General principles of substrate organization ↑

Regardless of whether a strip recessed foundation with a basement will be used or the rough floor screed will rest on the ground, it is necessary to organize a substrate or backfill, i.e. a layer that will serve as a barrier to moisture rising from the ground, as well as perform the function of thermal insulation.

Water tends to spread in a vertical direction through the smallest capillaries existing in the soil. If the cross-sectional dimensions of these capillaries are increased to sizes exceeding 0.5 mm, then such propagation becomes difficult. Thus, in order to organize an effective barrier, we need to create a layer with significant air pockets and gaps, which moisture in the soil layer cannot overcome. Also, this layer will prevent the floor from freezing, which can occur with direct contact with the soil.

For the substrate, coarse crushed stone is used, sometimes the bottom layer is sprinkled with cobblestones. The crushed stone should be at least 30 - 50 mm, and its layer should be at least 10 cm. After filling, the crushed stone is thoroughly rammed using rollers or vibrating equipment.

First add rubble

Then, river or quarry sand is poured onto a layer of crushed stone in a layer of 7 - 10 cm, which is also rammed using a special tool. From how well the backfill layers are laid and tamped, their water repellency and bearing qualities will depend, which will affect the integrity of the subsequent concrete screed.

Sometimes a layer of fine gravel is poured onto the sand and closed with a liquid cement mortar. This is done in places where the water table is too high.

Crushed stone is covered with sand

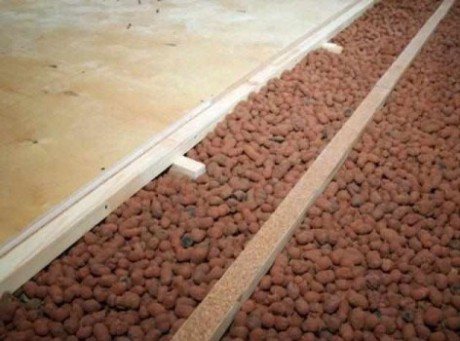

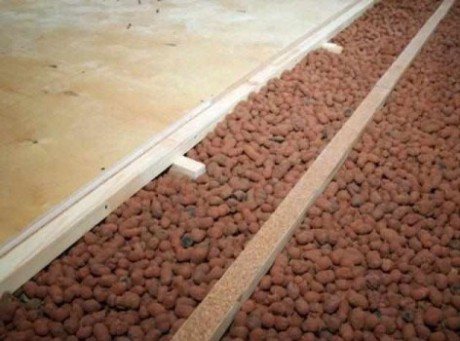

The substrate of large rubble or cobblestone creates a layer in which there are no small capillaries, instead of them there is a large number of volumetric air gaps or pockets, which water cannot overcome by capillary propagation. If the groundwater does not rise high, a layer of expanded clay may be part of the substrate, which will play the role of an excellent insulation.

Sometimes expanded clay is used as insulation

Sometimes measures are required to improve the waterproofing properties of the substrate. If, on the basis of measurements of the groundwater level and soil analysis, it is decided to carry out additional waterproofing measures, then the layers of sand and crushed stone are impregnated with bitumen or special polymer compounds, a rough screed must be performed and treated with mastics or penetrating waterproofing. Also, various materials are often combined.

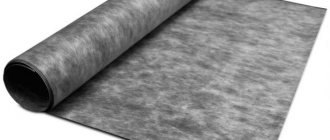

Waterproofing polyethylene film ↑

Specifications and types ↑

According to the specifications of GOST 10354-82, the waterproofing film is made on the basis of low density polyethylene with various additives (stabilizers, dyes, modifiers). It is also made of high density polyethylene (GOST 16338-85). In construction, a film with a T marking (stabilized or unstabilized) with a thickness of up to 0.5 mm is used. The material is produced in the form of a canvas, a sleeve, a half-sleeve in rolls of various widths and lengths. Operating temperature from -50 ° С to +60 ° С.

Along with the usual polyethylene waterproofing, a reinforced one is used, in which a mesh frame is sealed between the layers of the film. The indicator of its strength is not thickness, but density. Sometimes a geomembrane is also referred to as a type of waterproofing polyethylene sheet. It is quite elastic, resistant to mechanical damage, has good chemical inertness (PH 0.5–14), and is environmentally friendly.

Advantages and disadvantages of the material ↑

Pros of plastic wrap:

- Provides double-sided protection against moisture: the foundation is protected from the outside (from groundwater) and from the inside (concrete does not give off moisture, which guarantees good adhesion / hardening and uniform solidification).

- It is not subject to rotting, decomposition: bacteria cannot "process" polyethylene.

- Convenient to use: a wide canvas covers a large area at once. Small thickness and a sufficient degree of elasticity make it possible to use the material in inconvenient places (corners, etc.).

- Allows you to create tight joints: the joints are soldered with a special machine for welding polymers or glued.

- Minimizes the cost of waterproofing: polyethylene film is an inexpensive material for protecting buildings from moisture.

- Non-slip during styling. Manufacturers produce textured (profiled) canvas.

Correct waterproofing of the foundation ↑

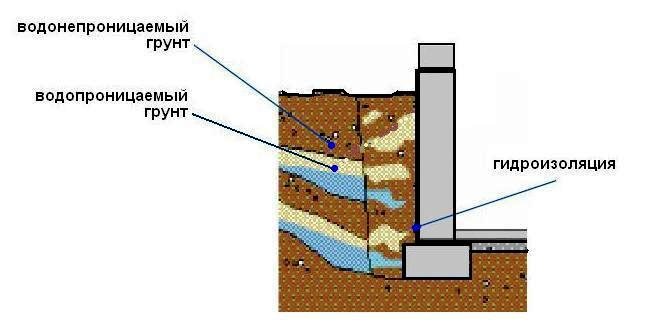

Another source of moisture penetrating the walls and floor of the first floor of a private house is a foundation that is poorly insulated from moisture. No matter how high-quality the waterproofing of the floor in the house is, if the foundation is not processed according to building codes and regulations, dampness cannot be avoided. This is especially true of basements, which can even be heated in the off-season and moisturize partitions and walls of the house. We will not list all the negative consequences of the lack of waterproofing of the foundation structures, but will dwell only on how this affects the moisture content of the floor of the first floor.

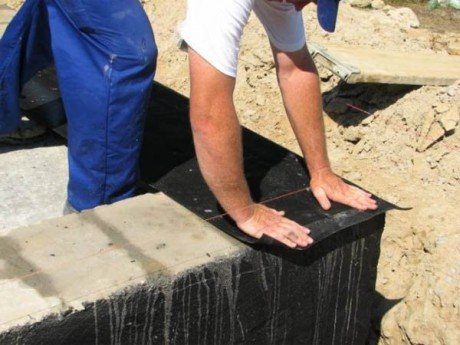

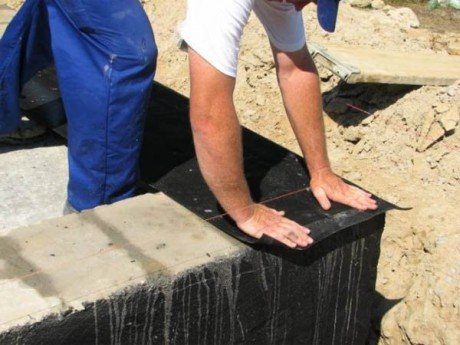

If the foundation is strip, then its structures smoothly pass into the load-bearing walls of the building, which means that the capillary movement of water can reach the rooms of your house. Waterproofing of strip foundations should be carried out using roll, bituminous, and in the case of a monolithic foundation - penetrating insulating materials.

Correct waterproofing of the foundation is a prerequisite

The choice of one or another method of isolation depends on the geodetic and climatic conditions of the area and should be made by an experienced specialist. Also, between the walls of the house and the foundation, there must be an effective vertical cut-off using roofing material or PVC membranes, which, in the event of soaking underground structures, will not allow moisture to penetrate the walls of the building.

Vertical clipping is done with roll material

If such a cutoff was made poorly or deteriorated over time, you can restore it using injection isolation. Insulation of the vertical ends is also required.

If a columnar or pile foundation is used in the construction of a house, then its structures must also be carefully processed with mastics, pasting insulation or penetrating compounds. In addition, it is necessary to insulate the upper surfaces of the ends of the posts, on which the wooden logs will lie. Wood reacts extremely negatively to constant moisture, therefore, roll materials must be laid between the wooden elements and the foundation structures: roofing material, roofing felt, PVC or polyethylene. The logs themselves can also be treated with mastics based on bitumen-latex compounds or impregnated with special solutions that prevent decay.

Roofing material is placed under the lags

Do-it-yourself concrete floor waterproofing

Preparation

Before waterproofing the floor, it is necessary to carry out preparatory work:

- Complete all previous floor work, install the necessary pipes and electrics;

- Remove all furniture from the room;

- Line up the walls and floor;

- Primer the floor surface

- Get rid of cracks on the floor (cover with concrete mortar);

- Prepare and, if necessary, buy the necessary materials for waterproofing (Roller - for coating waterproofing; Burner, knife, - for roll)

Roll coating technology

Before performing this technology, you must once again make sure that the floor is sufficiently flat and the deformation distance does not exceed 2 cm.

Execution plan:

- Make all joints between the wall and the floor tilted at an angle of 45 degrees.

- We treat the clean floor with mastic

- Before laying, roll materials for waterproofing should be laid down unfolded.

- We cut the material to the length we need

- We draw the markup where the material will fit

- On the underside of the roll, smear with mastic and lay on the concrete floor

Make sure that the material overlaps at least 1 cm

Coating waterproofing technology

You can do the coating waterproofing yourself. The mastic treatment technology is not needed in a perfectly flat surface, the main thing is to clean the floor from debris and dust before application, you can vacuum it.

The procedure for applying waterproofing mastic:

- Apply a primer on the concrete floor in 2-3 layers

- Between the joints of the floor and the mill, you need to glue with tape with airtight properties.

- If there are pipes in the room, we glue them with a rubber seal and also an airtight tape

- We knead the mastic according to the instructions on the package. Its finished consistency is reminiscent of warm plasticine.

- Using a roller, apply the mastic on the floor in an even layer

- We process walls adjacent to the floor by 20 cm in height

- Let the mastic dry within 24 hours

During the drying of the mastic, it is not allowed that there is a draft in the room, foreign debris and dust get in.

After the mastic has dried - the surface is ready for further use, you can now apply floor coverings, laminate, linoleum, parquet.

It is not difficult to make your own waterproofing for a concrete floor, the main thing is to know which material is best to use and follow the technology.

Waterproofing of the ground floor floor ↑

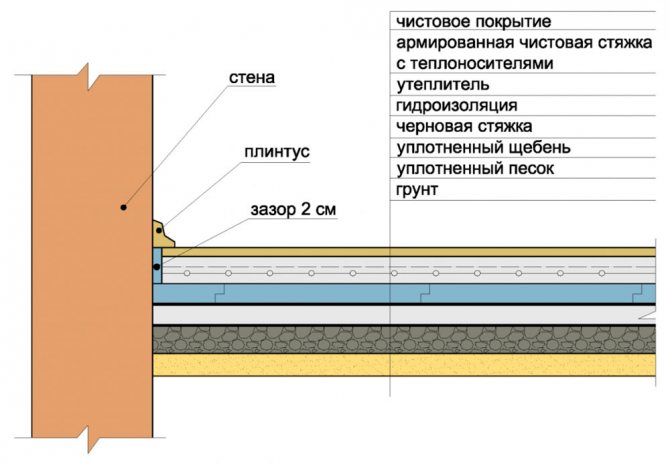

Now we will consider the activities that precede the construction of the screed. In the case of a basement structure, this will be waterproofing of the floor of the living quarters, in the case when a basement is built in the house - insulation of the basement floor.

After completing the appropriate damper filling or substrate, we proceed to the main work on waterproofing the floor in front of the screed.

For this, various materials are used:

- construction polyethylene films;

- PVC membranes;

- roofing material;

- bitumen-polymer roll products;

- polyisobutylene;

- waterproofing, etc.

From the choice of a specific material, the principle of work does not change. Let's just say that traditional polyethylene films are the cheapest and easiest method of waterproofing, however, membranes and bitumen-polymer materials, as well as other modern insulating carpets and coverings, have the best characteristics and performance, but far exceed polyethylene in terms of cost and installation complexity.

Roll materials are carefully glued

Roll material is laid on the sand. Separate strips are carefully welded or glued, in the case of polyethylene, tape is used. The polyethylene film should be 200 - 300 microns thick, it is better to use two layers with overlapping seams. The overlap of the strips should be at least 10 - 15 centimeters.In the case of using various modern diffusion membranes or other coatings, installation should be carried out in accordance with the manufacturer's instructions, since installation conditions can vary greatly for different materials.

If a rough screed or "skinny concrete" is not used, then when installing a reinforcing frame on the film, care should be taken to provide linings that will not allow the reinforcing elements to pierce the coating. However, a more practical solution would be to build a layer of "skinny" concrete 6 - 7 cm thick from a conventional cement-sand mixture with fine crushed stone, which is also covered with roofing material or membrane on top.

The rough screed is also covered with waterproofing

Next, a reinforcement cage is laid on the rough layer and a finishing screed is performed. A rough screed can be treated with bitumen or bitumen-polymer mastic, and a layer of extruded polystyrene foam or dense foam can be laid on top for insulation.

Creation of a hydro-barrier for a wooden floor ↑

In the case of frame-panel construction, the construction of a wooden house or a house from a bar, a concrete screed is not made. Typically, the floor is raised on columnar supports, which are constructed of brick or concrete poured into the formwork. These supports are treated with coating waterproofing from all sides, and the upper ends are covered with roofing material or other roll material, preferably in several layers.

Poles can be coated with bituminous mastic

Further, logs are laid on the pillars, and the installation of the subfloor begins. To do this, you can use moisture-resistant plywood impregnated with special water-repellent compounds. Often plywood is nailed under the logs, then covered with a layer of polyethylene or a rubber membrane.

Plywood is covered with a membrane

The coating must be airtight, the strips are glued with an overlap of 10 - 15 cm. Insulation is laid on top, which is covered with a vapor barrier (in the case of mineral wool). Next, a rough plank floor is mounted on the logs, which is also covered with plastic wrap or a membrane with a 15 - 20 cm outlet on the walls.

A plank rough floor is mounted on top

Such waterproofing is quite enough, and you can start finishing the floor. In places with high humidity - kitchens, bathrooms and toilets - moisture-resistant coatings or lightweight self-leveling floors treated with waterproofing materials should be used. Self-leveling floors can be used for bathrooms and kitchens.

Protection of wooden floor elements from moisture

Without exception, all elements of a wooden floor must be pre-treated with moisture-proof compounds. They penetrate the structure of the tree, making it impervious to water.

If you bought untreated wood, you will have to treat it yourself with a special tool. Usually these are complex impregnations that protect the wood not only from moisture, but also from mold, mildew and insects.

They are divided into two types:

- film-forming - require periodic processing (every 5 - 6 years);

- penetrating - form a reliable barrier to moisture.

It is better to use the second impregnation option. The composition is applied with a spray gun or simply with a brush. It penetrates well into the structure of the tree and dries completely within two to three hours. For reliability, it is better to carry out the processing several times.

Having protected the floor from direct exposure to moisture, it is equally important to ensure that its construction does not allow it, even hypothetically, to have a direct effect on the floor elements. To do this, use some constructive methods for preparing the subfloor.