TimeTrial pneumatic frame tents are equipment suitable for use in extreme conditions.

Modern materials and technologies used by our company make pneumatic tents not only reliable companions in hiking trips, but also irreplaceable assistants in geological and polar expeditions, in organizing temporary accommodation camps in emergency situations. This is largely possible due to the use of modern insulation.

Features of insulation for tents TimeTrial

The material used is essentially a heat insulator. It consists of foil and porous layers located between layers of protective fabric. The composition provides the isothermal properties of the insulation, which creates the so-called. "Thermos effect". The inner temperature of the tent remains for a long time, the air inside the control panel heats up for a long time in the heat or slowly cools down in the cold.

In addition to such an important quality as a high degree of thermal insulation, the material is lightweight, compact during storage and transportation, does not create conditions for the multiplication of microorganisms - molds, which is especially important when used in mobile pneumo-frame hospitals and operating rooms.

Login to the site

Table of contents

- What is blown cotton wool

- Advantages and disadvantages of blown cotton wool

- Features of the laying process

Reliable insulation is an important part of any, including the Canadian technology for the construction of frame houses. According to statistics, it is the laying of insulation that takes the most time, requires high costs of manual labor. The used roll materials always have joints, which often lead to the appearance of cold bridges.

Blown wool allows you to solve all these problems and significantly speed up the process of building frame structures.

What is blown cotton wool

The composition of the blown cotton wool corresponds to the well-known heaters, most often it occurs:

● basalt wool;

● ecowool (cellulose);

● glass wool.

The main difference from roll materials is the consistency and installation technique. The material is dense briquettes that are loaded into a special installation. In it, they are crushed and fed through a special hose, under pressure, to the place of laying.

As a result, the insulation lays down in an even layer, has an almost perfect consistency, and its thermal insulation properties significantly increase. Laying by blowing was previously used only in the Canadian technology for the construction of frame houses, now the method is gaining popularity due to the indisputable advantages of the technology.

Advantages and disadvantages of blown cotton wool

The list of advantages of the technique is quite wide. These include:

- Lightweight and fast styling. Two workers can stack up to 800 m3 of material per shift, which is about 8 times more efficient than other technologies.

- No seams. There is no reason for the formation of cold bridges and increased heat loss.

- The ability to lay insulation in hard-to-reach places.

- Low thermal conductivity. In comparison with conventional heaters, it is 3-5 times lower, depending on the material, basalt wool is best suited for blowing.

- Low weight. The weight of blown insulation is much lower than that of rolled insulation, it creates significantly less load on the frame and floors.

- High vapor permeability and hydrophobicity. Moisture is less hazardous to blown wool due to its low density. As a result, there are no conditions for the growth of fungus and mold, and the material does not lose its heat-insulating properties.

The Canadian technology for the construction of frame houses often implies laying communication in a layer of insulation, due to blown wool, the insulation process can be significantly facilitated and accelerated, and the formation of voids and uneven insulation can be avoided.

In addition to its advantages, blown wool also has some disadvantages:

● Special equipment is needed for crushing and supplying insulation under pressure.

● When laying on drywall, make sure that it is laid in two layers, otherwise there is a risk of swelling.

The Canadian technology for the construction of frame houses, like other methods of erecting frame frames, implies reliable vapor-waterproofing of walls and roofs. Blown wool has the same requirements, although it is less prone to moisture accumulation.

Also keep in mind that the installation equipment is quite expensive, so it is best to use the technique for large volumes of work, otherwise it will not pay for itself.

Features of the laying process

There are two main ways to apply blown cotton wool:

● dry method;

● wet adhesive.

Wet glue means the preliminary application of an adhesive solution, onto which a heat insulator is then sprayed. Due to this, the builder has the opportunity to control the filling of the frame with cotton wool. The wet-glue method was first used in Canadian technology for the construction of frame houses, now the technique is used much more widely.

The advantages of the method include good fixation of the material and a high degree of sound insulation. But after laying, it takes time to dry (about 3-4 days), at this stage you need to ensure good ventilation and a temperature above +5.

Dry installation is much easier, building cardboard is laid before spraying the material, with their help a closed space is created, which is filled with blown cotton. As a result, adhesion to the surface, sound insulation is less than with wet-glue installation.

Manufacturing of insulation for a tent according to individual parameters

You can buy insulation for a tent from us when ordering a pneumatic tent or regardless of its purchase. We can make it for pneumo-frame or awning tents from other manufacturers. For ease of use, the product is equipped with:

- sewn-in straps for fastening to the frame with slings;

- holes for windows, doors, ventilation and technical openings;

- transparent TPU film at the location of the windows;

- pockets for wires around the perimeter of the floor.

The insulation will exactly match the dimensions of your tent. You can also complement it with an insulated removable floor, which consists of two layers of wear-resistant tarpaulin with foam sewn into them.

What kind of insulation to choose?

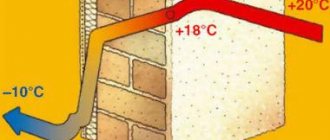

Regardless of what exactly you are going to insulate: an apartment, a country house or a summer cottage, there are a number of criteria that must be taken into account when choosing thermal insulation. First of all, you need to pay attention to the intended use of the building material: heaters for walls located inside the building are not suitable for the facade.

In addition, it is important to pay attention to the following technical characteristics:

- Thermal conductivity. The lower this indicator, the better the thermal protection of the room.

- Environmental friendliness. Some manufacturers include phenol and formaldehyde in their products, which function as binders. The content of these substances must not exceed the permissible values. If the concentration is high, the material is only suitable for thermal insulation of industrial facilities.

- Strength. This is the density of the building material, which determines the resistance to deformation and other loads.For thermal insulation of the outer walls of the house, it is better to choose an insulation with increased values of this indicator.

- Weight. If the material is light, there is no need to strengthen the foundation and supporting structures, which generally reduces the cost of construction.

- Water permeability. Relevant when insulating the walls of the lower floors, basements, rooms with a high level of humidity.

- Flammability. High-quality thermal insulation belongs to the NG class - does not burn, prevents the spread of open fire. They do not emit toxic substances into the atmosphere.

- Soundproofing. Responsible for the level of noise absorption.

Purpose of insulation for tents

Heat-insulating insulation is designed for operation at an external temperature of -60 to + 60 ° C. It can be recommended for purchase to organizations conducting field work, expedition organizers. The material was tested in real conditions, and today it is actively used in Arctic expeditions, in desert conditions, in rescue modules of the Ministry of Emergencies.

In addition to providing survival conditions for people in extreme situations, tent insulation can create additional comfort when hiking, fishing or hunting. With it, you can spend the night outdoors without fear for the health of children. You can buy insulation for a tent from any region - we will remotely coordinate the parameters and deliver your purchase with a convenient transport company!

Home insulation without phenol

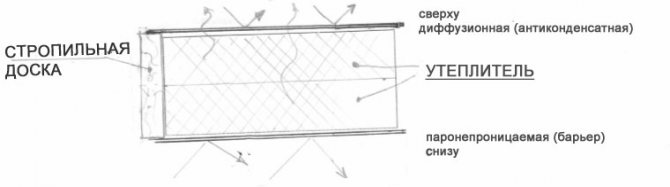

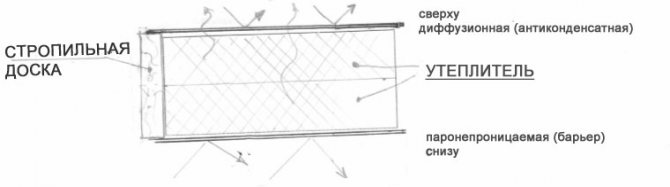

Heat-insulating plates with different weights are installed in the roof and in the walls.

Insulation for roofs and ceilings

Lightweight slabs with a density of up to 40 kg / m3. P-40 - slab size 1x0.6 meters, thickness 75 or 100 mm.

Packaged with a thickness of 100 mm. 5 slabs will cover 3 m2. With a thickness of 75 mm, 6 slabs will cover an area of 3.6 m2. Insulation is installed between the rafters. If the board height is 150 mm, 2 slabs of 75 mm are placed 200 mm, 2 slabs of 100 mm are placed

Films are installed in the roof:

Basalt bulk wool can be poured into horizontal attic floors. These are pieces of slabs without a binder. Cotton wool is packaged in bags of 10 kg. The density of such insulation is 60 kg / m3. The price is 39 rubles. for 1 kg.

Insulation for walls.

Slabs with a higher density are installed in the walls, because they will stand vertically, not horizontally as in the roof. With a low density, the slab can sag and cold bridges form in the wall.

The density of insulation boards for frame houses is recommended. P-60 ÷ 70 kg / m3 The same density of the slab is set for well masonry with facing bricks.

When installing insulation in walls with a ventilated facade, the density of the slab should be higher. P 80 ÷ 90 kg / m3. Such plates are attached to the wall with special plastic fungi with a nail. Films can be placed in the walls from the outside - diffusion wind protection. You don't need to put it inside.

If you want to plaster the facade, then the density of the insulation should be even higher P-125 ÷ 150 kg / m3.

All slabs have geometric dimensions: 1 x 0.6 meters, thickness 5 centimeters.

On request, we can produce slabs of other sizes.

Plates are packed in thermal foil. P 60 ÷ 70 6 plates per pack P 80 ÷ 90 5 plates per pack P 125 4 plates per pack

Basalt-Most produces basalt fibers without limestone and blast furnace slag additives. Thermal insulation boards without the use of phenol formaldehyde. We use a more expensive glue - PVA dispersion. It is an environmentally friendly binder for the production of insulation boards. The cost of production of insulation with such excellent characteristics is much more expensive production of conventional thermal insulation boards based on basalt from other manufacturers.

We sell products directly from the production site. We do not have dealers or other resellers.Therefore, the price of the manufacturing plant is comparable to the prices of the manufacturer of conventional basalt-based mineral slabs of the same density in stores and markets.

By calling us, you will receive additional advice and answers to all your questions.

We can offer more economical options for insulation and sound insulation. You can buy insulation from one package to any volume. Payment both in cash and non-cash payments. The issue of delivery is immediately resolved.

Special insulation

Insulation for pipes

The main problem faced by residents of private houses is winter freezing of pipes through which cold water is supplied to the house, or sewer pipes through which waste water is drained into a septic tank (or central sewage system). If the pipe is frozen, this greatly complicates life in the house and entails the cost of repairing and replacing the damaged part of the communications. Therefore, it is so important to pay attention to the prevention of freezing of pipes.

To prevent damage to communication systems, a heating circuit or thermal insulation material is used. At the initial stage, the cost of laying a heating circuit can be lower than for a thermal insulation device using mineral fiber insulation or expanded polystyrene. However, in the long term, electricity costs will exceed the cost of a special insulation... In addition, power outages often occur in summer cottages, and not everyone can afford to have their own generator. Therefore, most owners of private houses prefer to insulate pipes with thermal insulation materials. Moreover, modern industry produces for this purpose cylindrical heaters that are easily mounted around the pipe. Let's take a closer look at this option.

Special mineral fiber insulation

The group of mineral fiber insulation includes basalt and glass wool, which is made from basalt rock and quartz sand, respectively. These materials have low thermal conductivity, do not rot, do not absorb moisture, are not flammable and are resistant to chemical and biological destructive factors. Mineral wool can be used to insulate plastic and metal pipes, since it does not cause corrosion when in contact with metal and does not emit substances that can have a destructive effect on polymeric materials. This special insulation, price which can scare off the average buyer, is very economical in the long term - after all, its service life is more than half a century, and all this time it retains its thermal insulation properties. So you do not have to make repairs and additional insulation of communications every 10-15 years, which will save you from expenses in the future.

The only drawback of such thermal insulation is the need to spend time and additional funds for the device of external protection made of roofing material, glassine or fiberglass. But the installation process can be significantly accelerated if buy special insulation laminated with fiberglass or aluminum. This layer will protect mineral fibers from soil and atmospheric moisture.

Cylindrical mineral fiber heaters are produced for pipes of various diameters, and have a cut on one side, so this heat-insulating material can be easily put on an already installed pipeline. You can also purchase insulation in the form of mats, with stitching or reinforcement, which provide it with additional bending strength, and simply wrap the pipe with it. You can cut such insulation using any sharp tool. And they fix it with special tape, wire or with staples and casings made of plastic or metal. Also, insulation in the form of mats can be used to isolate septic tanks and drainage systems.

Also, mineral fiber plates with special characteristics of fire resistance are referred to the category of special heaters. They are successfully used for thermal insulation of heating boilers, stoves and fireplaces, using these plates to create an interlayer between heating surfaces and materials of walls, floors, ceilings and roofs.

Extruded polystyrene foam for heat insulation of communications

Extruded polystyrene foam (EPS) is especially relevant when it comes to insulating underground utilities - water supply, sewer pipes and a septic tank with a drainage system. It can be laid directly into the trench, having previously covered its bottom with a sand-gravel mixture. It can also insulate the side surfaces of the trenches, as well as place it over the septic tank and pipes. In this case, the EPS will form the basis for the backfill layer. When using this type of insulation, it is not necessary to lay trays in trenches. Extruded polystyrene foam is considered a reusable insulation, so it can be used when rebuilding communication systems.

Special heaters - on favorable terms!

In our online store you can buy special heaters with delivery of various types. We sell products of Russian and foreign manufacturers, which are of high quality and significant energy efficiency. An important advantage of cooperation with our company is the wholesale cost of all thermal insulation materials. At the same time, the price remains low even with a small order volume. In addition to special materials for thermal insulation, you can purchase heaters for home, which are created specifically for thermal insulation of roofs of various structures, the creation of "wet" and hinged facades, multilayer wall insulation with cladding. We also sell heaters for the floor, foundations, attic and interfloor ceilings, attics, internal partitions. All thermal insulation materials presented on the market of Moscow and the Moscow region can be purchased from us on the most favorable terms, with delivery to the place of construction or repair.

Inflatable car tents

Inflatable car tents are advantageously used as a mobile garage when traveling. The packing bag does not take up much space in the trunk, it is erected in minutes, organizing a reliable shelter anywhere.

Another application is as a car wash and for repairs. When it is difficult or impossible to deliver a car to a car service, a pneumo-frame hangar will help out, ensuring the tightness and safety of the internal space.

| Inflatable mobile tent Guangzhou BARRY Industrial BI-IT 127, (China) | Inflatable awning for the PNEUMOSITI car, (Russia) | ||

| The form | Rectangle | Rectangle | |

| Frame | Pneumocarcass | Pneumocarcass | |

| Size (L / W / H) | 6/4/3 (or upon request) Packing size - 110/80/70 cm | 3/5 m | |

| the cloth | 0.6mm PVC coated oxford, any color | Plain / camouflage PVC | |

| Price | 40,000 - 54,000 rubles | 199,900 rbl | |

| Weight - 50-75 kg Includes sheath, air blower, PVC carrying bag. | The shape of the frame will be maintained using an air compressor, while minor damage will not have the slightest impact on the reliability of the entire structure. | ||

| Installation time is a few minutes. Package Contents: Structure Shell, Carrying Case, Repair Material, Rigging Kit | |||