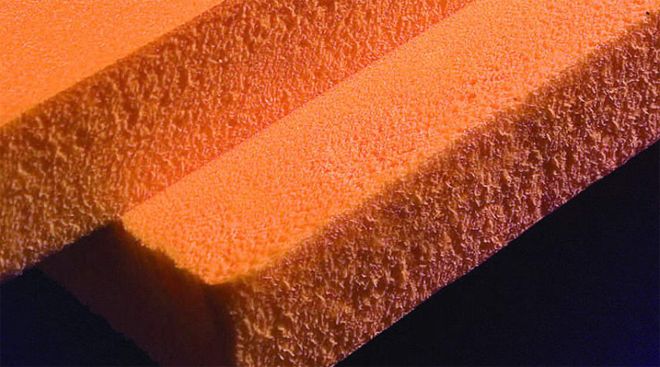

Penoplex building material became famous primarily due to its low price. Expanded polystyrene is chosen as a heater for residential buildings and industrial facilities. But what about its fire safety? Modern penoplex, the flammability of which belongs to the G1 class, is not dangerous and cannot cause a fire. Only if you bought it from a trusted manufacturer.

Investigating the flammability of extruded polystyrene foam

When choosing material in order to insulate a house, people are guided by different principles. For some, the price is important, for others - ease of use, while others pay close attention to parameters such as environmental friendliness and fire safety. In this regard, what can you tell about extruded polystyrene foam - is it slightly flammable or is it dangerous in case of fire? You can find many different opinions about the flammability of extruded polystyrene foam, and sometimes they are even opposite. Let's try to figure out what's the matter.

Flammability class of extruded polystyrene foam

Speaking about the flammability of extruded (extruded) polystyrene foam, it should be borne in mind that various grades of it are produced. With general similar thermal insulation characteristics, they, however, differ in fire hazard class. Thus, opinions that extruded polystyrene foam is low-flammable or non-flammable at all may also have a right to exist. But is it really so?

- G1 - slightly flammable

- G3 - normally flammable

- G4 - highly flammable

- NG - non-flammable

G2 - moderately flammable

It is only natural that sellers seeking to advertise a product claim fire safety. They claim that they do not sell flammable extruded polystyrene foam, but a material that is quite fire resistant. If you come across such an offer - do not believe it! You are either misled, or you yourself were confused: there is no non-combustible extruded polystyrene foam - the price of such a statement is zero. Another thing is that it can belong to class G1 - low-flammable materials. Is the difference small? Sellers think so. By the way, do not confuse it with simply non-flammable polystyrene foam (not extruded), that is, foam.

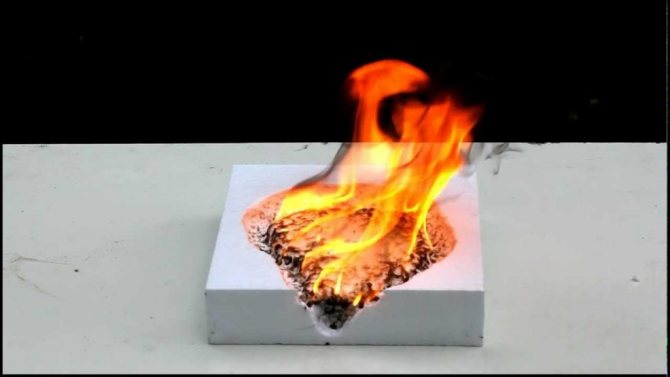

What about extruded polystyrene foam - is it dangerous when it burns? Let's take as an example the products that occupy half of the entire thermal insulation market in Russia. Until recently, insulation of this brand was attributed to hazard classes G3 and G4, indicating also the harmful substances that extruded polystyrene foam emits during combustion. Relatively recently, the products received a new fire certificate, in which class G1 was assigned to some of its types (in particular, Penoplex-35). To obtain low-flammable extruded polystyrene foam, a flame retardant additive was introduced into its composition, which significantly increased the resistance of the material to fire. According to the company's specialists, unlike many other organic materials, when burning, such extruded polystyrene foam emits no more harmful substances than ordinary wood - only carbon monoxide and carbon dioxide.

However, consumers are far from always inclined to trust the manufacturer and are certainly not going to heat the stoves with penoplex in order to verify this statement. Many believe that this study, carried out by the Independent Testing Center for Fire Safety of the City of St. Petersburg, is not entirely true, and are more inclined to believe government agencies. And they just assert that non-combustible extruded polystyrene foam does not exist in nature, and assign it flammability classes G3 and G4.

Penoplex characteristics

Since this material is made on the basis of polystyrene balls, like polystyrene, some of their characteristics are similar:

- Resistant to moisture.

- Light weight.

- Good noise insulator.

- Long service life, with a protective coating.

- Easy to assemble.

- Does not allow steam to pass through.

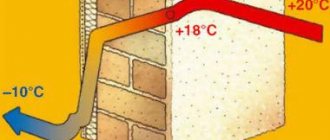

But there are also differences. Penoplex is more dense, so it is needed less than foam for external insulation. For example, a 3–4 cm thick foam board has the same effect as a 10 cm thick foam board.

Penoplex supports combustion. To eliminate this defect, a fire retardant coating is used, but then poisonous substances are released when heated. For the price, this material is much more expensive than expanded polystyrene, but it is more resistant to external mechanical damage.

Comparison by water absorption

When consumers think about the question of which is better - foam or foam, they pay attention to the ability to absorb water. It must be admitted that Penoplex does not like water, but absorbs it no more than 0.4% per month. But the foam also did not go far, its water absorption is 4% in 30 days. In this respect, Penoplex was also slightly ahead. It is also necessary to take into account the fact that penoplex is characterized by vapor permeability, which cannot be said about foam. The latter still has this indicator.

Comparison by strength

Quite often, experts ask themselves which is better - polystyrene or penoplex. Trying to decide on this, it is necessary to pay attention also to the strength. If the expanded polystyrene is clamped and pressure is exerted on it, it will become clear that the penoplex is capable of undergoing a pressure of 0.5 MPa, while for foam this parameter is 0.2 MPa. There is a significant difference here, so it is best to cover the floor with the first analogue, which is especially important for garages, runways and ice rinks. However, it is also necessary to take into account the density of the foam, which is lower and equal to the limit from 15 to 35 kg / m3, for the second material this parameter varies from 28 to 45 kg / m3. This indicates that the specific gravity is also lower.

Does Penoplex burn and not?

It is worth mentioning that on the official websites of Penoplex information that extruded polystyrene foam is not combustible cannot be found. There are only a few words about that very independent research and compliance with GOST. But it is precisely this moment that raises questions. In addition, not all consumers are convinced that the combustion products of extruded polystyrene foam are so harmless. It is possible that the distrustful simply did not have to meet with material treated with flame retardants. These substances prevent combustion (but not fire). That is, when exposed to a high temperature flame, the insulation will light up, but will quickly go out as soon as it comes out from under its influence. Apparently, this is why the processed extruded polystyrene foam is unofficially called non-combustible - by itself it cannot cause a fire and does not interfere with its extinguishing.

As for the combustion products of the same penoplex, it is still not necessary to compare with what is released when burning a tree. Say what you like, but this is an artificial product.During combustion, it emits not only CO (carbon dioxide) and water vapor, but also soot and hydrogen chloride, the inhalation of which is fraught with severe suffocation and pulmonary edema.

Let's summarize everything we've learned about extruded polystyrene foam - is it non-flammable, is it safe? how does its price differ from the usual one?

- The flammability of conventional extruded polystyrene foam is usually in the G3 and G4 classes

- Special flame retardant additives are able to raise the flammability class of the heat insulator to G1

- It can be called non-combustible only conditionally, meaning its high resistance to fire.

- The products emitted by extruded polystyrene foam during combustion are quite dangerous.

The price for "conditionally non-combustible" extruded polystyrene foam is not much different from the usual one. This is also due to the fact that, in principle, its density is higher - class G1 is assigned to penoplex with a density of 35, while penoplex-31 remains a fire hazardous material with class G4. A cubic meter of low-combustible Penoplex-35 costs about 4200-4300 rubles. Other manufacturers of extruded polystyrene foam - Technonikol, Ursa, etc., also produce products in the processing of which fire retardants are used.

It is worth remembering that fire safety depends not only on the material itself, but also on the correctness of its application. Highly flammable penoplex is intended for insulation of foundations, basements, floors, and in no case facades and walls. It is the fire hazard that is one of the characteristics that hinder the even wider use of this heat insulator. However, this problem is being solved by the manufacturer, and it is possible that soon the use of non-combustible extruded polystyrene foam will become the norm in construction.

Advantages and disadvantages

Summarizing all of the above, let's highlight the main pros and cons of expanded polystyrene.

Benefits:

- high resistance to fire (in comparison with similar materials);

- does not react with water;

- light weight;

- density;

- easy to install;

- conducts heat well;

- it can be safely laid on an untreated surface.

Disadvantages:

- with prolonged exposure to high temperatures, the insulation melts;

- vapor tight;

- when buying polystyrene foam treated with chemical compounds, the price of the material increases significantly.

Technical characteristics of the material penoplex

Among the extensive line of heat-insulating materials, one of the first places is occupied by penoplex. Most of those who like to do something with their own hands are attracted by the low price of the plates of this insulation and the ability to mount them on their own without resorting to the help of workers.

This allows you to significantly save on the insulation of private and country houses. Due to the low thermal conductivity of the foam, the finished structures are quite warm.

What is Extruded Polystyrene Foam

The complex technical name of the insulation alarms many who prefer to use only environmentally friendly, low-combustible materials in the insulation of their homes. Modern technologies make it possible not to use freons as a foaming agent. Therefore, only CO2 or freons are now used for expanded polystyrene granules. So we may well call it environmentally friendly.

The material has a number of characteristics that make it very attractive for private and low-rise buildings, as well as for use on an industrial scale.

- The insulation has no biological component, therefore it does not rot or decompose. These properties make it durable (service life ≥ 50 years).

- Eco-friendly insulation. Moreover, we can even talk about the environmental friendliness of its production.

- It has proven itself in floor heating systems. The entire structure of the "warm floor" is mounted on top of the 35 penoplex.A low coefficient of thermal conductivity will effectively save heat, due to which the cost of heating a house or apartment is significantly reduced.

- Wide range of applications. The insulation can be used both in a country house and at an airfield.

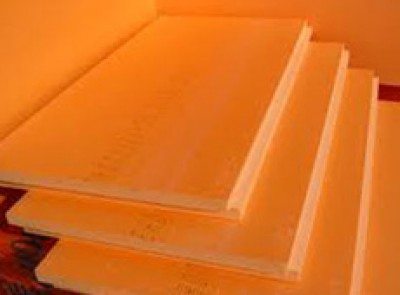

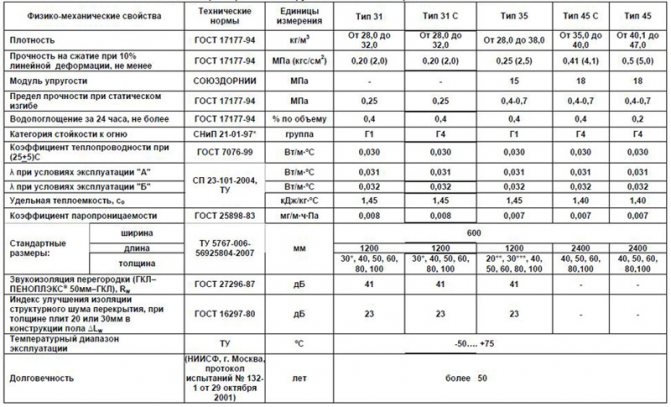

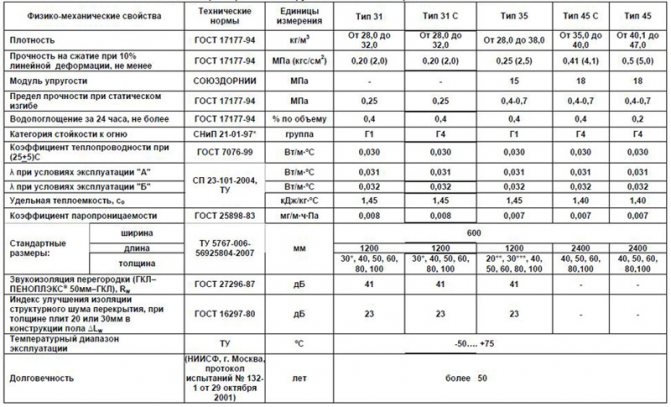

Penoplex technical characteristics are presented in the table below.

Where can Penoplex be used?

Extruded polystyrene foam has found its application in various fields, both in residential construction and repair, and in industrial.

Its technical characteristics have a wide range in terms of such indicators as plate thickness, flammability, strength, which allows them to insulate both runways at airfields (plates with a thickness of 100 mm) and walls of houses, foundations, etc.

Penoplex markings

There are several penoplex markings, such as M35, M45 and others. It should be noted that this is an old marking. They are currently not in production.

- Modern markings - 31C, 35, 45. Penoplex 31C has weak technical characteristics for compression, therefore it is used mainly for insulation of pipes or containers.

- Penoplex 35 is versatile, quite durable, so it can insulate both pipes and walls of buildings, foundations, and can be used in a screed on the floor. The characteristics of this brand have excellent thermal insulation qualities.

- Penoplex 45 can be successfully used for insulating runways at airfields, for insulating deep foundations, floors in industrial premises. It is indispensable for the arrangement of the road surface. Its density, higher than that of 35, perfectly withstands loads, and the almost complete absence of water absorption does not allow the canvas to swell after heavy showers and subsequent frosts. For 45 there are no prohibitions for use on a production scale.

Varieties of Penoplex

Penoplex has specially designed brands for insulation of walls, facades, plinths and other structures. The grades meet the increased requirements for adhesion of thermal insulation boards and substrates. Penoplex is often used for thermal insulation of walls of balconies and loggias.

Penoplex 45 - able to withstand the most impressive weight

It is noteworthy that this material can be used to insulate not only roofs, but also roads, railways and runways. It is the most durable in the entire list. Its main advantage is that it does not lose its qualities throughout its rather long service life.

By the way, insulation of roads for any purpose protects them from swelling after freezing. For example, if in spring and summer the soil accumulates moisture in itself, in winter a road laid on this soil can crack from an excess of water. Thanks to the insulation, the soil will not freeze.

Penoplex Comfort - universal heat insulator

The material (formerly referred to as Penoplex 31C) is truly multi-purpose. They can insulate a country house, loggia or roof. If there is a pool or you built it on a suburban area or, then Penoplex Comfort will be an excellent option for their walls.

The versatility is mainly due to the fact that the material is able to withstand not only high levels of humidity, but also high temperatures. Penoplex Comfort is a fully multifunctional heat insulator that is suitable for most types of insulation work.

Penoplex Roofing - what you need for a roof

Perhaps it is worth mentioning that in the past this heat insulator was called Penoplex 35. Suitable for any kind of roof insulation. In the construction industry these days, a "lightweight" roof is very often used. It is extremely important to take care of its reliability, strength and durability.

A similar problem is solved in the case of repair work on a flat roof, at the base of which there are profiled metal sheets. In this case, the best solution would be to use a refractory material called Penoplex Proof. Often it is he who is used to insulate a flat roof. Penoplex Proof is suitable for attaching attics and ventilated roofs.

Nowadays, non-standard inversion roofs are becoming more and more famous. Due to the lack of free space in densely populated cities, such roofs provide this space where you can make your own private resting corner or organize, for example, a small garden with flowers. Proceeding from the fact that it can easily withstand heavy loads, even a transport parking can be equipped on such roofs.

Penoplex Wall - inside and outside

This is a new name. Earlier it was called Penoplex 31 with fire retardants. However, the very essence has not changed much. Insulation of facades, walls, partitions of houses - this material is ideal for such work.

It is noteworthy that it is required to insulate the wall from the inside only if, for one reason or another, this process does not come out from the outside. Or, if in the process of express repair it is much more convenient to cover the walls with a heat insulator from the inside. Penoplex Wall is an excellent and convenient material that is not difficult to work with.

If we talk about using it outside, this heat insulator proved itself very well during the well laying of the walls. In comparison with the usual brick walls, these walls are much thinner, but they are not less reliable. As well as the ability to keep warm.

The Penoplex Stena brand can be used in the process of creating facades treated with plaster. Since, which is now in great demand, it boasts a large selection of colors and varieties, such a move will give the house an individual originality.

What is the difference between Penoplex Foundation

The name itself (which sounded somewhat earlier like Penoplex 35 without a fire retardant) makes the buyer understand that this insulation option is ideal for the underground part of the building. Its characteristics are endowed with a high degree of strength and are quite capable of withstanding heavy loads.

The “Foundation” type of thermal insulation proposal is very suitable for or floors in the house - that is, where there is no need for a high level of fire resistance. Some structures with a protective coating can be insulated with a “foundation”. For example, it can be a screed made of sand and cement.

The flooring from the Penoplex Foundation slabs will help in a short time to solve the tasks that are directly related to the creation of the foundation of the house and the equipment of the basement. A high level of protection against moisture, groundwater abstraction is not all the advantages of the described material. Additionally, it allows you to lower the groundwater pressure on the basement of the building.

Let's talk about the disadvantages

The disadvantages are predictable, to a greater extent apply to all materials from extruded polystyrene foam. The disadvantages are not significant and there are not many of them:

- bad;

- fire risks, poor fire safety;

- does not impede the raids of rodents and ants

- Cost of a mid-range product - Styrofoam is cheaper

Noting the risks of attacks by insects and rodents that spoil the insulation, we note that the disadvantage concerns any kind of thermal insulation material. Reviews on the use of the product found on thematic forums indicate efficiency, functionality and economy. If you have your own negative experience with the material, please add the deficiencies in the review in the comments block.

After its invention, foam c began to fill the modern building materials market very quickly, covering more and more areas of work.However, it has the greatest impact as a heater.

But the builders did not stop there, creating an even more effective insulation, which is called penoplex. In this article, we will look at the characteristics of penoplex, its features and methods of application.

What is good about penoplex

The properties of penoplex are varied, which is very convenient for do-it-yourself work, in the country or in a private house.

- Ease of installation and low weight make it easy to mount this insulation without the help of specialists.

- Such characteristics of foam as a low coefficient of thermal conductivity, density and others allow it to be used not only for external insulation, but also for thermal insulation of floors at the construction stage. Plates with a density of 45, with a thickness of 50 mm and more, can easily withstand a concrete screed, serving in the future as an excellent service. You will always have a relatively warm floor.

- Penoplex plates, 20 mm, 30 mm, 50 mm thick and higher, will make the walls, floor and roof warmer. Now you don't have to worry about buying warm slippers or a sweater. Penoplex will reliably protect you from bad weather.

- Such quality of penoplex as vapor permeability baffles many. After all, we are used to counting and hearing from sellers in hardware stores that the walls (floor, roof) must breathe. But think about it. Through these micropores, our house (wood or brick) not only breathes, but also loses heat. Using Penoplex insulation, simply organize high-quality ventilation in your room by equipping, for example, a micro-ventilation system and supplying an extractor hood. Thus, you will create a healthy microclimate in your home.

The specifics of the production of Penoplex and its special properties

The first extrusion plant appeared in America more than half a century ago. During the production process, polystyrene granules are subjected to high pressure and temperature. The catalyst is a special foaming agent. Usually it is a mixture of carbon dioxide and light freon. The resulting fluffy mass, reminiscent of well-whipped cream, is squeezed out of the extrusion unit. After a while, freon evaporates, and air enters the cells in its place.

Thanks to extrusion, the manufactured material has a finely porous structure. Each of its identical tiny cells is isolated. The size of these cells is from 0.1 to 0.2 millimeters, they are evenly spaced inside the material. This makes the material strong and warm.

Water absorption - minimal

For heat insulators, the ability to absorb moisture is an important characteristic. The following tests were carried out: Penoplex plates were left in water for a month, immersed in it completely. Water was absorbed by them in a small amount only for the first 10 days, after which the material ceased to pick up moisture. At the end of the term, the amount of water in the slabs did not exceed 0.6 percent of their total volume. That is, moisture can only penetrate into the outer cells of the Penoplex insulation, which were damaged when cutting the material. But there is no access to water inside the closed cells.

Thermal conductivity coefficient - small

Compared to many other heat insulators, the thermal conductivity of Penoplex is much lower. Its value is 0.03 W * m * 0 C. Since the material practically does not absorb water, it is quite possible to use it where there is high humidity. At the same time, its thermal conductivity remains almost unchanged - it can fluctuate only from 0.001 to 0.003 W * m * 0 C. Therefore, Penoplex plates can be used to insulate both roofs with attics and foundations with floors and basements, without using an additional moisture protective layer.

Water vapor permeability - low

Like any extruded polystyrene foam, Penoplex is also distinguished by its increased resistance to moisture evaporation.A layer of slabs made of this material with a thickness of only 2 centimeters has the same vapor permeability as a layer of roofing material.

Service life - long

By freezing Penoplex slabs many times, and then exposing them to thawing, the researchers found that all the characteristics of the material remain unchanged. According to the conclusion of the NIISF Institute, these plates can serve as thermal insulation for houses for 50 years, no less. Moreover, this period is far from the limit, it is given with a large margin. In this case, atmospheric influences are also taken into account.

Very stable when compressed

As already mentioned, extrusion allows you to achieve uniformity in the structure of the material. Evenly distributed cells of a tiny size (tenths of a millimeter) improve the strength characteristics of Penoplex insulation. It does not change its size even under heavy loads.

Installation and processing - convenient and simple

This material is easily cut with the most common knife. You can quickly sheathe walls with Penoplex plates, without using much effort. When working with this insulation, there is no need to be afraid that it will rain or snow. After all, Penoplex does not need protection from the weather.

A little about the flammability of penoplex

Most homebrew builders believe that penoplex is no different from polystyrene, except for its structure. Its properties such as flammability and water absorption are equated to the properties of foam. This is not true. Now, both non-combustible polystyrene and completely combustible polystyrene are produced. Therefore, trusting rumors that penoplex burns strongly, or not, is your decision. However, we note that penoplex is deprived of the possibility of spontaneous combustion. In the presence of a source of constant fire, it only melts, with the release of carbon monoxide (CO) and carbon dioxide (CO2) gases. If the fire is extinguished immediately, even smoldering will not be observed. Therefore, when choosing between modern foam and foam, give preference to the second material.

Important... Ordinary foam, which you can easily find in a box with some household appliances, burns perfectly. But it is foolish to think that there is no difference between it and construction foam. None of the varieties of penoplex burns, but only melts in the presence of an open flame source.

What class of flammability does Penoplex belong to?

I am studying the flammable properties of extruded polystyrene foam, it is necessary to take into account the fact that manufacturers produce various brands of this material. They all have different characteristics, and therefore there are different opinions about their flammability.

All building materials are divided into several groups according to flammability:

- G1 - materials are slightly flammable.

- G2 - moderately flammable materials.

- G3 - materials with normal flammability.

- G4 - materials with highly flammable properties.

- NG - absolutely non-combustible materials.

Most sellers prefer to keep silent about the vapor barrier properties of foam, since their main task is to implement it in any way. Some even claim that it is only from them that you can buy non-combustible extruded polystyrene foam. As soon as you hear such a statement, leave immediately. To date, there is simply no non-combustible foam, but it can be classified as a low-combustible building material.

Russian brands of penoplex

Russian craftsmen did not bypass the production of such a popular insulation as penoplex. In our market there are such brands as Technoplex from the TechnoNIKOL corporation and Polispen. Let's consider each of them in detail.

Technoplex

Technoplex is designed specifically for private construction, as well as for the arrangement of a warm floor system. In production, nanotechnology is used - graphite particles that enhance the effect of low thermal conductivity and further increase the strength of the material plates.Plates of this insulation are light silver and meet all standards for the production of foam.

Insulation Technoplex is produced with plates with different parameters. Even individual sizes are possible, if requested by the customer. The thickness of the slabs is different - 20, 30, 40, 50 and 100 mm. All plates, except for 20, have a special edge, which, during installation, excludes the appearance of cold bridges. Technoplex boards can be stored both indoors and outdoors, provided that the original packaging is intact. After installation, the surface of the Technoplex insulation must be insulated from atmospheric influences.

Polispen

LLC "Polispen" successfully produces extruded polystyrene foam under the brand of the same name. There are three types of foam boards in production, differing from each other in characteristics - compression density, thermal conductivity and flammability. These are the brands:

- "Polispen Standard"

- "Polispen 35"

- "Polispen 45"

The numbers 35 and 45 mean the density of the material, respectively 35 kg / m3 and 45 kg / m3. During production, special substances are used that reduce flammability - fire retardants.

Plates "Polispen Standard" are used where their combustible component is the least important - for internal floor insulation, in foundations. Plates with a density of 35 are used to insulate fences and load-bearing structures of buildings. Plates "Polispen" with a density of 45 are used in the arrangement of road surfaces, as well as structures that carry an excess load.

So, we have an excellent thermal insulation material made in the form of plates of various thicknesses - 20, 30, 40, 50, 60, 80 and 100 mm (depending on the manufacturer, the thickness range may vary, the standard range is 20/30/40/50 / 100), impregnated to varying degrees with fire retardants (the price of non-combustible material is more expensive), different density and compressive strength, used both in private housing construction and in industry. Russian penoplex brands such as Tenoplex and Polispen have proven themselves in the Russian market.

Types of "Penoplex"

"Penoplex" is one of the types of extruded polystyrene foam. The high technical characteristics of this material are determined by its cellular structure. Cells ranging in size from 0.1 to 0.2 mm are evenly distributed in the material, which gives it strength and a high degree of thermal insulation.

Depending on the type of surface to be insulated, there are several types of Penoplex:

- "Penoplex roof" is used for thermal insulation of pitched or flat roofs.

- "Penoplex wall" for insulation of internal and external walls of buildings.

- "Penoplex foundation" is used in the construction of foundations, basements, basements, cellars.

- "Penoplex Comfort" - improved technical characteristics are intended for use in houses and apartments.

- "Penoplex base" for thermal insulation of industrial and civil structures.

- "Penoplex 45" is the most specific type, it is used for thermal insulation of the runway at airfields.

The most versatile of them is Penoplex comfort.

Method of obtaining

On the websites of supplier companies, there are often similar names: expanded polystyrene (sometimes extruded), polystyrene, polystyrene foam, polyurethane foam and some others. It is useful to understand what is at stake in each case.

Foams are a class of polymers (plastics) in which cells with air are contained between the chains of the organic matrix. If the microcavities are connected to each other, the product is called a porous plastic.

Foams are produced by mixing large polymer molecules or medium oligomer molecules with solid blowing agents, low-boiling liquids or an inert gas.

There are technologies in which gas is formed by a chemical reaction of organic raw materials. The foamed product is shaped by cooling or special curing techniques.

Expanded polystyrene is the result of foaming a styrene suspension with pentane or isopentane. The primary product is in the form of granules. After heating, the granular particles are foamed and then sintered.

There is a modification of polystyrene foam obtained by polymerization of the monomer. The resulting polymer is mixed with pore-forming additives. The resulting mixture is passed through an extruder.

The result is a high density expanded styrene polymer. Extruded polystyrene foam, often called polystyrene foam. It is a product with good thermal insulation properties. It can be used to insulate houses even in the Far North.

Among the foamed products, polyurethane foam, which is also known as foam rubber, is very popular. It is obtained by foaming a liquid reaction mixture of monomers with the addition of organosilicon components, foaming agents (water or freon), substances of high surface activity.

By varying the process conditions, polymers of different hardness can be obtained. They have conditionally non-flammable properties. Foamed polyurethane products with a reinforced matrix are used as insulation.

Ignition and smoke production

Comparative characteristics of different brands of expanded polystyrene

Many foamed polymers are referred to by manufacturers as non-flammable. Strictly speaking, organic substances can become completely incombustible only if each structural unit of the molecule is enveloped with fire retardant additives. This degree of saturation with fire retardants occurs only in selected modified materials.

The flammability class of ordinary expanded polystyrene is the highest, fourth. Foamed polymer can ignite at 210 ° C. Some conventionally non-flammable plastics containing a large amount of additives can withstand temperatures of 440 ° C and then catch fire.

After the start of combustion, the temperature reaches 1200 ° C very quickly. The process is accompanied by the release of a large amount of smoke. This is due to the high mass fraction of carbon in the product.

There are ways to reduce smoke generation by adding smoke-absorbing components to the initial reaction mixture. Changing technology can improve non-combustible properties.

Reducing the volume of smoke reduces the hazard only to some extent. Combustion of ordinary expanded polystyrene is accompanied by the release of harmful substances:

- starting monomers;

- blowing agent vapors;

- products of their thermal oxidation.

To reduce the risk of ignition, subsequent combustion, it is possible to modify the technology, which consists in the addition of flame retardants. In parallel, another method is used to reduce the fire hazard, to increase the non-combustible qualities of expanded polystyrene.

For foaming, non-volatile solvents such as pentane are used, and carbon dioxide, which does not burn itself and does not support the combustion of adjacent substances. The resulting product is usually called self-extinguishing. It belongs to the flammability class, designated as G3. Therefore, a product cannot be called non-combustible.

Is penoplex dangerous in case of fire?

The fire hazard of polystyrene foam causes fierce disputes between manufacturers, experts and buyers. The former argue that the material is not subject to combustion, at least as long as the fire does not directly affect it. All thanks to the inclusion of a fire retardant in the penoplex. It does not allow the material to burn out. When fire stops acting on it, the expanded polystyrene dies out.

But why does the fire safety of penoplex cause mistrust among buyers? All because of his former glory. Older materials emitted hazardous gases that only propelled combustion. Modern polystyrene foam emits only gas and carbon dioxide, like wood, for example.

Flammability class

The production of heat-resistant polystyrene foam is more expensive, the products are more expensive. The more perfect the modified technology, the lower the flammability of the resulting expanded polystyrene. All characteristics of non-combustible material must be indicated in the certificate.

Some suppliers of expanded polystyrene claim exceptional heat resistance, the foam polymer belongs to flammability classes G1 or G2. This is controversial information, often based on outdated flammability testing.

According to stricter government requirements, the first two flammability classes can only include products that do not form splashing drops. Expanded polystyrene, which is called non-combustible, does not possess such properties.

Suppliers often show video footage of a sample of non-combustible insulation suspended in the air being set on fire. In this position, drops of expanded polystyrene fall down, really, they do not splatter.

A completely different picture will be observed when igniting a sample lying on an incombustible substrate. Such shots are not often shown, because sparks flying in different directions from the focus lead to the fire in the end of the entire polystyrene sample. Non-flammable properties are not confirmed by video recording.

Perhaps some manufacturers modify the technology for producing expanded polystyrene, saturating it with fire retardants to the level of incombustibility of class G2. This is reflected in the product labeling, technical recommendations for use. It is worth remembering that modern methods do not allow to obtain completely non-combustible polystyrene foam.

Polyurethane

The closest neighbor in the rating of heaters is polyurethane foam, made of different monomers: isocyanate and polyhydric alcohol.

Unlike non-combustible polymerized styrene, polyurethane contains nitrogen. Theoretically, this fact allows us to speak of its greater thermal stability. When monomers are combined under the action of water, carbon dioxide is released. It has absolutely non-flammable properties.

The volume of gas in rigid types of polyurethane foam reaches 90%. The material is very lightweight, much more heat-resistant than foam.

Non-flammable properties are enhanced by adding flame retardants to the alcohol component. Currently, this component is required in the production of insulation. Information about the belonging of products made of foamed polyurethane to class G2, especially to G3, can be trusted.

Application

Thermal insulation of buildings with foamed polymers is a good economic solution to energy conservation issues. The installation of an outer polymer layer significantly reduces heat loss.

In our country, this is relevant in almost all regions. The materials have gained particular popularity in areas of harsh climates. When buying products, you need to carefully study the certificates, pay attention to the instructions regarding the location of the insulation.

Some materials are intended for installation on plinths and foundations only. It is necessary to find out the possible atmospheric, mechanical loads; recommended installation technique.

Analyzing information about all types of expanded polystyrene and other foamed polymers, you can make the right choice and ensure maximum safety.