipe scheme.

- Two-pipe. Each radiator is a jumper between the supply and return lines. It is believed that two-pipe wiring allows for a more even temperature distribution.

Section of two-pipe wiring with radiator connections.

In practice, however, it is quite capricious, since it requires throttling of the devices closest to the boiler and precise adjustment of the throttles. The price of non-compliance with this recommendation is defrosted distant heating devices: without throttles, the entire coolant begins to circulate through the near batteries.

Each radiator in a two-pipe system must be supplied with throttles for adjustment.

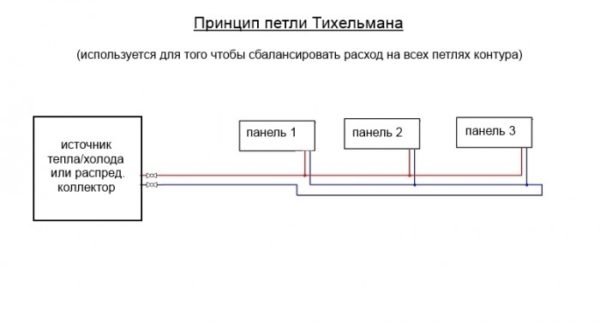

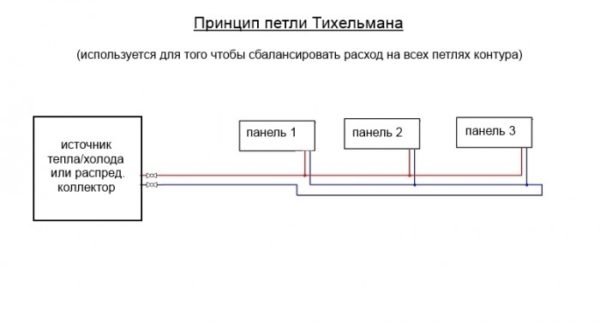

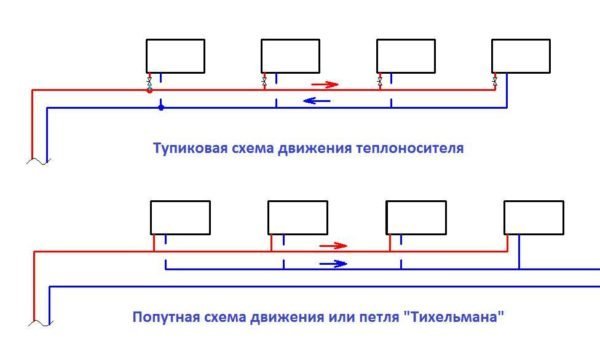

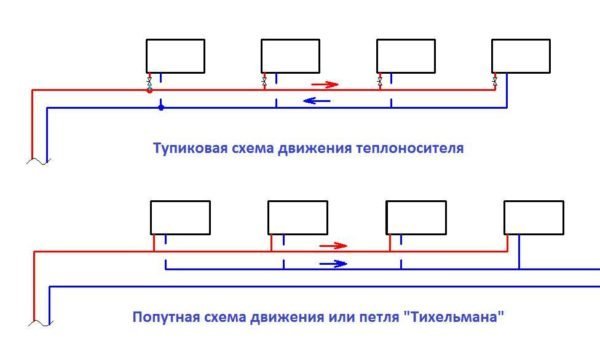

It should be noted that the problem of balancing a two-pipe system is very elegantly solved in the so-called Tichelman loop... In fact, it represents several parallel contours of the same length.

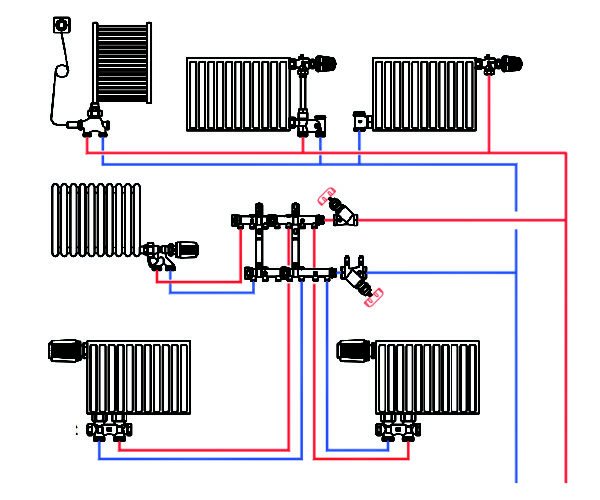

Another solution that allows you to evenly distribute the heat load - collector wiring... In this case, each device is connected by a pair of connections to the collectors responsible for switching off or regulating the temperature. This scheme involves laying the liners in a screed or grooves: hardly a dozen parallel pipes on the walls will decorate the design of your home.

Collector and series wiring can be combined in one heating system.

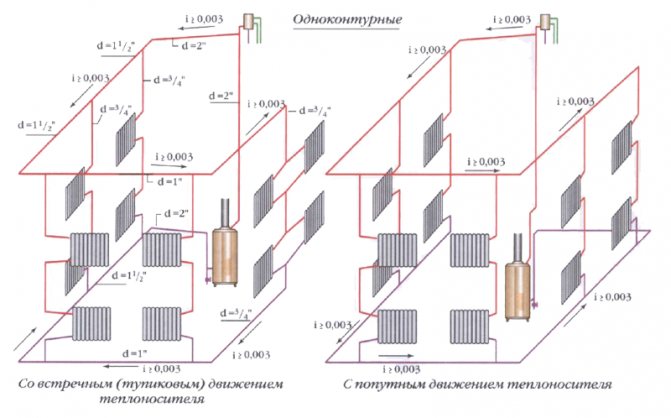

Finally, two-pipe routing can be dead end (when the direction of movement in the flow and return is opposite) and passing (the movement of the coolant in two lines in parallel, the system is a vicious circle).

What is the best layout for a studio apartment or a small cottage?

In my opinion - one-pipe ("Leningrad"), plinth (divorced in the lower part of the walls), with radiators connected parallel to the main ring and cut in according to the "bottom-down" scheme... It attracts with absolute fault tolerance, ease of start-up and undemanding balancing.

I'll elaborate on this statement a bit:

- Defrosting a separate section of the circuit is, in principle, impossible as long as the coolant circulates in it. The ring, however;

- The operation of a separate device (airlock, shutdown, throttling) does not have any effect on the operation of the remaining batteries. The circulation in the ring will continue in any case;

- To start the ring, it is enough to open the valves or latches. All air will be displaced into the batteries located above and can be vented at any time through Mayevsky taps or automatic air vents. Moreover, it will not interfere with the operation of the batteries even without bleeding: the circulation will go through the lower manifold of the device.

Payment

Finally, we will answer a few questions, one way or another related to the growing tariffs for heat and hot water every year.

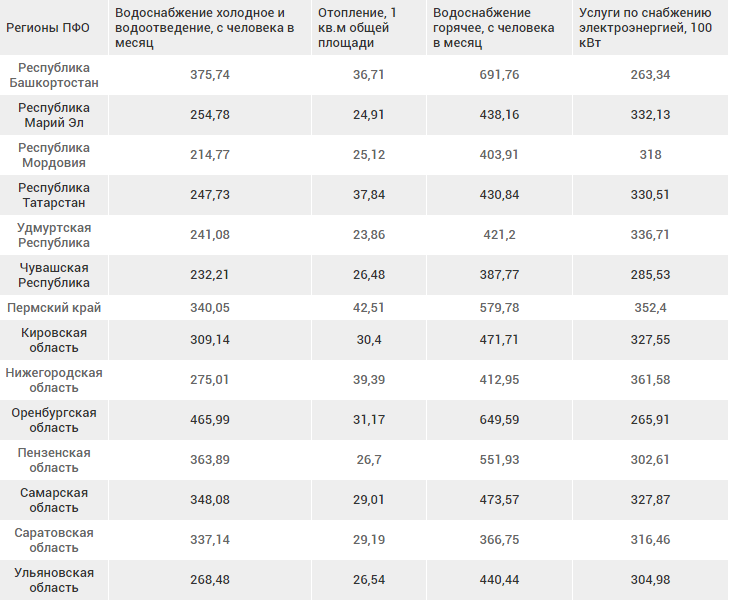

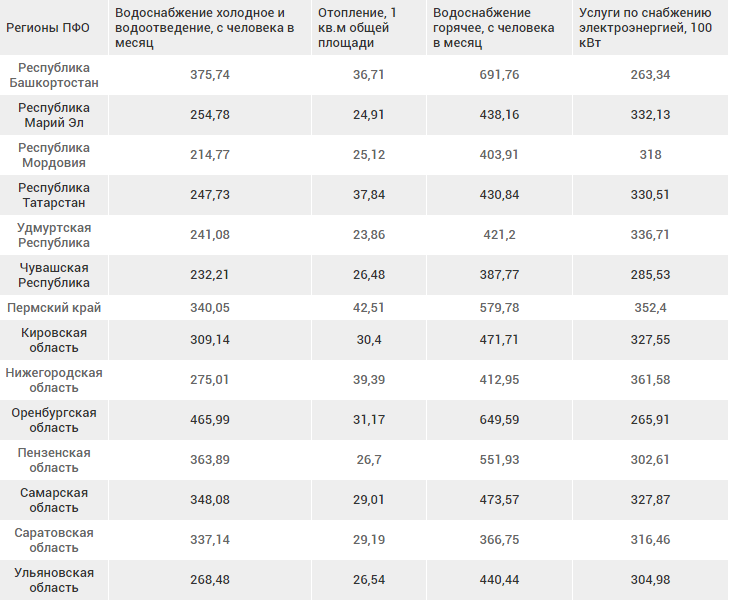

How is the payment for heating and hot water supply calculated?

The key parameter in calculating payment for heating is the amount of heat used to maintain a comfortable temperature in an apartment or to heat water. The cost of thermal energy for 2017 is 1000 - 1800 rubles per gigacalorie, depending on the region.

Utility rates for 2020 for the city of Berdsk

However, heat meters are far from being in all apartments, so receipts often include:

- Fixed payment for heating per square meter (it is calculated as the product of the heat consumption standard for a given region and the price of a unit of thermal energy);

Simplified scheme: the cost of heating is calculated by the footage of the heated area

- The cost of a cubic meter of hot water, taking into account the meter (90-170 rubles per cubic meter).

How can you save on heating?

To reduce costs, you must:

- Install heat metering devices on each radiator;

- Mount throttles or thermal heads on the connections to limit the flow rate of the coolant through the heater.

In the photo - a sectional radiator with a heat meter and a thermostatic head throttling the supply line

Can hot water be used to heat an apartment?

Technically, yes. To do this, it is enough to form a closed heating circuit (for example, the simplest one-pipe Leningrad) and connect it to the gap in the hot water riser. Since there are no metering devices on the riser, the heat obtained in this way will be absolutely free for you.

The simplest heating system - Leningrad

But:

- Any change in the configuration of public utilities requires approval from the housing organization and, in the case of hot water supply and heating, from the respective service providers. Of course, none of the organizations will give permission for such a change in the heat supply scheme;

- Uncoordinated re-planning of communications is an administrative offense and is punishable by a fine with an order to restore the original configuration at your own expense;

The Housing Code regards the uncoordinated redevelopment of communications as an administrative offense

- Finally, the main thing: you can disconnect from the DH system only by an entrance or a house, with the provision of a plan for an alternative heating scheme and agreement with suppliers of electricity or gas (alternative heat sources).Without an official termination of the supply of heating services, you will continue to receive bills that you want to get rid of.

To stop paying for central heating services, you need to cut off the heating devices from the heating pipes and draw up a shutdown certificate with the representatives of the housing dwellers

About autonomous heating

An autonomous heating system in an apartment building is the dream of many apartment owners, but the process of switching to independent heating is not easy and expensive. These are both lengthy legal troubles and a technical solution to the issue - the correct selection of equipment, installation and commissioning. And the problems associated with the technical implementation of the project are much simpler.

Autonomous boiler room of an apartment building

The market of household appliances, including heating, offers a wide range of boilers, radiators, pipes and all kinds of fittings, and in each city there are several dozen specialized companies working in this direction. The organization will not only do all the installation and adjustment work, but also draw up all the necessary acts and permits. But the cheapest way, of course, is to install a heating boiler and separate the pipes with your own hands.

The main documents required in order to connect the autonomous heating of an apartment building on your own:

- A statement with justification from the operating company that you can heat your apartment on your own, and the reason for refusing the centralized heating system;

- Project with technical conditions for connecting an autonomous system: Technical calculations about the feasibility of your autonomous heating and calculations that changing the general scheme of the central heating system will not damage the heating of the house as a whole;

- Calculations of heat consumption from the remaining risers in the DSP based on the residual principle;

- A conclusion from the operating company that after the installation of your autonomous heating system, the thermal-hydraulic mode of the DSP will not be violated;

Diagram of DSP malfunctions

Having completed all the certificates and acts, you can begin the practical realization of your dream in life, and cut off the radiators and pipes of the house or apartment wiring of the DSP. And do not forget to shut off the heat conduit entry and seal it. In houses to which a central heating system is connected, this is easier to do than in high-rise buildings - in apartment buildings, pipe risers were laid through the premises, and to dismantle them, you will have to enlist the consent of the neighbors from above and below, and loop the continuation of the cut pipes.

Important: Risers that are not connected to your radiators but pass through the apartment are considered a source of heat. In order not to pay for their heat energy in the housing office, the pipes should be well insulated - this way you can prove that you do not use central heating.

Replacing radiators

Parameters

What parameters do different heating systems work with?

For central heating, typical pressures at the inlet to the elevator unit are 5 - 7 kgf / cm2 at the supply and 3 - 4 kgf / cm2 at the return pipeline. The temperature of the heating medium varies depending on the outside temperature.

In most cases, a temperature schedule of 150/70 is used: at the peak of cold weather, the supply temperature rises to 150C, and the return temperature rises to 70C.

Temperature graph 150/70.

The temperature of the mixture (water after mixing the supply and return in the elevator, entering the batteries) is limited to 95 degrees in residential and industrial buildings and 37 degrees in kindergartens.

Under a number of force majeure circumstances, the standard parameters of pressure and temperature can be significantly exceeded.

Here are examples of such scenarios:

- If you quickly fill an empty circuit or abruptly stop circulation in it, an area of increased pressure is formed at the flow front. With a water hammer, its values can reach 25 - 30 atmospheres;

The consequences are not difficult to predict.

- After the end of the heating season, heating mains are tested for density. During the tests, the pressure in them rises to 12 or more atmospheres. In this case, the input valves of the elevator unit should be closed, but the human factor or a malfunction of the shut-off valves may well lead to the fact that not only the route will be tested;

- In extremely severe frosts and with a large number of complaints about the cold in apartments in the northern regions, the operation of an elevator without a nozzle is practiced. At the same time, the suction is suppressed by a steel pancake, and water enters the heating circuit directly from the supply line of the route. And its temperature at the peak of cold weather, as we remember, can reach 150C.

Water from the supply of the heating main goes directly into the heating circuit.

In an autonomous heating system, a typical pressure of 1.5-2.5 kgf / cm2 at a temperature of 70-75C at the supply and 50-55C at the return. With the correct calculation of the heating system, these parameters are stable and do not depend on external factors.