Building a brick house is quite popular throughout the Russian Federation, because brick walls have many advantages. They are reliable, fire resistant and can last for years. But there are also disadvantages, for example, they do not retain heat efficiently enough. The problem can be easily eliminated if additional external insulation of the brick walls of the house is carried out with special materials. Almost every owner thinks about how to insulate a brick house from the outside.

In the process of building a brick house, you have to spend a lot, which is why very often the question arises of how to carry out work on the house insulation with your own hands. Everything is quite simple and if you thoroughly approach the issue, study all the nuances and choose the right material, insulate the house from silicate bricks, it will work without the involvement of hired specialists. The answer to the question of how to insulate a brick house from the outside, knows any seller of a hardware store.

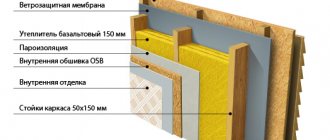

There are a lot of insulation technologies, for a start we will consider a type of insulation for siding.

The choice of material for insulating a brick house outside for siding

The question, what is the best way to insulate a brick house from the outside, is very common in specialized forums. It is worthwhile to thoroughly study all the information provided, and choose what suits you. The main division of insulation for walls occurs according to the principle of installation, there are those that require additional finishing, and which do not need it. There are simply a huge number of varieties of materials for insulation and sound insulation, many of them are similar in characteristics, and differ only in price and manufacturer.

- Mineral insulation (Minvata). It is very often used, due to the fact that the price for it is quite low, and the characteristics are suitable. For example, its thermal conductivity is 0.04 W / (m * K). In addition, it is quite environmentally friendly and even an inexperienced person can mount it. Minvata is capable of burning, so it has a low level of fire safety, which can be considered a minus, and during installation it will be necessary to carry out additional work related to moisture insulation of the walls, tk. the material absorbs condensation well.

- Expanded polystyrene (styrofoam). Thermal conductivity 0.036 W / (m * K). Lightweight, practical, with high moisture resistance. Just like mineral wool, it is environmentally friendly. The disadvantages of insulating a brick house outside with expanded polystyrene are toxic emissions during combustion, fragility, vapor resistance.

- Extruded polystyrene foam (penoplex), a warm brother of ordinary polystyrene. But it is produced using a different, fundamentally new technology. Due to this, it has improved characteristics of heat and sound insulation, as well as steam and water permeability. House insulation with penoplex is very popular.

- It is possible to insulate a brick house from the outside using modern methods, using foaming technology. Mounting polyurethane foam. The product is new, but has already conquered most of the market. Perfectly insulates and protects against moisture ingress. Minus, the application is carried out using special equipment.

insulation of a brick house from the outside by spraying polyurethane foam

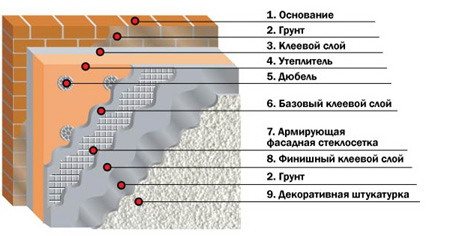

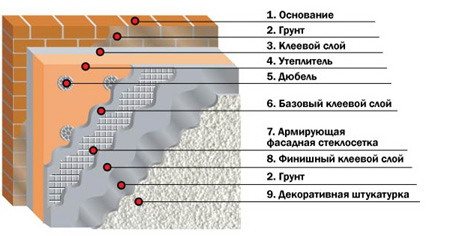

We insulate according to the "wet facade" system

Considering the technique of how you can insulate your brick house from the outside using foam, you can understand that it is very similar to the method of plastering.The essence of the latter is that it is necessary to completely cover all walls with insulation, preventing the appearance of gaps or cracks.

System - Wet facade

Thermal insulation scheme using Wet Facade technology

Do-it-yourself insulation of a residential brick house with polystyrene or expanded polystyrene is as follows:

- We make a visual inspection of the brickwork, its condition, the need for repair and disposal of contamination;

- Before insulating a brick house from the outside, we treat all surfaces with a deep penetration primer. It will provide better adhesion of the glue to the wall;

- We apply special glue for outdoor use on the foam, after which it is firmly pressed against the wall. It is worth noting that the insulation of the walls of a brick house from the outside always starts from the corner of the building, and goes from bottom to top. It should be noted here that before we insulate a residential brick house from the outside, we mount a galvanized corner around the entire perimeter of each wall. Its presence helps to set a uniform level of insulating material, remove excess moisture from the walls and prevent rodents from settling in the foam;

- To make the external insulation of an inhabited brick house even more reliable, we additionally fix the foam sheets with umbrella dowels;

- If necessary, you can make curly cutouts for windows, grooves and decorative stone finishing of the facade;

- After the foam has hidden all the walls outside the building, we glue the reinforcing mesh to its surface. We apply plaster on it, which, after drying, is covered with paint.

Advice... If cracks have formed in the brickwork over time, it is necessary to cover them with a cement-sand mortar.

Preparing the brick wall Applying adhesive to the styrofoam Fastening the styrofoam to the wall

Despite all the advantages of foam, you do not need to get hung up on it, deciding the question of what is the best way to insulate your own brick house from the outside. Insulation of a residential brick house outside with expanded polystyrene, mineral wool or foam glass occurs according to similar instructions, and the technology itself is applicable both to private inhabited buildings and to the outer walls of multi-storey buildings.

Two types of insulation that do not require additional finishing

- Another method of insulating a brick wall from the outside, using a thermal panel for a brick, is a fairly new technology. The main advantage is that there is no need to hide such panels under the siding. They have a beautiful appearance.

Thermal panels for brick

- insulation for a brick house using warm plaster, an innovative look. In our country, it is gaining more and more popularity due to its simplicity and low cost.

Insulation for a brick house using warm plaster

1Features and purpose

It is imperative to insulate brick houses. This applies to all people whose temperatures can drop below -15 degrees Celsius in winter. In such conditions, the walls quickly freeze through, collect the cold inside and give it to the room.

At the same time, the process of temperature exchange between the room and the wall will take place constantly, which contributes to a decrease in temperature throughout the house with thermal insulation materials.

Of course, you can also raise the temperature using conventional internal heaters. But electricity and gas are expensive these days.

Using them for excessive heating of the room and the fight against low temperatures will only lead to a disproportionate waste of resources. In simple terms, you will be wasting resources. After all, such a situation could have been avoided.

For example, if you insulate a house with mineral wool, use polystyrene, Penoplex or any other material, then its internal temperature in winter, even without preheating, will increase by several degrees.

Insulation here will play the role of a kind of barrier for low temperatures. Due to its extremely low thermal conductivity, this material practically does not exchange temperatures, and therefore does not allow the structures near it to cool.

Inside the house with the insulation of a wooden house outside with penoplex, the required temperature will be maintained longer, since the walls are protected by the insulation, and excessive heat consumption through their area can also be avoided.

As you can see, the insulation of walls or partitions between rooms can significantly increase the temperature inside the house, make living in it more comfortable, and the costs of life support are acceptable.

Installation of foam insulation on external walls

In Europe, for example, almost all houses are insulated without fail, as this contributes to energy conservation of resources, which means that it works both for an individual and for the entire state.

If we talk about cottages, then the insulation of a brick house from the outside is most often used here, since it is the outer walls that give off heat most of all, and in case of excessive heating, they “warm the street”.

If we are considering situational buildings or specialized buildings, then it would be more rational to insulate the internal walls or the space between the walls. For example, insulating a brick bath from the inside is considered a more efficient way to keep it warm.

While external insulation organizes processes in a different way. In this case, the internal temperature of the bath will be evened out by the temperature of the walls, which also need to be heated, and this is already a big minus.

In the traditional version, it is quite possible to insulate a house or a cottage with a house cladding with siding with insulation, even with your own hands. Moreover, all the work is done with their own hands, from the beginning of the marking and the purchase of materials, to the finishing.

A wide variety of heaters can be used in work: use mineral wool, mount Penoplex or polystyrene, pour penoizol, etc. Which one is better is up to you.

If you follow the standard scheme, then the insulation of a brick house from the outside provides for the installation of thermal insulation along the outer wall, and then finishing it with plaster.

But there is another interesting scheme.

This is the so-called three-layer wall. In such a wall, there is a space between the block of the outer and inner rows, which is approximately equal to the width of one block. Insulation is mounted in this space.

You can use, as in the previous case, almost all samples. Unless it makes much sense to mount Penoplex between the blocks, since it has unique technical characteristics.

Considering that the space between the rows must be filled completely, it is best to use Penoizol. This is a foamed thermal insulation material that is applied according to the principle of polyurethane foam.

Penoizol is poured into the opening between the blocks

Brickwork with insulation for the internal insulation of a country house is a kind of alternative to standard solutions and can help you out in a situation when circumstances develop in a certain way.

But from the point of view of construction, it is possible to work with it only if you have conceived insulation between the walls at the stage of design or construction of the foundation. Otherwise, it will be too late to perform such manipulations. And labor costs for their implementation will increase exponentially.

As you yourself understand, you will not be able to do such work with your own hands. Unless you build a house completely yourself.

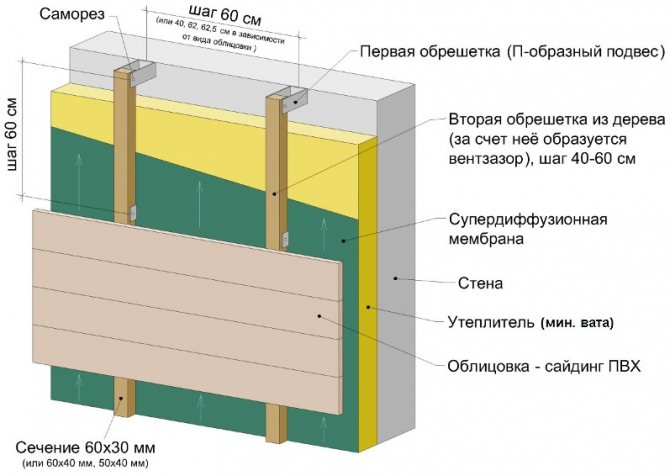

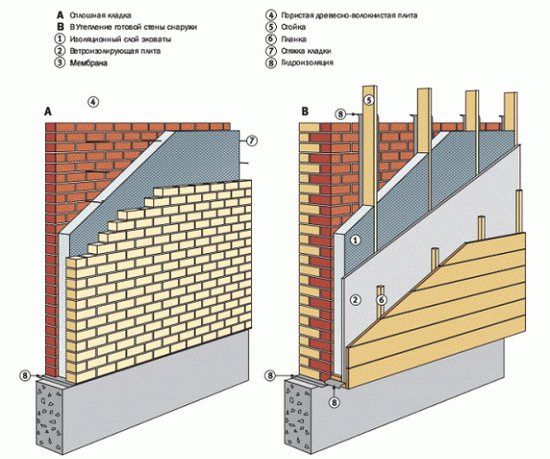

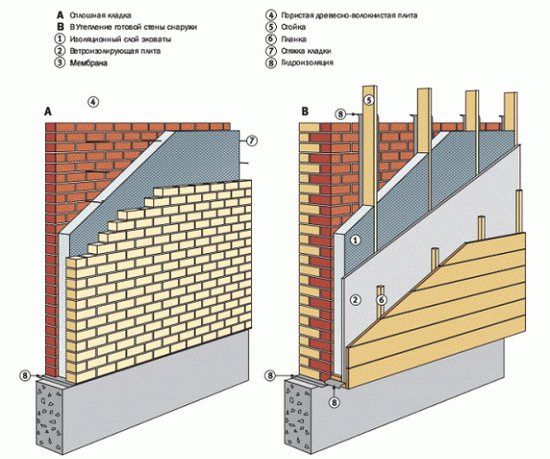

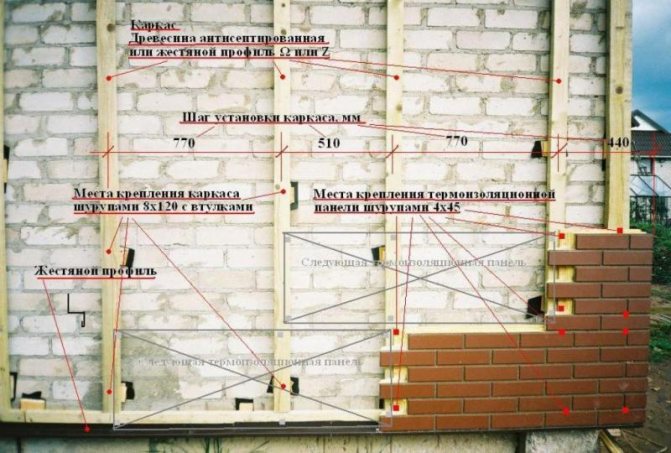

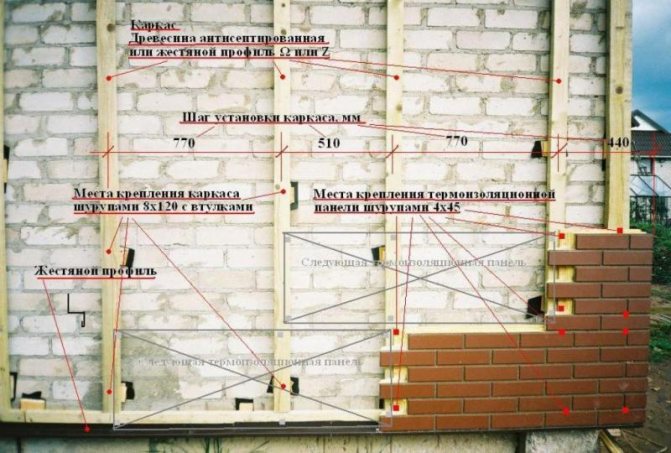

Installation scheme for siding

Surely not everyone knows how to properly insulate a brick house from the outside, or rather how exactly to mount the insulation. Installation, a group of heaters for siding, is fundamentally similar for all types of materials in this group.Before insulating a brick wall from the outside, it is necessary to expose the frame for the subsequent installation of siding. To do this, you will need to have:

- A hammer drill with an 8 mm drill, or an impact drill with a drill of the same diameter.

- Screwdriver.

- Construction level.

- Building corner.

- Roulette, hammer.

As a material for the manufacture of the frame, you can use a metal profile 60 * 27mm., Or wooden bars with a cross section of 50 * 50 mm.

Work should begin with cleaning the wall from anything that would interfere with the installation of the frame. Dismantle ebbs and slopes from windows. Then you can start installing the extreme bars. If the wall to be insulated is flat enough, then the frame can be made of wood, and the bars can be fastened with a dowel - nails, through and through. For exterior walls with irregularities, it is better to use a metal profile.

The extreme bars are installed, using a building level, strictly vertically. After that, between them, for convenience, a lace is pulled, it is convenient to control the installation of the remaining bars along it. All installed bars should be at a distance of 60 cm from each other in the same plane.

Insulation, cut into pieces of the required length and fit between the bars. It should be fixed using dowels - nails for insulating materials, having previously drilled holes for them in the wall.

If additional vapor barrier is necessary, it is mounted before installing the bars, directly on the wall, and only then proceed to the installation of the frame bars. If a metal profile is used as a frame, the whole scheme looks about the same, only instead of bars, profiles are installed using special suspensions.

Insulation with polyurethane foam

The process of insulating the brick walls of the house from the outside, using polyurethane foam, is slightly different in the order of work. You should start by cleaning the wall and removing anything that will interfere with the correct installation of the frame. The next stage is marking and installation of hangers on the wall for mounting profiles. After mounting the suspensions, they start applying the polyurethane foam. The last step after applying the foam is the installation of the profiles. As in the case of the bars, the extreme profiles are first installed, and then the lace is pulled and the rest are mounted with it. The profiles must be in the same plane.

Important: Before applying the foam, the hangers should be bent in such a way that they are ready for the installation of profiles in them, if this is not done, then after applying the foam, this will not work.

Siding installation

After installing the frame and insulation, the next stage is the installation of siding. The installation scheme depends on the type of siding panels, but general points are worth noting.

- Installation is carried out starting from the bottom of the house.

- Installation of the first panel is carried out strictly horizontally using a level.

- Each next panel is mounted in the previous one.

Finishing the facade of a brick house can be carried out using other technologies. For example, mount plates of mineral insulation (mineral wool) and then plaster and paint the surface. Or insulate the walls from the outside with foam and brick it.

Insulation outside

Insulation materials

Whether you like it or not, you will have to insulate a brick house. Experts unanimously recommend doing this even at the construction stage, but people do not always live in the houses they have actually built. Therefore, having survived one cold winter, the question rises squarely. Today, manufacturers offer a sufficient number of heat-insulating materials on the market, all of them cope with the task, differing only in the technology of installation, the cost of work and materials. You can choose any of the proposed heat insulators type:

- cellulose insulation;

- basalt slabs;

- foam;

- polyurethane foam;

- mineral wool.

The main differences between these materials are vapor permeability, moisture resistance, thermal conductivity... The first indicators must be taken into account for climatic conditions, and thermal conductivity must be known when calculating the required layer thickness for insulation. Using the SNiP reference books or contacting the design organization, the first step is to calculate the thickness of the expected thermal insulation layer, taking into account all possible heat losses through windows, doors, ceiling, floor. Only by calculating the thermal insulation layer for each type of material, you can choose by comparing it with finances, weight and other nuances.

When the choice is made, it is imperative to clean the wall from previous coatings such as plaster or others, remove it before the brickwork. If there are any irregularities or protrusions, then all this needs to be leveled, applying cement mortar, it is desirable to apply a primer with deep penetration.

In order for the heat-insulating surface to be flat, you immediately need install a system of beacons and plumb lines, this will determine the outer plane of the insulating layer and simplify the installation of the insulation layer.

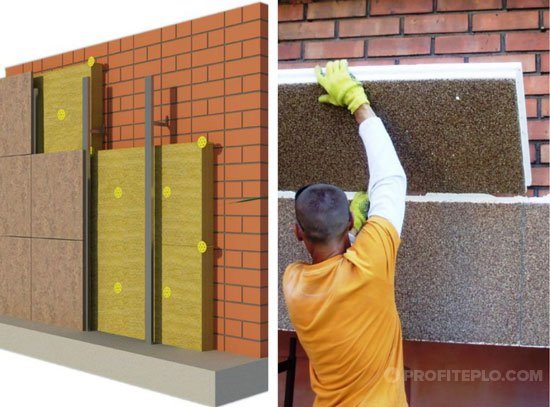

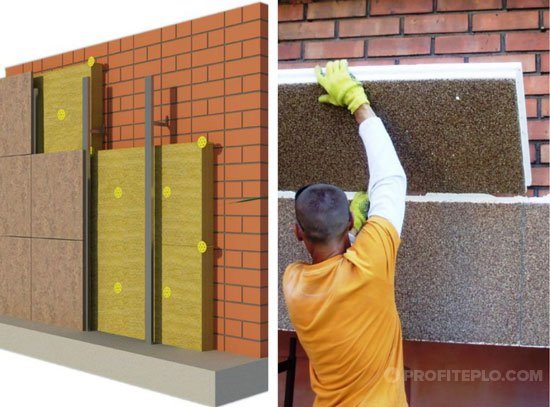

Further installation will be different for each type of thermal insulation. Let's consider it on the example of basalt slab insulation. Basalt slabs are an excellent fire-resistant insulation, high-tech and harmless; natural basalt fiber without formaldehyde additives is used as a raw material for its manufacture. As practice has shown, the installation of basalt slabs as a sealant leads to reducing heating costs up to 60%.

The procedure for insulating a brick house outside

For the outer wall, the thickness of the insulation must be at least 20-25 cm, that is, at least 2 layers. The second layer can close the seams of the first, which leads to the continuity of the coating, therefore it is preferable to take the slabs 5 cm thick... So, the wall is prepared, cleaned, it is primed with Ceresit C. T. 17. We carry out the following steps.

- We fix the basement profile with a shelf width equivalent to the thickness of the basalt slab. The profile is attached to the base of the building above ground level 40-50 mm with dowels 6 mm with washers every 35 mm from each other.

- Prepare an adhesive mixture Ceresit C. T. 84, vigorously shaking the balloon for half a minute.

- The glue is applied around the perimeter of the slab using an assembly gun, without reaching a couple of centimeters to the edges. Press tightly with a level and adjust along the wall, within 20 minutes the slab does not adhere and its position on the wall can be corrected.

- We lay the first row with an offset of the seams, securing them with a toothed dressing at the corners of the house. Gap between plates should not be more than 2 mm, otherwise, it must be filled with foam strips set on glue.

- Remove all irregularities on the slabs with a float.

- For additional protection of the slabs at the corners of the house, we use a reinforced mesh, thus preventing the occurrence of cracks.

- House corners to reinforce the structure we make out with plastic corners.

- We protect the upper surface of the thermal insulation by gluing the facade mesh onto the first layer of glue, after drying, we coat it again with glue to completely cover it.

- We rub to an even layer after 2 days, and already decorative plaster can be applied or other coating.

Clinker panel installation diagram

Insulation of the facade of a brick house using a clinker thermal panel has a fundamental difference from the installation of mineral wool and other similar types of insulation. It consists in the fact that the installation of the frame and, accordingly, siding is not required. The pattern of clinker panels can be different, there are panels for brick, natural stone, etc.

Before installation, as in the case of conventional insulation, the wall must be cleaned of dust, dirt and anything that might interfere with installation. The clinker panel is installed from the bottom up. The process from the outside resembles the assembly of a puzzle. First, the corners and the base are collected, then the inside of the wall is gradually filled. Fastening takes place using dowel nails for insulating materials, as well as a small amount of mounting foam, which is applied under the insulation and then glues it to it.

Features of external thermal insulation

When insulating the walls of a brick house externally, many nuances must be taken into account. The thermal conductivity of the wall depends on the structure of the brick, for example, it is hollow or solid. The quality of the selected heat insulator is important. It is unacceptable to use thermal insulation intended for internal insulation, for insulation of the facade. After all, it has significant differences in technical characteristics.

Materials for thermal insulation of external brick walls

Insulation of walls from the outside implies a change in the appearance of the house. The final result will be influenced by the chosen thermal insulation technology.

Thermal insulation of a brick house from the outside using modern methods allows

:

- To prevent freezing of the supporting structure, which increases its service life.

- Save valuable space from the inside.

- Reduce the load on the foundation.

- Reduce heat loss during the heating season.

- Reduce the likelihood of condensation between the insulation and the wall is reduced to zero.

- Eliminate the appearance of mold, mildew and other parasites on the walls from the inside.

- Move the dew point outward.

Among the advantages:

- Saving energy during the heating season.

- Extension of the service life of the bearing part.

- External insulation of the facade of a brick house allows you to change the appearance.

- Sound insulation is increased.

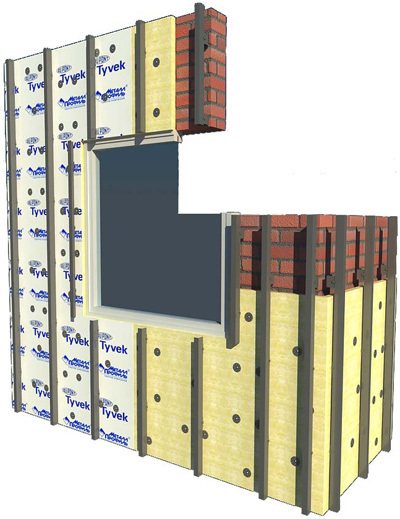

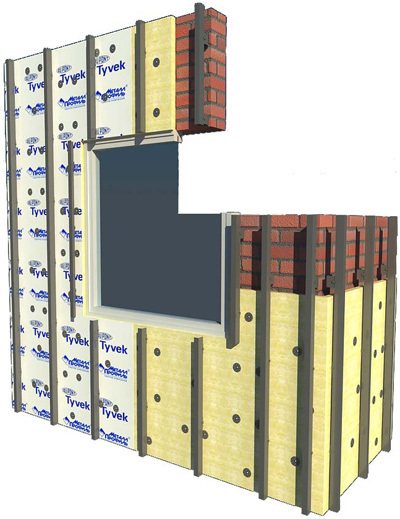

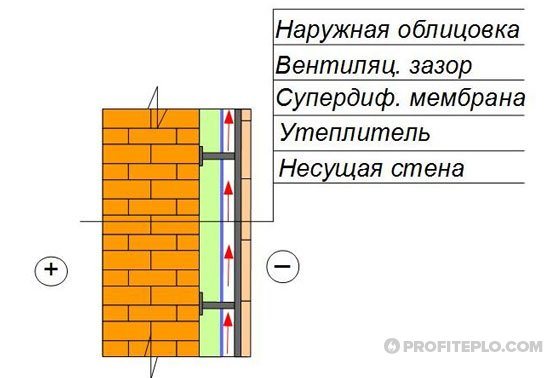

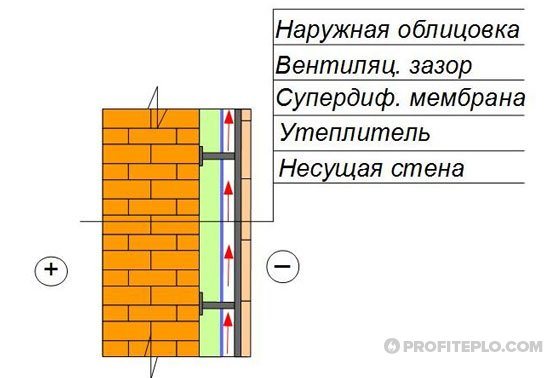

There are two known technologies, using which you can competently insulate a house from the outside.

:

- Multilayer.

- Wireframe.

In the first case, the insulation is glued directly to the wall. For this, a special adhesive mixture is used. Additionally, the heat insulator is fixed with plastic dowels. The surface is treated with special plaster mixes, with the help of which the external appearance of the facade is formed.

Thermal insulation of walls outside

In the second case, a frame is constructed according to the principle of a ventilated facade. Insulation is placed between the frame posts. The frame can be made of wood or aluminum profile. Cladding material is mounted on it, for example, lining, siding, etc.

Warm plaster

Abroad, for a long time, this type of insulation of the outer walls of a brick house is considered one of the best and is used almost everywhere. In Russia, the advantages of warm plaster have not yet been properly appreciated, although many builders are already using it in practice.

Warm plaster, has a composition almost the same as ordinary plaster, only instead of sand, bubbles of foam plastic, or perlite or vermiculite are added to it.

Polyfoam is a good insulation, any person even unfamiliar with construction technologies knows this. The use of plaster with the addition of polystyrene will allow you to insulate the house without high costs, and in a short time. Plastering does not require special preparation of the walls. Simply moisten with water and the mixture can be applied. Thermal insulation using warm plaster is quite effective because no joints, cracks or other defects remain on the wall through which heat can escape. Another indisputable advantage is the complete incombustibility of the plaster and the absence of the need to replace the slopes on the windows, which also allows you to save on finishing.

In addition to the article, watch the video:

Why insulate brick walls?

A single-layer brick wall with a thickness of 40-65 cm provides a level of thermal insulation three times lower than is necessary for a comfortable life. As a result, the walls have to be insulated. It is important to carry out competent external insulation. For this, the following materials are used:

- Styrofoam.

- Expanded polystyrene.

- Mineral wool.

At the same time, they will not affect the appearance of the facade, because in the future the structure can be sewn up with drywall or siding.

Note! Styrofoam and polystyrene foam are cheaper than mineral wool. But the latter has complete resistance to combustion.

It seems to many that heaters for walls outside a brick house will make being in it during the summer heat unbearable. But this is not the case. Any heat-insulating material is designed so that the warmth in the winter remains inside the premises, and in the summer they are dominated by the saving coolness. In addition, modern insulation makes it possible to remove steam and moisture in one direction. They do not let them into the house and do not absorb them.

Interestingly, about 40% of the electricity is spent on maintaining a normal temperature in the house. Thanks to competent outdoor insulation, you will get rid of such problems. The choice of insulation for the walls of a brick house is carried out according to the following scheme: 10 cm of insulation must correspond to the qualities of 1 m of brickwork. With this approach, you don't have to use air conditioners in the summer and spend extra money on heating your home in the winter.

When insulating a brick house outside, the following systems are used:

- Multilayer system.

- Ventilated facades.

Thermal insulation of a brick house

The process of insulating a brick house outside

Insulation of a brick house from the outside - this question arises before many homeowners. A material such as brick is especially popular for the construction of walls in the private construction of houses. Houses built from it can be found almost everywhere. But such a house, with all its excellent operational qualities, will still require insulation. Moreover, at the current cost of electricity, with the help of which houses are mainly heated. In such situations, an excellent solution is to perform good quality thermal insulation, with the help of which heat loss is minimized.

Insulation types

In order for the house to turn into a comfortable home for living, it should be thoroughly insulated. If this stage of work is carried out even at the stage of building a house, it is possible with a guarantee to avoid many troubles that await the owners of private housing in the future. With poorly executed insulation of a brick house, such troubles as freezing of the walls in winter, the appearance of mold, condensation and fungus, damage to the materials from which the decoration is made, and premature destruction of the walls can appear.

There are several types of insulation:

- internal;

- external;

- in-wall.

The most popular insulation is outside, which involves placing the material on the outside of the walls of the building. This provides additional protection to the walls from adverse natural phenomena. The disadvantages of this approach are only in the fact that the work is seasonal in nature, and the cost of materials will cost slightly higher.

In-wall insulation can be arranged only at the stage of wall construction. Those who buy ready-made housing will not be able to fulfill it.

Internal thermal insulation can be performed at any time (it also provides for insulation of the attic, floor and roof, interfloor floors). But this option also has a significant drawback.

Advantages of external thermal insulation

Why is it recommended to insulate walls outside? This circumstance is connected with the so-called dew point - when, at a certain temperature, condensation forms on the walls of a residential building.When installing insulating materials (for example, foam) from the inside, all moisture remains under their layer, and this leads to the formation of fungus, mold and other troubles.

Of course, the material chosen as insulation will also collapse. Therefore, to achieve good results, it will be much better to insulate the brick walls from the outside. This keeps the wall inside the house both dry and warm. Importantly, with this approach, the living area of the house will not be reduced.

What materials can be used to insulate a brick house from the outside

To ensure a cozy and comfortable room temperature, the construction of the house should be carried out in such a way that the brickwork against the walls is at least 3 meters thick. It is quite difficult to implement, and also irrational. The modern construction market can offer developers a variety of excellent and inexpensive insulation materials. For example, polystyrene, the thickness of which is small, does an excellent job and at the same time relieves housing from dampness.

You can insulate the outside of the walls of a brick house using the following materials:

- ecowool;

- mineral wool;

- penoizol;

- Styrofoam;

- expanded polystyrene;

- fiberglass.

The process of insulating a brick house outside with mineral wool

A building material such as mineral wool is made in the form of plates. They are very simple and quick to attach to a previously prepared surface. The material is distinguished by the fact that it perfectly retains heat, is fireproof, it permits air and steam well and is quite affordable in terms of cost. Ecowool has similar properties, but its cost is less, and by providing additional impregnation with an antiseptic, you can get rid of the appearance and growth of fungus in the wall voids.

Important! It is not recommended to independently carry out the installation of such building materials as fiberglass - it is quite toxic, and the specificity of the technology will require the use of many special devices.

Warming with penoizol, like foam, expanded polystyrene, makes it possible to preserve heat in the house as much as possible - this is perhaps the most effective way. Also, in order to insulate the walls of a brick house from the outside, you can use heat-insulating paint or plaster as an additional measure.

How to insulate a brick house from the outside

The technology of work will also depend on what material will be chosen for insulation. With their independent implementation, it is better to insulate with mineral wool or expanded polystyrene, foam. Installation of polystyrene is so simple that even non-professionals can do it. If you carry out work on the insulation of brick walls outside with mineral wool, you first need to make a crate - it must be dry and even.

Foam insulation process

When insulating with expanded polystyrene, polystyrene, you will need to perform a number of preliminary works. First, the wall must be completely free of any devices - these can be antennas, pipes, air conditioners or others. The old decorative trim is removed. It is hardly necessary to correct irregularities in the case of a brick surface. Expanded polystyrene or polystyrene is attached directly to the wall of the building - using special adhesives.

Important! Any adhesives should be checked for compatibility with the selected material.

Materials such as fiberglass, ecowool, penoizol cannot be laid without special equipment, in addition, when performing work, you will need to observe various nuances, so such operations should be entrusted to professionals. If you also apply heat-insulating paint or plaster to the walls, this will greatly increase the reliability of thermal insulation.For the first time, this can help to get rid of the costs associated with external finishing, and will provide an opportunity to save some money.

utepleniedoma.com