Perlite: a new word in the insulation market

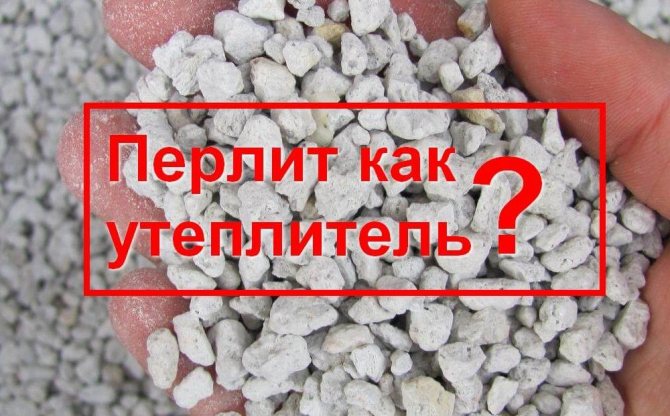

Perlite is considered a versatile material used as insulation for walls and floors. This is volcanic sour glass. Raw materials can be obtained by sharp heating up to 1100 degrees, when it swells. Fractional composition is different. Various components are added to the raw materials that improve heat and sound insulation properties.

Today this insulation is considered one of the most effective in the world. Due to its special properties, the product is used not only in construction, but also in other areas. The largest producer of perlite is the United States.

Modern insulation: expanded clay, vermiculite, perlite and expanded polystyrene

First, perlite sand is slightly coarser than vermiculite. In addition, if vermiculite is an entirely natural material, then perlite sand is an artificial material obtained by swelling glass. Perlite is neutral to soil, while vermiculite can cause soil acidification if added too much. Both elements make it lighter and more airy, and also stimulate moisture retention for plants.

Photo of packed perlite sand

Which one is better to choose to increase the level of floor insulation in a private building, while not overpaying? This question is asked by many buyers who do not have proper knowledge in the field of construction and reducing the level of heat loss in a building. Expanded clay as floor insulation has long lost its relevance.

Expanded clay is made from low-melting clay, which undergoes a number of treatments, including multiple heating at different temperature conditions at different rates. If the production technology is maintained correctly, then the output is a product of various fractional composition. Each particle of expanded clay is a closed capsule, the body of which consists of baked clay. Inside, expanded clay has a porous structure, due to which it is able to reduce the level of heat loss in the building.

Fractional composition of expanded clay:

- 0.05-0.1 cm - fine fraction, used for leveling the floor and for the manufacture of building blocks;

- 0.1-0.2 cm - the middle fraction - is relevant as a heater for the floors of a house, in particular for floors;

- 0.2-0.4 cm - coarse fraction, excellent insulation for heating mains, garage floor and other technical buildings.

For thermal insulation of the floor, it is recommended to use expanded clay of various fractional composition. This is due to the bulk compaction of the material and eliminates convection air currents in the thickness of the layer. Foamed clay for insulating wooden floors is suitable only in its pure form. On the concrete base, expanded clay is part of the floating floor screed.

The advantages of this type of building material:

- low coefficient of thermal conductivity - it lies in the range from 0.10 to 0.18 W / (mK). With a decrease in the fractional composition, the thermal conductivity of the foamed clay increases, since the number of pores containing air, the main heat insulator, decreases;

- environmental safety - expanded clay is made on the basis of natural materials, and therefore does not affect the health of living organisms;

- sound insulation characteristics - with an increase in layer thickness, the level of sound insulation increases;

- frost resistance - backfill insulation is able to withstand up to 15 freeze / thaw cycles without losing its technical characteristics.

Disadvantages:

- water absorption - it lies in the range of 15-20%, plus everything wet expanded clay dries for a long time, which negatively affects its properties;

- tendency to dust formation.

To ensure a normal level of thermal protection of a house, a layer of expanded clay up to 50 cm thick is required, which significantly reduces the usable area of the house. That is why, despite a number of advantages, the popularity of expanded clay as a heater is decreasing every day. Vermiculite, expanded polystyrene, perlite come to replace it.

Vermiculite is a bulk thermal insulation material, which is also made on the basis of environmentally friendly raw materials - vermiculite concentrate or hydromica. The raw material swells under the influence of high temperature and, depending on the parameters of the technological process, a material with a different fractional composition, bulk density and positive characteristics is obtained at the exit.

Insulation classification by fractional composition:

- vermiculite M100 - coarse fraction (4-8 mm) - high-quality insulation;

- vermiculite M150 - middle fraction (1-3 mm) - a structural element of building materials;

- vermiculite M250 - fine fraction (up to 1 mm) - a wide range of applications.

Depending on the size of elementary particles, vermiculite changes its bulk density and thermal insulation characteristics.

The advantages of vermiculite over expanded clay:

- bulk density - foamed hydromica with the same layer thickness has a bulk density of 65-150 kg / m³, while as expanded clay 150-800 kg / m³. In the first case, the load on the floor is less;

- thermal conductivity - vermiculite boasts a low coefficient of thermal conductivity (0.048-0.06 W / (mK)), compared to the same indicator of expanded clay (0.10-0.18 W / (mK)). This makes it possible to significantly reduce the thermal insulation layer when insulating floors, thereby it becomes possible to save useful space at home.

At the same time, vermiculite loses to expanded clay in its hardness. In the first case, it is 1-1.5 MN / m² on a scale, in the second - 0.3-6 MN / m². Expanded hydromica is characterized by high water absorption. The cost of vermiculite is 4 times more than expanded clay.

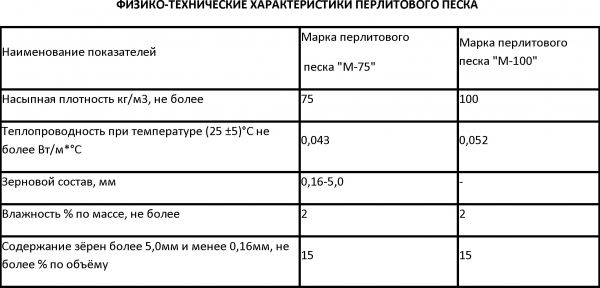

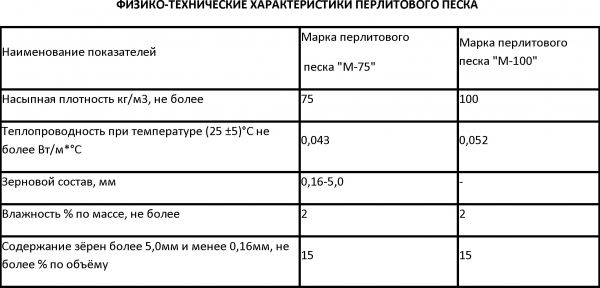

Perlite is a multifunctional material, 70% of which is used in construction to obtain various structural elements. These are slabs, asbestos-perlite-cement, silicate-perlite, bitumen-perlite and much more. Perlite is an acidic volcanic glass that swells when heated abruptly to 1100 ° C. The result is a material of different fractional composition:

- fraction 0.16-1.25 mm - building material;

- fraction 1-5 mm - agroperlite;

- fraction 0-0.16 mm - perlite filter.

Perlite and its benefits:

- it is an environmentally friendly product based on natural ingredients;

- low coefficient of thermal conductivity - 0.043 ... 0.053 W / mK, which can compete with the above-described heat-insulating materials;

- not flammable;

- not prone to saw formation;

- low cost.

However, one must remember that perlite perfectly absorbs moisture (up to 300%). By this, he loses to vermiculite and expanded clay. At the same time, perlite does not change its technical characteristics in the presence of moisture, which characterizes it only from the positive side.

Expanded polystyrene is a gas-filled material obtained on the basis of polystyrene and its derivatives by foaming them. The result is a bulk material with a closed cell structure. Expanded polystyrene can be extrusion and in the form of a plate, or it can be sold in the form of individual granules (non-pressed insulation). In this case, it can be compared with other bulk products (perlite, expanded clay, vermiculite).

As an insulating material, plates are in high demand, the main structural material of which is expanded polystyrene. They win in all respects if expanded clay, perlite and vermiculite are put in one row.

Advantages of expanded polystyrene:

- high compressive strength - it lies in the range of 0.05 ... 0.1 MPA;

- low thermal conductivity - 0.042 ... 0.038 W / (mK);

- static;

- expanded polystyrene is able to withstand up to 50 freeze / thaw cycles without losing its technical characteristics;

- low coefficient of water absorption - it is only 2-3%, which makes expanded polystyrene indispensable for warming the floor in the house and basements.

Expanded polystyrene is easy to install, durable, does not change its properties under the influence of adverse environmental factors. Disadvantage: high cost compared to other thermal insulation products.

The choice of thermal insulation materials depends entirely on the financial capabilities and taste preferences of the buyer. However, regardless of the type of insulation chosen, it must be certified without fail.

Scope of application of perlite as insulation

Since the insulation is available in different forms, it can be used in different areas. Perlite is used in:

- energy;

- construction of private and multi-storey buildings;

- metallurgical, food and oil refining industries;

- medicine.

Insulation can be used for external plastering of walls of buildings, when leveling and insulating internal surfaces. In this way, not only heat preservation is ensured, but also a change in the acoustic properties of the structure. Perlite is required to treat the roof. The material is also used when arranging a warm floor.

Perlite sand is used to make building mixtures. They are suitable for filling joints, cracks, cavities in walls, providing thermal insulation properties.

Characteristics of Perlite in the form of sand

Basic properties - they are also advantages

It is worth noting the main advantages of perlite insulation:

- Little weight. Despite the fact that rock and volcanic rocks act as a raw material, Perlite turns out to be quite light (this is achieved through heat treatment). As a result, there is no need to build a particularly strong frame.

- Increased temperature resistance. It can withstand temperature drops from −220 to +900 degrees. Therefore, it can be freely used for outdoor insulation, even in the Far North.

Important! In this aspect, it outperforms all its competitors. No other insulation can boast of an allowable amplitude of over 1100 degrees.

- Environmental Safety. Even when heated, this material does not emit any toxic substances and carcinogens.

- Chemical neutral to most acids and alkalis. This eliminates the possibility of corrosion and other unpleasant formations. It should also be noted that it is completely hypoallergenic.

- High sound-absorbing properties, which are achieved due to the low bulk density. As a result, when using this insulation, there is no need to lay an additional soundproofing layer.

- Does not deform as a result of heating. Therefore, Perlite is often used in floor heating systems.

- High efficiency. In general, stating the features presented above, we can note the impressive efficiency of this material. Despite the fact that it is not very popular (relative to Penoplex and mineral wool), its use seems to be very rational. Moreover, the cost of this material is in the middle range.

Where is this material used?

Such an impressive list of advantages predetermined the wide field of application of this insulation:

- External plastering of buildings. Here frost resistance comes to the fore.

- Any internal work related to leveling and increasing the heat transfer properties.

- Internal finishing of the roof.

- Thermal insulation of pipelines (including hot water supply).

- Underfloor heating systems.

Only the broadest construction areas are presented above. The substance itself, called Perlite, is used in medicine, metallurgy, energy, agriculture, oil refining and even the food industry.

Insulation features

Insulation can be laid in different ways, it all depends on the type of material. If you need to fill it up, then you should do it right from the bag. In this case, a convenient interval must be observed. You need to check the material to make sure it is dry. If there are cracks or holes in the walls, then they need to be repaired so that the perlite does not spill out.

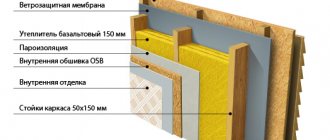

Cavities in the wall, which are located under windows and doorways, are subject to insulation. If necessary, the material is rammed. Insulation is also required between the exterior masonry and the interior trim.

Using perlite as thermal insulation

Home insulation with perlite. Types and properties.

If sand from rocks of volcanic origin is passed through a high-temperature furnace, you get swollen sand, or perlite. In addition to the production of perlite solutions, perlite is used as a heat-insulating material for floors, floor slabs and for insulating brick-lined walls.

The process of warming is carried out by filling perlite in the opening between the wall and the facing brick. The process of insulation is reduced to the fact that a space is left between the building wall and the facing wall for filling the insulation. The width of the space for the perlite backfill depends on the need for the insulation effect. The width of the backfill slot of 10-15 cm is quite enough for the insulation effect to be the highest.

The technology of filling the perlite heat insulator is not complicated at all. Together with the construction of the bearing wall and facing masonry, after every 3-4 rows, the perlite is backfilled and tamped. Perlite is highly water-resistant, therefore, when insulating with perlite, additional waterproofing is not required over the entire surface.

Perlite insulation is also used to insulate flat roof ceilings, floors or floors. For backfilling of perlite insulation, a crust is made with diffusion-permeable gypsum board or chipboard. A layer of perlite sand is covered with a layer of at least 1 cm. As a coating of the perlite layer, not films are used, but kraft paper, corrugated cardboard or fiberglass.

It is used for insulation and insulation of combined, flat roofs and other waterproofing, insulation works. For thermal insulation of technological equipment associated with electricity or high-temperature places, carbon perlite is used. This material is characterized by high bending strength. In house building, it can be used to insulate electrical wiring, fireplaces and chimneys.

In addition to these types of perlite materials, other types of perlite plates are produced, in which lime, clay, gypsum, water glass, basalt fiber and others are used as binders. In addition to slab perlite, fibrous heat-insulating material based on perlite and basalt fiber, and even pearlite, high-temperature bricks, is also produced.

First of all, they note the similarity in the origin of the materials. So, perlite and vermiculite with the desired properties are obtained artificially (swelling technology). Comparison is made in terms of the size of the fractions. If you need to select a material with the smallest particles, it is recommended to pay attention to perlite. Vermiculite is darker, it provokes soil oxidation.

Properties and advantages of perlite

Such insulation for walls as perlite has the following advantages and properties.

- light weight, which allows not to carry out additional strengthening of the strength of the walls - the structures remain light, and the load on the foundation practically does not increase;

- resistance to temperature extremes, therefore, the material can be used to isolate internal and external surfaces (the material can withstand -220 - +900 degrees);

- environmental friendliness: the insulation does not emit toxins, regardless of the operating conditions;

- hypoallergenic;

- fire resistance - the insulation not only does not burn, but also protects structures from ignition;

- resistance to aggressive chemicals: it is not affected by alkalis and acids;

- inertness to corrosion;

- providing a high level of sound insulation;

- no deformation when exposed to heat in the room;

- the average cost in comparison with other materials, especially since its use pays off within a few years after the start of operation, since the cost of heating the house is reduced;

- ease of use, high efficiency;

- bulk density - 45-500 kg / m3;

- thermal conductivity - 0.043-0.053 W / mK;

- porosity - 70-90%.

But pearlite also has some disadvantages. You should not insulate the walls with this material if the rooms are constantly humid. During work, protective equipment and protective clothing should be used, as perlite emits aluminosilicate dust. It irritates the mucous membranes of the respiratory tract.

Wall insulation with perlite video

Perlite is obtained by firing a volcanic mass, which contains crystalline hydrate water. As a result, products are born that have the form of white foamed granules up to 20 mm in length and up to 500 kg per cubic meter. In fact, this substance is chemically neutral. Perlite does not burn and can withstand heating up to +900 degrees Celsius. As for the thermal conductivity, this value is 0.05 W / (m * K). Due to its improved performance, perlite is in demand today in many industrial sectors.

The USA began to use perlite most actively in construction. This material is used for thermal insulation of floors, roofs, chimneys and even swimming pools. In industry, it is used for thermal protection of cryogenic melting furnaces.

Varieties of perlite insulation

The specified wall insulation is produced in different forms and their characteristics are somewhat different.

Backfill insulation

Perlite sand for wall insulation is the lightest. Thanks to him, you can lighten any design. Material is used for arranging interlayers between floors, filling cracks, and other voids. With this form of insulation, you can adjust the floor to the required level, plaster the walls. The material reduces heat loss by 40%.

Perlite in the form of slabs

The plate form of insulation is produced more often than others, since it is convenient to use, it makes it possible to quickly carry out installation work. The material is hygroscopic, so you should not use it for outdoor work. If such a need arose, then a waterproofing layer is required. The production of slabs involves hydraulic pressing of raw materials. The material contains other components that improve technical characteristics: cement, polymer substances, lime, liquid glass, bitumen.

Roofing models

Perlite as insulation is used to insulate roofing systems. The binder in the product is bitumen. Its characteristic feature is increased flexibility, as a result of which structures of any shape and type of complexity can be isolated. In addition to thermal insulation properties, the material provides reliable protection of the roofing system from fire.

For fixing the product, it does not require preheating, as is the case with other bitumen-containing products.The low coefficient of thermal conductivity will allow the use of insulation in the northern regions.

Dry construction mixtures based on perlite

There is a possibility not only of wall insulation with perlite, but also the use of material for the manufacture of building mixtures. In this case, fine-grained raw materials with the addition of cement are required. The mixture must be diluted with a sufficient amount of water. The mortar is intended for grouting cracks and joints. Raw materials are added to plasters to achieve a thermal insulation effect. Perlite is added not only to cement, but also to gypsum and lime compositions.

Perlite-based plaster is resistant to fire, does not weigh down walls, does not rot and is inert to the effects of negative temperatures. The product has good adhesion to the surface. The finish provides high-quality sound insulation and helps to retain heat in the room.

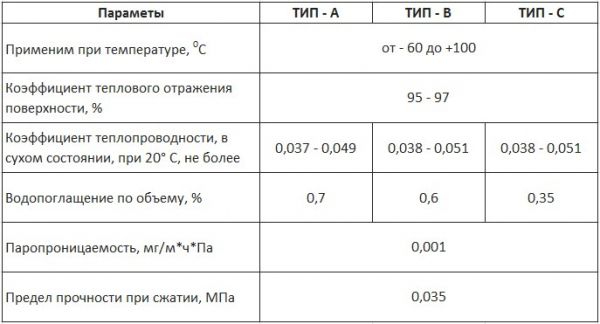

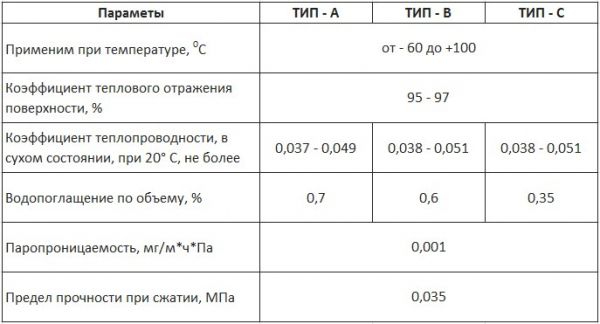

Advantages and disadvantages of penofol

This material is polyethylene that foams during production and is covered with an aluminum coating that reaches 14 microns in thickness and has a purity of 99.4%. The material can be covered with aluminum from different sides or from both at the same time.

Its class and properties of heat and vapor insulation depend on this..

First of all, you should familiarize yourself with its positive characteristics, which play a significant role when choosing a material for insulation:

- High degree of environmental friendliness... The components from which this insulation is made are not toxic, since their use is permitted for storing food products.

- Minimum thickness... Similar materials for insulation usually exceed the thickness of 4 mm. If we compare penofol and mineral wool, then 8.5 cm of the second material can provide the same insulation properties.

- No vapor barrier required, because penofol is characterized by a low level of vapor permeability.

- High noise insulation properties, which makes it possible to provide acoustic and structural sound insulation at no additional cost.

- The installation process is quite simple, there is no need for overalls and the use of specialized equipment.

- The insulation is not subject to fire.

- Easy transportation, the insulation can be rolled up and packed in a car.

- Rodents do not damage such material.

- Each batch produced undergoes mandatory certification at the sanitary and epidemiological station.

Specifications

In addition to the positive aspects, it is worth noting other nuances, which in some cases are disadvantages when using penofol:

- Due to the softness of the insulation, it cannot be used for internal insulation in the case of wall decoration with plaster or wallpaper.

- Difficulties in attaching all material classes, except for C, which is equipped with a self-adhesive coating. It is better to attach it with adhesives, it is believed that nailing foam foam worsens its properties as a heater.

- Penofol is significantly inferior in its characteristics to other types of insulation.

Penofol types

Basically this insulation used to decorate the walls of a house or apartment from the inside... If there is a need to insulate the house from the outside, then it is better to dwell on another type of heat-insulating composition, and use penofol as an additional layer, thereby enhancing the properties of reflection of thermal energy.

Criterias of choice

The choice of insulation depends on the purpose of its application. Several types of material are used in construction: M75, M100, M150. The numbers are an indicator of the bulk density of the raw material. You also need to pay attention to the weight of the product. The smaller it is, the better the noise and heat insulation properties.

Perlite with a size of 0.16-1.25 mm is used for work. The larger the granule size, the worse the quality of the backfill.The fluidity of the material is thereby reduced. When choosing a heater, you need to pay attention to its shelf life and the integrity of the package - these parameters affect its technical properties. If the material has been in a humid environment for a long time, it will be useless.

Perlite, advantages and disadvantages

Another type of wall insulation is perlite, or rather, materials based on it.

It can be both blocks, bulk materials, and seemingly ordinary plaster. Perlite is a volcanic glass in which molecular water is present in a bound state.

During the production process, such a composition is exposed to a temperature of 800 degrees, due to which a high level of porosity is achieved.

The advantages of perlite include:

- light weight;

- low level of thermal conductivity;

- soundproofing;

- good absorbent properties;

- hygroscopicity.

IMPORTANT!

Perlite is considered a completely natural and safe material, because it does not emit any harmful compounds during operation.

It is also worth paying attention to some of the disadvantages of using this insulation, although there are few of them:

- when working with perlite, there is a possibility of harm to the bodysince fine aluminosilicate dust is released when cutting blocks or mixing a solution;

- if the moisture level in the material rises to 10%, then this promises a loss of its properties by 90%... The material requires the obligatory equipping of the wall cake with a layer of waterproofing;

- it is very problematic to find such a heater on sale;

- on the market there are often fakes of this type of insulation, which is difficult to distinguish from the original in appearance.

It is prohibited to use perlite sand in structures with high vibration.

Specifications

Perlite insulation technology

The main advantage of perlite is its high level of fluidity, so it fills even the smallest cavities. The material is used to insulate walls and floors.

Wall insulation

The use of perlite for wall insulation is done in stages. The work is carried out as follows:

- Preparation of the base. It is carried out during the construction phase of the wall. For insulation, it is better to use a fine sand fraction of the material. For 1 cubic meter walls will require 60-100 kg of raw materials.

- Backfill. Insulation is laid in the space between the inner and outer parts of the wall. It is filled gradually, as the structure is being erected. The raw material should not be strongly rammed, but it must be compacted so that it does not shrink and the thermal insulation characteristics do not deteriorate.

As for the decoration of the walls with perlite plaster, preliminary surface preparation is also carried out here. The old decorative coating is removed from it. After the plaster has been applied and dried, a fine finish can be done. In this case, it will also perform its functions for a long time.

Floor insulation

Different types of floors can be insulated with perlite. It is often used when working with solid monolithic coatings. The sand fraction is 6 mm. The installation process is not difficult. The material is poured onto the prepared base directly from the bags. It must be distributed evenly, for which slats are used. If communications are laid on the floor, perlite sand should completely cover them. After that, you can mount the final monolithic coating.

When laying such floors, it is necessary to equip drainage branches so that it is possible to eliminate excess moisture. If the subfloor is made of wood, the perlite does not need to be compacted. Sand is poured into the cracks between the elements. Fiberglass is used to strengthen the insulation, but it can be replaced with fiberboard sheets.

Perlite is an innovative insulation material that is used to insulate walls, floors, and roofs. It has many advantages and provides reliable protection of the structure from unnecessary sound and cold.Subject to the technology of laying the material, it will last for more than a dozen years.

Pros and cons of perlite

Perlite plaster also has thermal insulation properties.

When choosing a bulk insulation, consumers have to compare several materials: expanded clay, expanded polystyrene granules, vermiculite or perlite. Each variety has features that are taken into account when making a decision. Volcanic glass bulk insulation is highly effective. The material does not shrink, like granular polystyrene foam, and does not get wet, like expanded clay. The main advantages of the insulation are:

- Low thermal conductivity of pearlite, which is provided by many voids of the porous structure of the mineral. Also, the structure of the mineral contributes to effective noise absorption.

- Low weight, allowing to reduce the total weight of the structure by up to 40%. Lightweight load-bearing walls do not require a massive foundation.

- The ability to operate in a different temperature range does not limit the use of the material.

- Fire resistance guarantees the fire safety of the insulation. He is able to stop the spread of fire. When heated, it does not emit smoke and toxic substances.

- The natural mineral is ecologically safe, there are no harmful impurities in its composition.

- Loose insulation fills the space evenly, fits tightly, leaving no cold bridges. The material does not cause difficulties when filling as foam granules.

We offer you to familiarize yourself with How to choose an entrance metal door to the house?

Brittleness is the main disadvantage of pearlite. The mineral is easily destroyed, turning into dust. The material loses mass when transported in an open way, creates inconvenience during filling. Working with it requires the use of protective equipment: respirators, goggles, gloves. To make the sand less dusty, it is moistened with water before use.