Good time of the day, dear reader! Are you familiar with the situation when the faucet in the kitchen or bathroom breaks down and starts constantly leaking?

If it is not repaired or even replaced in time, then you can flood not only your apartment, but also your neighbors below. In order for the repair to be able to suspend the water supply at the entrance to the apartment, a water valve must be installed. It is also desirable to have a separate valve-type shut-off device in front of the washing machine and each plumbing fixture, so that, in the event of an emergency, only a certain area is disconnected from the water supply system, and not completely the water supply.

What kind of valves are there?

The valve is a shut-off and regulating device mounted on a threaded spindle, which closes the passage in the horizontal plane.

The technical conditions for its manufacture are regulated by GOST 12.2.063-81, GOST 5761-74. The water valve is produced in several modifications, which differ in:

- body structures (straight-through, straight-through, corner, mixing);

- a method of sealing the junction of the cover with the movable element of the shutter (bellows, stuffing box);

- the location of the running nut (thread of a submerged or remote type nut);

- the material for the manufacture of the main elements (brass, cast iron, steel);

- the method of attachment to the pipeline (flanged, coupling, pinned, choke, welded fittings);

- locking element design (ball, valve, plug, wedge);

- the type of force transmission to the working mechanism (manual control, from an electric drive).

The main types of valves

The main types of valves are primarily a tap and a valve. They are the most common and essential elements of various piping systems.

The crane is locking device, structurally representing a fixed body made of various materials (metal, plastic) and a movable element. Basically, bronze and brass are used for the production of cranes. This is due not only to their resistance to corrosion, but also these materials are easier to process, since the surfaces of the valve and body require high-quality processing.

Case design features

Valves, depending on the shape of the body and the method of installation on the pipeline, can be:

- direct-flow - in them the flow of the transported liquid moves through the housing from the inlet to the outlet, without changing direction, the spindle axis is located at an angle to the axis of the passage hole. This design helps to straighten the flow and reduce hydraulic resistance, but increases the valve travel, the parameters of the face-to-face length and weight of the product;

- straight-through - a product with the same direction of flow of moving water at the inlet and outlet and the axes of the inlet and outlet nozzles displaced parallel to each other. Passing through the valve body, the water flow is forced to make at least two turns at right angles, which leads to the formation of high hydraulic resistance and the formation of stagnation zones;

- angular - in them the flow is rotated by 90º once, therefore there is a lower level of hydraulic resistance. Such products have restrictions on the area of use - they are placed on the pipeline plan only on its turning sections;

- mixing - in them, the adjustment of the proportions of water occurs due to the mechanical rotation of the internal elements of the body. Designed for shut-off and mixing of cold and hot water streams.

How to repair a valve

This applies to valves of the valve type, in which the gasket most often fails. It must be replaced with a new one, and the device will continue to work without creating problems.

Attention! The valve valve can be repaired without removing it from the pipeline.

- To do this, you will need a gas or adjustable wrench, which you need to unscrew the crane-axle box.

- The nut is tightening the gasket. It must be unscrewed using a wrench of the required number, or pliers.

- Ready-made gaskets are sold in stores, but you can cut it out of a piece of rubber with scissors to match the old one.

- In the center of the new cuff, a hole is made for a threaded pin protruding from the valve.

- The gasket is put on the pin and tightened with a nut.

- While the valve is disassembled, it is recommended to clean its internal cavities with a knife. The same must be done with the inner planes of the crane axle box.

- A new sealing thread is wound on the thread of the crane-axle box. Better linseed.

- The axle-box crane is screwed into the body by hand and squeezed with a gas wrench. It is not worth screwing in too much, so as not to disrupt the thread.

We recommend that you familiarize yourself with: Ball valve made of stainless steel - selection criteria and installation methods

Locking elements. Principles and structure

Water taps are available with different closure configurations: ball, valve, plug and wedge design.

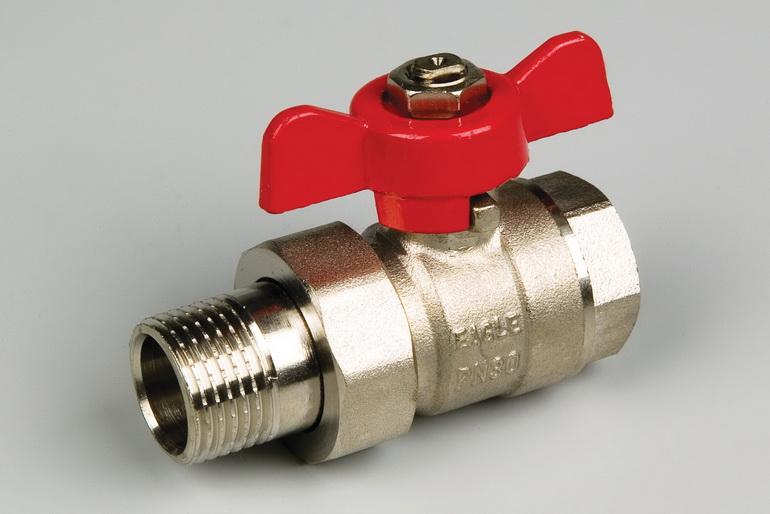

Ball valve

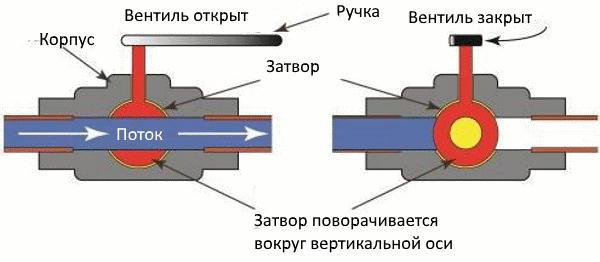

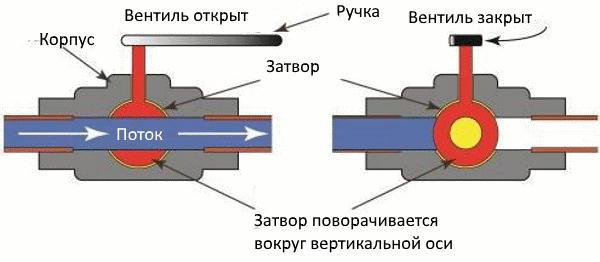

A ball valve is called a valve, the shut-off element of which has a spherical surface.

Its construction consists of the following elements:

- housing. It can be made in an all-welded or dismountable version. One-piece valves are lighter, cheaper, but not repairable. Collapsible products have a more complex design, are more expensive, but can be repaired;

- constipation in the form of a metal ball. Has a bore with a cross-section less than or equal to the nominal diameter of the valve, it can be floating or fixed;

- a movable spindle that rotates the locking part;

- removable handles;

- end fluoroplastic rings, ensuring the tightness of the connection between the body and the polished ball.

The ball valve has a through hole, the axis of which is parallel to the direction of the transported liquid. The stem is rigidly fixed, and together with the ball forms a rotating axis, which, when the valve is closed, is in a perpendicular position relative to the direction of movement of the water flow. When the stem is rotated by 90º, the axes of the ball and water flow holes coincide and water is supplied.

Valve

The block valve assembly includes a threaded rod and a piston (valve). The cross-section of the piston corresponds to the diameter of the through hole in the product body. When the position of the valve is changed, it is screwed into the landing nut, and as a result, the flow of the moving medium is shut off.

The valve can be used not only as a shut-off device, but also to adjust the volume of water supply.

Klinovoy

A wedge valve is a valve for water, the movable part of the gate of which has the shape of a plate (wedge) tapering towards the end.

When the handle is turned to the “closed” position, the wedge is tightly pressed against the seat in horizontal planes parallel to the direction of the flow, which at this moment is forced to bend twice at right angles.

Suberic

With a plug valve, the flow is shut off with a cone-shaped plug attached to the stem. Under the influence of the handle, the stem is lowered and the plug enters the through hole, tightly blocking it.

Worm

The elastomer gasket is tightly pressed against the seat by a worm-type mechanism, which is driven by a handwheel handle.

In the open position of the valve, the stem with the gasket is lifted and the water passage is opened.

Ceramic

Inside the body of such a valve, there are two plates with oblong holes. One of them is fixed motionless in the body cavity, the other is attached to the spindle. When you turn the handle, the movable plate is displaced until their holes coincide and the passage for the movement of water flow opens.

Electrically operated valves

Shut-off valves equipped with an electric drive are installed mainly on large-diameter main pipelines.

They are controlled in automatic mode remotely, they can also be configured for manual control using the steering wheel. The electric drive consists of two main units - a motor and a gearbox, for remote control it is equipped with indicators and position sensors of the shut-off element, to prevent overloads - with special limiters. For fastening to the valve, a flange or coupling type of connection is used.

Classification of water valves

This element of valves is classified according to various criteria.

- By the type and design of the locking device.

- By material of manufacture.

- By the method of connection with the pipe.

Type design of the locking device

There are three positions:

- Valve valve.

- Cork, it is conical.

- Ball.

Valve valve

A valve valve, often called a valve valve, is an instrument body divided by a horizontal or inclined partition. In the latter, a hole was made with a groove for the valve. This section is called the saddle.

The valve is the portion of the stem that is located at the bottom. An elastic gasket is inserted into it, which abuts against the saddle, thereby shutting off the water supply.

The stem itself in the upper part has a thread that enters the thread of the landing nut. It is through the threaded connection that the valve is lifted or lowered when the stem rotates.

| Benefits | disadvantages |

| Valve valves can withstand high pressure. | The gasket is quickly erased, because at the bottom it comes into contact with metal. |

| With their help, you can adjust the volume and pressure of water. | Short service life in comparison with other types. |

| The controls are simple. | You have to rotate the stem for a long time to shut off or open the water. |

| The possibility of repairing. |

We recommend that you familiarize yourself with: Types and rules of installation of valves for shut-off flange connections

Conical

A cone-type water valve is a subspecies of a valve device, because the design of the valve itself differs from the first only in the valve. It is a plug in the form of a cone, which, when the stem rotates, falls into the opening of the partition, closing it with itself.

All the pros and cons of a valve-type valve can be attributed to cone models.

Ball

The device got its name due to the shape of the locking device. This is a ball in which a through slot (channel) is made. If the latter turns out to be perpendicular to the pipeline when the stem is turned, the water flow is blocked. Conversely, when the channel is located along the pipe, the valve is considered open.

| Benefits | disadvantages |

| The simplicity of the opening and closing mechanism creates conditions for operating the valve for a very long time. | Not repairable. |

| Complete tightness of the structure. | According to the instructions, the ball valve should only be used as a shut-off device. It is possible to regulate water with them, but in this case, manufacturers do not guarantee long-term operation. |

| To close or open the water supply, you need to turn the handle only 90 °. |

Mounting methods

Water supply valves can be connected to the process in different ways: fixed with special elements or mounted by welding.

Flange connection

This type of connection uses a special metal flange with a rubber gasket.

Free flanges are put on the end of the pipe and the valve branch pipe, a gasket is installed between them, then the whole assembly is tightened with bolts.

Coupling fittings

The connecting branch pipe has an internal thread with a fine pitch, and the outside is designed in the form of a hexagon for ease of use with a wrench. The coupling is screwed onto the thread with a linen strand seal or FUM tape.

Tsapkovaya

This mounting method is characterized by the presence of an external thread at the end of the connecting pipe and a shoulder at the end of the pipeline.

The end pipe of the valve is pressed against the pipe and is fixed in this position using a union nut. The tightness of the connection is ensured by a metal gasket and special lubricants.

Choke

The nipple is a short length of pipe (sleeve) with female threads at both ends. With this type of connection, the connecting ends of the fittings are screwed onto the pipe and fixed with a union nut.

For welding

This is a one-piece type of connection, the tightness of which is ensured by welding.

Conclusions site

- The valve has two positions - this is the "open" position and the "closed" position.

- The design of the valve, in addition to switching on / off, also allows you to regulate the pressure of the working flow.

- Visually, the valve differs from the valve in the following way: if the handle is simple and its end is attached to the stem, it is a valve; if there is a "lamb" on the stem instead of the handle, this is a valve.

Since such a discussion has started, it's time to refresh for the next issue of linguists. Here is just the question of the bolt / screw will arrive in time.

1. Industrial pipeline fittings A device installed on a pipeline and a vessel and providing control of the flow of the working medium by changing the flow area. Note. The term "industrial pipeline valves" may also be applied to a set of devices installed on pipelines and tanks that meet this definition.

2. Shut-off valves Industrial pipeline valves designed to shut off the flow of the working medium.

3. Control valves Industrial pipeline valves designed to regulate the parameters of the working medium by changing its flow rate.

4. Distribution and mixing valves Industrial pipeline valves designed to distribute the flow of the working medium in certain directions or to mix flows.

5. Safety valves Industrial pipeline valves designed for automatic protection of equipment from emergency changes in parameters.

6. Backflow fittings Industrial pipeline fittings designed to automatically prevent backflow of the working medium.

7. Phase separation valves Industrial pipeline valves designed for automatic separation of working media depending on their phase and state.

8. Gate valve Industrial pipeline fittings, in which the shut-off or regulating body moves reciprocally perpendicular to the axis of the flow of the working medium.

9. Ndp valve. Valve Industrial pipeline fittings, in which a shut-off or control element moves reciprocally parallel to the axis of the flow of the working medium.

10. Crane Industrial pipeline fittings, in which the shut-off or regulating body has the shape of a body of revolution or part of it, which rotates around its own axis, arbitrarily located to the direction of flow of the working medium.

eleven.Valve Industrial pipe fittings in which a valve or regulator is rotated about an axis other than its own axis.

12. Straight-through fittings Industrial pipeline fittings in which the working medium does not change its direction of movement at the outlet as compared to its direction at the inlet.

13. Angle fittings Industrial pipeline fittings, in which the working medium changes its direction of movement at the outlet compared to its direction at the inlet.

14. Flanged fittings

15. Coupling fittings

16. Pin reinforcement

17. Choke fittings

18. Weld-on fittings

19. Stuffing box fittings Industrial pipeline fittings, in which the sealing of moving elements relative to the environment is carried out by stuffing box packing.

20. Bellows fittings Industrial pipeline fittings, in which the sealing of moving elements relative to the environment is carried out by a bellows.

21. Diaphragm fittings Industrial pipeline fittings, in which the sealing of moving elements relative to the environment is carried out by a membrane.

22. Wedge gate valve A gate valve with a shut-off or regulating body, in which the sealing surfaces are located at an angle to each other.

23. Parallel gate valve A gate valve with a shut-off or regulating body, the sealing surfaces of which are parallel to each other.

24. Gate valve with a rising stem (stem) A gate valve, when opened and closed, the spindle (stem) makes a translational or rotational-translational movement.

25. Gate valve with a non-rising spindle A gate valve, when opening and closing of which the spindle makes a rotational movement.

26. Shut-off valve A valve designed to shut off the flow of the working medium.

27. Regulating valve A valve designed to regulate the parameters of the working medium by changing its flow rate and controlled from an external energy source.

28. Single-seat control valve

29. Double-seated control valve

30. Mixing valve A control valve designed for mixing two or more working media of different parameters.

31. Distribution valve A valve designed to distribute the flow of the working medium in certain directions.

32. Safety valve A valve designed to protect the equipment from unacceptable pressure by relieving excess operating fluid and ensuring that the relief stops at the closing pressure and that the operating pressure is restored.

33. Non-return valve A valve designed to automatically prevent the backflow of the working medium.

34. Non-return shut-off valve

35. Non-return valve A non-return valve with forced opening and closing.

36. Regulator Industrial pipeline fittings designed to regulate the parameters of the working medium by changing its flow rate and controlled directly from the working medium.

37. Condensate drain Industrial pipeline fittings designed to drain condensate of water vapor.

38. Float-type steam trap A condensate drain with a float-operated shut-off element.

39. Thermostatic condensate drain A condensate drain, the shut-off element of which is controlled by a thermostat.

40. Thermodynamic condensate trap Condensate trap, the shut-off element of which is controlled due to the aerodynamic effect of the thermodynamic properties of the working medium.

41. Distribution valve A crane designed to distribute the flow of the working medium in certain directions.

42. Cylindrical valve A valve, the shut-off or regulating body of which is in the form of a cylinder.

43.Cone valve A valve, the shut-off or regulating body of which is in the form of a cone.

44. Ball valve A valve, the shut-off or regulating body of which has a spherical shape.

45. Reverse shutter. Ndp. Check valve A shutter designed to prevent backflow of the working medium.

46. Butterfly valve A valve, the shut-off or regulating body of which is made in the form of a disk.

Among the most common locking devices are gate valves and taps. What is the specificity of both?

Manufacturing technology and materials

Different materials are used for the manufacture of the valve:

- Brass. The brass product is characterized by small dimensions, low weight, corrosion resistance and long service life. It can be installed in both cold and hot water supply systems made of steel and plastic pipes. The disadvantage is the high cost of such products.

- Cast iron. Cast iron valves have a rather large mass, but are reliable, capable of withstanding an increased level of pressure, resistant to various kinds of deformations. They have a low price, therefore they are often used for the construction of a water supply system in private and apartment buildings, country houses and garages.

- Steel. In steel products, instead of a handle, a wheel is installed on the body, turning which you can adjust the pressure level or stop the pressure of the moving medium. They are lighter than cast iron, have a simple design, maintainable, can be used in heating systems with a higher operating temperature and pressure, as well as in networks where there is a risk of water hammer.

Brass valves

Brass valves are often installed on pipelines to shut off or control the movement of water through them. The position during its installation can be any, and brass LTS40Sd is used as a material for the manufacture of body parts.

A brass valve is a shut-off device that, by moving the shut-off element, can reliably shut off the movement of any liquid working medium. The product has a spindle in its design, which is a movable mechanism screwed into a nut thread. The presence of a thread allows stopping the shut-off element in any required position. At the same time, this position will be stable and constant, so that even strong enough pressure is not able to change it.

What kind of taps / faucets are there?

Depending on the purpose, there are 4 main types of water taps: valve, single-lever, with a thermostat and sensor.

Valve

These mixers are considered to be the most common appliances.

They are of two types:

- with one valve. These mixers can supply only one type of water - cold or hot. It is mainly used for installation in the kitchen or washbasin. The body of the single-valve valve is made of copper or brass alloy. Locking mechanism - in the form of a ceramic or worm valve - the axle box is driven by a valve;

- with two valves. Their device includes a chrome-plated brass body, two valves that control the cartridges (valve - axle box).

Due to the work of the cartridges, the pressure and temperature of the water are regulated. The spout, depending on the modification of the mixer, can be integral with the body (not swivel) or freely rotate in different directions. Two-valve mixers are intended for mixing hot and cold water;

Single-lever

The single-lever mixer has only one knob (lever), with which the intensity of the supply of cold and hot water is regulated. The pressure can be increased by lifting the handle up.

The temperature is adjusted by turning the lever to the left or to the right; to completely block the water, the handle must be lowered down.

With thermostat

This is an innovative type of device. Adjustment of the temperature and intensity of water intake occurs when a certain indicator is set on a special thermostat scale.

Contactless

The device of such mixers includes special sensors, the principle of which is based on the reaction of infrared rays to heat and motion.

Therefore, as soon as hands are brought close to this mixer, it immediately works. Most often they can be seen in public places: bathrooms of airports, train stations, entertainment centers, healthcare institutions, etc.

Brass valve selection

When choosing a valve, first of all, you should pay attention to its ergonomics, especially if you live in a small apartment. Another important parameter is the reliability and appearance of the device - it should be aesthetic and not conspicuous. Today's market for pipe fittings is filled with products of various shapes and sizes that look very futuristic, but for a bathroom it is best to choose more compact valves.

The most popular are two types of valves - valve and ball. Valves are installed on household pipelines. They are excellent for regulating the flow of water with a high chlorine content. The cost of their repair is low, since often they only need to replace the seals if the valve begins to leak.

The ball valve has an elegant appearance and in some cases can act as a decorative element. It is equipped with one handle that rotates in different directions. With the help of a brass ball valve, you can change the temperature of the water, as well as its pressure. These products are highly demanded elements of locking equipment, and the areas in which they are used are increasing every day.

Which one is better to choose?

Choosing a mixer can be tricky. After all, I want it to be compact, reliable, firmly "sit" in the workplace, fit the style of the room and not fail for a long time.

- For the kitchen, it is advisable to choose a valve faucet made of brass, bronze, copper with chrome or gold plating, on which grease does not stay and dirt is easily washed off. These faucets are durable and expensive, they are not susceptible to oxidation and rust. The faucet should also have a swivel spout with a gooseneck height convenient for washing dishes. The price of a quality product starts from 5 thousand rubles.

- For a bathroom - the body and spout of the faucet should be made of brass, preferably a replaceable cartridge. It can be a ball mixer equipped with a single lever handle or a two-valve valve. Many people prefer a ceramic faucet, i.e. with ceramic cartridge. In it, the sealing element is a ceramic ring. Such products resist hot water better, regulate more smoothly than taps with a rubber seal, serve for a long time, and require less repair and maintenance. Of course, with such characteristics, a ceramic faucet has a considerable price - from 4.0 to 35.0 thousand rubles (depending on the manufacturer).

- For other situations. In the back rooms, the garage, an inexpensive single-valve crane will be enough. The price of such products varies from 1.5 to 3.5 thousand rubles.

Choosing the optimal technical solution

When choosing the optimal type of shut-off valves, the individual characteristics of the upcoming operation mode are taken into account. In addition to technical parameters, the choice of equipment is influenced by price indicators, which are especially relevant when it is necessary to purchase a large number of valves.

Areas of application of valves

To complete pipelines of relatively small diameter, shut-off valves (valves) can be used, which are distinguished by a simple design and low cost.The valves function stably with surges and pressure drops in the system. Compact devices with a low headroom are optimal for equipping pipelines running inside tight industrial and utility rooms.

The design of the valve shut-off mechanism allows the use of practical fittings for completing pipelines with various characteristics of the transported medium, ensuring the stable operation of technological equipment. Manual control, which eliminates the need for a stable power supply for the operation of the electric drive, ensures the guaranteed operability of the valve in emergency situations, when the possibility of promptly shutting off the pipeline is especially important. The small travel of the flywheel makes it possible to extremely speed up the operation of shutting off or opening the pipeline. The seal of the valve plug during movement does not rub against the seat, which has a positive effect on the period of trouble-free operation of the valve.

Features of the use of valves

When equipping pipeline networks with a diameter of more than 300 mm, it is advisable to use valves adapted for uninterrupted operation in difficult technical conditions. The small face-to-face length of the gate valves allows for the most dense installation of equipment, which is especially important in an industrial environment when a rational layout of numerous devices is required. Depending on the operating mode, gate valves with a rising or non-rising stem are used, which have individual technical advantages.

Retractable spindle

Rising stem fittings with increased headroom can only be installed in spacious rooms without physical restrictions. Free access to the valve running assembly provides convenient maintenance of the equipment during operation.

The absence of negative impact of the working environment helps to maintain the perfect functionality of the undercarriage for convenient control and trouble-free operation of technological equipment. The main disadvantage of using gate valves with a sliding spindle is the need to plan a place for the free movement of the working unit when closing and opening the flow of the transported medium.

Non-rising spindle

Valves equipped with a non-rising stem have a reduced headroom, ideal for mounting equipment in confined spaces. The lack of maintenance of the undercarriage immersed in the working environment reduces the period of maintenance-free operation of the equipment. Gate valves with a non-rising stem are not recommended for use in critical facilities.

The scope of maintenance-free gate valves with a non-rising stem is limited to water and non-aggressive oil products. The working environment must be free of abrasive particles, solid impurities and corrosive properties. Compact valves are conveniently located in small rooms, process wells, oil wells and underground utilities.

How to install it yourself?

Correct installation of the water valve is essential for safe operation and a longer service life. In principle, the installation itself proceeds according to the following scheme:

- Shut off the water supply system.

- Open all taps to drain the remaining water from the pipes.

- Dismantle the worn out device. The choice of dismantling method depends on the type of connection of the old product:

- tsapkovy - loosen the union nut with a key;

- clutch - by dismantling the clutch;

- flanged - loosen the bolts used to fix the mounting flanges;

- welded - cut a section of the pipe using a welding machine.

- Clean the pipe at the installation site from the remnants of the sealant and rust;

- A new valve is installed, sealing the threaded part of the fum connection with a tape or Tangit Unilok thread. For a flanged valve, no sealing material is required. Unlike fittings with a collapsible type of connection, a special apparatus for soldering pipes is required for mounting a welded device.

However, there are a number of nuances that should be taken into account when working:

- choosing a convenient place for installing the product so that there is no interference with the movement of the lever - handle;

- the thread may need to be lengthened. If the valve is being replaced, then after dismantling the old device, you need to clean the thread of the branch pipe from the remnants of the sealing material and try to screw a new product onto it. Quite often, during operation, corrosion destroys the metal on two or three turns of the threaded part, therefore, it is required to cut the missing turns;

- it is necessary to install the product taking into account the direction of flow of the working medium indicated on the body of this type of shut-off valve.

Installation of cast iron valves

Installing these valves is not the most difficult task. To do this, you only need bolts, a few fasteners, tools, and, of course, the valve itself. The installation of a cast-iron valve at the beginning of the water supply system greatly simplifies and speeds up the process of repairing it, if required. In this regard, the installation of this device in the basement or in the underground will allow you to easily shut off the water supply and you do not need to seek help from the appropriate specialists or service personnel, thereby avoiding unnecessary costs.

Cast iron valves will undoubtedly be appropriate both for use in domestic water supply systems and in other pipelines, since they are quite undemanding and easy to use. These devices efficiently cope with their primary tasks and perfectly restrain the water pressure. In addition, their cost is extremely affordable, which makes cast iron valves even more attractive for operation.

Selection of valve material

The water shut-off valve can be made:

- made of brass. The material is lightweight, small in size and durable. The main disadvantage is the high cost. The brass valve can be installed on both cold and hot water;

- made of bronze. The cost of a bronze valve is higher than that of a brass one, and the characteristics of the devices are almost identical;

- made of stainless steel. Relatively cheap devices are more susceptible to scale settling. Therefore, they are practically not used for hot water;

- made of plastic. Plastic valves are also durable and inexpensive. Plastic is practically not subject to corrosion and scale settling.

Brass or bronze valves and stainless steel devices are installed on metal pipelines. Plastic valves are installed exclusively on plastic water pipes.

How to choose a valve

The thermostat valve must be selected according to the following parameters:

- type of device;

- device characteristics;

- price and manufacturer.

Types of thermostatic valves

Control valves for heating systems are divided according to the following criteria:

- by the method of installing the valve on the heating pipe. Allocate:

Valve designed for installation on a pipe parallel to the wall

angle valve installed on pipes brought out of the floor;

Valve for installation on a pipe coming out of the floor

axial valve mounted on pipes extending from the wall;

Valve for installation on a pipe coming out of a wall

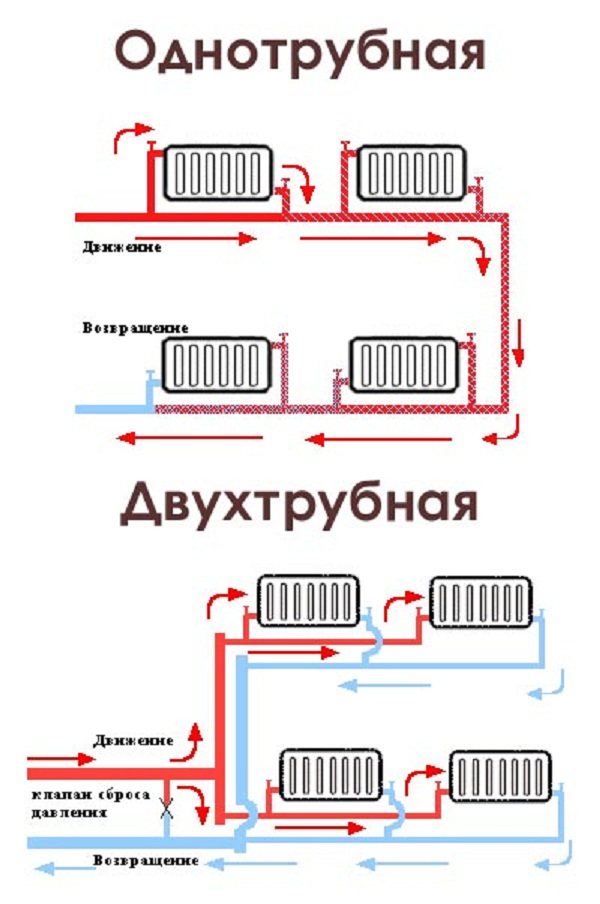

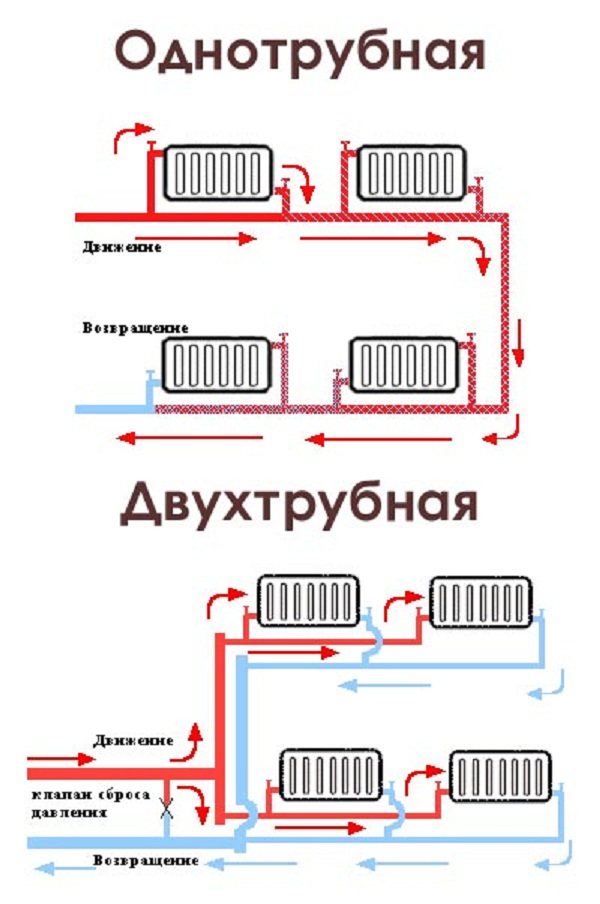

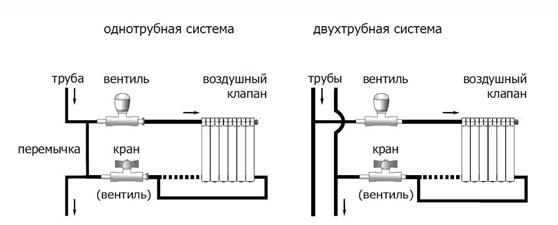

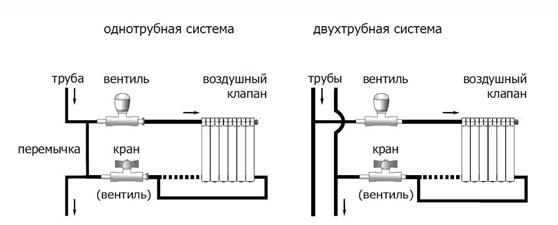

- by the type of heating system installed in the dwelling. Valves for a one-pipe system have a higher flow capacity than valves for a two-pipe system;

Varieties of indoor heating systems

- by the type of working substance in the thermoelement.The substance can be:

- gas;

- liquid;

- paraffin;

More accurate and reliable valves are gas compression valves. The most fragile and less accurate thermocouples on paraffin are considered. The liquid is in the middle position.

- by the type of thermoelement adjustment, there are:

- valves with pre-setting, which is carried out by specialists based on the average data of the home heating system;

- valves with open regulation. Such devices can be configured by the user independently;

- by the type of the installed thermoelement. Distinguish:

Manually adjustable thermostatic valve

valves with a thermostatic head, which is controlled in automatic mode according to the specified parameters;

Valve for heating system, automatically controlled

valves with a remote thermocouple, which is installed separately.

Thermal head with separate temperature sensor

The selection of the valve should be based on the requirements and convenience of the users.

Selection of the device by performance

After selecting the type of thermostatic valve, it is necessary to determine the operating parameters of the device. The valve installed in the heating system must:

- withstand temperatures up to 200 ° C;

- maintain pressure in the range of 16 - 40 bar;

- be made of materials that are resistant to corrosion and mechanical stress. Valves made of bronze are considered the most durable. It is also possible to install devices made of steel or brass;

- coincide in diameter with the diameter of the heating pipes;

- be able to install on a specific system. If a threaded valve is installed, then the thread parameters on the pipe and the device must match.

Popular manufacturers and cost of valves

The cost of thermostatic valves depends not only on the type of device, but also on the manufacturer. The most durable and reliable valves are considered to be made:

Valve installation

Installation of valves on radiators is carried out in several stages:

- selection of the device connection scheme. Specialists have developed standard schemes for heating systems with one and two pipes;

Standard wiring diagrams

- preparation of component parts and equipment. For installation you will need:

- stopcock;

- valve;

- a pipe cut for arranging a lintel (bypass), if a one-pipe system is installed in the apartment;

- welding machine for inserting a bypass;

- pipe threading tools;

- flax or FUM tape for sealing joints;

- wrench for tightening the thread;

- in the next step, the liquid is completely drained from the heating system. If the installation of taps is carried out in a private house, then you can drain the system yourself. How do I open the valve on the battery to drain the system? The valve is considered open if the valve control lever is located along the pipe. If the valves are inserted in an apartment building, then to drain the system, it is necessary to involve employees of the service organization;

Draining water from the heating system of a private house

- the locations for the valves are selected. It is recommended that the cranes be positioned on the pipes in such a way that they can be accessed as soon as possible. The thermostatic valve must be installed at a distance of 0.7 - 0.9 m from the floor level;

- pipes are cut in selected areas;

The length of the section to be cut must match the length of the valve to be installed.

- if necessary, a bypass is installed;

Installing a jumper for the passage of water in the system

- on the pipe cuts, a thread is cut, the size of which coincides with the size of the thread on the valve;

Preparing the thread for connecting the pipe to the valve

- the thread is sealed with linen thread or FUM tape;

- the control valve is fixed to the pipe with a key.

Fastening the valve to the heating pipe

For normal fixation of the valve on the pipe, it is enough to make 4.5 turns. Overtightening can lead to cracking, and weak tightening can lead to poor tightness.

- the tightness of the heating system, threaded connections and welds is checked.

How to cut the threads and correctly install the valve on the radiator is described in the video.

Experts recommend installing thermostatic valves in apartments that allow you to independently regulate the temperature of the radiator. Installation of the device is not difficult and is done by hand.

The device and principle of operation of the ball valve

The main working body of the valve is a ball with a through hole. When the handle is positioned along the pipe, the valve is open. If you turn it perpendicular to the pipe, it closes. The hole in the ball can be round, square, trapezoidal or oval. In valves of small diameter, the crane is made floating, and for large-sized devices it is made on special supports. High tightness of the shutter is ensured by an elastic seal. This allows this type of models to be installed on gas pipelines.

The water supply ball valve operates in two extreme positions when turned 90 °, when it is fully open or closed. Attempting to control the flow will result in rapid seal wear.

They have wider possibilities for connecting branch pipes when installing water supply systems:

- checkpoints;

- corner;

- with three or more branches in order to redirect transported streams.

Connections with pipes are made by nipple, flanged and welded. The latter option allows you to permanently install a plumbing valve in the system.